A modern home is unthinkable without comfortable and functional furniture. Its serial samples do not always fully satisfy the tastes of the owners and harmoniously fit into the interior. Wooden furniture made to order is too expensive. But what if you try to do it yourself, for example, a wardrobe made of drywall? This material is available, easy to process and install. In addition, a piece of furniture made independently will reflect all the wishes of the owner and bring the joy of creativity, not to mention serious money savings. Let's find out how you can make a drywall cabinet with your own hands.

Advantages and disadvantages of homemade furniture made of plasterboard

Advantages of plasterboard furniture:

- Complete freedom in choosing the size and configuration of cabinets. This allows not only to place shelves, niches and other elements in the most convenient way for the owners, but also to fit the furniture into the interior of the apartment as organically as possible without taking up precious space.

- There is no easier way to divide a room into certain zones, how to do drywall partition wall. But this partition can also carry a payload: plasterboard furniture, unlike wooden furniture, in principle does not have a nondescript back side. It can at least be finished to match the interior of the room, or better, make a double-sided cabinet or shelving using drywall.

- Home-made furniture made of plasterboard, subject to the recommendations, turns out to be quite durable and reliable.

Some of its shortcomings limit the appearance of such furniture in apartments:

- This is a stationary piece of furniture. It can be changed, but not moved.

- Such furniture is not suitable for storing items that can damage drywall with their sharp edges. A homemade closet is ideal for storing clothes or personal hygiene items, but not tools.

- In a drywall construction, it is undesirable to use elements such as hinged doors. This is not always convenient for the cabinet during its operation, but the profiles are not designed for such a load. So the do-it-yourself drywall compartment type option is more preferable and common.

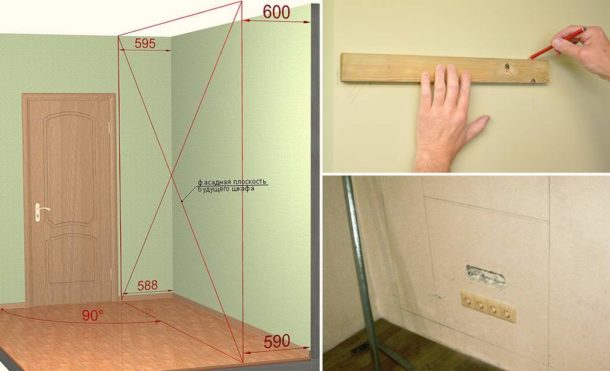

Surface preparation and marking

Before you start making your drywall cabinet, you should decide on its dimensions and appearance, think over, determine the place where we will build it. Here you can not do without a drawing. It should be detailed enough to accurately calculate the amount of material needed for the cabinet.

The walls and floor at the location of the cabinet must first be prepared: remove the old coating, clean from dust, degrease if necessary. A durable finish without significant defects can be left untouched.

All profile fastening lines are transferred from the drawing to the walls and floor. Not only the guides of the vertical racks of the cabinet, but also the places where shelves, niches and other elements of furniture construction will be made. Marking is carried out using a level, ruler and square.

Before you make a built-in wardrobe, you need to decide on the material of the frame. Wooden bars will give the cabinet greater strength, it is more convenient to attach drywall to them. But the tree is less durable and more susceptible to the influence of the external environment. Therefore, it is preferable to use a galvanized profile.

Frame assembly

Making a wardrobe with your own hands, you can plan local lighting in it. In this case, all wiring work is carried out simultaneously with its assembly, and it is better to mark the location of fixtures and communications in advance.

Before fastening the profiles, glue sealing tape on their surface adjacent to the wall. It will significantly increase the sound insulation of the structure. Drywall itself also dampens sound waves quite well, so the cabinet will still serve as additional protection from noisy neighbors.

- Guide profiles are fixed to the walls, ceiling and floor with dowel-nails. The recommended distance between vertical posts is 400 mm.

- Vertical profiles that create the outer plane of the cabinet are attached to the rails on the floor and ceiling by means of small self-tapping screws for metal - “bugs”.

- Attached horizontal bars. The smaller the distance between them, the more stable and reliable the cabinet will turn out. Particular attention should be paid to those places where it is planned to place shelves: here the structure must be reinforced in order to be guaranteed to withstand the weight of things placed inside the cabinet.

Masters recommend reinforcing the attachment points of the shelves with other materials, for example, using wood or metal in individual cabinet elements. The inclusion of such elements will also allow you to create an exclusive appearance of the product being created, if placed with a certain artistic taste.

- The back wall can be completely omitted if the wall surface has a decent appearance. In this case, most of the horizontal jumpers on it become unnecessary, only supports under the shelves are mounted.

More clearly, the process of forming the frame is presented in the video.

Drywall fixing

GKL is being cut. It is better to use real dimensions taken from the installed cabinet frame, and not indicated in the drawing: minor shifts during the assembly process are more than possible.

You can cut drywall with a carpenter's saw, but in order to process cuts less, it is better to use a paint knife. In this case, an incision is made on one side of the drywall sheet, cutting through the cardboard layer. Then the sheet is carefully broken along this line, the cardboard is cut off on the other side.

Separate cladding elements are attached to the frame with self-tapping screws, the heads of which must be slightly recessed into the drywall.

The corners of the cabinet are necessarily reinforced with perforated metal corners, fixed in the process drywall putty. It is carried out as standard: the seams are glued with a sickle tape, the heads of the screws are smeared, after which the finishing layer is applied.

Due to the impossibility of placing hinged doors, the cabinet shelves can be left open or you can purchase elements for installing compartment doors. Their installation is simple, but it will help to acquire a functionally finished look for cabinet designs.

At the final stage, the surface of the cabinet is finished in accordance with the general interior of the room.