HEAT FLOWS

2.1. Maximum heat flows for heating Qomax, ventilation Qvmax and hot water Qhmaxresidential, public and industrial buildings should be taken into account when designing heat networks for relevant projects.

In the absence of projects, it is allowed to determine heat flows in accordance with the requirements of clause 2.4.

2.2. The maximum heat fluxes for technological processes and the amount of condensate returned should be taken according to the projects of industrial enterprises.

When determining the total maximum heat flow for enterprises, one should take into account the discrepancy between the maximum heat flows to technological processes, taking into account the sectoral affiliation of industrial enterprises and the ratio of heat loads of each industry in the structure of district heat consumption.

2.3. Average heat fluxes for hot water supply Qhmbuildings should be determined according to hot water consumption rates in accordance with SNiP 2.04.01-85.

| Contributed by the Ministry of Energy and Electrification of the USSR | Approved by the Decree of the State Construction Committee of the USSR of December 30, 1986 No. 75 | Effective date January 1, 1988 |

2.4.* Heat flows in the absence of projects for heating, ventilation and hot water supply of buildings and structures are determined by:

for enterprises - according to consolidated departmental standards approved in the prescribed manner, or according to projects of similar enterprises;

for residential areas of cities and other settlements - according to the formulas:

a) maximum heat flow, W, for heating residential and public buildings

(1)

b) maximum heat flux, W, for ventilation of public buildings

(2)

c) average heat flow, W, for hot water supply of residential and public buildings

; (3)

or

; (4)

d) maximum heat flow, W, for hot water supply of residential and public buildings

(5)

| where k1 | — | coefficient taking into account the heat flow for heating public buildings; in the absence of data, it should be taken equal to 0.25; |

| k2 | — | coefficient taking into account the heat flow to the ventilation of public buildings; in the absence of data, it should be taken equal to: for public buildings built before 1985 - 0.4, after 1985 - 0.6. |

2.5. The average heat flow for heating residential areas of settlements, W, should be determined by the formula

; (6)

the same for ventilation,T, at tO

. (7)

2.6*. The average heat flow, W, for hot water supply of residential areas of settlements in the unheated period should be determined by the formula:

(8)

2.7. When determining the total heat fluxes of residential and public buildings connected to heat networks, one should also take into account the heat fluxes for hot water supply of existing buildings subject to centralized heat supply, including those without centralized hot water supply systems or equipped with gas water heaters.

2.8*. Heat losses in heat networks should be determined by calculation, taking into account heat losses through isolated surfaces of pipelines and with average annual coolant leaks.

2.9*. Annual heat consumption by residential and public buildings should be determined according to the recommended Appendix 22*.

Annual heat consumption by enterprises is determined based on the number of days the enterprise operates in a year. the number of work shifts per day, taking into account the mode of heat consumption of the enterprise For operating enterprises, annual heat consumption can be determined according to operational data or according to departmental standards.

Ventilation

The calculation of air exchange in individual heat points is carried out in accordance with the regulatory data and requirements specified in: SP 41-101-95 "Design of heat points"; SNiP 41-01-2003 "Heating, ventilation and air conditioning" and GOST 30494-96 "Residential and public buildings. Indoor microclimate parameters.

Initial data

The design of ITP air exchange systems begins with an analysis provided by the customer or from an additional calculation.

- Thermal emissions from equipment.This is the most important parameter, since the power, type and performance of the ventilation system depends on it. Most often, heat dissipation data is provided by equipment manufacturers. You can also perform additional calculations.

- Type of fuel. It is relevant when the power supply is not carried out from the central heating system.

- Geometric characteristics of the room.

- climate zone.

Norms and rules

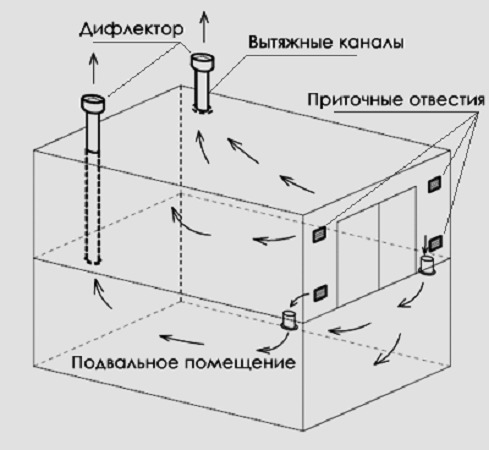

Individual heating points can be part of the building or located separately. In both cases, ventilation is calculated the same way. The supply and exhaust system with natural impulse is mainly used.

Heating points with a capacity of less than 0.7 MW can be designed without a natural supply and exhaust ventilation system. This rule applies to free-standing or built-in premises equipped with mesh or steel wire fencing.

The ventilation power is determined by the maximum total heat release from the equipment. The air exchange rate is taken equal to 1-3 times per hour, it depends on the area, the height of the ceilings.

It is important to choose the correct design air temperature: in winter for the working area, it is + 28 ° С; in summer - no higher than 5 ° C from the outside air. When the IHS is part of the building, then the heat flows from the considered room to the adjacent ones are checked.

If the air temperature in adjacent rooms rises, then measures are taken to additionally insulate the separating partitions. The standard method of thermal insulation consists in pasting the walls with foam plastic, followed by plastering.

When the IHS is part of a building, then the heat flows from the considered room to the adjacent ones are checked. If the air temperature in adjacent rooms rises, then measures are taken to additionally insulate the separating partitions. The standard method of thermal insulation consists in pasting the walls with foam plastic, followed by plastering.

Often, designers resort to such tricks: if there is a general house mechanical supply and exhaust ventilation, then changes are made to the project by inserting the existing forced ventilation system into the ITP. This improves the quality of ventilation.

Basic technical requirements for pipeline fittings

The main technical requirements for pipeline fittings include:

- Tightness in relation to the external environment and tightness in the gate.

- Structural strength and ability to withstand loads (constant and short-term pressures, forces and torques) without deformations that disrupt the normal operation of the product.

- Absence of stagnant zones and cavities; ensuring reliable functioning after a long stay of the valve in the closed or open position.

- Maintainability, allowing the replacement of wear parts without cutting valves from the pipeline.

- The performance of parts in conditions of frequent starts and stops of equipment; simplicity and ease of maintenance, ensuring a guaranteed number of opening-closing cycles at operating parameters.

Safety valves are subject to special requirements, the main of which are the following:

- When the maximum allowable pressure is reached, the rotary check valve must open without fail and pass the working medium in the required amount.

- When actuated, the valve must operate stably without vibration.

- The valve should close when the pressure drops.

- The valve in the closed state at operating pressure must provide the required degree of tightness.

Shut-off fittings must have:

- minimum hydraulic resistance;

- the necessary tightness in the gate;

- ease of working.

Regulatory fittings must:

- provide the necessary throughput characteristic and regulation accuracy;

- perform, if necessary, the functions of shut-off valves for the tightness of the shutter;

- have a flow part resistant to erosive wear;

- emit a noise level of not more than 85 dB at a distance of not more than 1 m;

- do not create vibration of the adjacent pipeline.

The materials of valve bodies and covers should be selected based on the strength properties of steels at operating temperatures.

Sealing surface materials must be resistant to corrosion in water and steam, resist the erosive effects of the flowing medium, which is especially important for control valves, the parts of the flow part of which operate at high flow rates of the medium. Seal materials for steel gates must have a high tensile strength (at least 400÷500 MPa) at operating temperatures, sufficiently high hardness (HRC>40) and high scuffing resistance

Seal materials for steel gates must have a high tensile strength (not less than 400÷500 MPa) at operating temperatures, sufficiently high hardness (HRC>40) and high scuffing resistance.

Valves produced by factories must comply with the standards given in the Rostekhnadzor Rules.

The warranty period for the operation of pipeline valves is established in accordance with the manufacturer's specifications (but not more than 24 months from the date of commissioning of the products and not more than 36 months from the day of crossing the border of the Russian Federation for export deliveries).

D. Testing of heat pipes

B3-1-52. Testing of heat networks for design pressure and design temperature should be carried out under the direct supervision of the shop manager or his deputy in accordance with the program approved by the Chief Power Engineer (mechanic) and agreed with the power supply organization (workshop).

The design pressure test should be carried out at a water temperature in the network not higher than 40°C.

Simultaneous testing for design pressure and design temperature is not allowed. B3-1-53. The time of testing the heat network for the design pressure and design temperature of the coolant must be notified in advance (at least 48 hours in advance) against receipt by the responsible authorized consumers (workshops) connected to the tested section of the network.

B3-1-54. At the time of testing the heat network for design pressure, heat points and local consumption systems must be disconnected from the network under test. When testing for the design temperature, heating systems for children's and medical institutions, heating systems with direct connection, open hot water supply systems, as well as non-automated closed hot water supply systems must be disconnected from the heating network; Shutdown must be carried out by the first valves (from the side of the heating network) installed on the supply and return pipelines of the heating point, and all drain and air cocks at the heating point must be fully open. B3-1-55. In the absence of the required density of shut-off fittings at the heating point, consumers should be disconnected by valves installed in the chambers for connecting consumers (workshops) to the heating network, or by installing plugs at heating points. B3-1-56. At the time of testing the heating network for the design parameters of the coolant, a permanent duty of personnel at heating points and in local systems of consumers (workshops) should be organized.

At the time of testing the heating network for the design temperature, monitoring of the entire route of the heating network is established, for which, according to the instructions of the test manager, on the basis of local conditions, observers should be placed along the route from among the operating personnel of the heating network (workshop) and the consumer with the participation of the relevant services of the enterprise (organizations)

Particular attention should be paid to sections of the network in places where pedestrians and vehicles are moving, sections of channelless laying, sections where cases of corrosion failure of pipes have previously been observed, etc.

B3-1-57. When testing the heat network for the design parameters of the coolant, it is prohibited:

a) carry out any work not related to testing on the test sites;

b) to be in chambers, tunnels and at heating points by persons not participating in the tests;

c) be located against flange connections of pipelines and fittings;

d) when testing the heating network for the design temperature, it is allowed for personnel to descend into thermal chambers and tunnels in case of emergency only at the direction of the person in charge of the tests.

When testing the heating network for the design pressure of the heat carrier, it is also prohibited to make a sharp increase in pressure and increase the pressure above the limit provided for by the test program.

B3-1-58. Increasing or lowering the temperature should be carried out at a rate of not more than 30 ° C / h. It is forbidden to increase the temperature of the coolant above the limit provided for by the test program. B3-1-59. Prior to the start of testing for the design parameters of the coolant, the person admitting to work must check the correct installation and condition of the shut-off valves and instrumentation, as well as the compliance of the installation of plugs with the test program and existing rules. B3-1-60. The bypass of chambers and tunnels of heating networks during tests for the design parameters of the coolant (temperature, pressure) must be carried out according to an approved program in accordance with the rules for servicing chambers and tunnels with high temperature.

List of terms and definitions

|

Heat consumer |

An enterprise, organization, institution, workshop, object, site, building connected to heating networks (or a heat source) and using energy using existing heat energy receivers (heat consumption systems) |

|

Heat supply organization (TSO) |

An enterprise (association) that has a source of heat and supplies it to consumers from its networks or collectors or through heat networks of wholesale consumers-resellers or main consumers on the basis of contractual relations |

|

Subscriber |

A consumer of thermal energy that has a contractual relationship with a heat supply organization, including the boundary of balance sheet ownership and operational responsibility between them, drawn up by an act |

|

Wholesale Consumer-Reseller |

An enterprise (organization) has heating networks on its balance sheet and carries out wholesale purchases of thermal energy from TSOs and its resale to various consumers. In relation to TSO, it is a subscriber, in relation to its consumers - a heat supply organization |

|

Main consumer |

A TCO subscriber who consumes part of the thermal energy for his own needs, and transports the rest through his networks and resells it to other subscribers (sub-subscribers of the TCO) |

|

Subsubscriber |

A subscriber who has a contractual relationship with a wholesale consumer-reseller or main consumer |

|

The boundary of the balance belonging of the heat network |

The point of division of the heat network between the TSO and the subscriber, the main consumer, the wholesale consumer-reseller, determined by the balance sheet of the heat network |

|

Thermal load of the subscriber |

The sum of the calculated heat loads (MW, Gcal/h) of all heat receivers within the limits of the issued technical conditions for connection, the value of which is specified in the contract with the TCO |

|

Device for commercial accounting of heat energy consumption |

A metering device (complex of devices), on the basis of which the amount of thermal energy consumed by the subscriber, subject to payment, is determined |

|

Node for commercial metering of heat energy consumption |

A set of a device (a set of devices) for commercial metering of heat energy consumption, connecting lines, a cabinet for placing devices and sections of pipelines of the heat consumption system, with which the elements of the devices are connected, ensuring without distortion the accounting of all heat energy actually consumed by the subscriber during its operation |

|

System of commercial metering of heat energy consumption |

The totality of the system for measuring the parameters of the coolant, algorithms for processing the measurement results and methods for calculating the amount of thermal energy consumed by the subscriber, payable, including sanctions for violations of the heat consumption regimes by subscribers and the supply of thermal energy to subscribers by the heat supply organization |

|

Heat energy consumer accounting groups |

A consumer of thermal energy with various systems for commercial accounting of its consumption, adopted by the Rules for Accounting for Thermal Energy |

GENERAL PROVISIONS

1.1.* These standards should be observed when designing heating networks transporting hot water with temperatures up to 200 ° C and pressure Pat up to 2.5 MPa and water vapor with temperature up to 440 °C and pressure Рat up to 6.3 MPa, and structures on them (pump houses, pavilions, etc.).

The requirements of the standards apply to water (including hot water supply networks), steam and condensate heating networks from the outlet valves of external collectors or walls of heat sources to the outlet valves of the heat points of buildings and structures.

When designing heat networks and structures on them, the requirements of other regulatory documents approved or agreed with the Ministry of Construction of Russia should also be observed.

Clause 1.2. exclude.

1.3. For heating networks of regions with a heat consumption of 100 MW or more, as a rule, repair and maintenance bases should be provided.

Basic requirements for the installation of valves

Shut-off valves are an integral part of any pipeline, regardless of its location or purpose.

Along with proper storage and compliance with production standards, the direct installation of valves in the pipeline is important. In this article, we will focus on the basic requirements for the installation of valves, without which you simply cannot do:

In this article, we will focus on the basic requirements for the installation of valves, without which you simply cannot do:

1. Before the installation of shut-off valves, it is mandatory to clean the pipeline, as well as the valve itself (if it was in storage). Cleaning is done manually using brushes and pressure of water or steam.

2. When installing gate valves, it is not allowed to move by the stem, as this may lead to breakage.

3. The installation of shut-off valves is carried out on straight sections; installation of valves on a bend in the pipeline or on uneven sections is prohibited. Compliance with this condition is due to the fact that pressure drops occur in these sections of pipelines, which will negatively affect the operation of shut-off valves, and also affects the tightness of the connection between valves and the pipeline.

4. If the shut-off valves to be installed are heavy, then it is necessary to provide supports that will support it, otherwise there will be an additional undesirable load on the pipeline and joints.

5. If flanged devices are being installed, then before installation it is necessary to check the condition of the flanges, there must be no defects.

6. If there are arrows on the valve body showing the direction of flow in the pipeline, the installation instructions should be followed, taking into account this direction when installing with the pipeline. As a rule, such arrows can be seen on check valves or gates.

7.Bolts and other fasteners are tightened without excessive force, as excessive tightening can lead to cracks in the body of the locking device.

8. If the installation of the locking element is carried out by welding, then it is carried out with the valve in the open position.

In addition, we note that when installing shut-off valves, the installer must protect it from shock and other damage, because any such excesses can significantly reduce the durability of the valve.

CHAMBER HEAT NETWORKS

- facilities on the route of heat pipelines for the installation of equipment that requires post, inspection and maintenance during operation. Valves, stuffing box compensators, drainage and air devices are located in the chambers of heating networks, control and measure. instruments and other equipment. In addition, they usually install branches to consumers and fixed supports. Transitions of pipes of one diameter to pipes of other diameters must also be within the limits of K.t.s. To all K.t.s, installed. along the route of the heating network. numbers, to-rymi they are designated on the plans, diagrams and piezometric. charts. The equipment placed in the chambers must be up to the wall for maintenance, which is achieved by ensuring sufficient distances between the equipment and the walls of the chambers of heating networks. Height K.t.s. choose at least 1.8-2 m. Their vnutr. dimensions depend on the number and diameter of pipes to be laid, the size of the installed equipment and imaginary ones. distances between builds, structures and equipment. K.t.s. built of brick, monolithic concrete and reinforced concrete. Openings are left in the end walls for the passage of heat pipes. Floors in K.t.s. made from prefabricated reinforced concrete. slabs or monolithic. For water runoff, the bottom is made with a slope of at least 0.02 towards the receiver, which, for the convenience of pumping water from the K.t.s. located under one of the drains. The ceiling can be monolithic or prefabricated reinforced concrete. slabs, lay. for reinforced concrete. or metallic. beams. For the installation of hatches, slabs with holes are laid in the corners of the ceiling. provided for at least two at vnutr. chamber area up to 6 m and at least four with an area of more than 6 m2. For the descent of service personnel, brackets are installed under the hatch, arranged in a checkerboard pattern with a height step of not more than 400 mm, or ladders. If the dimensions of the equipment exceed the dimensions of the access hatches, mounting openings are provided, the width of which is equal to the largest size of the fittings, equipment or pipe diameter plus 0.1 m (but not less than 0.7 m). Industrial chambers of thermal networks made of prefabricated reinforced concrete are widespread, the installation of which takes less time and reduces labor costs.

Prefabricated structures of rectangular K.t.s. are also used. with vertical walls. blocks, to-rye are of two types: solid and with rectangular holes for passing heat pipes. When building heating networks of small diameter K.t.s. can be made from round reinforced concrete. rings. Round floor slabs have two openings for inspection hatches.

On the master, thermal networks with a diameter of 500 mm or more, sectional valves with an electric drive are installed, as a rule, in K.t.s, over which above-ground structures in the form of pavilions are built on. Dm repair work in the pavilions provide for lifting equipment. For waterproofing. protection outer surfaces of the bottom and walls K.t.s. in the presence of a high level of groundwater, despite the existing associated drainage, cover

pasting waterproofing from bituminous

roll materials in several layers,

what is defined by the project. In conditions

increase waterproof requirements

bridges, except for the outer pasting

waterproofing is used additionally.

plaster cement-sand waterproofing vnutr.surfaces applied at large volumes of work by gunning.