The use of special technology will help to avoid mistakes in finishing and prepare the plasterboard ceiling for painting. The absence of flaws and irregularities after puttying will not only allow you to enjoy a perfectly smooth ceiling, but also prevent subsequent peeling of the paint. Let's find out how to putty plasterboard ceiling according to all the rules.

Selection of putty

From right choice of putty depends on the quality and general appearance of the base. When choosing it, the following criteria should be used:

- According to the degree of readiness for use. Putties are produced in a dry and ready state. The former please with low cost, long storage time in the package and resistance to temperature changes. The latter require thorough mixing at the beginning of work; in a hermetically sealed container, they remain in working condition for a long time.

- By composition. Gypsum types are used for finishing the ceiling in dry rooms, they are affordable and successfully cope with any flaws. Cement types are used to level the ceiling in bathrooms, kitchens, indoor swimming pools and in rooms without heating. Polymer varieties are universal and are used in any conditions, regardless of humidity and temperature changes.

- By appointment. Starting putties are designed for roughing the ceiling, hiding large flaws, cracks and joints. Finishing types are used for puttying a plasterboard ceiling for painting at the final stage of finishing.

Universal putty can be used at any stage of work. When choosing, it is necessary to pay attention to the drying time and the level of environmental safety. Preference should be given to options with the highest parameters, even if they are more expensive than others.

Primer selection

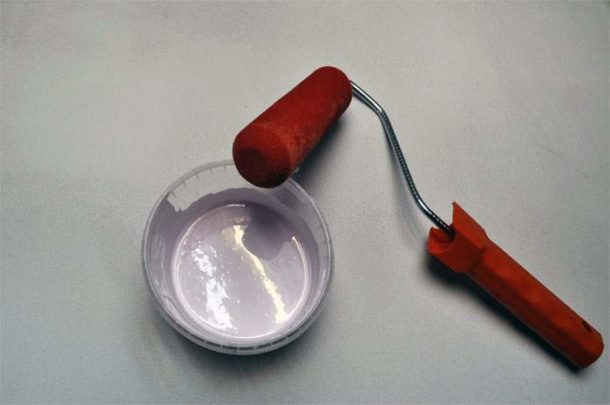

Before plastering the ceiling, it is necessary to prime it. The primed surface increases adhesion properties and increases moisture resistance.

For priming drywall, much less primer is required than for surfaces made of other materials. The average consumption is 1 l / 10–15 sq. m with a two-layer application. It should be borne in mind that the primer consumption before painting is 2 times more than before puttying.

The most suitable option for a drywall ceiling is an acrylic primer. With a low cost, it is very economically spent.

Preparatory activities

The question of how to properly putty a plasterboard ceiling must be resolved at the preparation stage.

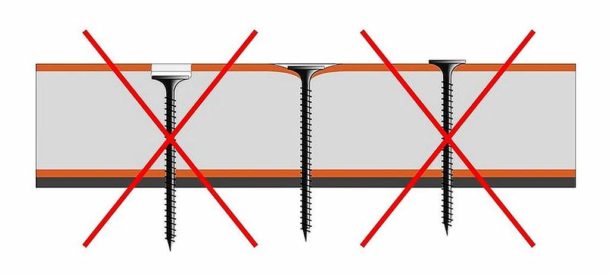

Before starting puttying, you need to level the sheets of drywall: get rid of the protruding caps of the self-tapping screws and the recesses from them and close up the joints.

Self-tapping screws are twisted so that their heads do not protrude on the surface, but not deep from it, the optimal depth is 1 mm. If during installation they were twisted so that cavities appeared around them, they must be removed. Then cover the holes from them with putty and tighten new self-tapping screws next to them.

Sealing seams and recesses from self-tapping screws

After completing the work with the screws, you can start seam sealing in the following sequence:

- to start with a brush, you need to sweep the dust from the ceiling;

- the edges of adjoining sheets, on which there are no factory or chamfers made in advance with a special planer, should be cut with a paint knife at an angle of 45 °;

- carefully primed the seams, dry them;

- prepare putty;

- qualitatively fill the seams between sheets of drywall;

- putty the seams, gluing them with a sickle or reinforcing with a special paper tape;

- cover the heads of the screws with cross-shaped movements;

- after the putty composition has dried, re-puttying the seams;

- sand all treated areas.

For sealing joints, the usual starting putty is suitable, but the best choice would be a special mixture for joints - Fugen or Uniflott from Knauf.

Corner processing

Finishing the ceiling with drywall may involve the manufacture of multi-tiered structures that have internal and external corners. To strengthen them, metal or plastic corners with perforations and sickle or paper tape specially designed for this purpose are used.

Internal corners are processed in the following order:

- a sickle is placed in the center of the corner or paper tape is glued to the putty layer;

- the entire area of \u200b\u200bthe sickle or tape is covered with putty;

- an angle trowel is used to level the corner.

To process external corners you need:

- Prime the entire surface of the corner, after drying, apply putty. Until it dries, apply a corner and press it to the desired depth.

- Remove excess putty squeezed out through the holes in the corner with a spatula.

- After drying, from top to bottom, apply a layer of putty on the entire surface of the corner.

- To completely level the corner, apply the required number of layers, each time waiting for the previous one to dry completely.

Stages of putty

The GKL surface does not have large irregularities, but in order to obtain an ideal ceiling, it is recommended not to be limited to one layer of putty.

To putty plasterboard ceiling, you need:

- using a wide spatula, apply putty to the ceiling and level it with a layer no thicker than 2 mm;

- then clean the spatula from the remnants of the putty and, having applied another portion next to the treated area, repeat the operation;

- if it was not possible to immediately create a smooth layer, you need to add more putties on it and level it to the desired condition, and remove the excess with a cleaned spatula.

The thickness of the layer is formed depending on the inclination of the spatula. With a smaller slope, the thickness of the layer increases. The application of the mixture is carried out at an inclination of 60 °. For final alignment, the angle is reduced to 15°, and the process is carried out with the capture of a part of the adjacent area.

In total, 2-4 layers of putty may be required. For the first, you can use the starting mixture, for the last one or two - the finish.

A few nuances:

- The puttying cycle of work should be carried out at a positive temperature in the room, from +5 to +30 ° С.

- During leveling, avoid direct sunlight on the surface, as it will distort the perspective.

- Do not take any measures to speed up the drying of the putty, this can cause it to crack.

- To obtain a perfectly flat ceiling surface, you can use the building rule.

The final stage

The plasterboard ceiling before painting should not have even the slightest roughness, since after painting they will be conspicuous. To eliminate all defects, the entire surface is polished. This finish at the same time will ensure the adhesion of the paint to the base.

Grinding is carried out using a special grater and emery cloth or grinder. To ensure personal safety during work, it is necessary to use a respirator and goggles.

At the end of the elimination of visible roughness, you need to use a flashlight or lamp to identify hidden irregularities and eliminate them.

At the last stage, the surface is primed. The plasterboard ceiling is now ready to be painted.