DIY spiral drill

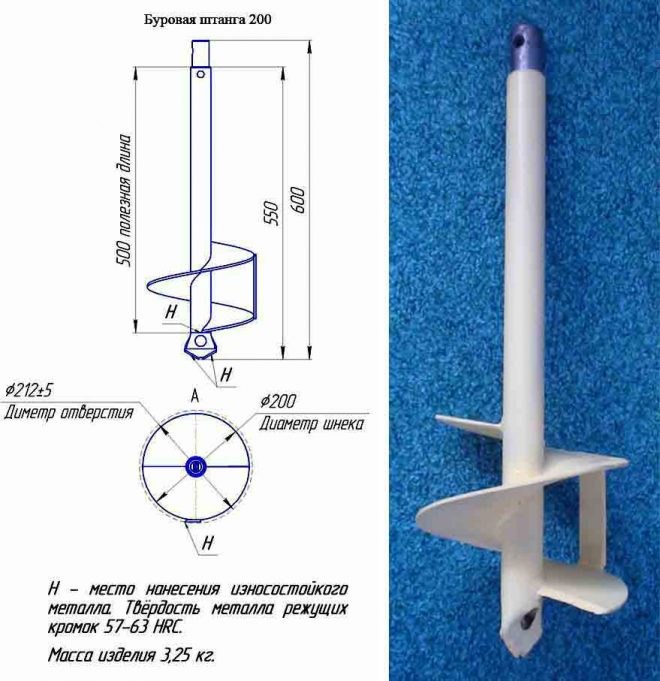

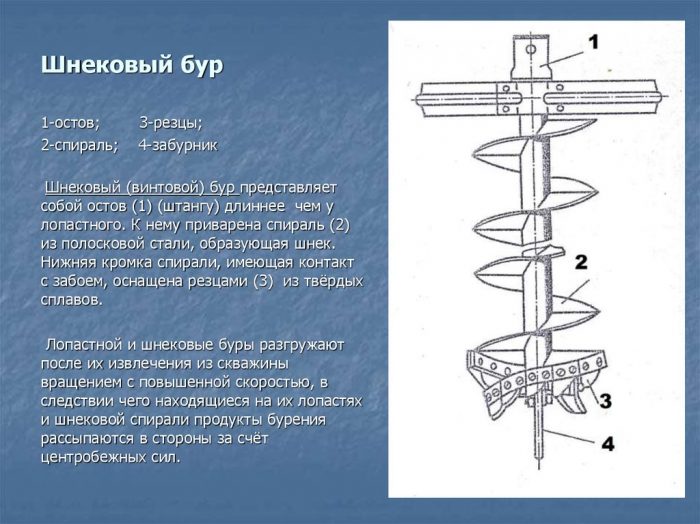

Making such a drill with your own hands is a task for a professional. Correctly welding a steel spiral at home is quite difficult. This process requires heating a strip of tool steel, twisting it into a spiral with the required diameter, hardening the part and welding it to the rod. It is possible to perform such a task qualitatively only in production.

Experienced craftsmen have simplified the technology. The assembly of the drill begins with the creation of blades for crushing rocks. To do this, use several disks of steel 10–15 mm thick into two semicircles. Most often, four disc elements are cut out of a steel sheet with a radius of 15 cm according to the pattern, and holes with a radius of 2.5 cm are made in them. Radial cuts are made in the metal rings and their edges are displaced so that they overlap each other. The lower edges of the blades - blades - are sharpened and hardened. This will help reduce the time spent on drilling a well.

Further work on creating the tool is as follows:

- A handle is attached to the rod.

- The other end is sharpened and hardened.

- Finished parts from steel rings are welded to the bar.

The blades are attached at a distance of 20 cm from the sharp tip at an angle of 40 ° to each other - first the lower part, then the rest in sequence. Welding bladed elements is required with an overlap along the cut of the rings or butt.

There is also a modified version. Such a drill is equipped with steel plates: they are welded between the turns of the spiral. This helps to cut the roots of the bushes and reduce the risk of collapse of the well walls due to their compaction with additional plates. It is possible to modify in this way not only a hand-made, but also a purchased tool.

Distinctive features of the method

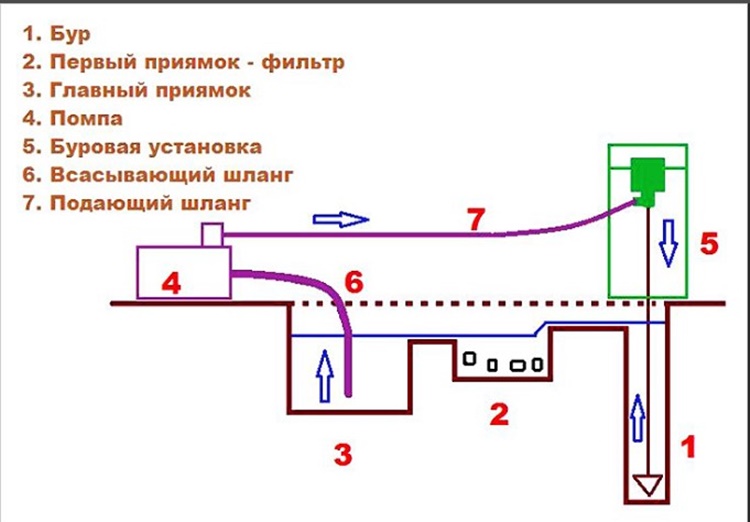

The method consists in extracting the waste rock with water injected into the mine cavity under pressure. The drilling tool for removal of the destroyed layers is not used.

The technology consists in a combination of 2 processes:

- the formation of a vertical well in the ground through the alternate destruction of soil layers;

- extraction of crushed soil fragments from the wellbore under the action of a working fluid.

The process of mixing the solution for drilling.

The creation of the necessary force required to plunge the cutting tool into the rock is facilitated by the dead weight of the equipment, consisting of a string of drilling rods and equipment for pumping fluid into the well.

To make a washing solution in a separate pit, a small amount of clay suspension is mixed in water, it is stirred with a construction mixer to the consistency of kefir. After that, the drilling fluid is directed into the borehole by a motor pump under pressure.

During hydraulic drilling, the liquid medium performs the following functions:

- removal of fragments of destroyed rock from the body of the water mine;

- cutting tool cooling;

- grinding the internal cavity of the pit;

- strengthening of the mine walls, which makes it possible to reduce the likelihood of the collapse of the working and falling asleep with the dump of the borehole shaft.

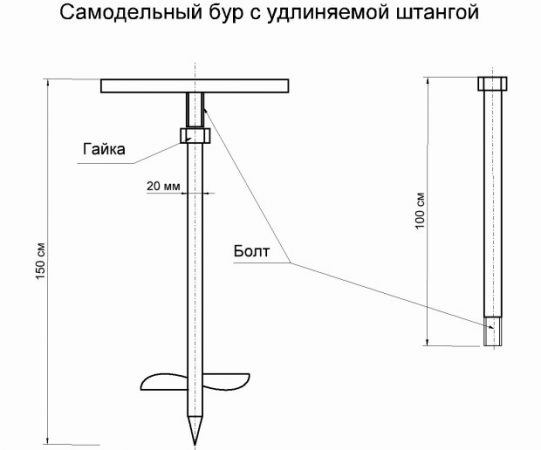

From pipe segments 1.5 m long, connected by threaded fasteners, a column is formed, which lengthens due to the growth of fragments as the well is deepened.

Hydrodrilling technology is optimal for rocks with a high concentration of sand and clay. It is not advisable to use this technique for arranging an autonomous source on rocky and swampy soils: massive and viscous soil layers are heavily washed out with water.

Advantages of hydrodrilling wells

Hydro drilling technology has the following advantages:

- simplicity, allowing even non-professionals to do all the work with their own hands;

- small dimensions of the equipment used;

- the minimum number of technological processes;

- no restrictions on the depth of the well, it is possible to drill to an aquifer located 200 m from the surface;

- affordable cost;

- high productivity, allowing under favorable conditions to pass up to 10 m per day;

- environmental safety and harmlessness to the surrounding landscape.

Many people prefer hydraulic drilling to other ways of creating an autonomous well on their own due to the absence of design violations in landscaped areas - there is no need to ennoble the territory upon completion of the procedure.

Diagram of the water well drilling process.

Materials and tools

In order to make a hand drill for poles, as a rule, you do not need much effort. But the master needs materials and components to create a product.

List of required parts:

- Nut and bolt M20;

- Discs with a diameter of 100-150 mm - 2 pieces;

- Drill with a tip (20 mm in diameter);

- Pieces of metal pipe: two 500 mm and one 400 mm. The wall thickness should be 3.5 mm, the outer diameter should be 40 mm.

From the tools when creating a product you will need:

- Bulgarian;

- hammer;

- welding machine;

- drill;

- drills for metal;

- blade sharpener.

If there is no tip with a drill, then you can replace it with a drill with a cone shank. Its diameter must match the screw. In order to avoid injury, it is recommended to use soft bicycle handles.

How to make a cable-impact drill

The mechanism of the percussion drill is quite simple in design. To make and assemble it, you will need the following material resources and equipment: a thick-walled pipe of the required dimensions, corners, sheet steel, a tape measure, a grinder, a welding machine and a manual or automatic winch. To make and assemble an impact drill, you must perform some steps in the following sequence:

- A tripod is assembled with a height not lower than 2 meters.

- The top of the tripod is equipped with a special assembly that allows you to install a manual or automatic winch.

- A percussion instrument is being made.

To do this, you need a pipe with an outer diameter that matches the diameter of the future well. A piece of thick steel is welded onto one end. Then a hole is made in it in order to fix the cable. And at the shock end of the pipe, sharpening is made around the entire circumference. To ensure the strength of these elements, they need to be hardened. And also the tool should be equipped with additional weighting agents.

The basis for placing the working tool is being prepared. A shallow hole is cut in the ground. The wireline drill is then mounted on tripods and positioned so that it can fully sink into the prepared area under its own weight.

Necessary equipment for work

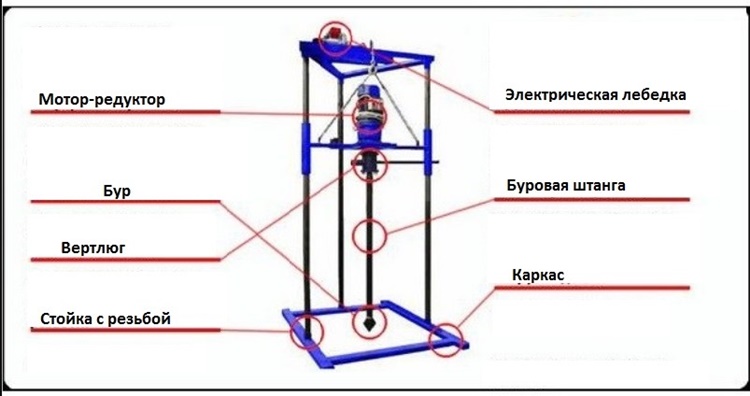

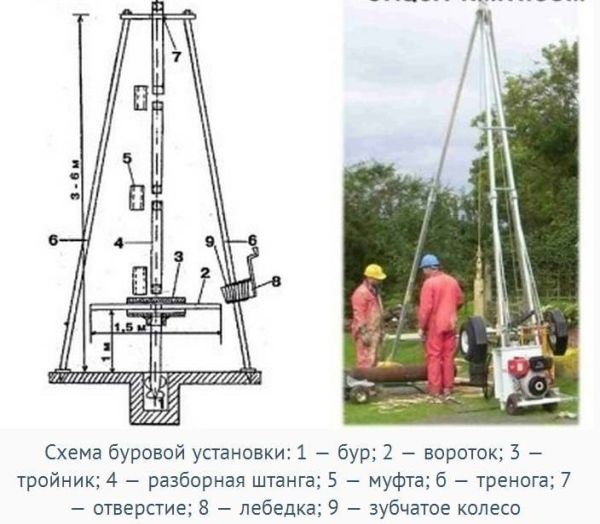

The basic unit of equipment is small-sized (MBU). The small size of the device is optimal for its use in limited spaces of private areas.

To create the pressure necessary to remove crushed rock from the mine shaft, a borehole pump or motor pump is used that is capable of pumping untreated media. When choosing a suitable model, they are guided by the power of pump equipment.

In some cases, the breakdown power of the drilling fluid is increased by adding sand or coarse shot.For crushing large fragments of pebbles found in sandy layers of destructible rock, it is recommended to use cone or cutting bits.

Drilling wells in areas with boulders or large pebbles requires additional reinforcement of the starting rod with a special drill.

MBU is a prefabricated structure with a diameter of 1 m and a height of 3 m.

Elements of the installation for drilling.

The installation consists of the following elements:

- metal frame body, easy to assemble and disassemble;

- well gate or winch;

- an electric motor that drives the drill;

- swivel providing sliding fixation of structural parts;

- borehole pump or motor pump;

- drilling tools, incl. reconnaissance drill;

- rods from pipes for building up the column;

- control automation units;

- hoses connecting the pump unit supplying water to the swivel.

For a stable power supply, it is recommended to include an electric current converter in the list of necessary equipment. The use of a special lifting mechanism makes it easier to raise and lower casing strings and extension rods; a winch is considered the best option.

Since the technology is based on the removal of waste rocks from the body of the well with a high pressure of water, a motor pump should be selected with increased power.

For work, you will also need plumbing equipment: a pipe wrench, a transfer plug and a manual lock.

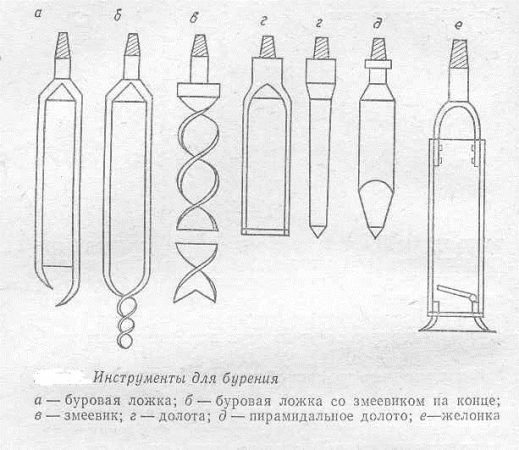

Making a drill spoon

This tool is suitable for working on crumbling-resistant soil. A hand drill consists of a rod with a handle and a cylindrical spoon with a longitudinal slot in the side.

The length of the small-scale mechanization tool is 70 cm. The diameter of the device depends on the size of the intended recess in the ground. The soil extracted from the well enters the cylinder through a slot and is retained there by sticking and tamping. If the soil is dense, you can make a fairly wide inlet. The looser the earth, the narrower the slot will be.

There are three ways to make such a drill with your own hands:

- based on a metal pipe;

- from an old cylinder;

- by rolling and welding steel sheet.

The sheet steel method is more labor-intensive - it will require skillful welding to create the rod and secure the tip. At one end of the finished cylinder, cuts are made with a grinder, then the metal is bent and the edges are sharpened. Sometimes cutting blades are welded on instead. Then a cut is made in the bottom of the cylinder.

The spoon is welded to the bar at a right angle. For easy entry into the soil, a metal drill tip can be attached to the carrier rod.

In addition to the manufacturing technology of a drill of any kind, you need to know the rules for caring for such a tool. After completing excavation, be sure to clean the knives from adhering earth. Store such devices in dry rooms.

Video: How to work with a hand drill

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

A simple garden tool

It is easiest to make such a tool yourself. Its design includes:

- cutting part made of steel sheet;

- drill tip;

- rod from a pipe of round or square section;

- pen.

The cutting blades of the drill are made of two steel semicircles with a thickness of 4 mm or more with pointed edges. Their diameter is calculated according to the size of the required wells.In the center of the semicircles, a recess is cut out in the shape of a rod for a better fit. Blades are usually welded to a rod with a diameter of ¾ inch or 20 × 20 mm, but it is more convenient to make several interchangeable pairs and bolt to the rod. To do this, you need to weld the mounting shelves made of strong steel at the right angle, and make holes in them.

A handle 0.5 meters long is attached perpendicular to the rod, the length of which is made up of the depth of the pit and an additional 60 cm. A drilling tip is fixed on the other side. It is needed for stability and initial loosening of the earth. If the garden drill turns out to be too long, you can make a prefabricated, folding or telescopic rod.

Blade knives can be made from two round halves or from an open circle with offset edges. In any case, the edges of the blades must be separated by 30°. This is necessary for successful work on dense soils. Corners or stops made of thick steel will enhance performance.

Features of manual drilling

Favorable conditions for drilling a well manually are:

- groundwater at a depth of up to 20 m;

- soil without hard rocks that make manual drilling difficult.

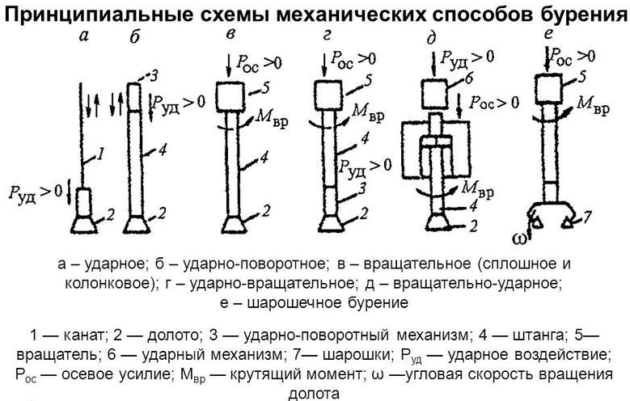

Manual drilling of a well can be done in two ways:

- rotational;

- percussion rope.

The meaning of the rope-impact method is to build a well, from a relatively high height, a heavy pipe with a sharp end is thrown into it, tied with a rope to the frame. The soil is separated from the blows by this structure, and gets inside it. Then the pipe is lifted to the surface by a winch and freed from the rock accumulated in it. This is how deepening happens. The advantage of impact drilling is that one person can be involved in it.

Rotary drilling is performed with a tool capable of cutting into the ground with the help of rotation and lifting the soil to the surface. For this method of drilling, two people are required to rotate the drill rod using rebar or pipe. As the drill design deepens into the ground, it is built up with additional detachable tubes.

Upon completion of drilling operations, the casing string is lowered into the well.