How to make a traction booster

It does not make sense to consider all the structures, since the profile of the pipes, the section, the materials from which they are made are different. The operation of each chimney has its own specifics. For a brick pipe, the amplifier looks like this.

The best option is considered to be a round section - the most effective engineering solution. It is these chimneys that are mainly mounted in the private sector. Consider how to make a simple do-it-yourself chimney draft booster.

Deflector for round pipe

The principle of its operation is based on the creation of a rarefaction zone on the path of ascending hot air by partially blocking the channel. The resulting vortex flows reduce the pressure in this area, thereby increasing the speed of movement of smoke, that is, thrust. But putting “just a cap” on the pipe is not a solution to the problem. All its linear parameters are interconnected and calculated using special formulas.

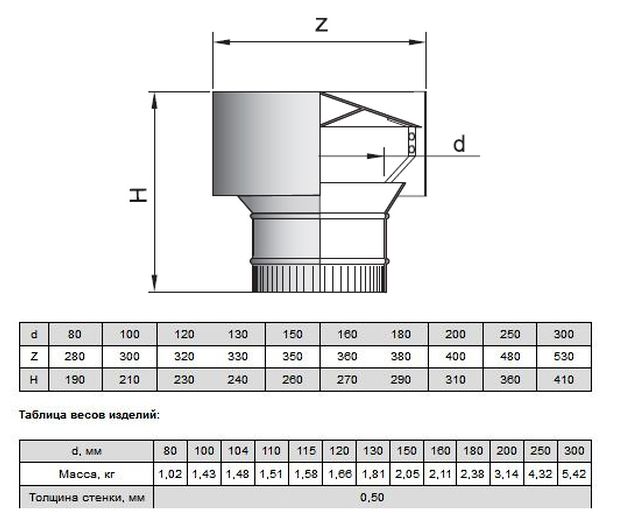

To simplify the reader's work, the author suggests using a ready-made table with all the necessary data:

This information is quite enough to make the simplest deflector - a traction amplifier. Well, how to cut, bend, rivet sheet iron is not worth painting - these are elementary things. Without having the simplest skills in working with a household tool, it makes no sense to design and assemble an amplifier.

In order to avoid "leakage" of air, the place where the deflector adjoins the pipe is sealed with a sealant of the "heat-resistant" category.

Wind vanes or wind vanes for forced draft

This is a device to protect the chimney from the effects of wind. Its principle of operation is that, like any weather vane, it turns in the wind, protecting the head of the chimney from the wind flow. Flowing around this device, the wind itself creates a rarefaction above the mouth of the chimney, thus creating a forced draft of the chimney. The heat-resistant material for the manufacture of such a wind vane is usually stainless steel with a thickness of 0.5 millimeters or more. Rotation around the axis occurs on the support bearings of the closed type, which do not require maintenance. There is no condensation on the body of the device and no soot is deposited.

However, it needs maintenance to get rid of ice. The disadvantages of the design include unstable operation with a significant wind force. Under normal conditions, the weather vane works steadily and efficiently, creating forced draft inside the chimney.

Best Answers

Vladimir:

Easy! There are no contraindications, neither according to the laws of physics nor according to the laws ... uh. )

Valery Bondarchuk:

Can. If you do not insulate with mineral wool, then at the transition point it will condense and rust heavily!

Blackjack:

It is possible - the thicker the zinc, the longer it will burn out, and also if it is insulated with mineral wool, then due to the deterioration of the cooling conditions, the pipes will also burn out faster

Sergey08:

So even better there will be less load on the pipe, as if it were all made of asbestos. It probably won’t burn out as they write at the outlet of the pipe, the temperature is not higher than 70-100 degrees, I touched it many times. Millimeter galvanizing is enough for 15-20 years, so don't worry. Better yet, put silicone sealant on a greased pipe, it can withstand up to 200 degrees.

Yuri:

It is possible, just keep in mind that the galvanized pipe should be put on asbestos, and not be inserted into asbestos.

Elina Linberg:

Asbestos pipes are generally not used for a chimney. . When heated, asbestos tends to burst. Remember how slate scatters from burning houses. But what can I say, they themselves once lay in the garden when the neighbor's pipe shot like that in the neighbor's bathhouse .... Replace the entire pipe with metal, don't risk it.

Stas Shabanov:

asbestos pipe is generally a risk.

System check

Before checking the draft, it is necessary to make sure that the gas duct is in good condition, that there is no clogging, that the dampers along the tract are open. You can verify the normal operation of the exhaust system using the instrumental method. Gas workers use an anemometer. There are vane, thermal and ultrasonic anemometers.

If you choose this option, replace single wall double wall pipes or double wall pipes with three layer pipes. Place a brick under each leg of the fire grate. Light the fire and see if the chimney smokes. If not, go to the next step. Cover the bottom half of the holes on the front of the wood stove. Watch the smoke to see if it goes up the smoke system. If this works, permanently raise the floor of the wood stove by placing a layer of cladding over the surface of the floor.

Position the extension ladder safely on the side of the house

Move carefully into the metal chimney and remove the top cover. When removing the chimney cover, observe all safety precautions

Take a professional if you're unsure or don't have the right tools. Slide the new section of metal chimney pipe onto the current chimney. The pipe section has a "male" and "female" end. Rotate the new pipe so that the female end is at the bottom. Position and insert the female end into the male end of the top tube.

Useful information about chimney draft

Secure them with the appropriate screws. Different brands of furnace metal pipes use different connectors. Slide the metal chimney cap onto the top of the newly installed piece of chimney pipe. Add another section if necessary. Increasing the chimney height by 2 feet when the chimney is 10 feet high will result in a 20 percent increase in draft. But adding 2 feet to a 30-foot chimney only adds a 7 percent increase. An easy way to experiment with height is to temporarily add a section of pipe and start a fire.

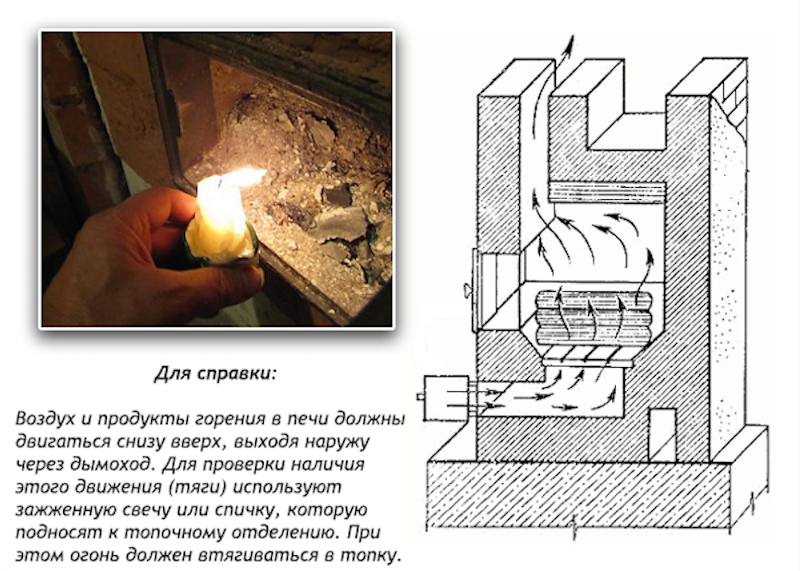

- The fire is drawn into the chamber. Indicates the readiness of the furnace for kindling.

- The flame burns evenly, without deviations. This case indicates that the traction is gone.

- The tongue of fire is directed towards the room. Characterizes the appearance of a reverse flow.

The magnitude of the thrust force can be judged by the color of the flame. Dark red indicates insufficient oxygen for complete combustion of the fuel. Traction is not enough. Otherwise, with excessive exhaust, the fire is painted in bright, white shades. Burning is usually accompanied by a hum.

Check if the project has been improved. Permanently install the pipe if it matters. Measure the width and height of the firebox. Repeat the process with the chimney opening. The width and height of the firebox should be no more than 10 times the opening for the chimney. Let's say the firebox is 20 by 20 inches for a total of 400 and the chimney opening is 6 by 6 inches for a total you multiply 36 by 10 by 360 showing that the firebox is going to be too big.

Determine the correct size for the firebox. For example, the firebox should be reduced by 40 inches. Divide the excess according to the depth of the firebox. For example, 40 divided by 20 in total The answer is the height of the required smoke protection. Cut a piece of aluminum foil to the width of the firebox and the height of the required smoke protection. For example, you cut a piece of aluminum foil 20 inches long and 2 inches wide.

Measurement methods

If you doubt that the draft of the chimney channel of the stove, fireplace or heating boiler is sufficient, you need to check. The easiest way to dispel doubts is to check with your own hands using an anemometer. If the device shows a thrust of 10-20 Pa, then it is considered normal. The problem of this method is the low measurement accuracy of inexpensive anemometers, if the thrust is less than 1 Pa, then they will show that it does not exist. More accurate professional instruments are expensive, stove-makers use them.

If you do not have an anemometer, use one of the popular methods for determining the chimney draft force:

-

By smoke. The most obvious sign that there is no draft is the presence of even a small amount of smoke inside the room, a large amount of smoke indicates a high risk of fire and carbon monoxide poisoning.

Puffs of smoke are a sure sign of reverse thrust

- By the color of the flame. By looking at the color of the flame, you can check the level of thrust force. If the flame inside the firebox is white and crackles while burning, the draft is too strong. Orange-red color indicates insufficient traction. If the chimney is designed correctly, the flame has an even golden yellow hue.

-

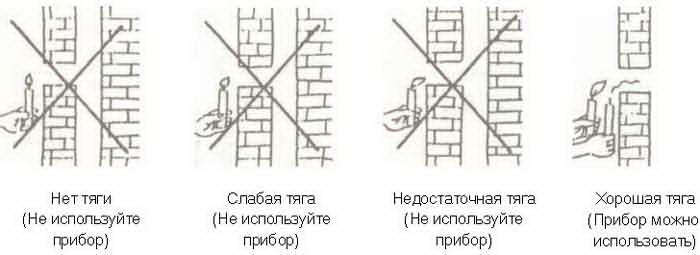

With the help of a match. If you light a match, candle or other source of fire and bring it to the heater, the flame should deviate towards the firebox. If it stays level, you can be sure that there is no traction. When the flame deviates in the opposite direction from the firebox, there is a reverse draft in the chimney.

Checking the draft in the chimney with a match

- With the help of a mirror. Another method to test the draft inside the chimney is to hold a pocket mirror close to the firebox. The appearance of condensation on its mirror-like surface means that smoke removal is difficult.

Traction check methods

Checking traction with a spark plug

Special adjustment devices

Modern instrument makers have taken care of the release of special devices that regulate draft in the chimney:

- Regulators. They are installed on the chimney outlet to normalize the draft in the heating system, and also as a means of influencing the heating efficiency.

- Deflectors. Such devices are fixed on the chimney from the outside. The draft speed is improved due to the fact that the diameter of this device is much larger than the chimney pipe, and, therefore, a low pressure area appears in it when air flows around it.

- Chimney flue. It is a special design that performs several functions at once: improves traction, protects the pipe from raindrops and snow whirlwinds. The operation of the device is similar to the operation of the deflector; the thrust speed is normalized due to a decrease in external air resistance.

- Smoke fan. It is very popular among owners of houses with a heating system. An artificial air vortex is created inside the chimney due to the operation of the ventilation system, which requires electricity to connect. Compliance with all necessary safety measures is a prerequisite for the installation and operation of such a device to improve chimney draft.

All devices installed on the chimney pipe to improve draft require mandatory control, especially in winter. This is due to the fact that additional appliances attached to the chimney from the outside can clog, freeze (in winter) and thereby prevent the chimney from working properly. A blockage obtained "with the participation" of devices can cause back draft and the penetration of carbon monoxide into living quarters.

Do not forget to regularly inspect along with the chimney and devices that help increase traction.

Photo gallery: draft control devices

The most common device among users of stove heating

Such a device is especially relevant for improving the operation of stoves and fireplaces.

Useful and beautiful device

By installing such a device, you can increase the performance of the entire heating system

Strength test

Before you throw your energy into fighting bad traction, make sure that the traction really leaves much to be desired.

You can check the traction with the help of special devices or on your own. Simple ways to fix traction:

- Light a paper sheet, let it burn a little. Bringing it to the stove or fireplace, extinguish the paper and observe the direction of the smoke. If it goes to the pipe - good traction, deviates in the opposite direction - reverse thrust, if it maintains "straightness" - there is no thrust. Similar manipulations can be done with thin cigarette or toilet paper without setting it on fire.

- If there are smokers in the house, then follow the direction from the smoke of cigarettes or from the flame of a match, lighter near a fireplace or stove. Draw conclusions in the same way as the first paragraph.

- The flame of an ordinary candle can also help in determining the draft in a home.

- A pocket mirror brought to the firebox and covered with condensate may indicate problems with removing smoke from the stove.

- The presence of too much draft, which takes away useful heat from the room, is indicated by an audible hum in the furnace - a loud hum.

- The color of the fire in the furnace can be an indicator of different traction. Golden hue - good traction, white flames - excessive traction, red color and black smoke - poor traction, high probability of reverse thrust.

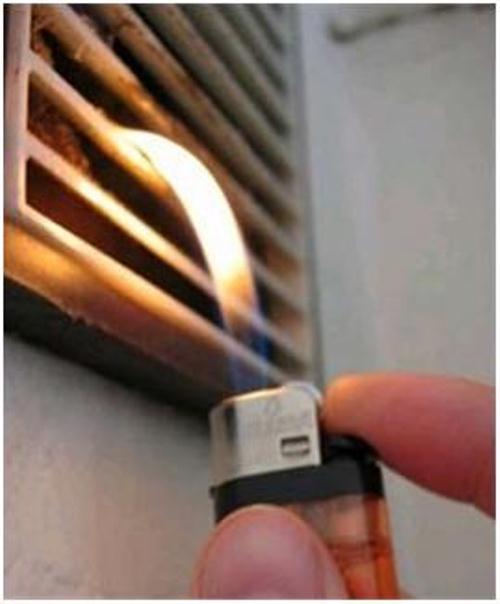

A regular lighter can help check the draft.

Anemometer is a device familiar to many people of the Soviet period. With this device, it was possible to measure the draft of the chimney. Readings within 10–20 Pa were considered normal. The disadvantages of the device are its low accuracy when the wind strength is less than one meter per second.

Such a simple device will help protect your life in a house with stove heating.

Modern industry offers a sufficient number of devices for measuring draft, there are devices that fix draft at the inlet and outlet of the chimney.

Troubleshooting

If you have stated problems with traction, then, of course, they need to be eliminated as soon as possible.

The choice of means to deal with bad or reverse draft depends on the reasons that led to the abnormal operation of the chimney.

Pipe cleaning

One common method for improving traction is pipe cleaning. Fuel, burning in the furnace, releases various substances that settle on the inner surface of the chimney. Soot adheres well to pipes if they are uneven or bent.

When carrying out work, do not forget about safety measures

How to clean the chimney so that there is good draft?

First of all, acting purely mechanically. Chimney channels can be made wider by getting rid of plaque in the following ways:

After cooking about one bucket of potatoes, peel and cut them. Potato peels will work too. Throw a little into the furnace and wait. When burned, potatoes will release starch, which will become a tool that can soften soot formations. Soft pieces of soot will fall off on their own, and firmly adhering ones will have to be removed mechanically.

Aspen firewood. Heat the oven with two or three logs. They will heat up the chimney pipes very much and help get rid of soot.

But this method requires special care, because

the probability of fire will be very high (soot may ignite).

Rock salt. This method is more suitable for prevention. Salt added at the time of burning improves the condition of the chimneys.

Pipe brush. A heavy load is attached to a brush suspended on a steel rope and lowered into the chimney openings. By lowering and raising this structure, it is possible to force soot formations to fly off the pipe walls and fall into the furnace. These fragments are then removed from the firebox.

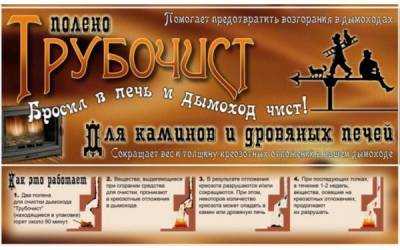

The second group of anti-soot measures is based on the use of chemicals.The most popular chemicals for cleaning the chimney are Log Chimney Sweep, Kominichek. According to the instructions, chemicals are added to the coals formed during the burning of a stove or fireplace and continue to be heated. After all the fuel burns out, it is advisable to leave the coals, because they continue to “work” in terms of cleaning the chimney (at least, this is what the manufacturers advise).

When used correctly, chemicals will not harm your home.

Do not believe the spiteful critics who talk about the mandatory ignition of soot when using the chemical method. This method does not pose any danger, since the beneficial effect is due to chemical reactions, and not due to the ultra-high combustion temperatures of the reagent.

Special mention should be made of the observance of safety measures during all work related to the chimney. Do not fix chimney problems in windy weather! Try to use safety devices while working at height!

Structural Troubleshooting

If certain features of the chimney design are identified that adversely affect the traction force, adjustments should be made to eliminate them. Such actions should include:

- dismantling of several disparate pipes and installation of a single chimney channel;

- pipe superstructure on the roof to the required height;

- insulation of chimney elements, etc.

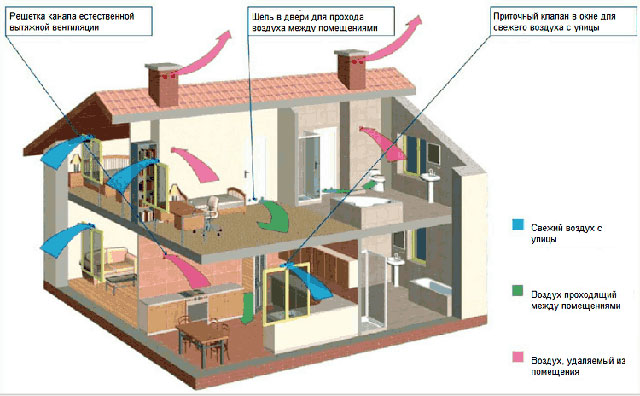

Arrangement of ventilation

In some cases, draft may improve if drafts are not allowed in the house or bath. To help with problems with traction, you can install ventilation devices on windows.

In the absence of the desired effect after all the above methods, modern devices should be adopted to improve draft in the chimney.

Installation of appliances

To improve the operation of the chimney, it is best to use special devices that allow you to regulate and control the draft. Such devices can be bought in a store or made by hand.

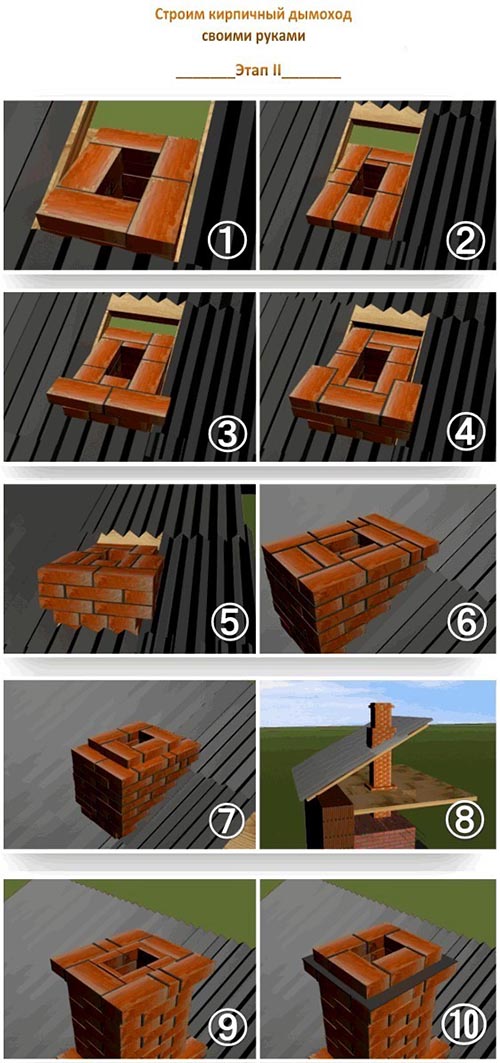

Step-by-step instructions for creating a brick chimney with your own hands

Building a high-quality brick chimney is not an easy task, and it is very important to complete the masonry so that everything is airtight, fireproof, and every seam plays a big role here. The priority direction of the functioning of the chimney is the removal of smoke and burning from the burnt fuel with the help of draft, which not only draws, but also supplies air flows to the furnace, and due to this, the combustion process is maintained and ensured.

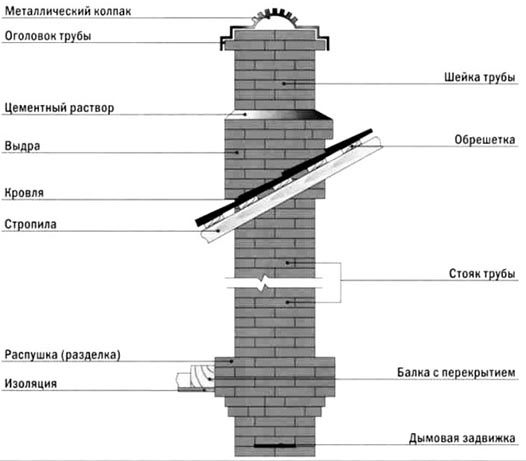

Do-it-yourself brick chimney construction scheme

The big advantage of such a chimney is that it has good draft in all weather conditions and an extended service life compared to metal pipes. Let's consider the question of how to build a brick chimney with your own hands in accordance with all the rules.

We advise you to study the recommendations in more detail: what to make a chimney from in addition to this article.

Brick chimneys are laid in three steps:

Step 1. Carrying out preparatory work and laying the foundation.

Bricklaying of the foundation of the future chimney channel

At this stage, you need to carefully familiarize yourself with the construction drawings of the future chimney channel. For a conventional and traditional wood stove, full masonry is required, for a brick chimney for a gas stove, a metal pipe made of a specialized alloy will be required as an addition. Before you start laying out a brick chimney, you should build a foundation. Construction is carried out from solid brick or reinforced concrete.

The second stage of the construction of a brick chimney with your own hands. masonry

The chimney is built from a height of five meters or not lower than the roof ridge, as this plays a big role in traction. This type of chimney is laid out exclusively with specialized refractory or full-bodied red bricks.For their bonding, a solution of cement and sand or limestone is used, and for places with especially high temperatures, a specialized mixture is needed, which is used for oven masonry.

To chip off the required piece of brick, a grinder and a marker (felt-tip pen) for measuring are useful. Using these tools, you can create absolutely accurate plates that will be needed in the area of \u200b\u200bthe otter, as well as cutting.

Brickwork chimney for a gas heater

During the construction of such a chimney, it is imperative to leave specialized openings for cleaning.

Holes at the top of the brick chimney for smoke and cleaning

Inside, the walls should have a perfectly smooth and even surface, and the corners should be made at 45 degrees. It is best to plaster the inner walls for smoothness, since soot will settle more on a rough surface, thereby worsening traction. This may cause a fire, which is unsafe. Also, many experienced stove-makers recommend whitewashing the stove not only inside, but also outside, which will allow you to immediately determine where smoke and soot can leak.

Stage 3. Fixing and thermal insulation.

If the chimney is built near the wall, it must be fixed - it will be more reliable. To do this, apply metal anchors at a distance of thirty centimeters. Where the chimney will be connected to the ceiling, as well as the roof, it is imperative to place non-combustible material or glass wool, thereby reducing the risk of fire.

The brick chimney should be half a meter above the roof ridge. The upper part of the chimney duct should be insulated and overlaid with a specialized roofing finish or brick for cladding.

Fastening masonry to the wall with anchors for reliability

If the chimney is made according to all technologies, then it will be strong, safe, reliable and will last a long time. All these steps are saved if you need to build a chimney for a brick solid fuel boiler.

Video: stages of construction of a brick chimney

You can lay a chimney with a brick yourself, following the advice, and save on calling professionals. The main thing during the construction is the construction of the correct drawing and the availability of free time. You should not rush, speed is not the best indicator here, you need to focus on the quality of the masonry.

Carrying out installation work for natural and forced ventilation

After the material, cross section and diameter of the ventilation pipe in a private house are selected, installation work can begin. "How to choose the diameter of the pipe for the hood - the characteristics of the ventilation pipes." Be sure to mark the entire installation route according to a previously drawn up scheme.

Natural ventilation is equipped even at the stage of building construction, or installed in channels prepared for this.

Work is carried out as follows:

- Grilles and deflectors are installed.

- A constant air supply is ensured by installing supply valves.

- Mounted hood for the kitchen unit.

- Fans are installed for plumbing units. They are placed in the ventilation duct, where they will work for blowing.

Humid air and moldy surfaces are the result of a weak outflow of air masses. This problem is eliminated with difficulty and the most reasonable option is to organize forced ventilation as a separate system. "Which ventilation pipes to choose - requirements for the installation of ventilation."

Forced ventilation is optimal for private houses with a multi-room layout and a high humidity index.

The work is carried out as follows:

The ventilation unit is installed first. Most often, its place is in the attic (necessarily insulated).

Air pipelines are connected to the block.

At a distance of at least 10 meters from the sewer riser and the chimney, an air intake structure is mounted in the wall of the building (about “Advantages of installing ventilation from sewer pipes and installation methods”).

Missing air ducts, if they were not laid at the stage of building the house, are mounted clearly according to the scheme, but in an open way

It is important to make sure that the supply pipes are as close as possible to the window blocks or placed in that part of the room that is opposite the front door.

Connection of air ducts to the block is carried out by means of corrugated pipes.

All ventilation pipes are insulated.

Grids are installed at the edges of the air ducts, and rosettes-anemostats are installed on the supply pipes.

Outcome

Only with the optimal selection of pipes for the ventilation system, as well as with full observance of the rules for installation work and regular maintenance of the system, it is possible to ensure effective air circulation throughout the house. In such buildings, comfortable microclimatic conditions are established in which each tenant feels comfortable.

Advantages and disadvantages of sandwich pipes Sandwich ventilation device Features of installation of ventilation pipes

When arranging fireplaces or bath stoves, high-quality ventilation is necessary, which will not only keep heat within the room, but also increase the level of fire safety of the system as a whole. A good material for arranging ventilation are sandwich pipes that fit perfectly into the design of any chimney. It is about sandwich pipes for ventilation that will be discussed in this article.

Traction problems

Canal blockage

The easiest case. It is enough to clean the chimney (on your own or by inviting a specialist), and the draft will be restored. This is one of the most common "diseases" of pipes lined with bricks, and it is "treated" quite simply.

On a note!

The sufficiency of thrust can be judged by the shade of the flame in the furnace. If it is dark red, then the thrust is below normal. Golden color indicates that everything is within acceptable limits.

Partial depressurization of the channel

A thorough inspection of the structure and repair is sufficient.

This is interesting: Modular paintings for the interior - we consider thoroughly

Self Troubleshooting

Let's try with our own hands to make the firebox process safe and efficient. The most common way to deal with the accumulation of soot in pipes is a brush with a sinker.

We clean the pipe with a brush

First, let's prepare everything you need:

- Hard bristle brush. The diameter of this device is selected taking into account the cross section of the pipe (from fifty to three hundred millimeters).

- Thin metal cable (can be replaced with a very strong rope or rope).

- Weight for hanging to the brush.

This is what the device for cleaning the chimney pipe looks like

Do not start work if there is strong wind or excessive humidity outside. Try to think over and use reliable insurance to protect yourself from unforeseen events.

Ruff is weighted with a sinker, attaching it to the bottom of the device. The brush itself is hung on a cable. All fasteners must be especially reliable, otherwise the structure will fall apart and you will have to perform additional actions - to “fish” them out of the pipe.

First, they clean all the inspection holes in the chimney, and then they start cleaning the pipe itself. By making a few up and down movements, you can get rid of the soot that will fall from the pipe into the furnace. It is best if someone else is near the oven to signal efficiency and when to stop working.

Finish cleaning the pipe should be when the soot stops pouring.

You can also clean the pipe with the help of improvised means, about which many videos have been shot.