Copper pipe soldering process

The soldering time of copper pipes will help to reduce the marking on the fitting itself with recommendations for solder of the required size.

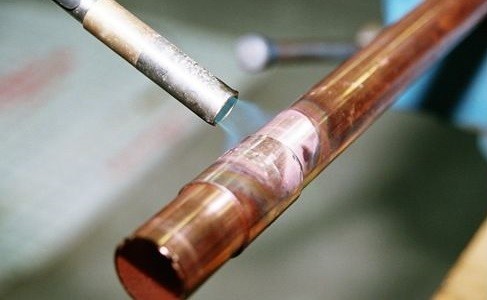

Before soldering, the outer part of the end of the pipe and the inner fitting are processed with sandpaper to a state of pure metal. Next, a thin layer of solder paste or flux is applied to the cleaned end of the pipe. These materials, when molten, dissolve the oxide films on the joined elements, protecting their surfaces from further oxidation, which is caused by high temperatures.

However, given the fact that the flux destroys the surface of the metal, when soldering with your own hands, it must be applied just before the start of work and only on the area that will be included in the fitting. After hardening, the flux is a film that does not require removal.

Next, the pipe is inserted into the socket of the capillary fitting until it stops. Places are evenly heated with a flame of a gas burner or a hot air gun. For this purpose, it is desirable to use a lamp equipped with two burners or spray nozzles.

If the flux used contains tin, then when it is heated to the desired temperature, silvery drops will appear. In other cases, you can make sure that the desired temperature is reached by touching the solder to the heated surface - the solder should spread. The molten solder must be injected into the joint immediately. Moreover, it does not matter from which side it will be introduced. Due to the capillary effect, the solder fills the entire joint evenly. Flux residues are removed from the fitting with a rag.

To reduce the soldering time will help the use of a variety of fittings, in which the manufacturer applied a solder bead of the desired size inside. The fitting is put on a pipe covered with flux, heated with a torch or a hot air gun until the solder is in a liquid state.

After cooling, the design of the water supply and heating pipeline is ready for operation.

Assembling the pipeline with fittings

The connection of copper pipes with fittings is carried out exclusively in places accessible for inspection. This rule is due to the fact that the connection is not completely sealed and leaks may form over time.

The advantage of a threaded connection is that, if necessary, repairs can be made without additional effort, since the resulting connection is detachable.

Tools and materials

To assemble the pipeline, you will need the following materials and tools:

- copper pipes of suitable diameter;

- connecting crimp or press fittings;

Special Devices for Piping Assembly

The types and number of fittings are selected in accordance with the pipeline scheme.

- pipe cutter or hacksaw;

- pipe bender for copper pipes. The device is used to organize a pipeline with fewer connections, which increases the strength of the system;

- file for processing pipes after cutting (before joining). Additionally, you can use fine sandpaper;

- FUM-tape for sealing threads. In addition to the FUM tape, you can also use linen thread, Tangit Unilok thread or any other sealing material;

- wrench.

Assembly instructions

Do-it-yourself assembly of a copper pipeline using fittings is carried out in the following way:

- cutting pipes for the pipeline. The length of each pipe must fully comply with the scheme drawn up during the development of the system;

- removal of the insulating layer. If pipes with insulation are used for an equipped pipeline system for any purpose, then the insulation layer is removed for a strong connection. To do this, the desired section is cut with a knife and the pipe is cleaned;

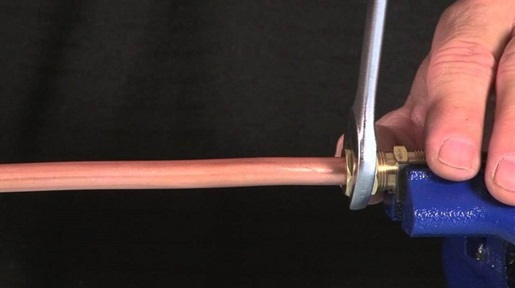

- the cut edge is processed with a file, sandpaper until a smooth surface is obtained. If burrs, potholes or other irregularities remain at the end of the pipe, the connection will turn out to be less airtight;

Stripping the pipe before connecting to the fitting

- if necessary, pipes are bent;

- a union nut and a compression ring are put on the prepared pipe;

Installation of fitting elements for connection

- the pipe is connected to the fitting. Initially, the tightening is done by hand, and then with a wrench. During tightening, the ferrule completely seals the connection, eliminating the need for additional sealants. However, when connecting a copper pipe to a pipe or fitting made of a different material, additional sealing with FUM tape is required.

Fitting fixation

It is important not to overtighten the threads, as soft copper is easily deformed.

Tight joining of copper pipes without soldering

In addition, it is worth noting that, despite the fact that connecting pipes by soldering is considered the most reliable method in most cases, there are still situations when it is not possible to use this method. In such cases, you can resort to connecting copper tubes without soldering. You will need special fittings that will ensure a secure connection due to the clamping effect that is formed during the threaded connection.

In this case, the connection is made in the following sequence:

- First, the fittings are disconnected, which often have two components.

- One of the elements is put on the pipe. As a rule, this is a nut and a clamping ring.

- Next, a pipe is threaded into the fitting and the nut is tightened.

It is worth noting that before you connect copper pipes without soldering, you should be aware of all the risks, since it is quite difficult to get a high-quality connection. Minimal distortions of the connected parts are not allowed at all, otherwise the technology is grossly violated. To make the threaded connection extremely tight, it is desirable to additionally seal it with special threads. At the same time, it is worth making sure that they do not end up on the inside of the pipe, since subsequently the water may not pass through the system properly.

Pipe connections of various materials

How is a steel pipe connected to a copper pipe? For this, a fitting is used, at one end of which there is a thread for fixing on a steel pipe. There is no thread on the other end, it is completely smooth, since the copper pipe will be fastened by soldering.

When installing a pipe in such a fitting, the threads should be wrapped with plastic sealing tape, after which the coupling is screwed onto the pipe. Such a sealing tape is necessary so that corrosion does not begin in the junction of two types of metal.

Steel and plastic fitting

Another example is a steel and plastic fitting. It is also made in two parts. The first part looks like a nut with a threaded segment that is screwed into a steel pipe. The other part is plastic, with a gasket and a nut also made of plastic.

Standard fitting consisting of steel and plastic parts

The nut is screwed onto another extension of the first part, which has an external thread. Further, a special solvent is used to fasten the plastic insert with a plastic pipe.

Fitting made of plastic and copper

There is also a popular fitting made of plastic and copper, which also includes two components. The first component has two ends. One is made of copper and has a thread, but the other end is completely smooth - it is he who is attached to the copper pipe by soldering.

Plastic fitting with copper thread

The other component is a plastic nut with a gasket. The nut is screwed onto a copper thread, and its other end is glued to a plastic pipe.

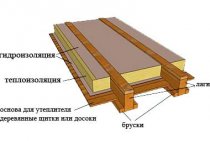

Capillary soldering method

Before starting the laying of the water supply, it is necessary to cut the copper pipes to the desired dimensions.

This method is based on the capillary effect, which contributes to the uniform distribution of the solder over the entire section, regardless of the position of the pipe. To create a capillary effect, special fittings are used, the diameters of which must differ from the diameters of the pipe by a strictly defined value. For open flame soldering, a gap of 0.1-0.15 mm is recommended.

Connections using capillary soldering are carried out using special fluxes and solders - thin wires made from metal alloys with a low melting point, usually tin with small additions of copper and silver. Solder joints are used in cases where either water supply is carried out by hand in the floor or walls, or in other cases when visual control of the integrity of the joints is not possible.

There are two soldering methods: high temperature and low temperature.

High temperature soldering, otherwise known as brazing, is used where the operating conditions of copper pipelines are associated with the presence of high temperatures. Such soldering is carried out using special fluxes and hard solders. For do-it-yourself installation of pipelines, this type of soldering is practically not used.

Low-temperature, or soft, soldering is used for pipelines used to transport liquid and gaseous media, the operating temperature of which does not exceed 110ºС. With do-it-yourself low-temperature soldering, the joints are heated to a temperature that is approximately 300ºС.

Communications from copper pipes and fittings

High-quality copper pipes and fittings, the technical and operational characteristics of which comply with the international standards ISO 9002, BS2 and DIN, are now produced by both foreign and domestic companies. Such pipes, as well as connecting elements for them, successfully withstand the high pressure of the media transported through them, high and low temperatures, and mechanical stresses that they may be subjected to during operation, transportation and storage.

Unlike polymer pipes popular in our time, copper pipe products do not deteriorate from exposure to sunlight, they are not afraid of corrosion, which is a real scourge for products made from ferrous metals. In terms of the service life that copper pipes and fittings differ in, no similar product made from another material can be compared with them. It is noteworthy that copper products are practically eternal, the service life of communications from them is at least 100 years.

Heating and water supply system from copper pipes in a private house

Pipe products, as well as fittings made of copper, are used for arranging engineering networks for various purposes:

- heating systems;

- air conditioning;

- cold and hot water supply;

- gas communications.

Those consumers who decide to use copper pipe products and copper fittings mainly use them to equip reliable and durable water supply networks. Fittings made from copper are more compact and look much cleaner than those made from ferrous metals. This is explained by the fact that when designing and manufacturing copper fittings, there is no need to make their walls thicker, taking into account their further corrosion, since they are simply not subject to it.

Do-it-yourself installation of copper pipes in the heating system

There are several reasons explaining the high popularity of pipes and fittings for them made of copper:

- copper, as you know, has antiseptic properties, therefore, pathogens do not develop in water pipes made from this metal, and the quality of the water transported through them even improves;

- installation of pipelines for which pipes and fittings made of copper are used is much easier than communications from black pipes;

- due to the high plasticity of copper, pipes made of this metal, when water freezes in them, do not burst, but simply deform; to destroy a copper pipe, it is necessary to apply an internal pressure of 200 atm to it, and such pressures simply do not exist in household communications.

Scopes of copper pipes

The installation of copper pipes in heating systems is possible due to their high resistance to working with high-temperature liquids. This property is especially relevant for a single-pipe heating scheme, in which, in order to ensure the coolant temperature in the last radiator is about 70ºС, it is necessary that in the first one it be equal to approximately 120ºС

The connection of pipes with compression fittings does not give an absolute guarantee of reliability and requires constant monitoring during operation.

The maximum temperature that the polymers used in heating systems can withstand does not exceed 95ºС, and media with temperatures up to 300ºС can be transported through copper pipes. An important property of a pipeline made of this metal is its ability to withstand a pressure of 200-400 atm, while the do-it-yourself soldered connection of copper pipes remains airtight.

At the same time, metal-plastic products can withstand, on average, a pressure of 6 atm, with a possible operating pressure in the system of 6–8 atm. Heating pipes made of soft copper easily tolerate 3-4 freeze-thaw cycles.

Due to its antibacterial properties, copper is able to resist the infiltration of contaminants in urban water supply networks. Sanitary copper is resistant to chlorine. Moreover, chlorine, being a strong oxidizing agent, contributes to the formation of a protective oxide film on copper, which prolongs the life of the pipeline. However, it should be remembered that do-it-yourself hidden laying of copper pipes can only be carried out if there is a polymer sheath on the pipes, which protects copper from stray currents.

Copper pipes are universal: in addition to water supply and heating systems, they are used to transfer gases, refrigerants in refrigeration systems, and are used in air conditioning systems.

Connecting pipes by soldering

Consider the connection of copper tubes with fittings, followed by soldering, which can be low- and high-temperature. In the first method, soldering is carried out at a temperature of 300 ºC. The second method is used in the arrangement of systems with high loads for industrial purposes.

Couplings act as connectors for copper pipes; tin-lead solder and flux are additionally needed.

The pipe soldering technology will be as follows:

- First of all, a pipe of a certain size is cut. This process must be carried out carefully, taking into account the dimensions of the existing fittings.

- Pipe ends should be inspected for any defects such as chips, cracks or burrs. If they are not eliminated, then there will be problems with the tightness of the connection after all work has been completed.

- After making sure that the ends are cleaned, you can start connecting. Due to the fact that several pipes will be connected, and they can be with different sections, the fittings must be selected accordingly.

- Next, the end of the pipe and the inner walls of the couplings should be treated with a flux that will degrease the surfaces to obtain the highest quality connection.

- Now the end of the pipe is threaded into the copper tube connector and heated. It must be selected so that the cross section is 1-1.5 cm larger than the pipe section. The pipes are heated with a gas burner. The gap between the pipe and the coupling is filled with molten solder.Nowadays, you can find any type of solder to suit your needs on the market, so choosing should not be any problem.

- After the solder is evenly distributed around the circumference, the parts to be joined must be left until it has completely hardened.

At the final stage, you need to check the connectors for copper pipes and the entire system by running water into it. At this point, not only the system will be checked, but it will also be cleaned of flux residues, which over time can cause metal corrosion.

Capillary method of connecting copper pipes

Soldering copper pipes, which is rightfully considered the most reliable and durable method of connecting copper parts, is performed based on the principles of capillary technology. In accordance with this effect, which is based on the laws of physics, a liquid can rise through a capillary, overcoming gravity, if there is a certain distance between the lower and upper points of its rise.

Solder fittings

This physical effect allows you to solder copper pipes in such a way that the solder melted by a gas burner is evenly distributed over the entire area of \u200b\u200bthe connection being created. In order to effectively perform such soldering, pipes can be placed in any spatial position, the main thing is that the molten solder is supplied from the bottom of the joint being formed.

In more detail, the process of performing capillary soldering is as follows:

- using a gas burner, the place of the future connection is thoroughly heated;

- molten solder is supplied into the gap between the ends of the pipes to be connected or between the pipe and the fitting used, which completely fills it due to the capillary effect;

- the resulting compound is allowed to cool completely;

- after complete cooling of the formed joint, its elements are thoroughly cleaned using a special cleaning compound.

With the help of soldering based on the capillary effect, pipeline elements are connected not only from copper, but also from ferrous metals. In the event that a steel fitting is used as a connecting element for copper pipes, then a layer of a special flux is applied to the place of the future connection. As a solder, when performing soldering using capillary technology, a very current wire is used, which can be made of tin, copper, and in some cases even silver.

Installation of copper pipes

In the process of installing plumbing systems with your own hands, it often becomes necessary to connect copper pipes with products made from other materials. In heating systems, cold and hot water supply, copper compounds with steel, plastic and brass are safe from the point of view of the occurrence of corrosion processes. But the contact of copper with galvanized steel is dangerous for galvanized pipes and leads to their destruction due to electrolytic processes. In order to avoid failure of the pipeline, it is necessary to make the connection with the help of, and ensure the direction of the water flow from steel to copper.

Before starting work, it is necessary to prepare a tool for installing copper pipes in a heating system or supplying hot or cold water. To do this, you will need: a pipe cutter or a hacksaw for metal, a file or a scraper, in the presence of sections of complex configuration - a pipe bender, gas burner or hot air gun.

Do-it-yourself laying of a copper pipeline begins with sections of a pre-calculated length. Then it is necessary to deburr the outer and inner parts of the pipe, if necessary, align the cut. The use of a pipe bender will prevent flattening of the pipe and the formation of creases, which can cause a decrease in the performance of the pipeline in these places.

If the pipe diameters do not exceed 15 mm, then their bending radius must be at least 3.5 diameters, and if more than 15 mm, then four diameters.When bending by hand, a high-quality bend can only be obtained with a radius equal to 8 diameters.

Despite their resistance to corrosion, copper pipes, due to violations of manufacturing technology, improper soldering and severe water contamination with abrasive inclusions, can undergo very dangerous pitting corrosion. The pipe corrodes in places where the oxide film is destroyed. One way to avoid this process is to install filters on water supply and heating pipelines.

In the modern construction market, copper pipes, due to their unique performance, quite successfully compete with steel, plastic and metal-plastic products, despite their high cost.

Even with the fact that polymer pipes are used more and more often, metal products are still a great success. As a rule, copper, brass and steel are used as the metal. For the better in terms of resistance to corrosion and high temperatures, copper is distinguished. Actually, the connection of copper pipes will be discussed in this article.

Even despite the fact that copper pipes are distinguished by their high cost, given all the characteristics of the material, their use is quite justified.

First of all, before connecting copper pipes, it is worth deciding how to connect them, by soldering or otherwise.

Necessary materials and devices tin and others

The following tools are required for working with copper pipes:

- pipe cutter, hacksaw or grinder with a thin disk;

- beveler;

- pipe expander (expander);

- soldering flux;

- solder;

- soldering iron for copper, for example, a propane torch for soldering copper pipes;

- rubberized gloves;

- paper napkins.

To cut the pipe, pipe cutters of various sizes are used. Larger samples have a large turning radius, they are inconvenient to use in hard-to-reach places, so if there is a need to cut off a section on a finished mounted water supply, use a small pipe cutter. You can cut the pipe with a hacksaw or a grinder with a thin disk, but a better cut can only be obtained with a pipe cutter.

After the pipe is cut, the burrs are cleaned. This is necessary so that there is no swirling of the fluid flow in the system. When there are no obstacles, the water supply does not experience stress and works like a clock.

Before welding copper, the ends of the pipe are polished with fine-grained sandpaper, which can be purchased at hardware stores. Both surfaces are cleaned, preparing for soldering. Sometimes for these purposes small brushes are used, the diameter of which is Ø 22 mm, they fit almost all pipes. For stripping, the brush leg is inserted into a screwdriver or drill, with which the process is carried out faster and better.

A flux is applied to the cleaned, smoothed outer surface - a composition that prevents the oxidation of copper.

Flux can be used by various manufacturers, such as Sanha

Rubberized gloves are used to protect hands, since when cutting off copper and burrs, many small metal elements are formed that stick into the skin like splinters. In addition, when cleaning the surface with a drill, a rotating brush chews up rag gloves.

In order to properly solder copper, it must be borne in mind that no more than half an hour should pass from the moment of stripping and applying the flux to soldering, otherwise the stripping must be repeated again. If the flux is applied with a brush, no bristles or hairs from it should remain on the surface - otherwise the connection will not be tight, and after the water is supplied, the pipeline will leak.

After inserting the pipe into the socket, the flux residues are not completely removed with a napkin, it remains on the connection in the form of an edge of 1–2 mm, and when soldering, the solder is pulled inward - a capillary effect is triggered.First, the joint is heated with a burner, while the moisture between the walls is evaporated. Then the burner is brought a second time, gradually the copper heats up, and the flux takes on a tin look. At this moment, solder is placed on the front side, soldering occurs, while the molten alloy flows down to the wrong side, solidifying in the process of movement. The excess overhangs of metal formed from below are separated by themselves. There are many ways to solder copper.

Elements for copper pipe connections

Copper fittings, which are used to connect copper pipes, are presented on the modern market in a wide variety of sizes and designs. The most well-known types of such connecting elements are:

- threaded fittings for copper pipes;

- self-locking connecting elements;

- compression or crimp type fittings;

- so-called press fittings;

- connecting fittings of capillary type.

Of all the listed types of connecting elements, press fittings for copper pipes are the least commonly used in our time, which is explained by the following reasons: their installation requires the use of complex and expensive equipment: special presses. The design of press fittings was originally developed in order to connect plastic and metal-plastic pipes with their help, so their use for mounting copper products is not always advisable.

Press fitting pliers

In order for the pipeline, in the arrangement of which copper parts are used, to serve as long as possible and be highly reliable, it is advisable to use elements of homogeneous materials during its installation. Connecting copper pipes with fittings that are made from other raw materials should only be done in rare exceptions.

If it is not possible to avoid the use of fittings made of dissimilar materials during the installation of pipelines, then such a process must be carried out, adhering to the following simple rules:

- copper pipes in communications, for the creation of which elements from different materials are used, are always installed after ferrous metal products: in the direction of the liquid;

- copper parts of pipelines cannot be connected to fittings made of galvanized and non-alloy steel, failure to comply with this requirement will cause electrochemical reactions to operate in such systems, which will significantly accelerate the corrosion process of steel parts;

- copper elements of pipe structures can be connected to parts made of acid-resistant steels, but if possible, it is better to replace such parts with fittings made of polyvinyl chloride.