Styrofoam under the screed as a heater is used quite rarely. Usually, when leveling floors, other types of insulation are used. But it is worth noting that for the first floors of apartment buildings, foam plastic is the best option for performing a screed. There are two ways to insulate floors with this material: use granules or whole sheets. In the first case, foam granules are added directly to the solution. One can argue about the effectiveness of this method, but given that the technology is gradually gaining popularity, there is still a result. We are more interested in the second method, which we will tell you about.

Why styrofoam?

The answer to this question is unambiguous: the material has a number of undeniable advantages. For instance:

- The structure of the foam is porous, which provides the material with low thermal conductivity. Accordingly, heat will not leave the room, and cold air will not get inside.

- Due to its structure, the foam is not exposed to moisture. Therefore, in some cases, you can save on laying a layer waterproofing.

- Polyfoam belongs to the category of fireproof materials. It, of course, burns, but without the constant presence of an open source of fire, it quickly fades.

- In addition, the material is lightweight, easy to use and is not subject to rotting and destruction over time.

Execution method screeds on polystyrene has its own characteristics and nuances. It is worth noting that the technology is quite simple, so absolutely anyone can cope with the work.

Technology

The workflow begins with the preparation of a rough coating. To do this, the concrete base of the floor is leveled with cement mortar. After that, the base is cleaned of construction debris and dust. Then you need to fill in the initial screed. This is necessary for the final leveling of the subfloor. The recommended thickness of such a screed varies from 3 to 5 centimeters. We recommend using the minimum thickness. Do not forget that waterproofing, insulation and the main screed will be laid. To this you can add the thickness of the finish coating. Too thick floors will reduce the height of the rooms in the apartment.

After the preliminary screed rises, you can start laying the waterproofing layer. Usually, special waterproof films are used under the foam. They are overlapped, all seams are glued special tape. Remember that the waterproofing layer should go on the walls of the room by about 10 centimeters.

Under foam plastic, it is not recommended to use mastic or bitumen as waterproofing. There will be a conflict of materials and as a result, the foam will begin to melt. If you still decide to use bitumen, then a plastic film should be laid between the layers of waterproofing and insulation.

Styrofoam sheets are laid on the moisture-proof layer. Remember that the higher the apartment is, the thinner the foam can be used under the screed.

Sheets are smeared with glue and stacked on waterproofing. This is done in such a way that the seams of adjacent sheets are not in one straight line. After all the sheets are laid, a small gap should remain between the wall and the insulation. This is a precaution in case the building shrinks. The gaps are closed with a damper tape. The gaps between the sheets of foam are covered with adhesive.

To link the insulation with the finishing layer of the screed, it is necessary to perform reinforcement. To do this, pour a thin layer of cement-sand mortar. The recommended thickness is 1-1.5 centimeters. A metal plate is installed in the poured solution. reinforcing mesh.

It should be noted that the screed on polystyrene foam can be performed without reinforcement. This material has a denser structure, so it is quite capable of providing reliable adhesion.

Then the main screed is poured. For this, a concrete mixture is usually used. The thickness of the coating must be at least 5 centimeters. To pour the screed evenly and without much difficulty, it is recommended to use special lighthouses. The role of beacons is played by a metal profile, which is laid on a reinforced layer and set according to the level. The screed is poured between the beacons and leveled with a special rail or rule. The final smoothing is done with a spatula.

When leveling the screed with a spatula, do not forget to periodically pierce the surface with a thin metal rod. This is necessary to remove air from the structure of the solution. This nuance will positively affect the strength of the floor.

The screed must dry for at least 28 days. This is how long it takes concrete to gain maximum strength. If work is carried out in the summer, then it is recommended to periodically spray the concrete with water. After that, you can start floor finishing.

Conclusion

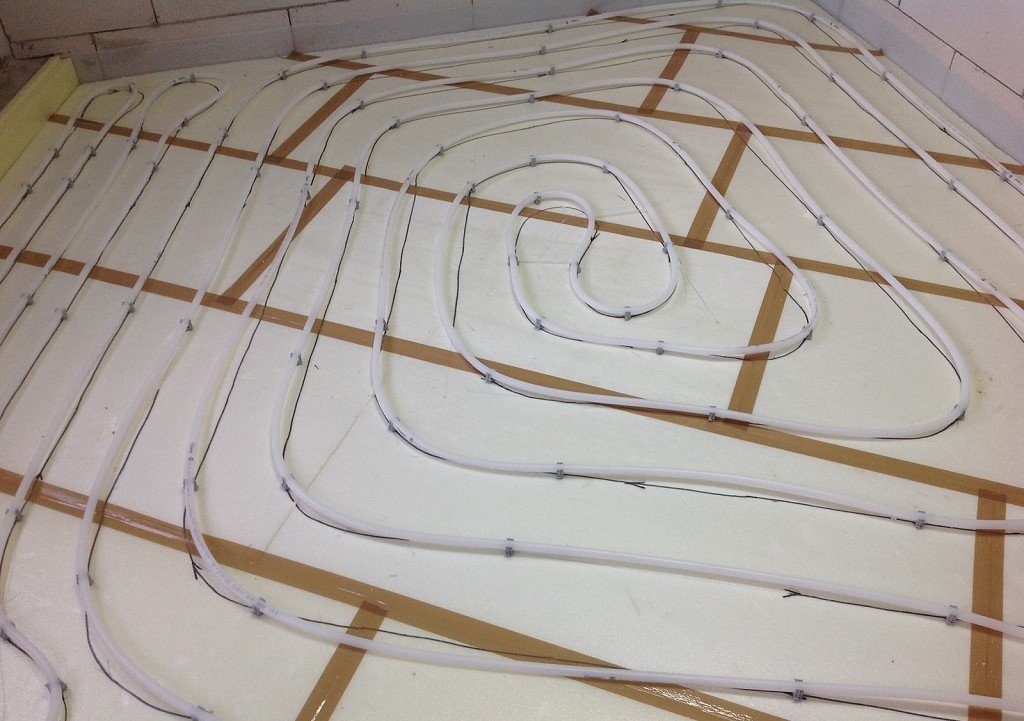

Styrofoam screed is a cost-effective technology, in which the floors in the apartment acquire additional protection from moisture and noise. This is especially true for homeowners whose apartments are located on the first floors. It is worth noting that the laying of foam plastic under the screed goes well with the technology "warm floor". In this case, you will need to use two layers of waterproofing. One fits under the insulation, the other on top of it.

There is foam covered with a layer of foil. Such material will not only retain heat, but also reflect it into the living quarters. This will create a certain microclimate in the apartment. True, the cost of foil foam is noticeably higher than conventional.

In any case, the use of foam under the screed is a cheap and effective way to insulate the floors in the apartment.