Barbecue from a barrel

It is desirable to find a barrel of almost the same volume - 50-60 liters - this is the optimal size. Moreover, its diameter should not be too large: skewers usually go 50-60 cm. In order for them to lie tightly on the brazier, at least 10-12 cm of free length should remain. So it turns out that the diameter of the barrel should not be more than 40-50 cm.

Brazier from a barrel with a lid. Production to the smallest detail coincides with the process when using a gas cylinder

If it is wider, there are two ways out - to make skewers according to the required sizes or to weld a corner on the far side from the inside, on which to rest their tips. You won’t be able to win much, but 5-6 cm, depending on the size of the corner, can be won back.

Barrels must have walls at least 2-3 mm thick. By itself, you can not use containers from under fuels and lubricants. You can’t fall them out to such an extent that you can cook food.

The sequence of manufacturing a brazier from a barrel is no different from those described above. By itself, only the preparatory stage goes away - there is no need to fill with water. With very different sizes, you will need to make adjustments to the markup - in the direction of decreasing or increasing - see for yourself.

From the barrel, you can also make the simplest brazier - weld the legs to the cut along the container and cut along the edges of the recess for the skewer

They make very functional barbecues out of barrels - they add a container for coal or firewood (also with a lid) next to it. One of these is in the photo.

Brazier from a barrel with a container for coal

Although, no one bothers to make the same from a cylinder: next to a 50-liter propane tank, attach the same design, but already 27 liters.

Brazier from propane cylinders with a capacity for coal or firewood

Scope of oxygen cylinders

For what purpose the cylinder is intended depends on the composition of the gas:

• Technical. May contain minor impurities. The total proportion of pure oxygen is not less than 99.5%. Obtained by the method of low-temperature rectification and electrolysis of water. It is used in welding and metal cutting, soldering, energy, oil industry, chemistry and agriculture.

• Medical. The proportion of oxygen is not less than 99.5%. The gas is odorless. May contain trace amounts of water vapor (0.009%) and carbon dioxide (0.01%). Obtained only by low-temperature distillation. It is used in medical, health-improving institutions and at home to compensate for the lack of oxygen in the air.

• High purity oxygen. Maximum purified from impurities, the proportion of the substance is 99.999% of the total volume. It is used in the production of electronics and measuring equipment.

The capacity of the cylinders is different: from 1 to 50 liters. The pressure can be 150-200 kgf/cm2. The delivery of oxygen cylinders of various sizes and purposes is carried out by the Gaz Expo company.

Preparing for cutting a balloon for barbecue

Before making the first cut, you need to protect yourself. To do this, you need to fill the bottle with water. How it's done? Before you start the robot, you need to make sure that the tank is empty. To do this, open the shut-off valve, which is located at the top of the cylinder and by ear determine if there is a hiss of gas. Then, in the same way, with the tap open, turn it down with the tap so that all the available liquid flows out from the inside.

The stopcock is made of bronze alloy, and bronze is a very soft metal to work with. Therefore, we take a manual hacksaw for metal and at the bottom of the faucet - where it is twisted into a cylinder, we cut off the faucet completely. We have formed an inlet into which we can insert a watering can or hose to fill with water. It must be understood that the water that will fill the balloon will displace the air saturated with gasoline, therefore it is forbidden to smoke or use open or hidden fire during this operation.

The bottle must be completely filled with water. After that, we make a cork. This is where a cork stopper from a bottle of wine or something like that can help us. Having slightly tucked it, we hammer it tightly with a hammer into the hole. Then we lay the balloon in a horizontal position and make a cut.

Advantages and disadvantages of a do-it-yourself brazier

Empty gas cylinders can be found in your own shed or garage. Even the purchase of this material to create an unusual brazier will be quite cheap. But this does not exhaust all the advantages of the container, from which you need to build a heat-resistant body of a barbecue grill for a summer residence.

Among the advantages of a gas cylinder, as the basis of an outdoor brazier, the following qualities are highlighted:

- Standard sizes. If to fulfill the plan you need not 1, but several identical containers, it will be easy to pick up a second one.

- metal thickness. It is more than 3 mm and allows you to make items in which a layer of charcoal will burn. Thick steel will not burn through or deform.

- Fire safety. The large and deep body of the brazier will not allow the coals to fall out. If you need to put out the fire, then just close the lid.

- Low cost of the product. A homemade apparatus will be slightly cheaper than a brazier made of metal of the same quality and having the same dimensions.

- Hearth size. A propane tank is a fairly large capacity (at least 50 liters). The body of the brazier made of it will allow you to place portioned dishes on it for a large company.

The case made of thick steel has practically no drawbacks in the design and strength plan

But its minor shortcomings also need to be taken into account:

- The used balloon does not have a very attractive appearance. Craftsmen decorate an ugly container with metal fittings, decorative details, and paint it with special paint. They manage to create beautiful and functional cooking utensils.

- Danger of working with a balloon. There is always some gas left in the tank. The explosive substance must be removed, and only then proceed to work.

Cylinder marking

Most often, a propane tank of 50 liters is taken for the brazier. It turns out the optimal size for cooking 6 servings of barbecue. These products are standard, because the markup will be common to all.

The outer diameter of the balloon is 96 cm. It is perfectly divisible by 4: it turns out 24 cm. There is also a mark, relative to which it is convenient to make markings: this is a longitudinal seam. With respect to it, it is worth postponing all distances: then everything will be smooth, without distortions.

First, we set aside 24 cm from the seam in both directions, draw lines. Putting the balloon horizontally, seam down, on one of the lines we make markings for skewers. We retreat 3 cm from the circular seams on the right and left, and then we put marks every 8 cm. We get 6 marks. They will need to drill holes with a diameter of about 1 cm.

From the line on which the markup was carried out, we set aside 10 cm upwards (34 cm will be obtained from the seam-middle). This is where the lid of our barbecue will end.

Marking the gas cylinder for barbecue

Next, mark the lid itself. This will be the distance between the first marked line and the one just drawn. Between them, stepping back from the circular welds of 3 cm, we draw lines. You and I drew a brazier cover on the balloon. It occupies less than half the diameter (in the photo it turned out below).

Do-it-yourself rocket stove from an oxygen cylinder

- Step one: cutting the balloon

- Step two: loading chamber

- Step three: loading hole

- Step four: ash pan

- Step Five: Vortex Flow

- Step Six: Welding

- Step seven: insulation

- Step eight: afterburning system

- Step nine: cover

- Step ten: support

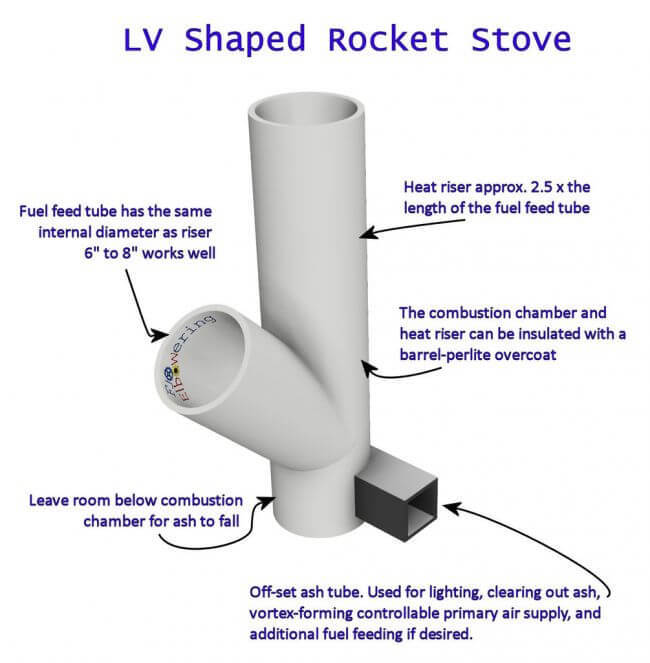

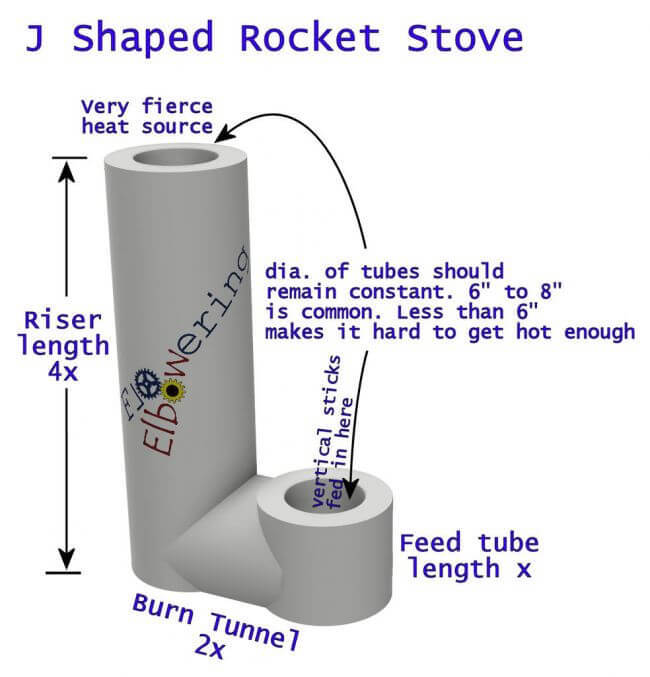

There are several options for building such a furnace. The master combined two such variants of photo 1, and 2., and made his own photo 3.

For the manufacture of the master do-it-yourselfer used the following

Tools and materials:

- Oxygen balloon;

- Cardboard;

- Marker;

- Insulating tape;

- angle grinder;

- Magnetic square;

- Welding machine;

- profile pipe;

- Band saw for metal;

- Channel;

- Roulette;

- Metal brush;

- Hammer;

- Clamp;

- Metal container;

- Pliers;

- Bolt;

- Two bushings;

- Perlite;

Step one: cutting the balloon

For proper functioning of the furnace, its vertical part must be 2.5 times longer than the fuel chamber. With this in mind, the master makes the layout of the cylinder. For an even cut, wrap a piece of cardboard around the balloon, align the edge and outline with a marker. When marking volumetric parts in this way, you can be sure that the cut point will be even.

Then the master cuts off the balloon according to the markup.

Step two: loading chamber

Now you need to properly cut off the edge of the loading chamber. The master makes a template from paper. Transfers the template to the workpiece.

Cuts according to the markup.

Step three: loading hole

With the help of a magnetic square fixes the loading chamber on the workpiece. He outlines it along the contour from the inside and outside.

Cuts out a hole.

Checks fit, adjusts if necessary.

Step four: ash pan

The ash pan provides access to the combustion chamber, and it can also be used to control traction. The master made the ash pan from a profile pipe 100 * 100 mm. Cut off the right size.

Adjusted to the radius of the pipe.

Cut a hole in the pipe.

Step Five: Vortex Flow

To ensure greater traction, the master makes forced ventilation. The pipe will draw in air, and as it passes through the curved pipe, it will increase the draft.

Cuts the shelves of the channel.

Makes a notch.

Bends the edge of the workpiece around the pipe.

Step Six: Welding

All parts are prepared and you can start welding.

Welds the loading chamber.

Grabs the ash pan.

Now you need to measure where to cut the hole for ventilation. The master applies the workpiece to the ash pan and circles the place where the curved part belongs.

Cuts out a hole.

Welds the workpiece, scalds the ash pan.

Step seven: insulation

For thermal insulation of the upper part of the riser, the master uses a barrel. Cuts a hole in it. Makes petals.

He puts a barrel on a pipe.

Subsequently, the master filled the internal space with perlite.

Step eight: afterburning system

To improve efficiency, the master makes a gas afterburning system. The air rising through the chamber will enter the upper part of the furnace and mix with the gas. Due to the influx of oxygen, the gas will be afterburned.

A box is made from a channel.

Marks a place for a hole on the furnace body.

Cuts a series of holes and welds plates on them.

For the ash pan, the master makes a lid. The cover is fastened with a bolt and two bushings machined on a lathe.

Step ten: support

For safety and stability from below, the master welds the plates.

The rocket furnace is ready. published by econet.ru

If you have any questions on this topic, ask them to specialists and readers of our project here.

P.S. And remember, just by changing your consumption, we are changing the world together! econet

Leg welding

The legs or stand can be welded from improvised material, can be made collapsible or stationary, with or without tables. You can even use a stand from an old sewing machine, but I got by with the most economical option.

We take a corner and cut off two blanks of 14 cm each, we find a longitudinal welding seam on the cylinder, which we took as a reference line. We put the cylinder on a horizontal platform or on a table, so that the seam is at the bottom and, placing a corner parallel to the platform, weld it at a conventional distance from the edge of the cylinder so that the center of the corner shelf coincides with the welding seam of the cylinder. We do the same on the other side. So we got the base for attaching the legs. And now we look if we need to make the legs not separate from the brazier, then we simply cut a 30x30 pipe or a corner in length, which will be convenient for us for the height of the brazier - about 50 to 70 centimeters. Next, weld it to the corner, which is on the cylinder.

And if we plan to make a collapsible structure, then we also cut the blanks into legs, but do not weld them to the corner, but drill holes of about 8 millimeters in the upper part of the leg and in the corner welded to the cylinder. Thus, we get a collapsible design: the cylinder is separated from the legs and can easily fit in the trunk of a car for going to a barbecue in nature. It should be noted that the legs must also be mounted observing the identity of the dimensions and diagonal of the structure. In the lower part of the legs, it is desirable to weld the support patches, after cutting them out of sheet metal and placing the brazier on the legs on a flat area. This is necessary so that the brazier does not fall into the ground under its own weight and has good resistance to tipping over. For more convenient transportability, small wheels can be mounted on two legs.

Rules for the use of an oxygen cylinder for medical purposes

Oxygen is used for respiratory procedures and preparation of oxygen cocktails. It favorably affects the state of the cardiovascular and nervous system, respiratory organs, skin, and brain.

An additional source of oxygen may be required for the following purposes:

• in the treatment of asthma;

• with heart failure;

• with pneumonia;

• with angina pectoris;

• in case of poisoning by substances with a suffocating effect;

• with weakened breathing;

• for hypoxic therapy;

• for deworming purposes.

Sometimes oxygen in cylinders is also used by relatively healthy people living in adverse environmental conditions and experiencing a lack of air. The substance is used for general healing and strengthening the body of children in kindergartens and sanatoriums, most often for making cocktails.

Contraindications to the use of oxygen in cylinders

On this topic

4747

Scientists talk about the benefits of interactive pets for pensioners

Scientists from the University of Exeter, in the UK, reported that the benefits of electronic pets are almost the same as from conventional ones, but the harm is much less. Their only drawback is their high cost.

The use of oxygen for medical purposes is contraindicated in acute respiratory viral infections, epilepsy, with violations of the patency of the sinuses and auditory tubes, in the presence of cavities in the lungs. Use is also limited in diseases of the gastrointestinal tract: ulcers, tumors, inflammatory processes.

Oxygen therapy is prohibited for pregnant women in the third trimester. It is better for healthy children to consume oxygen in the form of a cocktail from the age of 2-3 years. The use of oxygen from a cylinder for children is possible only as directed by a doctor.

Instructions for use

It is impossible to breathe pure oxygen; before it enters the lungs, it must necessarily be mixed with air; for this, various devices and devices are used. In pharmacies, oxygen is sold mixed with nitrogen in an oxygen bag or a miniature canister.

Prophylactic dose 3-5 breaths in the morning and evening. With more breaths, take breaks of 5-10 minutes between sessions. The maximum number of breaths per day can reach 50. A compact pharmacy spray, weighing 200 gr. enough for an average of 100-150 breaths.

It is necessary to receive oxygen from a pillow and a spray bottle through a special mask, it must be suitable for a person in age and size.

Oxygen cylinders are used in many areas and greatly help a person

But when using them, it is important to remember that oxygen is a strong oxidizer and supports combustion, so there should be no fire, grease or flammable substances near the gas source. After working with the balloon, it is necessary to ventilate the clothes for 30 minutes.

Places for skewers and grill nets for barbecue

For a comfortable arrangement of skewers on the back wall of our barbecue, we drill holes.The skewer has a pointed part in front, which clearly enters these holes and holds steady there. As we see in the photo above, six skewers are conveniently placed on the grill. To do this, we make a markup, stepping back from the top edge of our cutout of the brazier cover, 10 cm. down on both sides, put marks and draw a line with chalk. This is the hole level. Then retreating from the edge of the radius cut 4cm. and mark the drill. And then every 10 cm we put the same marks. Using a drill and a drill, we drill holes according to the marks. To do this, we first use a thin drill, for example, 4mm, and then we drill it with a 10mm drill, and at the end we chamfer the holes with a 12mm drill. or round file. On the front side of the brazier, we also make markings on the upper edge of the brazier and cut out the grooves for the skewers with a grinder. When this operation is completed, cover the brazier with a lid and transfer the marks of the places where the cut was made to the brazier cover. We do the same cutting. This must be done so that when the skewers are installed, the brazier lid closes more tightly.

You can also make seats for the grill - a grid. To do this, we just need to weld metal shelves between the holes for the skewer. We cut blanks 3 cm long from the corner, and weld them to the walls of the brazier, having previously marked the places of welding so that the grid has six points of support along the perimeter of the brazier. We clean the places of welding and cut off sharp corners.

To cook meat on a grill grid, you can use a stainless steel grid, with a cell of 10x10, or 15x15mm, after cutting out the size of the perimeter of the seats as in the photo below.

Brazier from a pipe and with a pipe

Building a brazier from a pipe is a little more difficult. In the sense that it will be necessary to weld the ends. All other operations are no different. Even the designs are exactly the same.

Braziers from a pipe - manufacturing will take a little more time: you need to weld the sides

But when using a pipe, there are advantages: since we will weld the sides anyway, why not make a door (in the photo on the left). You can use the old one from the stove - you can put firewood through it, as well as regulate the air supply while the coals are “preparing”.

Barbecue with a pipe

To ensure better traction and so that the smoke does not interfere with those nearby, you can attach a chimney pipe to the side of the barbecue from a cylinder, pipe or barrel. It will add work, but not very much. But it will be more comfortable to use: the smoke is good on barbecue, but they don’t feel like breathing at all.

Braziers with a pipe are more comfortable - the smoke goes up. Everything can also be arranged in different ways.

How to make a simple brick barbecue, read here.

Making legs

They can be from a corner, a round or shaped pipe, fittings, a strip of thick metal. What is in the economy, then use it. Some ideas are in the photo below.

The simplest legs from a pipe and a corner were welded to the bottom. You can make spacers at the bottom, and arrange a shelf on them

Almost the same can be done from strips of steel of great thickness.

Thick metal strip legs

Convenient legs for a brazier from a propane cylinder can be made from a profile pipe. They can be in the form of an inverted "T" and welded to the middle. You can make a support in the form of a frame by making a shelf (or several shelves) at the bottom for firewood, bowls, etc.

Legs from a profile pipe for a brazier from a gas cylinder

You can make legs from a round pipe and / or fittings. If you want to have a portable brazier, then small pieces of reinforcement are welded to the body, and pieces of pipes of a suitable diameter are placed on them (the inner diameter of the pipes is slightly larger than the outer reinforcement). You can do the opposite: weld pieces of pipes, and insert fittings.

How to make legs for the barbecue from pipes and fittings

Just keep in mind that with such legs it will be difficult to move it: the legs will fall out. To avoid this, cut the thread.

See below for a video example of making one of the homemade braziers from a propane cylinder.

March 14, 2018. Read 20604 times

Good day, dear readers of our magazine.

My name is Rostislav, I am 37 years old and I am a builder with twelve years of experience. Today we will talk with you about outdoor recreation. And nature, as you know, is friends, family and barbecue. To cook meat in nature, you can use all sorts of improvised means - bricks or sticks, or you can make a beautiful brazier from a barbecue gas cylinder with your own hands and surprise everyone

If such a barbecue will stand in the yard, then it will immediately attract the attention of your guests and neighbors. Also, this brazier is compact enough to take it with you in the trunk of a car.

Making a brazier with your own hands will not take much time and labor, you just need to be able to use a grinder and a welding machine or ask a specialist. All photos and drawings of such a brazier from a gas cylinder are attached.

So what do we need for this:

Materials:

- Gas bottle.

- Pipe, diameter 90mm. Length - 0.7m

- Handles, 3 pcs.

- Profile pipe, 30x30mm. Length - 4m

- Corner, 40mm shelf. Length - 1m

- Sheet metal, 2mm thick, 1m2

- Fungus on the pipe.

- Sheds.

- Priming. Enamel paint for metal.

- The paint is heat-resistant, the temperature of use is up to 600 degrees.

- Chain, length no more than 0.7m

Tools:

- Welding machine, electrodes.

- Bulgarian, cutting discs and cleaning disc.

- Roulette

- Pencil.

- Hacksaw for metal.

- Drill, drill bit 4,8,10,12mm.

- Gloves, goggles, welding mask.

- Piece of chalk.

- Clamp clamp.

- Square.

So: let's get to work.

To start the robots, we need an empty gas cylinder with a capacity of 50 liters. Such cylinders were previously used on the farm in the private sector. It consists of three parts: a valve, a reservoir tank and a cylindrical stand.

Installation of a chimney for a barbecue

A chimney is not an essential element of our homemade barbecue, but it gives a more aesthetic look and works as a regulator of the degree of smokedness of the cooked product.

For the manufacture of this element, a pipe with an outer diameter of 90m is quite suitable.. and 70 cm long. Since the factory corners have a very smooth turn, you can weld the sharp corner yourself by first cutting out a pipe segment, which is marked from the turning point with a square in two directions at 45 degrees around the circumference of the pipe. Having cut a segment with a grinder, we bend the smaller part to the larger one, with the help of a corner we check the angle of 90 degrees and weld them in place. After that, we expose the pipe to the place of welding, where we installed the damper, and weld the pipe well in a circle. It should be noted that each seam must be cleaned with a cleaning disk. So it acquires a more aesthetic appearance and the quality of the weld is clearly visible.

When the pipe is welded, install a protective cap. It is fixed with a clamping bolt.

Making a mangal cover

When starting to cut the cylinder, it must be taken into account that water will flow during the through cut. Therefore, we remove the electrical wires as much as possible and it is better to cut on an inclined base, controlling the flow of water. Yes, I agree that the event is "wet", but this is the safest method of cutting a gas bottle.

We make a cut with a grinder along our marked lines. They are marked in red on my diagram. The disk for the grinder must be chosen thicker, at least 1.6 mm. The width of the cut is compensated by the expansion of the metal when heated. It must be remembered that the metal on the cylinder “tenses” during welding and, when cutting, can wedge the disc a little, so we use wedges. At the same time, we cut off the threaded connection for the shut-off valve cover. It is located on top of the balloon.

So, when the brazier cover is cut out of sheet metal, we cut out strips 3 cm wide, one meter long - three pieces, and weld along the perimeter of the cover so that the edge of the strip protrudes 1.5 cm beyond the edges of the cover. With the help of clamps, periodically pressing the strip to the lid. This will prevent the lid from falling into the middle of the grill. We also weld the handle. We clean the welding places with the help of a grinder and a cleaning disk. After installing the cover on the cylinder, you need to center it and weld the curtains, having previously retreated the same dimensions from the edges of the cylinder.

I recommend welding a locking chain along the edges of the lid, which, when the lid is open, will fix its position and thereby relieve all tension from the canopies and not break them out.

From the side of the top of the gas cylinder, where we cut off the threaded connection, you can make a valve that will regulate the smoke output, that is, the degree of smoked meat. We cut out three strips of 10 cm from sheet metal and bend the edge with pliers or in a vice so that we get a corner and scald around the perimeter of the hole, observing the evenness of the dimensions. And from the same sheet metal we cut out the valve itself, making an allowance of no more than 1 cm so that there is free play.

From the bottom of the gas cylinder there is a cylindrical stand, which we also cut off with a grinder. It is welded with a burst seam around the circumference of the cylinder.