How to choose the right water pump for heating

Thus, when choosing a circular pump, you should pay attention to such technical characteristics

power;

limit temperature level;

internal pressure responsible for pressure

For one-story houses, this criterion is not so important, but when heating multi-story buildings, this parameter should be paid close attention. To be in direct proportion to the diameter of the pipes in the system and this indicator is reported by a special marking 30, 40, 80 and so on, indicating the height of the coolant rise in decimeters, respectively by 3, 4 or 8 m;

device performance

which is the volume of the heat carrier pumped over per unit of time and depending on the boiler power, pump flow rate and water temperature in the supply pipe and in the return pipe;

amount of electricity consumption. as well as the possibility of adjusting this parameter with a switch. On the case, as a rule, the highest consumption is indicated, although many "household" models do not have adjustment and have average indicators.

But before making the final choice, experts recommend not focusing on peak performance, since in this mode the device operates for an exceptionally short time, it is better to take into account the average values and then there will be no noise from the movement of the coolant in the pipes. In addition, this approach will save at the stage of purchase, as well as during operation.

In addition, this approach will save at the stage of purchase, as well as during operation.

How does a well pumping station work?

The principle by which a submersible pumping station works in a well is as follows.

- The water pumped out of the well rises through the intake hose to the surface and enters the reservoir of the accumulator, putting pressure on its elastic membrane.

- After the water pressure in the accumulator tank reaches the required value, the relay will automatically turn off the electric pump.

- When the valves are opened at the points of water intake, water from the accumulator, under the influence of pressure exerted on the membrane by the air medium located on the reverse side of such a diaphragm, will begin to flow into the pipeline system.

- When the water pressure in the accumulator drops to a critical level, the relay will automatically turn on the submersible pump, which will start pumping fluid into the hydraulic tank again.

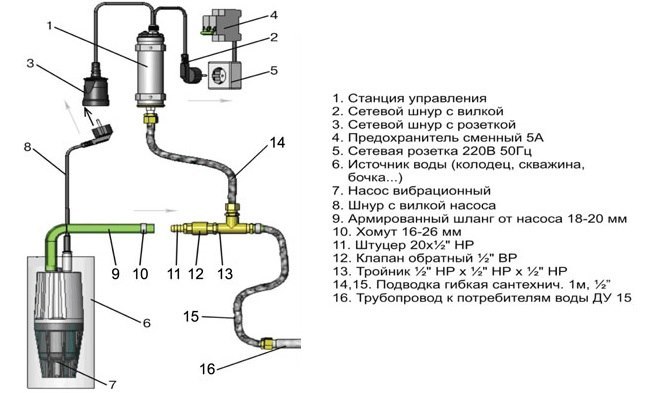

Control station - the easiest way to automate the supply of water from a submersible pump

Submersible well pumping stations for even greater automation of the water pumping process can be equipped with float switches that automatically stop the installation if the water level in the well drops to a critical level.

Vortex

In vortex submersible pumps, the intake and expulsion of water occurs with the help of a single impeller with blades, which is located in the upper part of a vertically suspended casing near the outlet pipe. To reduce hydraulic losses, the design provides for a very small distance between the side face of the vortex wheel disk and the working chamber - this makes it impossible for vortex devices to work in an environment with sand particles.

Vortex-type devices have good pressure characteristics (liquid lifting height reaches 100 m) and average pumping volumes (about 5 cubic meters / hour).

Although vortex electric pumps are rarely used in everyday life, there are Belamos TM, Sprut, Whirlwind, NeoClima, Pedrollo Davis models on the market.

Rice. 7 Vortex submersible pump - design and appearance

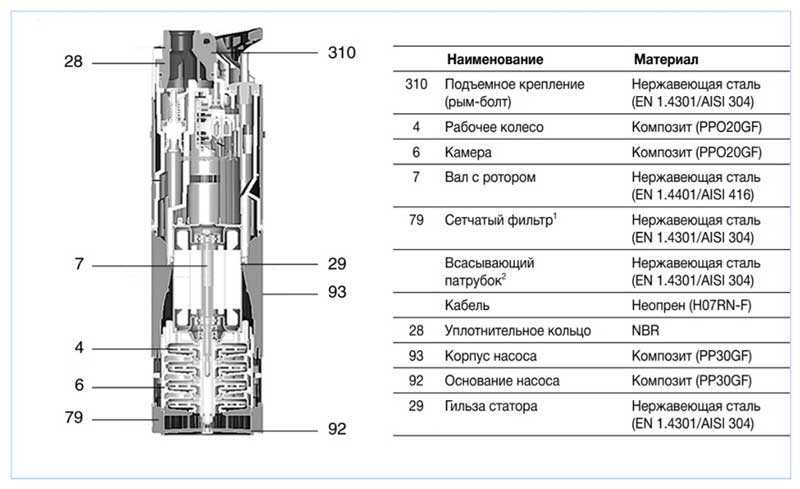

Centrifugal

Centrifugal devices have achieved such distribution due to the following properties:

- Their coefficient of performance (COP) is the highest of all analogues, in large-sized industrial units it reaches 92%, in household models it reaches 70%.

- Structurally, the working chamber is designed in such a way that the liquid enters the central part of the centrifugal wheel, and is pushed out through the side pipe. This allows you to make multi-stage centrifugal devices in which the ejected fluid is fed to the axle of the next wheel, which further increases its pressure. Thanks to the use of several centrifugal wheels with separate working chambers (stages), it is possible to obtain pressure parameters in the system that are several times higher than those of other pumping equipment (in household models, the pressure does not exceed 300 m).

- Centrifugal types are capable of pumping liquid in large volumes at high pressure; for domestic use, this figure rarely exceeds 20 cubic meters / h.

- Centrifugal type units are less affected by fine sand particles on the working mechanism, they are widely used in sand wells, choosing a model to work with a suitable particle size indicated in the passport.

- A significant advantage of centrifugal types is the high level of automation, the world's leading manufacturers of pumping equipment (Grundfos, Pedrollo, Speroni, Dab) supply their devices with units with frequency control of the impeller rotation speed. This innovation allows not only to significantly save electricity during the operation of the electric pump (up to 50%), but also significantly increase its service life.

If we list all manufacturers of centrifugal pumps that represent their products on the domestic market, the list will be quite voluminous, so we will limit ourselves to the world's leading manufacturers listed above. Of the domestic brands, Aquarius, Dzhileks Vodomet, Whirlwind, Belamos, Caliber, Unipump received the greatest fame.

Rice. 8 Centrifugal submersible pumps - design and materials of manufacture using the example of Grundfos SBA

Complete set and principle of operation

Pumping station - a device designed for pumping liquids. It may differ in technical and quality parameters, structural structure and method of water intake, is characterized by high performance, long working life subject to the rules of operation, availability of service and functionality.

Component parts of the National Assembly:

- Self-priming pump - a mechanism responsible for the supply of fluid from the depths. Its advantage is the possibility of installation in a place remote from the well or well.

- Pressure switch. Provides constant pressure in the water supply, minimizes interruptions in the supply of water.

- Hydraulic accumulator. Its allowable volume is from 10 to 50 liters. The device optimally softens water hammer in the water supply system and serves as a reserve pressure tank.

- Anti-vibration hose. Connects the hydraulic accumulator to the pump, ensuring an uninterrupted working cycle of the mechanisms.

- A manometer is a device that determines the pressure of water with extreme accuracy.

If desired, the National Assembly can be equipped with mechanisms of the necessary parameters, in which case it will meet the stated requirements as much as possible. But it is best to give preference to devices assembled at the factory, they have their own advantages and ensure the stable operation of all component parts in specific given conditions.

Next, we will analyze the principle of operation of the pumping station. Self-priming pump, filling the tank with water, creates the appropriate pressure in the system. Separation of the hydraulic accumulator for air and water is carried out using a rubber membrane.

Water from the tank through the tap enters the sink, helping to reduce the pressure in the water supply.After the pressure indicators drop to 2.2 bar, the relay automatically starts the motor, which raises them to 3 bar and turns off the HC. The unit is cooled by water circulation. Its overload is controlled by automation.

Some models are equipped with a special sensor that protects the motor from overheating and excessive loads during idle operation. If there is no water in the suction pipe, it transmits a certain signal to the control system, which automatically turns off the motor.

Advantages of the considered devices

- Increased operational safety. The non-return valve, equipped with a filter for cleaning water from impurities and located at the end of the suction pipe, provides reliable protection of the engine from idle operation, as a result of which the mechanism does not overheat and retains its working life for a long time.

- Ability to work without power supply. In the event of an emergency power outage, the pumping station will function until the water from the tank is consumed.

- Long service life even without service. The hydraulic accumulator that completes the installation creates pauses for its rest, thereby increasing the working life.

- Maintaining pressure in the water supply, due to which the normal operation of the water heater, washing machine and other household appliances is ensured.

- Availability of repair and maintenance services. The NS is completed with parts and mechanisms that can be easily replaced if desired. The structure of the devices is quite simple, so you can find the problem and fix it if you wish.

The main disadvantages of the units

- Excessive noise. The mechanisms are quite noisy, so it is not recommended to install them in a residential area.

- High price. Not every user can afford pumps with an electronic control system, excellent quality indicators and low noise levels.

What are water pumps

The circulation pump is a small device with a metal case. The following materials can be used in the manufacture: cast iron, aluminum, bronze, stainless steel. A rotor is attached to the body of the device from the inside, and an impeller is attached to it. The rotor rotates thanks to the bearing system. All these elements are driven by electricity.

Hot water, falling on the impeller blades, is transferred by them through the pipe. This increases the efficiency of the heating system.

It is important to install the water pump vertically, otherwise its performance will decrease by 30%

There are two types of devices - with a wet and dry rotor.

Wet rotor pumps are used in heating systems of private houses. Such devices are in contact with water, so their parts need to be lubricated infrequently. The advantages of these models include simplicity of structure, long service life without maintenance, low cost of repairs and low noise level. They also consume a small amount of electricity, while their efficiency does not exceed 50% - for this reason they are not installed in large buildings.

Pumps with a dry rotor have a high efficiency and are used in heating systems of apartment buildings and high-rise buildings. In this case, the rotor does not come into contact with water, so the parts of the device need regular lubrication and service. Also, the device makes a lot of noise, so the installation of a circulation pump in the heating system is performed in a separate room with good sound insulation.

The market offers equipment with various characteristics, so the choice is not so easy to make. You also need to consider that in order to install a pump for heating of sufficient power, you will need to allocate a separate room.

With the right choice, you will be able to:

- maintain comfort and coziness in the house;

- increase heating efficiency, regulate the flow rate of water in the system;

- reduce the cost of electricity, with the help of which the pump works, and sometimes the entire heating system.

Before you go for the water pump, you need to draw up a detailed diagram of the entire heating system of the building. You also need to decide where the pump will be located and how it will be connected to the water source (read: "How to connect the pump to heating: installation and tie-in")

When choosing a device, it is necessary to pay attention to its most important characteristic - the pressure of the coolant. This indicator does not depend on the power of the heating system.

The water pressure can be 2-4 meters - when choosing, you need to take into account that the minimum indicator will not be enough for an apartment building. Thus, the greater the length of the heating system, the stronger this indicator should be.

When calculating the pump for heating, you need to focus on the maximum operating mode. All auxiliary elements (docking, plugs, fittings), and not just the circulation pump, must correspond to the functioning of the system to the maximum

In this case, errors are unacceptable, depressurization of the structure will be very expensive, so it is important to make the correct calculation of the circulation pump for heating. Also, experts recommend installing a critical pressure drop sensor in the heating system together with the water pump, so that in an emergency you can immediately turn off the pump

Criteria for choosing NS

Before you buy a pumping station, you need to pay attention to such an important indicator as performance. Many users believe that the higher it is, the more efficient and stable the mechanism works.

This is absolutely not true! Excessive performance of the PS will cause not only additional costs for paying for electricity, but also significantly harm the well. What characteristics of the well have a direct impact on the performance of the National Assembly?

- Mine depth. It must be measured from the bottom to the ground level.

- dynamic level. It is measured from the bottom to the water table, provided that the source is operated for 1-2 days.

- static level. It is measured from the bottom to the water table, provided there is no water intake for 1 to 2 days.

When choosing a HC, it is necessary to calculate the daily productivity of the well as accurately as possible. It should match the needs of the user or slightly exceed them.

Types of NS and their technical characteristics

The following types of pumping stations can be used to supply water from a well or well:

Mechanisms with built-in ejector and centrifugal self-priming pump.

| Device Specifications | Permissible indicator |

|---|---|

| Innings | 2.4 to 10 m |

| pressure | 33 to 68 m |

| Fluid temperature | -15 °С to +50 °С |

| Max working pressure | 6 to 8 bar |

| Maximum ambient temperature | 40°C |

| Gauge suction depth | 8 - 9 m |

| Degree of engine protection | IP44 |

| Voltage | 230V-50Hz - for single-phase motors

230/400V-50Hz - for three-phase motors |

Self-priming centrifugal pumps equipped with an external ejector. They are considered the best solution for a well up to 45 m deep. They are installed in utility rooms with high sound insulation.

| Specifications | Permissible indicator |

|---|---|

| Performance | 15 - 190 l/min |

| pressure | 10 – 80m |

| Gauge suction lift | up to 9 m |

| Liquid temperature | +40°C |

| Ambient temperature | +40°C |

| Insulation | class F |

| Degree of protection | IP 44 |

| Number of phases | 1 x 220-240V~/50Hz 3×230V~/50Hz 3×400V~/50Hz |

| Power | 0.44 - 1 kW |

Submersible pumps. Designed to work in areas with groundwater levels up to 10 m.

| Specifications | Permissible indicator |

|---|---|

| Performance | From 3.8 to 10 cubic meters |

| pressure | 16 to 30 m |

| Maximum engine speed | 2850 rpm |

| Number of steps | 3 |

| Pump diameter | 86 to 105 mm |

| Power | 400 V |

| Liquid temperature | +40°C |

Selection criteria for circular pumps

Taking into account the features described above, the consumer, when choosing the equipment he needs, should pay attention to:

Performance

This indicator is calculated at the minimum level of system load is directly related to several parameters that can be combined in a single calculation formula: Performance \u003d Q. (1.16 x DT)

measured in kg/h.

Each indicator needs an explanation:

- Q is the heat consumed by the room. Measured in watts (W). For each type of premises, SNiPs define their own norms for such consumption. The indicator depends on the region of location and the type of building. For example, in Europe, 100 W are allocated for heating 1 m² of a private house, and 70 W for an apartment building. For the countries of the former CIS, the norms established in 1986 apply, which are: - 173 - 177 W per sq. m. in buildings up to three floors; - 97 - 101 W per sq. m. in buildings with more than 3 floors.

- 1.16 - an indicator of the heat capacity of water. For other liquids, this number is different.

- DT - the difference in temperature values of the return and supply branches of the pipeline.

Pump selection by power:

This characteristic shows the ability of the device to overcome resistance:

- pipeline;

- locking system;

- fittings;

- appliances;

- height differences.

To calculate the indicator, the formula is taken:

Head = (R x l + Z) / p x g

In it: R - the value of the resistance of a straight pipe, measured in Pa / m; I - the length of the entire system, shown in meters; Z is the resistance of the fittings, indicated in Pa P is the density of the coolant, given in kg. per cubic meter; g - free fall acceleration, which is indicated in m / sq. With.

The final head of the pump is taken into account in meters. The heating systems installed in specific buildings cannot be accurately measured for the specified values, therefore, average values are taken in the calculation: R = 100 - 150 PA per meter; Z = 30% of the R value. The latter indicator can be increased due to the presence in the system :

- thermostatic valve, which will increase the number by 70%;

- three-way mixer, giving an increase of up to 20%.

When calculating the pressure, it is recommended to use another formula in which the pressure is equal to:

R x l x ZF The last two letters (ZF) define the safety factor of the circuit, which is not equipped with additional devices.

- The base loop safety factor is 1.3.

- If there is a thermostatic expansion valve, then the ZF value is 2.2.

- When adding a three-way mixer, an indicator of 2.6 is taken.

This indicator greatly simplifies the calculations.

Video instruction for calculating the required pressure and volumetric flow:

Choosing a pump for a heating system in a private house

In heating systems, the circular pump was almost never used before. The boiler was located at the lowest point of the heating system, and the water moved through the pipes under the influence of the laws of physics.

With the advent of powerful heat-generating units, which are designed to work in large areas, it has become important to accelerate the passage of the coolant through the system for a more uniform heat supply. Another aspect was the popularity of arranging underfloor heating, which in buildings without basements is always located below the level of the boiler.

A properly selected pump will not create unnecessary noise, save money and ensure high efficiency of the entire heating system. The main parameters, features of choice and the most popular models of such devices will be described below. When choosing a drainage pump, the selection principle is significantly different, it is described in a separate material on our website.

How does the principle of operation of the heating system affect the choice of pump

It is not enough to know that the operation of a circular pump can significantly reduce the cost of heating a house, it is necessary to take into account all the necessary criteria when choosing it. And first of all, you should decide on the type of the heating system itself, its characteristic features.

This work can be done independently, but given that the pump is selected for more than one season, it is better to contact a specialist.

So, before dwelling on a specific brand of pump, you need to decide on:

type of heating system. If the existing network has natural circulation, then it is recommended to install a "wet" pump with a power of up to 50-60 W

For systems with forced operation, a more powerful apparatus will be required - up to 80 W, and then, subject to the presence of a slope, and without it, attention should be paid to devices over 90 W;

heated area and volume of coolant circulating in the system

Naturally, with the growth of these parameters, it is necessary to pay attention to more powerful pumps. But in order to calculate the exact power of the device, you will need the help of a heat engineer.

Sometimes the organization of the heating system assumes that an additional pump will be installed in the heating system. for example, to increase power or separately for underfloor heating;

restriction on the maximum noise level - it is precisely because of this parameter for private houses, without the possibility of installing a pump in a separate room at a maximum distance from living rooms, it is not recommended to use devices with a "dry" operation cycle;

the technical condition of the existing heating system. Any device can be connected to the new system, but for networks that are 15-20 years old or more, the presence of impurities in the coolant should be taken into account. An additional 25-35% should be added to the calculated power, especially if it is planned to install a pump with a “wet” engine. But, if possible, pumps with a dry motor are better suited for older systems, since, due to the closed design, they are less sensitive to the quality of the coolant.

Be sure to take into account the type of fuel on which the boiler operates, as well as its design features, including the temperature level of the coolant at exit and entrance.

Installing a pump in the heating system of a private house

It is best to install a circulation pump at the same time as installing the entire heating system. But since the need to operate this device also exists in existing systems, we should dwell on this option.

First you need to prepare a "field of action", for which you need to free the system from the coolant. Also, you should prepare in advance all the necessary tools and consumables.

Next, you need to make threaded connections on the pipes, taking into account the diameter of the pump holes.

Before installing the device, first mount a filter in front of it for cleaning

The absence of this element does not directly affect the operation, but the likelihood that the circulation pump will need to be repaired soon is quite high, since dirt and sand particles will disable the device.

In order to properly install the pump, it is imperative to pay attention to the arrow marked on the body of the device: it must coincide with the direction of movement of the coolant.

It is also mandatory to install taps on the inlet and outlet pipes. the so-called shut-off valves and check valve, as well as a bypass, the presence of which greatly facilitates the performance of repair and maintenance work.

As a rule, the pump is mounted in a horizontal position.

For "wet" engines - mandatory, and for "dry" - preferably.

After completing all the installation work, you need to check the reliability of the connections and perform a test run of the system. for which it should be filled with coolant.

Filling the system is recommended to be carried out using the lower pipe - this contributes to the fact that all the air in the pipes rises up into the expansion tank, through which it will be removed from the system.

The circulation pump can be installed both on the return pipe and on the supply pipe. In the first case, it will work in a more gentle mode, since it will not be affected by high coolant temperatures.

But installation on the supply pipe is the most effective, because most modern devices are able to withstand liquid temperatures of more than 105-110 ° C. Basically, pumps with a "wet" motor are installed on the supply, and with a "dry" motor - on the return.

You need to enable JavaScript to vote

Technological features of connecting the National Assembly

The connection of the pumping station to the well is carried out in several stages.

-

The first stage: preparatory work. First of all, a suitable place for installation is selected. The water supply device can be installed both in the utility room and in a specially equipped caisson.

The room selected for installation should be located near the well, characterized by high rates of heat and sound insulation. It is carefully removed, an elevation is mounted on the floor, on which the National Assembly is subsequently installed.

- The second stage: laying a water pipe to the National Assembly. Pipes are best laid in the ground below the freezing level, otherwise the water may freeze in winter, which will lead to a rupture of the water supply.

-

The third stage: installation of the device. There are two outlets on the NS body. One of them is designed to connect to the well, the second - to the water supply system of the premises. To connect the PS to the well, it is necessary to select a polyethylene pipe of a certain diameter, attach a coarse filter and a check valve to one end of it, then immerse it in the well, and connect the other end to the pump.

To connect the second outlet to the water supply, you will need a polypropylene coupling and a tap. The tap is attached to the thread of the device, a coupling is screwed onto it, to which a water pipe is subsequently soldered. After checking the system, it can be fully exploited.

Overview of popular NS manufacturers

- Marina is a Spanish manufacturer whose HCs have established themselves as reliable, functional and practical devices that are easy to maintain and easy to operate. They are represented by the widest model range and on average serve up to 15 years.

- Gardena is a well-known German manufacturer, whose mechanisms are distinguished by high technical parameters and good performance. The model range of the NS of the brand in question includes both stationary and portable devices.

- Metabo is another German company specializing in the production of high quality well pumps. Its devices are represented by a wide range of models, are equipped with reliable and wear-resistant components, are sold at a fairly low price, and meet all technical standards.

- Hammer is a manufacturing company whose priorities are high quality and reasonable prices. Pumps of this brand have one important feature - they are highly efficient.

- Gileks is a Russian manufacturer whose devices are designed taking into account the climatic features of our belt. They stably respond to sudden changes in temperature and voltage, are equipped with cleaning filters and can be used for pumping liquids from clogged reservoirs.

For a well, a pumping station, selected correctly, will be the best solution. It will provide uninterrupted water supply to the dwelling, regardless of the conditions of its operation.

We recommend that you see how to install the National Assembly in the house:

Heating system installation and maintenance

The installation plan for the heating system is created in advance. This is exactly the kind of work that is best left to the experts. Even if you know the purpose of each device and have instructions for it, this will not help much. To create a heating system with high efficiency, you need to have special knowledge, since each element must have a specific place. In addition, during the installation of the water pump, additional elements will be required: taps, filters, sensors, fittings.

There are many models of water pumps on the market, among them there are industrial devices - they have much larger dimensions, but at the same time, their capabilities make it possible to use these devices in heating systems of large buildings. Therefore, it will not be superfluous to consult with experts about the choice of a product that is suitable for a particular home.

In the future, the heating system requires regular maintenance

This is especially important if the coolant will come from a common source of water that does not have cleaning filters.

After a certain period, noise may occur during operation of the water pump. You should not be afraid of this, since most often the cause of it is the presence of air in the heating system. If you remove air from it before the first start of the structure, and then do it as needed, the water pump will not make noise. The pump in the heating system, watch the video:

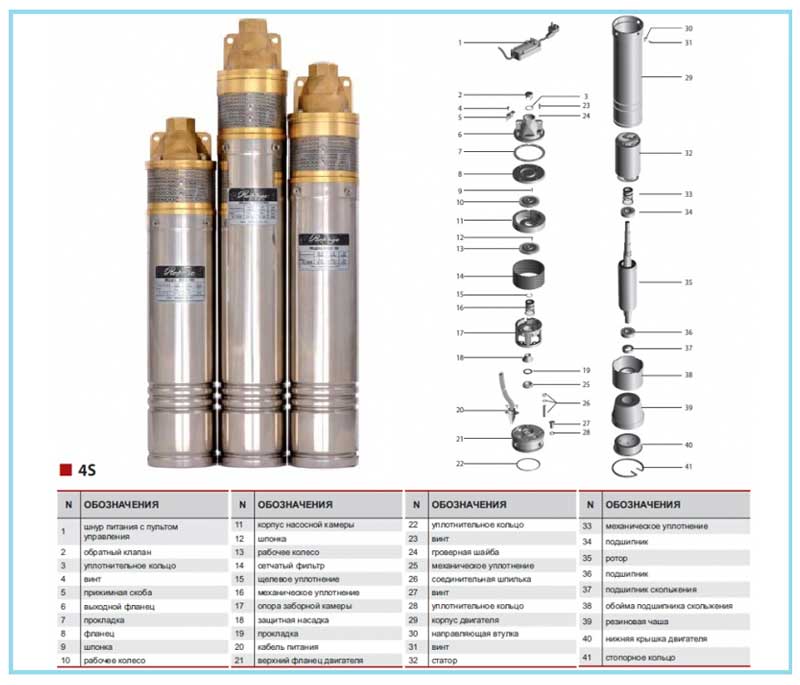

What is a submersible well pump, its advantages and scope

Unlike wells, wells have a shallow depth of up to 15 meters if concrete rings are used in their construction, as well as a depth of up to 25 meters or more in the construction of plastic wells with walls made of high-strength corrugated polyethylene pipes (Korsis).

For water intake from wells with a water mirror distance from the surface of less than 9 meters, surface water pumps or pumping stations of a centrifugal principle of operation with automation are widely used, which are distinguished by their budgetary cost and ease of operation. If the static level of the water supply source is more than 9 meters, or it drops to a greater depth during water intake (dynamic level), it is necessary to use a submersible electric pump in the well.

The main parameter of submersible types is high pressure characteristics, which allow water to be supplied over long distances with a source located remotely from the house.

Centrifugal electric pumps specially designed for water intake from wells are equipped with float switches that prevent their operation when the water level in the source drops to certain limits.

Fig. 2 Scheme of home water supply with water intake from a well with an electric pump Gileks

A submersible well pump for individual water supply systems for domestic use can perform the following functions:

- Produce water intake to supply a private house from depths of more than 9 meters, providing a supply volume within a wide range.

- To supply water to the surface for irrigation, it can be used to fill barrels, tanks and various containers with water, which, after warming up in the air, water the garden. If drip irrigation is organized on the site, using a submersible electric pump, you can fill a large volume tank and turn it off with a float switch installed on the walls of the tank when filling.

- A submersible well pump can fill pools, artificial reservoirs, ponds or pump water out of them.

- In critical situations during flooding during the spring flood of underground basements, garages, cellars and other premises, an electric pump can pump out water if it is not very dirty, or install a home-made filter on its suction pipe, which prevents dirt particles from entering the working mechanism.

- With a submersible electric pump, you can immediately pour the coolant into the heating system directly from a well or barrel, with a pressure of about 1.5 bar necessary for its operation, or use it to fill an expansion tank located in the attic of the house.

- Some types of submersible pumps (vibrating, screw) are effectively used to combat silting of water sources - for this, the unit is released into the well at a short distance from the bottom and the turbid liquid is pumped out with its help.

Wells collect water from shallow water layers (perch water), and are designed for the use of mechanical means of supply using a gate and a bucket. If it is planned to draw water on the site for the constant supply of a residential building using an electric pump, it is much easier and cheaper to drill a shallow Abyssinian well (many people drill with their own hands) and use it as a water source. The use of a well is justified only if the site is completely absent or often loses electricity.

Rice. 3 Well electric pump for water supply at home in the source

Types of circular pumps

The main division of the described units exists according to the type of rotor operation. There are two types - dry and wet.

Its main difference is that the pump rotor has no contact with the liquid. This provides a sliding type mechanical seal that isolates the pump end from the main mechanism. This prolongs the life of the device. Such equipment is preferable to use in pipelines with an increased length index.

If we consider the positive and negative sides, then the pluses should include:

- good indicator of efficiency;

- long service life.

The cons are:

- The presence of sealing rings, which are located between the working part of the rotor and the main motor. These seals require replacement once every three years.

- Noisy work. If there is no basement, then installed in a common space with living people, such devices will interfere with the normal rest of residents.

- Mandatory control over the clean environment in which the device operates. Equipment can be damaged due to dirt particles in the coolant and atmospheric dust getting into the mechanism.

wet type

The difference from the above type lies in the rotor operating in water. There is an impeller on the rotor, which, being integrated into the general circuit of the movement of the liquid, accelerates its movement through the pipes. The coolant itself is a coolant and lubricating medium for this unit.

- no need for maintenance;

- noiselessness;

- ease of operation;

- the ability to adjust the intensity of work;

- durability.

Minus - in low efficiency. Its indicator is within 50% of the value. This prevents the use of such devices in long or thick pipelines.