Features of electric boilers

Household heating electric boilers are devices consisting of a powerful heater (usually up to 24 kW) and a circulation pump. There are also household electric boilers for heating up to 240 kW. Sometimes water circulation is provided due to natural convection - hot water, which has a lower density, rises up.

Using heating equipment that converts electricity into heat is an expensive way to heat a home. Economical electric heating boilers do not exist. The efficiency of each such device is 100%, so all the electricity consumed is converted into thermal energy. Therefore, choosing an electric boiler for the heating system, you must immediately be ready to pay huge amounts for electricity.

At the same time, this equipment has its own advantages, which other types of heating devices are deprived of. For example, this is a simple connection of an electric heating boiler, the absence of combustion products, compact dimensions, the ability to adjust the operation of devices.

Disadvantages of electric boilers

Electric boilers have many disadvantages. These include:

- Large power consumption. In order for the heating of the house to be highly efficient, it is necessary to use powerful equipment that consumes a significant amount of electricity (for more details: “Electric boiler: electricity consumption - economical calculations“). In terms of economy, installing an electric boiler is not the best solution.

- Equipment is improving at a slow pace. Electric heaters appeared a long time ago, but the principle of their operation has not changed much. The purpose of the boilers is to transfer the coolant within the house. Recently, low-temperature ceramic and film heaters have appeared - they are quite efficient (there is no heat dissipation during water transportation) and economical.

- Water is usually used as the heat transfer medium.. Therefore, when the heating system is turned off, pipes and radiators can be frozen. Electric convectors and oil coolers are deprived of this shortcoming. To solve the problem, you can also use oil or antifreeze instead of water in the heating system.

Thus, the use of electric boilers is not the best heating option.

Induction boilers

The principle of operation of such boilers is based on electromagnetic induction. A dielectric pipe is surrounded by a winding of insulated wire. The current flowing through it forms an electromagnetic field that contributes to the heating of any ferrimagnetic element inside the pipe.

Induction boilers are small in size. A circulation pump is not required for the operation of such equipment, although there are models with it.

Due to the fact that induction boilers do not have moving and collapsing elements over time, they serve for a very long time. But the device can break - this happens if there is no water inside the device, and electricity continues to flow. These boilers, as well as equipment with heating elements, can work with any type of coolant - not only with water, but also with antifreeze, distillate, etc.

Useful features and disadvantages

It is also worth considering installing a universal solid fuel boiler with built-in electric heaters. Some models even have a hob, which does not require additional external finishing.

Electric boilers can easily endure a power outage for up to 6 months. This makes them a good option in case of irregular use of the system or in the event of power outages needed to heat a private house.

The disadvantage of using an electric boiler is the need for powerful supply cables with a large cross section.

Boiler characteristics

Usually, when buying, people pay attention to such characteristics of electric boilers as their power, dimensions, thread diameter at the inlet and outlet. The very principle of operation of consumer equipment is often not of interest, but absolutely in vain

When choosing a device, you need to pay attention to all its characteristics.

The connection diagram of an electric heating boiler depends on its power. If the device consumes no more than 3.5 kW, then it can be connected to a conventional outlet. Boilers with a power of 3.5-7 kW are connected to the shield using a dedicated cable. For them, a voltage of 220 V is sufficient. The use of a separate cable is mandatory - for safety reasons, the maximum current at the outlet is limited to 16 amperes. For operation of boilers with a power of more than 7 kW, a voltage of 380 V is required. In any case, grounding is mandatory.

When choosing this device parameter, you need to consider:

- ceiling height - the higher they are, the greater the volume of the room;

- the thickness and material of the walls - for example, if they are made of 20 cm sip panels, they transmit less heat than from 10 cm reinforced concrete;

- the number and total area of windows, the material from which the frames are made (metal-plastic and wood have different thermal conductivity), the number of chambers in a double-glazed window (two-chamber with special energy-saving glass transmits half as much heat as a single-chamber);

- type of roof, the presence of an attic or attic.

When choosing a boiler, you should give preference to a model with more power - in reserve. To calculate the approximate power of the device, you need to divide the area of \u200b\u200bthe house by 10. For example, with an area of \u200b\u200b80 "squares", an 8 kW unit will be enough. If the building is poorly insulated (the walls are thin, the frames are old), it is better to buy a boiler with a capacity of 10-12 kW.

In the northern regions, for efficient heating of a house of a similar area, equipment with a capacity of 12-16 kW will be required, in the southern regions of the country - only 6-7 kW. Thus, when choosing the power of an electric boiler, you need to focus on the area and degree of insulation of the building, as well as on the climate.

Electric boiler installation

Do-it-yourself heating of a private house with an electric boiler is possible! Installation of an electric boiler, in comparison with gas, solid fuel boilers, is quite simple. But you must strictly follow all the rules and requirements.

- There is no need to allocate a special room for the equipment. Due to their minimal dimensions, most electric boilers can be installed anywhere. And the modern design of the equipment can fit perfectly into any interior of the room. If desired, you can hide the boiler in a special niche.

- Special ventilation systems or chimneys can be omitted. This equipment does not create waste that threatens human life and needs to be disposed of.

- Connecting equipment is easy.

- The heating scheme with an electric boiler is quite simple, so the installation and connection of this type of heating does not require approval and coordination of the relevant authorities. Also, in the future, systematic checks will not be carried out, which often bring discomfort and conflicts.

Heating a private house with an electric boiler is an innovation, but every year it is gaining popularity. Due to the presence of various modifications of equipment for heating with electricity, you can find a suitable option for a particular building. Before purchasing equipment, each home owner needs to calculate the power of the electric boiler for a particular room, taking into account all heat losses. Therefore, you should worry about the insulation of the building in advance. This will avoid the troubles associated with the heating system.

Boilers on heating elements

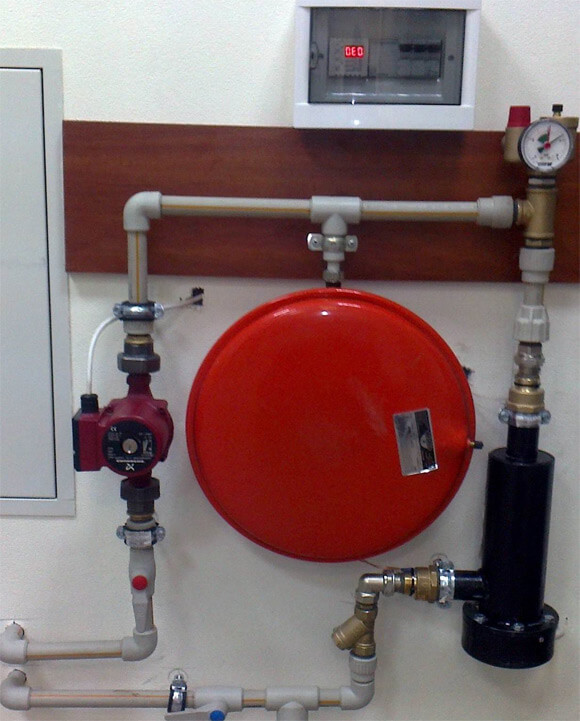

This equipment is arranged as follows. Inside a container filled with running water, there are several simple tubular heaters. Circulation is provided by a pump. The device also includes an expansion tank.

The power is regulated stepwise by turning on one or several 1.5 kW or 2 kW heaters at once. You can set the maximum power of the electric boiler, while during operation it will be able to change the level of power consumption within acceptable limits.

Boilers of this type have many disadvantages. Among them:

- When water leaks, the heating elements overheat and, as a result, burn out. In theory, they should automatically turn off, but this does not always happen.

- Over time, scale appears on tubular heaters, due to which the power of the equipment decreases, and the likelihood of heating elements overheating increases. But at the same time, because the water circulates in a closed circuit, it doesn't contain enough lime to make scale a problem.

- Boilers with heating elements are not suitable for small rooms, since they have significant dimensions.

Connecting the electric boiler to the heating system

There is nothing complicated in how to connect an electric heating boiler. The main thing at the same time is to follow all the recommendations of the manufacturer and the requirements of safety regulations. Only in this case, the heating system will work efficiently, and the operation of the boiler will become completely safe.

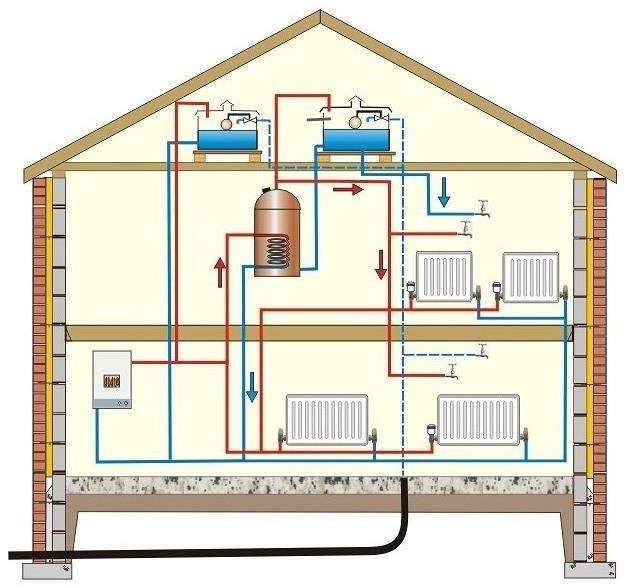

To reduce the amount of electricity consumed, it is advisable to resort to the following scheme:

- equip a floor heating system that evenly distributes heat throughout the room;

- install a heat accumulator - a heat-insulated storage tank. In it, the water will heat up at night, when there is a lower electricity tariff, and during the day it will slowly cool down, giving off heat to the room (for more details: “Correct heating scheme with a heat accumulator“).

Electric boilers are very easy to install, no special permission is required to create a heating system with them, as, for example, in the case of gas equipment (read: “Connecting an electric boiler to a heating system: instructions“). The main disadvantage of electric boilers is a significant consumption of electricity and a relatively short service life, which is associated with the possibility of overheating of the heating elements.

The most common faults

The most common malfunctions of electric boilers can be conditionally divided into two categories:

• Failure of heating elements.

• Failure of control and monitoring equipment.

In case of failure of the electric heating elements, it is necessary to replace the heating elements in the electric boiler in electric boilers of the heating element type, or to replace the electrodes in the electrode-type boiler. Below we will look at how to do it yourself.

In case of malfunctions in the control and monitoring system, it is necessary to first identify the faulty unit and either repair it or, if repair is not possible, replace it. If you do not have a special radio engineering education and the necessary circuit diagram, then it is better to contact a specialized workshop and entrust the repair to the master. Since without the necessary knowledge and skills it is impossible to make proper repairs and the consequences can be very deplorable.

Installation Procedures

To hang the device, you need a mounting plate, which is included in the delivery package: it is fixed to the wall with four dowels or anchor bolts with mandatory horizontal and vertical alignment. If this is a floor boiler, then it is installed on a special stand.

The machine must be grounded, inspected to make sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected.

Electric heating units must be connected with a wire, the cross section of which is indicated in the documentation for the equipment. Wires are conducted in special protective boxes.

Circuit options

There are various schemes: a scheme for connecting an electric boiler with heating radiators, schemes with the possibility of mounting a cascade. The latter option is used if it is necessary to heat large areas. For the operation of devices in a cascade, the terminals of the control unit are connected to the terminals of the controlled unit. If the room thermostat controls the installation system, its control contacts are connected to the terminals of the master equipment.

Heating apparatus piping

Binding can be carried out in a straight line and mixing scheme. The direct scheme involves temperature control by a burner, mixing - by a mixer with a servo drive. The binding is carried out as follows. A boiler collector is installed, a pipe of the required diameter is connected to the boiler.

A three-way mixing valve is installed at the inlet, which will regulate the temperature. A circulation pump is installed on the return line and a control unit is mounted. After tying, you can fill the system with coolant and test the equipment for correct operation.

This stage should not be underestimated: in reality, it is not as simple and insignificant as it might seem. Normal piping allows the use of equipment without an automation system, and this greatly reduces costs. Therefore, it must be performed at a professional level and taking into account the design features of the system and the boiler.

The piping of the electric boiler must be done by a specialist. If you still have to do it yourself, then you need already assembled distribution nodes. General scheme for the implementation of the heating system in the house.