According to surveys conducted using a thermal imager, from 3 to 15% of the total heat loss can escape through the floor surface. A more accurate value depends on the design features of the building and its location. Properly executed thermal insulation will help to reduce heat loss and reduce heating costs. One of the options for its device is the laying of foam plastic under the floor screed, which is applicable both for a balcony slab and for interfloor reinforced concrete floors. The popularity of panels based on extruded polystyrene is due to thermal insulation properties and ease of installation.

Characteristics and properties of insulation

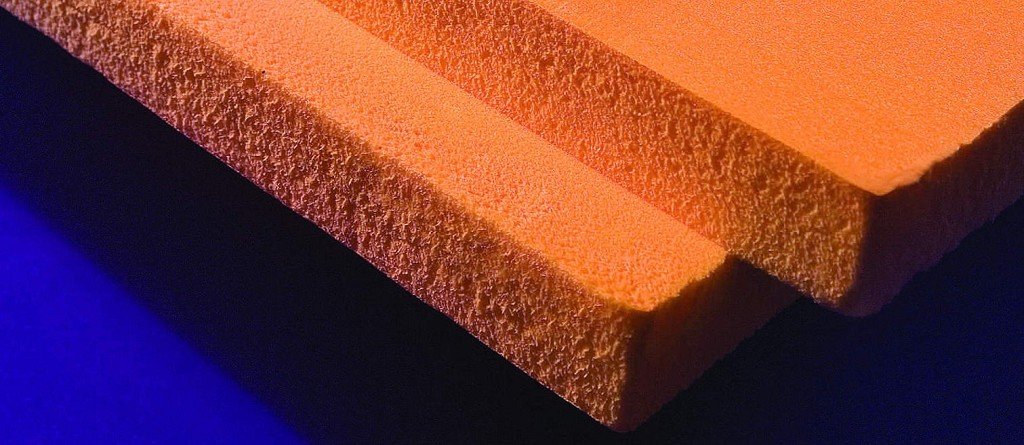

The main criterion for choosing thermal insulation for the floor is the coefficient of thermal conductivity. The low value of this indicator for foam plastic is due to the fine-mesh structure of the material, which is formed due to a special production technology. It allows to reduce thermal energy losses by up to 20%.

Laying foam under a concrete screed has other advantages, since it is characterized by the following properties:

- strength;

- good sound insulation;

- environmental friendliness, therefore, insulation with its help can also be performed in residential premises;

- durability;

- low degree of moisture absorption;

- resistance to fire and non-susceptibility to the appearance and spread of mold and fungus.

Penoplex is lightweight and easy to process. Using it for insulation screeds with your own hands, you can do without complicated tools and special equipment.

Materials and equipment

To install a floor based on a concrete screed, you need a set of tools and fixtures, which includes:

- a container for preparing a solution of concrete, with a volume of at least 20 l;

- construction mixer, ensuring the homogeneity of the mixture;

- the rule necessary to level the floor surface;

- level and tape measure for control and marking;

- stationery knife;

- spatula and needle roller.

The list of additional equipment is determined by the type of finishing flooring.

For a concrete screed, within the framework of which insulation is carried out, the following materials are needed:

In rooms located above the first floor, it is advisable to use comfort foam for insulation. It combines a low density of the structure with strength and the ability to withstand a significant temperature difference from -50 to +75 °C. Which penoplex to choose under the screed? It depends on the place of thermal insulation work and further operating conditions. For insulation of basement floors and balconies, which are exposed to dampness, the best choice would be a penoplex foundation. It is characterized by minimal moisture absorption, low thermal conductivity and retains its characteristics for about 60-80 years.

The final stage of work on the construction of a concrete screed with your own hands is the laying of a floor covering, which can serve as laminate, linoleum and other materials.

Laying technology

Starting the installation of a concrete screed with its simultaneous insulation, you first need to perform a number of preparatory work: clean the surface of debris and other contaminants, repair chips and cracks. Large irregularities are removed using a chisel or perforator.

The list of further actions depends on the location of the object of work.

To insulate the floor on a loggia or balcony, you must:

- Level the surface with a concrete screed to prevent damage to the slabs due to height differences, and allow to dry.

- Lay a vapor barrier layer, which is used as a polyethylene film or various membranes. Glue the joints of the canvases with adhesive tape.

- Lay insulation with minimal gaps between the plates. As an additional protection when performing thermal insulation with your own hands, you can treat the edges with a sealant.

- Lay the second vapor barrier layer and lay the reinforcing mesh.

- Fix the guides according to the level (their presence and number is determined by the size of the room).

- Pour the screed onto the penoplex, starting work from the far corner. Layer thickness ─ not less than 40 mm. To exclude air cavities, the surface is rolled with a spiked roller.

- After the surface has dried, lay the floor covering.

When insulating the balcony with your own hands, you can also provide for the installation of the "warm floor" system. In this case, the thickness of the screed is at least 70 mm.

The thickness of the foam boards for thermal insulation of the first floor or balcony should be 40-60 mm, and for apartments 20-30 mm is enough.

The interfloor reinforced concrete base is leveled using special mixtures, and then the following is done:

- lay insulation boards;

- spread a vapor barrier film on the surface and fix it;

- make a concrete screed, leveling its surface;

- after drying, the finishing floor covering is mounted.

Special Recommendations

In order for floor insulation with penoplex to bring the desired result, it is necessary to follow not only the technology of laying the material, but also some rules:

- It is necessary to carry out thermal insulation work at a positive air temperature, otherwise their quality will deteriorate significantly.

- When storing thermal insulation for the floor, you should follow the regime recommended by the material manufacturers.