What is it needed for

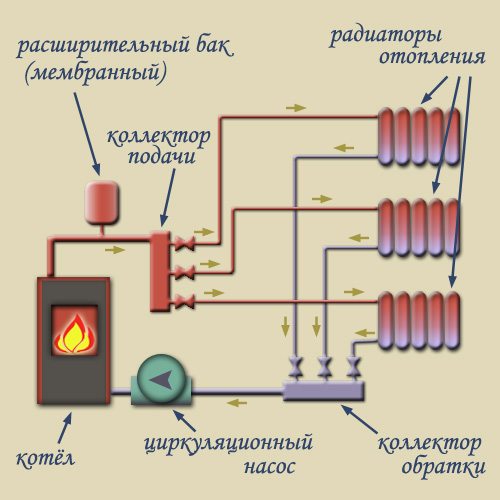

When installing water pressure systems, there is a rule: the total diameter of all branches should not exceed the diameter of the supply pipe. With regard to heating equipment, this rule looks like this: if the diameter of the boiler outlet fitting is 1 inch, then two circuits with a pipe diameter of ½ inch are allowed in the system. For a small house, heated only with radiators, such a system will work efficiently.

In fact, there are more heating circuits in a private house or cottage: warm floors. heating of several floors, utility rooms, garage. When they are connected through a tapping system, the pressure in each circuit will be insufficient to effectively heat the radiators, and the temperature in the house will not be comfortable.

Therefore, branched heating systems are performed by collectors, this technique allows you to adjust each circuit separately and set the desired temperature in each room. So, for a garage, plus 10-15ºС is enough, and for a nursery, a temperature of about plus 23-25ºС is required. In addition, warm floors should not heat up more than 35-37 degrees, otherwise it will be unpleasant to walk on them, and the floor covering may be deformed. With the help of a collector and a shut-off temperature, this problem can also be solved.

Video: using a collector system for heating a house.

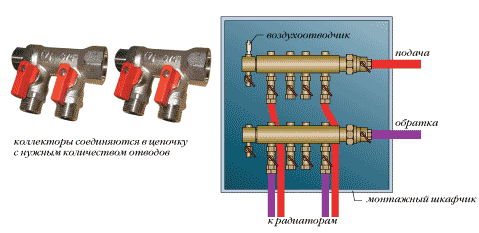

Collector groups for heating systems are sold ready-made, while they may have different configurations and the number of taps. You can choose a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are universal and do not always fit the needs of a particular home. Their alteration or refinement can significantly increase costs. Therefore, in most cases it is easier to assemble it from separate blocks with your own hands, taking into account the features of a particular heating system.

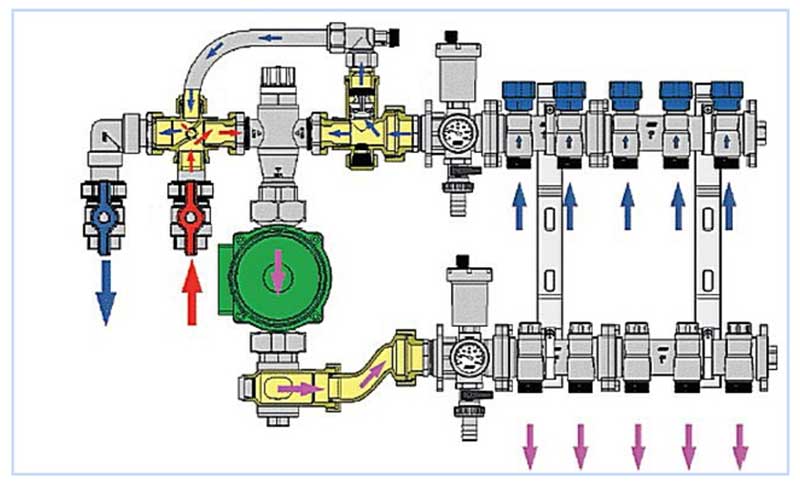

Collector group for heating system assy

The design of the universal manifold group is shown in the figure. It consists of two blocks for direct and reverse flow of the coolant, equipped with the required number of taps. Flowmeters are installed on the supply (direct) manifold, and thermal heads are located on the return manifold to control the temperature of the return water in each circuit. With their help, you can set the required flow rate of the coolant, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves. The supply and return manifolds are combined into one unit with brackets, which also serve to fix the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles. and if some of the taps are not involved, installing it will be clearly inappropriate.

The rules for mounting the finished block are shown in the video.

Comb - manifold assembly

The most expensive elements in the manifold distribution block are flow meters and thermal heads. To avoid overpaying for extra elements, you can buy a collector assembly, the so-called "comb", and install the necessary control devices with your own hands only where necessary.

The comb is a brass tube with a diameter of 1 or ¾ inches with a certain number of branches with a diameter for heating pipes ½ inch. They are also connected to each other by a bracket. The outlets on the return manifold are equipped with plugs that allow you to install thermal heads on all or part of the circuits.

In order to save money, the collector for heating systems can be assembled from individual elements on your own or completely done by yourself.

Features of the installation of the collector system

Installation of heating systems is carried out before finishing work on laying floor and wall coverings, the pipeline passing through the floor is tied to a strong metal mesh and poured with a screed located on the insulation layer.

Apartment house

The implementation of collector heating in a residential apartment building is practically not used in everyday life, this is primarily due to the presence of radiator heating in buildings, in which all rooms in the apartment are heated by batteries. Laying circuits for space heating through floors is associated with significant financial costs and is inefficient, besides, a comb is not required for laying a small number and small lengths of loops. A significant factor that makes the installation of collector heating in an apartment building useless is the imbalance and violation of the temperature regime of the entire house system, as a result of which penalties and dismantling of the laid warm floor are possible.

Cottage

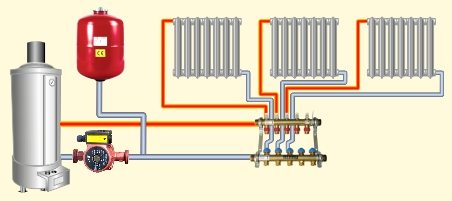

Collector combs are the main elements in organizing the heating of country houses and cottages, they are usually placed in the wall of rooms located in the center of the house on each floor, attached to the riser built into them.

To do this, a recess is placed in the wall at the construction stage, in which a comb is placed, to increase the aesthetic appearance, a collector cabinet with closing doors is placed in the place of the insert.

One circuit is used for each room, if there are several radiators in the room, they are connected in series according to a single-pipe passing or through circuit (Leningrad). Several small circuits are mounted if the area of \u200b\u200bthe premises is large and the maximum length of the pipeline does not provide coverage with a given step.

Rice. 14 Combined heating system

Advantages and disadvantages of radiant heating systems

Positive sides

The main advantage of the beam scheme is ease of use.

Special equipment makes climate network management as ergonomic and convenient as possible:

- You can set the temperature of each heating radiator in the house without leaving the manifold cabinet. In addition, if necessary, you can completely shut off the water supply to any element of the system without disrupting the operation of the entire heating network.

- Each pair of pipes connects the collector to only one radiator. Therefore, small diameter pipelines can be used, which are easy to disguise under the floor covering. Among other things, this allows you to partially warm the floor surface.

Pipes of the radiant heating system are laid before the floor is poured

- Thanks to the use of special devices (the so-called hydraulic arrows - collectors with a large diameter), it is possible to form several heating zones in the house with different coolant temperatures.

In this case, a short circuit is organized between the supply and return pipes. Heated water constantly circulates in the hydraulic arrow, and its intake can be made at different distances (the temperature will also depend on this).

Negative sides

To complete the picture, it should be said about the disadvantages of using a radiant heating system.

It is because of them, despite all the advantages, it is not very common:

- Greatly increased consumption of supply and discharge pipes. The more spacious the house and the more complex the geometry of the rooms, the more details you will need.In addition, the complexity of installation increases, which cannot but affect the estimated cost of construction.

The radiant heating system requires the use of a huge number of pipes and collectors

- The need for hidden installation. If the traditional tee system can be mounted along the walls, then you cannot place a huge number of pipes this way. They must be hidden under the floor. You can wall up in the walls, but in this case, the consumption of material will increase even more.

- No joints. When designing pipelines, care must be taken to ensure that the pipe under the floor does not contain a single joint. In this place, gusts most often occur, and the cost of repairing the breakdown will be far from low and very laborious.

- If the system design provides for several circuits with different coolant temperatures, then each of them must be equipped with a circulation pump.

Self-assembly of the heating manifold

Heating manifolds are usually supplied by the manufacturer in assembled form, a standard-length circulation pump is installed later on an American-type threaded connection. Sometimes components are delivered to consumers separately, the assembly order consists of the following operations:

- Flow meters are installed on the supply comb and the end air outlet is screwed into the right end.

- A valve is connected to the return manifold with previously installed caps on the shut-off valves through an American on the right side.

- On both combs on the left, through the American, they install the drives for connecting the compression electric pump, while they are arranged in such a way that the fitting for installing the thermometer is on the front side.

- A tee is screwed into the return manifold, to which the thermostatic head is attached.

- Using a threaded connection (American) for mounting electric circulation pumps and gaskets from the kit, the pump is connected to the upper and lower combs.

- At the end of the work, pipes of standard diameter are connected to the collector block using the Eurocones included in the kit.

All main connections are sealed with rubber gaskets that come with the unit and the electric pump, sometimes there are no seals in the tap and tee of the supply comb, then linen tow or other plumbing materials are used for sealing

To carry out the work, one adjustable wrench is enough, while it is important not to pinch the nuts - this can lead to rupture of the gaskets

Rice. 18 PEX and PE-RT pipes

The nuances of homemade work

The main condition for the correct operation of heating is the creation of a hydraulic balance in the system. The ring collector for heating must have the same capacity of the inlet pipe (section of the main pipe connected to the supply line) as the sum of the same indicators in all circuits. For example, for a system with 4 circuits, it looks like this:

D = D1 + D2 + D3 + D4

When making a heating manifold with your own hands, remember that the distance between the supply and return sections of the pipe must be equal to at least six comb diameters.

When installing the device, the following nuances are taken into account:

- an electric boiler or a gas boiler is connected to the upper or lower nozzles

- the circulation pump cuts only from the end side of the comb

- heating circuits lead to the upper or lower part of the collector.

For heating a house with a large area, circulation pumps are installed on each circuit. In addition, to select the optimal volume of the coolant, additional equipment is installed on each inlet and outlet pipe - balancing flow meters and valves for adjustment. These devices limit the flow of hot liquid to a single nozzle.

In order for the boiler wiring collector to perform its functions in full, it is necessary that the length of all circuits connected to it be approximately the same length.

It is possible to additionally (but not necessarily) equip a mixing unit in the manufacture of heating collectors. It consists of pipes that connect the inlet and return combs. In this case, to regulate the amount of cold and hot water as a percentage, a two or three-way valve is mounted. It is controlled by a closed-type servo drive, which receives a signal from a temperature sensor installed in the heating circuit.

All this design allows you to adjust the heating temperature of a room or a separate circuit. If too hot water enters the collector in the boiler room, then the flow of cold liquid into the system increases.

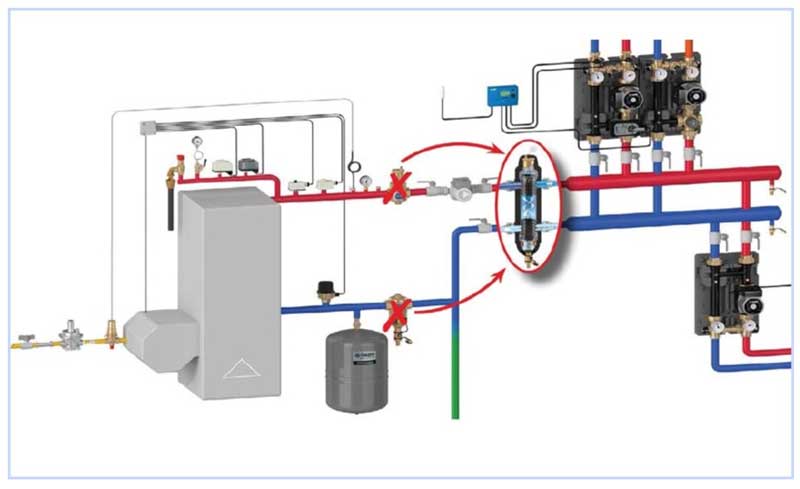

For a complex heating system in which several collectors are installed, a hydraulic arrow is installed. It improves the performance of the distribution combs.

The collector for the boiler room, which you make yourself, will ensure the normal functioning of the heating only if the parameters of the system stroke are accurately selected. Therefore, you first need to entrust the calculations to a professional, and then get to work.

Remember that the comfortable temperature in the house depends on many factors. Only a fully balanced system will ensure correct heating operation.

Definitions

A collector (comb) is a type of sanitary fittings that distributes a coolant along the contours of consumers. Simply put, this is a section of a thick pipe with one inlet and several outlets. Its appearance was facilitated by the complication of heating systems, the spread of flooring and radiant radiator wiring, and an increase in the number of heat consumption points in the house.

Heating collector. Click on the photo to enlarge.

The heat carrier on the main line comes from the boiler room to the floor collectors. They have as many inputs/outputs as there are thermal energy consumers (radiators, convectors, etc.) on the floor.

Unlike a serial connection (using tees), the collector heating system is distinguished by an independent connection to each heater. Such a scheme makes it possible to control the temperature regime of each radiator, if necessary, allowing you to turn it off without prejudice to other thermal devices. To do this, each outlet of the collector is supplied with its own shutoff valves.

Mixed wiring is possible when several small circuits with independent control are connected to the collector. In this case, a serial system for connecting heating devices is used inside each circuit. In the presence of a collector, the heating circuit becomes simpler, allowing you to abandon seals, additional shut-off and control valves. Using collectors and collector units, you can significantly reduce the cost of designing, installing and commissioning a heating system.

Is it possible to make a heating collector with your own hands

Sometimes it happens that autonomous heating in your own house does not work very efficiently. It seems that the power of the boiler was chosen correctly, and the piping was done correctly, and all installation work was carried out at a professional level, and the temperature in the house is not what you would like. What to do in this case? There is only one way out - to install a distribution manifold. By the way, there is no need to buy it ready-made, the design of the collector is not very complicated, so making it yourself is not the biggest problem. So, in this article we will answer one question, how to make a distribution manifold with your own hands?

Collector types

From two to twelve circuits can be connected to the collector, and the number of involved circuits may vary during the operation of the system.

At the moment, the distribution manifold for heating can be made of the following materials:

- polymers;

- copper;

- brass;

- steel.

For ease of use, the basic types of collectors can be equipped with additional options, among them:

- thermostat;

- circuit pressure control detector;

- automation for protection against emergencies;

- air release valves;

- programmable mixers;

- electronic valves.

How to design a collector

Designing a heating manifold is not so difficult. The device is simple, and you do not need to have special knowledge in plumbing to create a sketch and subsequent drawing. Let's break down what you need to consider when creating:

What material are you planning to use?

Collector System Diagram

Remember! Metal is considered the best option for a heating manifold, because this material has a high resistance to high temperatures, is durable and reliable in operation, fairly easy to install, and also unpretentious in maintenance.

how many branches you need - how many consumers of the coolant the heating collector should provide.

Having calculated all this, you can begin to create a sketch of the future product.

- Take a sheet of paper and draw two rectangles parallel to each other - this will be the basis for the heating manifold.

- Draw the connection for the boiler and the boiler on the ends of the base.

- Draw the number of pipes that will fit the hot and cold tanks.

- Then remove from the hot tank the required number of pipes for all elements that need a coolant.

This completes the creation of the project, now transfer the drawing under the heating manifold of a private house to a blank sheet of paper and mark the diameter of your pipes there. After that, you can begin to select materials in order to mount a collector for heating with your own hands in your own home.

Pipe selection

The collector heating system must be equipped with pipes selected in accordance with certain requirements:

- It is best if the pipe is in a bay, since the best choice for collector wiring is the absence of connections.

- The material must be resistant to corrosion, the pipes must serve for many years. The reason for this requirement is the same as in the first paragraph: the possibility of premature intervention in the monolithic screed should be minimized.

- The material must be sufficiently flexible, as the pipes are not always laid in a perfectly straight line.

- The characteristics of thermal stability and tensile strength are dictated by the environment in which the heating system operates. For a private house, the recommended figures are approximately as follows: pressure - up to 1.5 atmospheres, temperature - up to 75 degrees for batteries and up to 40 degrees for a system of underfloor heating. If we are talking about an apartment building, the maximum possible indicators should be higher: pressure - up to 15 atmospheres, temperature - up to 110-120 degrees above zero.

multistory building

In this case, the best choice is corrugated stainless steel pipe. The technical capabilities of this material make it possible to successfully cope with loads: coolant temperature up to 110 degrees above zero, pressure level up to 15 atmospheres, breaking pressure up to 210 kilogram-force per square centimeter.

The stainless steel pipe has good flexibility, as the bending radius can reach the diameter of the product. Installation work is carried out according to a simple algorithm: the pipe is sent to the fitting and secured with a nut.

Private house

The use of stainless steel is expensive.Since the autonomous heating system has a predictable performance, it is possible to take a more affordable route using cross-linked polyethylene. Polyethylene pipes are sold in coils of 200 meters. The material is able to withstand temperatures up to 95 degrees, and in the short term up to 110 degrees above zero. The permissible level of pressure for destruction is 10 kilogram-force per square centimeter.

Polyethylene pipe fittings are made of plastic or brass. Each fitting is equipped with a retaining ring that is threaded onto the pipe. A feature of cross-linked polyethylene is the memory for mechanical effects: if the material is stretched with the help of an extender, and a fitting is installed in the clearance, after a short time the pipe will tightly compress this part. The fixation of the connection is carried out by a retaining ring.

What is a heating manifold

A heating collector is a device whose task is the correct distribution of the coolant throughout the heating system of a private house. The collector helps to rationalize the heating of the home, allowing you to spend less on fuel consumption, and therefore save money. He is:

- two pipes for hot and waste coolant;

- pipes through which liquid will be distributed to all elements of the heating system;

- pipes designed to return the cooled coolant back to the boiler;

- pumps;

- regulators.

Such a device is usually made of metal pipes, but the price of such products will be quite high, because if your room is large, you will need a lot of material.

Collector for heating system

Tip: If your budget does not allow you to connect each element to the manifold for heating, there is an option to use polypropylene pipes.

The advantages of such a device are:

- uniform distribution of the coolant in the pipeline;

- full heating of the entire room, and not just certain places;

- improving the efficiency of the hydraulic heating system;

- reduced fuel consumption;

- the ability to install additional pipe bends on the manifold if you want to add elements to the wiring.

It is best to mount the collector on the heating system in a special cabinet that will protect and hide the system from dust or other influences. It is desirable that such a unit be mounted in a boiler room or a separate room, but nothing bad will happen if you simply fix the collector on the wall near the heating boiler.

Collectors for radiators and underfloor heating

The difference between the floor collector and the radiator one is in the design, associated with the difference in operating temperatures and lower hydraulic resistance of the radiator elements. The design of the block for connecting underfloor heating is much more complicated, it includes a large number of control valves and a circulation pump for multi-circuit systems.

The standard collector block for household radiators has a simple design: it consists of a large-section supply and return manifolds, from which fittings for connecting pipes leading to radiators exit. The device usually does not have any regulating, tuning valves and other complex devices, so its connection and installation does not cause difficulties for most homeowners. Heating radiators are connected to the unit through pipes running in the floor and connected from below at one point; it is not necessary to make a screed to place a direct pipeline, it can be laid in a strobe cut or knocked out in a slab.

A typical collector block is a technically complex element with a large number of adjustments and settings, often a circular electric pump is mounted in the system.When installing the block, one should distinguish between forward and reverse feed combs; for convenience, they are marked with red and blue paints, respectively. Also, in a straight line, adjustable flow meters with a transparent cap and applied divisions are most often placed, indicating the volume of liquid passing through them, it is marked with a red internal indicator head.

Usually the maximum value of the passed flow does not exceed 5 cubic meters per hour (corresponds to division 5 on the cap), the minimum mark is 0.5. If the indicator heads are in the upper part, then when the water flow passes through the feed comb, the indicator drops and shows the volume of the passing liquid. Sometimes the heads are located at the bottom, in this case the flow moves in the opposite direction from the heating circuit to the comb and, accordingly, the flow meters are installed in the return bar.

The standard unit provides a place for the location of the thermostat sensor, there are exhaust valves for bleeding air in the supply and return combs, valves are installed, in place of which there are seats for servo drives that perform automatic control of operating modes.

Rice. 11 Hydro gun - installation and connection diagram

Why do you need a distribution manifold for a heating system

A complex and branched heating system with a liquid heat carrier implies the correct organization of the movement of flows along numerous circuits. Only in this case the heating of the house will be efficient and manageable. But do not put a separate boiler in each room - it is much easier to use collectors in the circuit that will distribute the heated flow with the required indicators to the heating devices. They will not only be able to control the temperature of the circulating fluid, but also ensure its uniform supply to all connected branches.

The distribution manifold outwardly resembles a hollow volumetric comb, at the base of which the total coolant flow enters, and then it is divided into separate sleeves in the side pipes and sent through all active channels. Exactly the same unit collects back all the waste liquid and supplies it to the boiler, closing the cycle. Thanks to this scheme, one water heater can be connected to heating devices with different characteristics: to a DHW storage tank, underfloor heating, classic radiators.

Each branch pipe of the collector is equipped with valves with thermostatic heads. Depending on the set heating values, they dose hot and cold water in those systems where its pre-mixing is required. For example, a warm floor works at only + 40-50 ° C, and wall-mounted radiators need a temperature of at least +80 ° C. The heating collector must pass the hot flow to the batteries without changes, and in the sections for floor threads, dilute it with cold water. To do this, the supply valve in its section partially overlaps the "red" pipe, reducing its cross section.

Tricky meter that saves electricity Pays for itself in 2 months!

The use of a comb simplifies the design of a branched system, eliminating the need for additional pumps and thermostatic valves. Everything that is necessary for the normal operation of the heating is collected in one place - this makes it easier to set up and maintain a complex circuit. In addition, almost any distribution manifold has a built-in end air vent, which allows you to remove bubbles from pipes that reduce heating efficiency.

Collector-beam heating system

Collector in a beam-type heating system.

The heating collector should be considered together with the consideration of the radiant heat carrier wiring diagram, so it will be easier to understand its main functions and advantages.

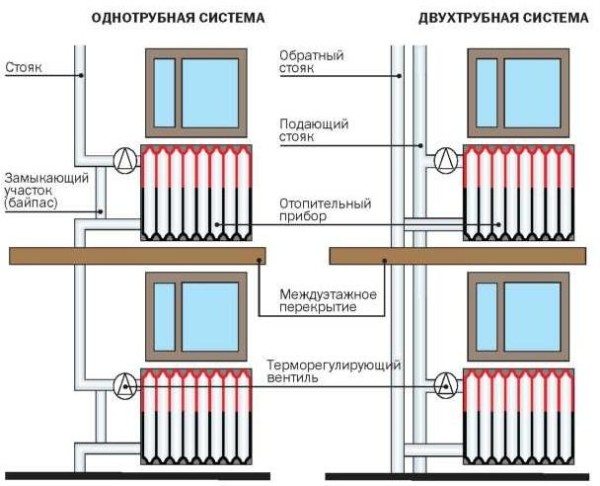

As you know, there are three main types of piping.

- One-pipe scheme.Here, the radiators are connected in series, that is, the coolant is supplied to the first device, then passes through the battery and enters the next, gradually passing through the entire circuit and returning to the boiler. Obviously, after each radiator, the water cools down, and the heating of the batteries occurs unevenly;

- Two-pipe scheme. This solution provides for the supply of water through one pipe, and the outlet - through the second, that is, the circuit consists of two lines, between which radiators are connected in parallel. This scheme allows you to warm up the devices more evenly;

- Beam scheme. The coolant is supplied to the distribution unit (collector of the heating system), from where it goes to each radiator through a separate pipe, and then returns back through the return pipes, is collected by a comb and enters the boiler. Thus, it is possible to achieve the most even distribution of heat in the room.

One-pipe and two-pipe wiring diagrams.

Beam wiring diagram.

Important! As you can see, there are many circuits in the beam circuit, one for each battery. Therefore, for the normal operation of the system, a circulation pump is required, which can provide the necessary parameters for the pressure and circulation rate of the coolant.

The beam scheme allows you to warm up each individual radiator as evenly as possible, moreover, it makes it possible to regulate the intensity of heat supply to each battery.

Manifold cabinet for radiator heating with supply and return combs.

Also, in such a scheme, you can turn off any device without changing the operation of the entire system, and in multi-storey buildings, you can turn off entire floors without interrupting the supply of coolant to other sections of the building.

To realize these advantages, heating collectors are used, which are included in the distribution unit in the form of a pair of devices - the supply and return combs. Tying the heating manifold with shutoff valves, air and drain valves, flow meters and thermostatic heads allows automatic control of temperature conditions on each individual heater.

The use of flow meters makes it possible to regulate the supply.

Important! Most often, such wiring is used in the construction of heating systems for private houses and cottages, however, this scheme can also be applied in an apartment with a centralized supply of coolant. It should be remembered that pipes are best carried out under the floor.

Another advantage of beam wiring is the ability to hide the pipeline under the plinth or in the thickness of the floor. Often it is this feature that influences the choice of wiring diagram.

In the "warm floor" system, a collector for floor heating systems is necessarily used.

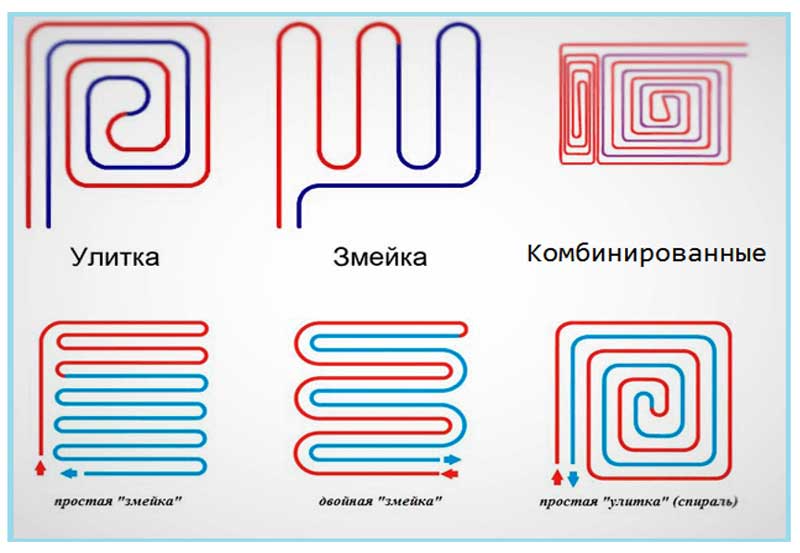

It is also impossible not to mention such a system as a "warm floor". Here, the circuits are not connected to radiators, but are laid in a special way in the floor screed in order to warm it up.

The only significant drawback of this solution is the high price of materials and work.

Pipe selection

Although pipelines of various materials can be used for water supply and circuits, polymers are mainly used in everyday life, which are supplied in coils of various lengths and are easily bent when laying loops.

The main materials of heating pipelines are: cross-linked PEX polyethylene with an aluminum layer between the inner and outer shells, cross-linked PEX and heat-resistant PE-RT polyethylene.

It should be noted that metal-plastic is not very practical as a material for underfloor heating - due to its high rigidity, it is difficult to bend with a small radius, and mechanical impact on the surface during installation or before laying the screed leads to bends and breaks.It is possible to repair a pipeline made of metal-plastic by inserting a section connected using compression or crimp fittings - this leads to a decrease in the passage channel and an increase in hydraulic resistance.

Pipes made of cross-linked and heat-resistant polyethylene have the same service life of about 50 years, it is believed that the PE-RT pipeline is easier to install in rooms with low temperatures, and if damaged, it can be easily repaired by soldering, although the technology is not very well known. Also, the cost of PE-RT is lower than PEX, although there are enough products of both categories on the construction market at a relatively low price.

Rice. 19 Basic piping schemes for underfloor heating

Ready-made designs of collectors for heating

The construction market presents products from various manufacturers of collector heating equipment, among them such popular brands as ProfLine, Valtec, Luxor, Rehay, Shout can be distinguished.

The most commonly used materials in the manufacture of collectors are stainless steel and chrome-plated brass, much less often in domestic heating equipment is selected from budget polymers (polypropylene), which do not provide for the installation of flow meters and valves for servo drives.

Rice. 16 Audytor C.O. 4.0

The principle of operation of the collector system

The collector system works according to the following principle: the coolant heated by the boiler with the help of a circulation electric pump installed between the supply and return lines enters the collector distribution comb, to the outlet fittings of which the heating circuits are connected. The total temperature of the heat carrier in all circuits is set by a temperature controller located on the inlet fitting of the supply manifold, and each outlet to the loop is equipped with a flow meter, with which the volume of the heat carrier passing through the circuit is manually set.

After passing through the circuits, the cooled coolant enters the return line and is pushed by the electric pump to the boiler, in which it is heated. Circulating in a circle, the heated liquid returns to the supply manifold, which distributes it to individual heating circuits.

In most designs, return distribution units are equipped with shut-off valves - this allows them to be equipped with electric servomotors to automatically regulate the flow passing through the circuits.

Rice. 2 The principle of the collector heating device

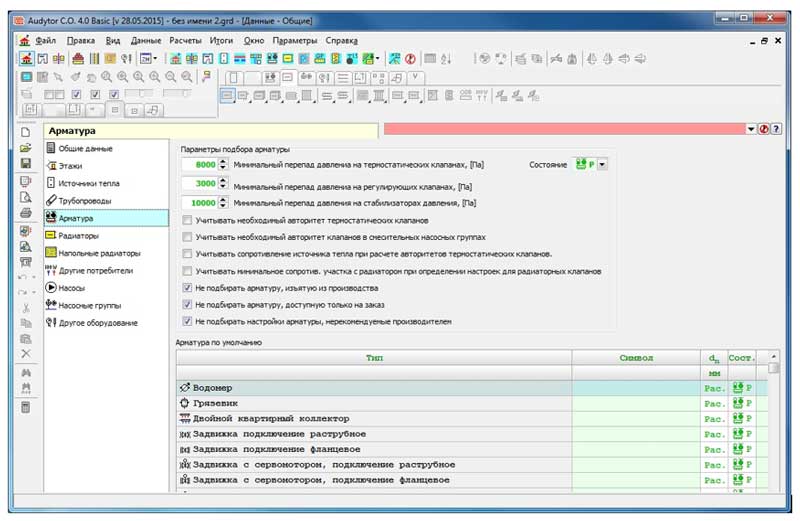

Calculation of collector heating

The homeowner does not need to calculate the parameters of the collector (its passage diameter, length, cross section of the outlet fittings) and the diameter of the pipes when purchasing a standard product. If you want to make such calculations, you can find the necessary formulas on the network, although in this case it is easier to focus on the standard dimensional parameters of manufactured factory products.

The main task of the calculations is to determine the length of the pipes to ensure the required temperature in the room with known temperature characteristics of the coolant. To do this, there is no need to resort to complex engineering calculations, which can only be done by narrow specialists in the field of heating; for an ordinary layman, it is easier to use an online calculator or a computer program.

To obtain the desired result, the initial data on the required temperature in the room and its area, the diameter and spacing of the pipes, and the carrier temperature are entered into the program or calculator. On the Internet, you can find reviews of Audytor CO calculation programs from Sankom, Valtek Complex from the company of the same name, Raucad / Rauwin 7.0 from Rehau.

Rice. 17 Manifold block assembly