If the pump sucks air from the well. Why is air in the water from the well and what to do

Residents of private houses, dachas, country houses often urgently need to install a pumping structure for pumping water from a well or well. For some, this is the only way to have water indoors. Therefore, when, one day, the pump stops buzzing, it is urgently necessary to understand the origin of the breakdown.

If the pumping station stops pumping water, it is urgent to find the cause of the breakdown

Often the stumbling block is the air that enters the pump along with the liquid. Everything can be prevented, only initially you need to find out what elements the pumping structure is assembled from.

Key components of the pumping unit

There are many varieties of stations, but the main components are common to all.

- Self-priming pump. Principle of operation: the pump independently draws liquid from the recess with the help of a tube, one end of which is in the well, the other is connected to the equipment.

The pump is located a short distance from the water tank. The depth of the tube is also adjustable. - All units are equipped with a hydraulic accumulator. The vessel, using the energy of compressed gas or a spring, transfers liquid under pressure to the hydraulic system. It accumulates hydraulic fluid and releases it at the right time, thereby avoiding water surges in the system. Outside, it is metal, inside there is a rubber membrane, above it there is a gas cavity filled with nitrogen, and a hydraulic cavity. Water is filled until the pressure in both cavities is equal.

- Electrical engine. Through the coupling, it is connected to the pump, and with the relay - using the electrical circuit. Due to the fact that the pump does not turn on for short liquid intakes, the motor does not wear out.

- Air outlet.

- collector element.

- Pressure gauge. It allows you to monitor the level of pressure.

- Relay. By changing the pressure, by opening / closing the contacts, it supports the independent operation of the equipment.

The main purpose of pumping stations is to maintain continuous pressure in the water supply structure.

In order for all components to function like a clock, it is important to correctly select the required volume of the hydraulic accumulator and control the connection between the regulator and the pump itself.

The order of operation of the unit

When turned on, the electric motor is the first to come into play, it starts the pump, and it pumps the gradually incoming liquid into the accumulator. When the accumulator is full to the limit, excess pressure will be created and the pump will turn off. When the faucet is turned off in the house, the pressure decreases and the pump starts working again.

The house has a battery connected to the water supply. The pipes fill with water when the pump starts. When the pressure in the station reaches the required peak, the pump is switched off.

The pump unit will solve the difficulty of supplying water to houses, baths, summer kitchens, outbuildings and other premises on the territory of your site. Having familiarized yourself with the details of the operation of the station, it is necessary to study the possible causes of the failure of the device and ways to eliminate them.

Breakdowns most commonly encountered

In the process of using any equipment, there comes a moment when it either wears out or breaks.

So in the second case, it would be important for the owner to understand the causes of damage. Here is a short list of grounds that disrupt the operation of the pumping station:

- no electricity - trite, but also not excluded, since the operation of the unit directly depends on the electric current;

- the pipeline is not filled with liquid;

- pump malfunction;

- hydraulic accumulator broken;

- damaged automation;

- cracks in the hull.

The pump spins but does not pump water

What to do when the station does not pump water? A frequent cause of failure is the lack of fluid in the pipes or in the pump itself. It happens that the unit is functioning, but the water is not pumping. Then you should inspect the tightness of the entire water supply, if there are any places where the pipes are poorly connected.

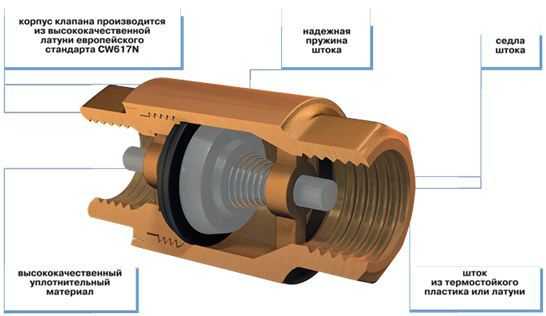

Check that the pump is not empty. The check valve is not working properly. The throughput must be one-way. This is one of the most important parts of the station, because, after the pump is turned off, it prevents water from flowing back into the well.

Diagram of a pumping station valve that can become clogged with debris

It happens that the valve is clogged and does not physically close, debris, salt, grains of sand can get into it. Accordingly, the liquid does not reach the pump. We solve the problem.

Before spinning the unit, we advise you to check the voltage of the electric current. It happens that it is below normal, and the pump is simply unable to turn on. Etc

Causes of air in the well for water

As a rule, households using small volumes of water from a source or seasonal use of pumping equipment face the problem of air entering the water. The causes of this phenomenon may be the following problems in the system:

The suction of the air mass at the place of water suction has failed. The problem will not be solved until the pipeline is completely replaced with all the necessary parts. It is easy to make sure that it works properly - just pump water in the pipeline, for example, in the bathroom.

Breakdown of the pumping equipment itself due to irregular or poor-quality maintenance. Air bubbles are formed as a result of a fragile stuffing box seal. The solution to the problem is to disassemble the working unit of the station and fix the breakdown.

Insufficient filling level of the well with a large pumping out. Drilling a new well, purchasing a less powerful pump, reducing the volume of water used - can solve the problem

However, when drilling a new well, it is important not to reach the same aquifer where the chance of re-airing the system is very high.

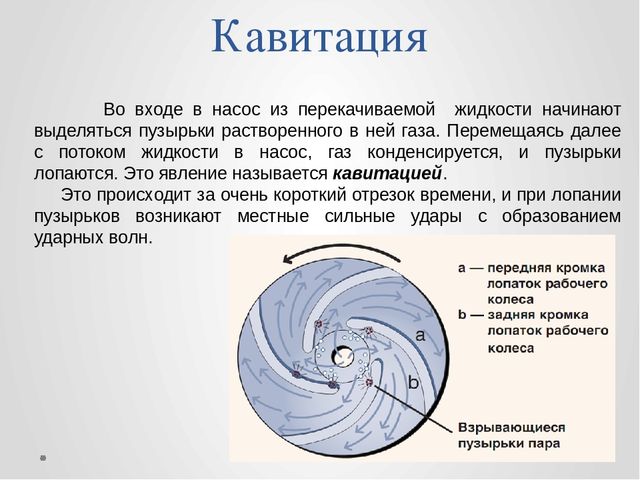

Cavitation and its elimination

The cause of cavitation is improperly selected pumping equipment. Water devices are selected taking into account the diameter of the well. For sizes less than 100 mm, plunger or circular models are suitable, 100 mm or more - submersible.

Cavitation is a violation of the density of the water column, in other words, the filling of the pipeline with air bubbles. It is formed in areas with reduced pressure at a critical level. The phenomenon is accompanied by the formation of voids in the pipeline, bubble formations resulting from the interaction of gases and vapors released by well water.

It is not always possible to calculate the faulty section on your own, since special equipment is required. It is also worth adding that this section can be unstable. If you do not take action, the consequences will hit hard "on your pocket" - dynamic effects on flow and vibration will lead to breakdown of pumping equipment.

To reduce the likelihood of a problem developing, you need to choose the right water pumps, taking into account the volumes of water consumed and the technical characteristics of the well.

To get rid of such an unpleasant phenomenon as the appearance of air in water, you need to consider the main ways to solve the problem:

Replace the small diameter pipe with a large diameter pipe.

Install pumping equipment closer to the storage tank

When transporting the pump, it is important to take into account the established standards: the interval between the container and the pump must be no less than 5 diameters of the suction pipe.

Replace the gate valve with a gate valve and remove the check valve. To reduce the pressure in the pipeline, the pipe is replaced with a smooth one.

There should not be many turns in the suction pipe

To solve the problem, you need to replace the small radius bends with large ones or simply reduce them. At the design stage of an autonomous water supply system, it is recommended to place all outlets in the same plane and use flexible pipes rather than rigid ones.

Why does a well pump pump water with air

Increasingly, wells are used instead of wells in rural areas and private houses in holiday villages. Water is pumped from the well. The design of the pump also depends on the diameter of the well. For a 100 mm well, a submersible pump is suitable, for a smaller diameter well, circular or plunger pumps will be used

Over time, during operation, you can notice that the pump began to pump water with air bubbles. There may be several reasons, and all of them require a thorough check and replacement of worn parts.

To identify the causes, you should carefully consider the essence of the problem.

- The simplest option is air leakage in the suction pipeline, while the water column in the pipe can hold for a long time. It is treated by replacing the pipeline and replacing the related elements, so as not to change them later.

- The second option is an insufficient debit of the well, when, with a large flow of water, the well does not have time to fill up and the pump sucks in air.

- The third option is a malfunction of the pump itself, when air enters the discharge chamber through a faulty stuffing box seal. To replace the seals, it is necessary to disassemble the pump unit, ideally to give it to a repair shop.

- The fourth option is when the pressure chamber of the pump creates conditions for the manifestation of cavitation (this is when a liquid substance at high pressure turns into a vapor state. It manifests itself when the suction level drops below 8 meters.

The same laws work in hydraulic systems as in electrical circuits. For a specific definition of a breakdown, it is necessary to carry out a number of technical measures, which is unlikely to be performed by a simple layman on their own. Most owners of borehole pumping systems turn to pump service specialists.

Causes of air locks in pipes

Such a by-product contains approximately 32% oxygen, that is, there is a third more oxidizing substance here than in the atmosphere. The freely expressed form of these clusters is not the same. Only bubbles up to 1 mm can be considered spherical. More may have an ellipsoid or mushroom topology. On vertical sections of water supply risers, air-gas inclusions rise up or remain in suspension. In horizontal pipelines, they always “stick” to the walls at the highest point, which can create conditions for active rusting of pipes.

Converting reasonable heat into latent heat

For cooling, the heat pump can be used directly and cooled by underfloor heating. The advantage of this action is that we preheat the earth's heat exchanger during the winter season. The conversion of reasonable heat into latent heat is based on the so-called adiabatic cooling. We use the fact that evaporation is cooled or energy, expressed by the temperature of the air, is consumed by the process in which water changes from a liquid to a gaseous state.

When the water speed begins to exceed ½ m/s, air accumulations begin to move with it. If the liquid flows in the circuit faster than 1 m / s, then the air in the water supply system breaks into tiny capsules and a kind of emulsion is created from gas and liquid. Practical observations revealed that the minimum rate of destruction of such accumulations in the water supply system is about ¼ m / s.With a lower flow rate, air pockets are able to stay for a long time in the same areas, which is undesirable.

Therefore, heat is not consumed to raise the temperature of the water, but to change the structure of the substance. The stored energy is what we call latent heat. Direct adiabatic cooling is achieved by spraying water into the inlet air. Such cooling can be used in hot and dry climates or in special operations where we need high humidity. This is an air conditioner called an air washer.

The advantage of direct adiabatic refrigeration is that it does not represent an investment where mechanical air conditioning is already installed, since air humidification is usually part of it. The disadvantage is the higher maintenance requirements. The shower enclosure needs to be cleaned regularly to avoid dangerous bacteria.

To get rid of air accumulations, various bleed / bleed devices are used. These are automatic air vents, and mechanical valves (for example, the Mayevsky valve), and conventional shut-off valves (valves, ball valves). A standard regulator of this kind is made in the form of a cylindrical shell with a flat cover. In the center of the latter, a threaded plug with a hole of 3-5 mm is mounted. A float ball made of polymer or cork is placed inside the body. When there is no air in the pipes, this element tightly closes the hole in the cover under the action of network pressure. If there is air accumulation in the device, then the ball falls for a moment and allows this mixture to exit through the hole in the lid.

Air vents are also able to perform the opposite action - to introduce a certain amount of oxygen into the pressure network. This happens by accident or is necessary when the resource is quickly drained before the inspection and repair of the water supply system.

In order for the air in the water supply system to be removed in a timely manner, it is necessary to correctly install the mechanisms that discharge it at the right points. They are mounted at the highest points of pipelines, at breaks or bends, since it is there that the air-gas mixture accumulates.

Why is there air in the plumbing

In our work, we have focused on electric compression heat pumps because they are currently more competitive than getters, although the latter significantly reduce their costs. The machine is still warm, but it consumes more. We are talking about costs: how much does it cost depending on the technology you choose?

Because air is the cheapest and easiest to install; air-to-water and water-to-water are more expensive because you have to add the costs of integration with the heating system, the boiler and, secondly, the well. Then a heat pump with a capacity of 10 kW for water, the size of which is suitable for a cottage, can cost about 5-6 thousand euros.

There are two reasons for the appearance of air in the water supply system at home:

-

Outside

. Through leaky connections, air enters the pipes; -

From within

. Approximately 30 grams of air is dissolved in the flow of water passing through the pipes per 1 ton of water. Gradually the air is released. The slower the water flows, and the hotter it is, the faster the process. That is, in hot water systems, the likelihood of air jams is higher.

In the water supply systems of private houses, air appears for the following reasons:

In your work, you have made various economic models. In what areas have you found that heat pumps deliver the most savings? The highest level of convenience in commercial utilities: in general, the payback period for these users is 2-3 years, shorter than domestic ones. It mainly depends on two factors.Firstly, there is usually no need for hot water heating in a business, so the cost of equipping a boiler or integrating a heat pump into an installation is lower. Secondly, in commercial environments, heat pumps use much more for summer air conditioning, since these environments, unlike residential ones, live a lot during the daytime.

- when the water level drops, air can be sucked in through the check valve;

- poorly tightened fittings with rubber seals;

- in hot water supply systems, a cavitation process is observed: steam is formed, air bubbles collect in the water, forming voids or cavities;

- the air in the water supply pipes remained from the first start-up of the equipment.

There is 30% more oxygen in air bubbles than in atmospheric air. This explains the high oxidizing power of air in hot water systems. Air bubbles can be of various shapes: spherical - small, no more than 1 millimeter in diameter, mushroom-shaped, oval.

Can we give some rough estimate of the savings a heat pump can make and the time it takes for the investment to return? In the simulation we did for the business sector, the investment matures in 3-6 years without incentives, in 2, 4, 5 years with deductions, and under 5 with heat accounted.

According to wells, many people who drift to their own water supply often ignore water amenities. They will call when they run out of withers or even clean water. Each well with a thorn brings even minor unhealthy into the trench, which then calm down. It depends on the composition of the ground in which it is kicked. Holes in the hardwoods of this mining hazard, which are well into muddy mud, would need to watch more.

When the water speed in the pipes is more than 0.5 meters per second, the bubbles move without stopping. When the speed exceeds 1 meter per second, the bubbles break into very small bubbles. It turns out like an emulsion of water and air. Air bubbles in the water supply system of a private house begin to collapse at a fluid velocity of 0.25 meters per second. If it is lower, traffic jams can stagnate in some places for quite a long time.

The big danger of large layers of sediment at the bottom is the likelihood of infection with bacteria that can get into the well not only with water, but also with a weak clogging of the well. Sludge is good for them, anyone who wants to use water for drinking should keep this in mind.

Fountains are often faced with the fact that a seemingly "dead" well has a water supply that the owner has not known for a long time. It is impossible to say in general in what period of time this is found out, it usually takes place once every two or three years, it can still remain on the well in a stone bed, but the condition of the well is checked twice a year. and there is no need to tackle the mosses on the walls,” Elfer explains.

How to get rid of air in pipes

If there is already air in the water supply system of a private house, but it is not equipped with bleeders, you must:

- Turn off the pumping station.

- Open all drain taps, bleed water and air from the water supply system. Then the pipes are filled again.

You can remove air from the water supply system once and for all using bleed or drain devices:

- mechanical valves such as Mayevsky valve;

- automatic air vents;

- ball valves;

- valves.

Mechanical valve device for air release

from the water supply system is as follows: a cylindrical box, closed with a lid on top, a thread for connecting to a water supply system from below. There is a threaded plug in the middle of the cover. A plastic ball-shaped float is suspended inside the cylinder. If there is no air in the hot water supply system, the ball rises to the hole in the plug and closes it tightly under network pressure. As soon as air enters the device, the ball moves away and the air is removed.Through bleeders, air can enter the system, which is useful when repairing or inspecting networks and speeds up the draining of water.

But once a person invests in a hostage, it may not be a bad idea to get one test before and one before the hospital. This allows you to compare the difference between water quality and spring quality. Whoever polluted the water before and after it has a certain guarantee that the spring provides drinking water. And to conclude that he only neglected regular maintenance.

If contamination occurs within the next three days, it is worse. Obviously, the water is obvious, and if it is to be used for drinking, it is necessary to find a water filtration specialist and prepare for a multi-level edition. Patience is not difficult for those who are afraid of hard and dirty work. However, it must adhere to a few key principles.

Homemade air accumulator

In rural water pipes, air often flows interspersed with water. It is difficult and inconvenient to use such a water supply system, and automation does not always cope: if there is a lot of air, water overflows in a fountain directly from the valve. Therefore, instead of an automatic bleeder for air discharge in the water supply system, air accumulator

. You can make it yourself, this is a tank with a drain pipe and a tap. The diameter of the drive must be 5 times the diameter of the water pipe, then it can work effectively.

Especially in deep fountains, there is a layer of poisonous gas. Therefore, it is necessary for an unfortunate person to go into the depths to secure the rope. In case of danger, his colleague can leave. After the shots, you don't fall into a deep well, you need to get a wand with a rope. Don't even think about using a small hobby market mud pump for a thousand crowns. Often the spring is so prolific that even professional pumps do not place well "dry". And these are tools worth up to 40 thousand kroons with a three-phase electric motor.

Then it is not enough to use a rental company, prices vary from 250 to 500 kroons per day, but a deposit of about 10,000 is required. With the wells we went to the hospital, neglected by the owners for 15 years. An old well in a 200-year-old building. Although the original hole was equipped with springs, no one thought about the wellbore around the caine. The old vaults and quarters have already begun to collapse, the remains of the gardens fall directly into the well. Now is the time to start with the reconstruction.

Well water comes with air. Why is water supplied with air

The idea is popular among the people that artesian water is something like gold and it is pure, like the soul of a baby. But in reality, this is just a well drilled into a confined aquifer. This means that having reached the water-bearing limestones, the water level will rise higher than it was before. That's all, such waters are called artesian, from this the quality of artesian water is no better and no worse than in ordinary free-flow limestone wells. Artesian is just a term, but today they have begun to designate all limestone wells. Sometimes the water level rises so high that it begins to pour itself out of the well. We wrote about self-draining.

The most important thing in artesian wells is not the purity of the water, the main thing is the flow rate. It is enough for the water supply of any private house, production or even a village. That is why the drilling of artesian wells for water has gained such popularity today.

Now we will tell the whole truth about artesian wells and what is important to know about them.

How deep is artesian water?

No one will unequivocally answer to what depth to drill an artesian well, including magical dowsers. And there is only one reason for this - geology.Artesian water lies in limestones (which is why it is sometimes called a limestone well) and these water-bearing limestones can be located at any depth, sometimes it is 50 meters, and sometimes 150 meters. To find out at what depth artesian water lies, you need to look at a map of the depths of wells in the Moscow region (or your region), or even better, interview neighbors who have already drilled a well. It is very likely that you will have something similar. In your area, artesian waters may occur in other rocks, but this does not change the essence of the matter.

Artesian well pros and cons

It is important for you, as the owner of the house, to have enough water, which means that there are no alternatives and you need to drill into limestone. This is the first and most basic plus of an artesian well - a high flow rate. No sand wells can match it in this component

The second plus and the second advantage of an artesian well: there is always water. Regardless of the season, whether it is summer or winter, it rains or drought, the water level in the well is stable, the pressure is also stable.

Maintenance of an artesian well, correct, is never required at all, this is another plus. A well-made (!) design will work out its entire service life and you do not need to worry about it. Typically, the service life of an artesian well is more than 50 years. This is with proper arrangement, subject to the use of high-quality pipes, materials and high-quality work. Unfortunately, today no one does this, today everyone is trying to give the lowest price. Only water-lifting equipment requires maintenance, but that's a completely different story.

- Debit.

- There is always water.

- Does not require maintenance.

- Water quality.

Cons of artesian wells

There are no shortcomings in limestone wells. You can often hear about hard water with an excess of iron in the composition ... This is possible, but if there are no alternatives, then you need to work with what is. To find out the benefits or harms of your water from an artesian well, for starters, pump the water thoroughly for 2-3 weeks. Then, you can hand over artesian water for analysis, and if there are excesses, then under