Choosing a sealant for the shower tray and cabin

Sealant is a paste-like material widely used for sealing various joints. The sealant has found its application in strengthening the connecting seams in building materials, gaps around windows or doors, heating and water pipes, during the installation of ceramic tiles and plumbing.

Along with special silicone sealants, you can use transparent aquarium silicone.

Silicone sealants are used to close gaps and glue parts together. This material, due to water resistance, is well suited for kitchen and bathroom. Silicone sealants are UV resistant.

Natural antibacterial silicone is used as a sealant, for the installation of washbasins, installation of shower cabins, gluing ceramic surfaces, aluminum, glass, metal.

High-quality silicone sealant is made from a hydrophobic pigment filler (more than 45%), silicone rubber (more than 45%), a related plasticizer, catalyzate, fungicides, a thixotropic agent. This type of sealant is produced by ANTIA, STERN, Somafix. The best sealant for a shower tray is one that consists only of silicone without the addition of other impurities. Such material has the smallest shrinkage (up to 2%). In small quantities, the following impurities may be present:

- organic solvents;

- organic extenders;

- mechanical fillers (quartz flour, chalk).

If the composition of the material contains a fungicide, it can also be used for a bathtub tray, since the fungicide does not allow fungus and mold to grow in a damp room. When making a choice between neutral and acid silicone, the first option will be preferable. It does not have a strong odor and is more versatile.

Cabins are sealed not only with widely used special silicone sealants designed directly for, but also with transparent aquarium silicone.

Best Answers

Grandfather Stupid:

Good fresh cement, diluted on liquid glass. In general, the sealant should not come off. Two options: when they smeared it, didn’t degrease it, or the cab was shaking, it came off.

@@kosyak@@:

cement =)

errare humanum est:

there is white - then you can’t pull it off. I didn’t clean it when I scored - it’s worth it in chunks (((

Michael:

there should not be sealant, if where it should be, then there it should be closed with moldings, overlays. Silicone is applied to the parts of the cabins that are joined together, at the junction with the wall

Gugumot:

What are you for G ... oh, and not the sealant bought it. When I sealed it at home, I degreased everything from the beginning, and then went through the sealant. For the past 4 years, nothing has happened in the sense of a sealant, not a drop has been missed.

Charm:

my husband said with a ceramic border, on tile glue, and grout with grout ... as it dries ...

Valli:

Special epoxy resin with synthetic additives using special fiberglass

Expert answers

Rus Ivashkevitch:

1. The outlet of the "sewer" from the shower should be higher than the entrance to the existing sewer in the house. If lower - make a "podium" according to the size of the cabin. 2. Compare the height of the shower cabin (taking into account point 1) + the ventilation outlet from the cabin with the height of the room. The height of the room should be greater. 3. Provide (before installing the cabin) the supply of water to the corner (faucets for shutting off in an accessible place) and electricity. 4. Before installation, I would prepare the wall behind the cabin in such a way that it would be possible to safely remove the cabin (you never know) and not do repairs in the room after that. 5. When choosing the size of the cabin (pallet), try to bend in it.I can't fit in a 90*90 cabin in a bent state.

Anfalova Elena:

It’s not worth spending that kind of money on a shower stall, my husband bought a pallet from me and made glass doors plus a faucet and shelves. It looks no worse than a booth and is 3-4 times cheaper! And a large acrylic tray.

RED:

There is an opinion that the Chinese cabin, so that everything is “smooth” and not dripping from anywhere, can only be assembled and installed by the masters who ate the dog on this. The Finnish cabin, for example, can be installed by yourself if your hands grow from the right place.

My wife has been kicking me for the second month already, but China is somehow dumb to buy. And other cabins here are completely indecent money.

Lesya Ivanova:

My husband laid out a brick pedestal so that it was higher. For what it is necessary, either so that the water leaves better, or for some other purpose. We installed it, then this problem arose. I had to take it off and redo it.

Sveta:

the main thing is that all the spare parts are in the cabin, otherwise there is often a lot of understaffing, you need to carefully check everything

White Oleg:

Often there are problems with the equipment - when buying, check right away, the native screws are no good, we throw them away and twist our own, you need to silicone all the joints between the glasses, panels - otherwise it will leak later, install the screen last, already when the water was let in and tried no leaks. . . All probably... Questions will be - write ...

neangelOK:

take waterproof main thing. Moment-germent

andrezz:

Any bathroom sealant, waterproof.

come to the store and ask which one is suitable for the bathroom - they show you a new quantity, and then which one you like.

Mr. Bond:

Yes, the fact of the matter is that they show a lot of numbers, but it’s still difficult to choose. Doubts torment the veracity of what is written on the bottles. Of those that I tried, I personally liked Dow Corning 7091 more. In general, I took it for headlights, because it is for flexible joints, glass and plastic, for example, or glass and metal, thicker than other sealants and goes deeper into the crack. It is suitable for aquariums, and for showers - in general, for those places where water is constantly present. In general, buy goods from trusted manufacturers so that there are no such problems in a month ...

Irish McClaud:

The sealant must be waterproof and provide insulation. Yes, and should not highlight anything bad. Therefore, go to the trick and take the thing that was developed for aquariums -

Installation of side walls in the shower

All work is done on a dry surface. The assembly of the shower cabin should be carried out according to the instructions:

- Install side walls.

- Pre-fix all joints with screws.

- Make fasteners for the top and the shower itself.

At each stage of assembly, it is necessary to carefully coat all joints and joints with a sealant. At the same time, you need to ensure that all the screws remain on the outside of the cabin.

If you follow this sequence, you can assemble without damaging the sealant itself.

After all the seams that are covered with sealant are processed, everything is fixed with screws and left to dry completely. If there are areas where silicone remains, you need to remove it with a rag.

Then you need to seal the cabin from the outside (front). To do this, you can use a sealing cord. First you need to insert it into place where the cab frame is adjacent to the glass. Then seal with sealant. This will improve the waterproofing properties of the zones.

Then, as everything dries, check the level of tightness of the structure. To do this, a strong jet of water is directed to any connection. If leaks are found, re-sealing is necessary. Be sure to go through the tool again in problem areas.

There were cases when, for high-quality sealing of the shower cabin, it was necessary to carry out repair work and dismantle the old sealant. It is easy to remove silicone sealant from the bottom using white spirit.

You need a rag, blades and cleaning agent. Moisten a rag in the product and wipe the place with the old sealant, leave for 30 seconds. Take the blade and peel off the old layer from the surface (glass or tile). If a yellowish stain remains in this place, then it is necessary to wipe it again with the help of White spirit.

It is possible to remove silicone from the pallet mechanically only from surfaces that are not scratched. It is removed with a sharp knife or pumice stone. First, large silicone growths are removed. Everything must be done with extreme care so as not to damage the surface.

Additionally

After the sealant has been removed, you need to disconnect the cab from the pallet. In the case where the silicone was not completely removed, it can be cut off with a knife. To do this, the tool must be inserted into the opening between the pallet and the wall.

After the walls have been removed, the residual silicone must be removed using a hard pumice stone. If all the work was done carefully, then you can be sure that the acrylic surfaces will remain safe and sound.

After all procedures, it is recommended to wipe the shower cabin completely with a dry and clean cloth.

Why is it needed

The shower stall is usually a plastic or glass "corner" attached to the wall, with a drip tray to drain the water.

The wall, in turn, is usually covered with ceramic tiles. And if, separately, ceramics and glass easily resist moisture, then cracks often form at the joints, through which water seeps through.

In addition to constant puddles outside, this can threaten to reduce the life of the booth and the appearance of mold due to constant humidity.

To prevent this from happening, all cracks must be treated with a sealant. This is a building material, the consistency of which resembles thick sour cream. When applied, it forms an elastic film that does not allow moisture to pass through and additionally holds the parts together. Used on glass, metal, ceramics and aluminium.

At high humidity (in the kitchen and in the bathroom), a waterproof sealant is used. It perfectly resists drops and does not change under the influence of ultraviolet radiation. For additional protection against mold and fungi, an antifungal version is produced.

This is interesting: Features, scopes and popular brands of butyl sealants: we lay out the points

The subtleties of sealing the shower

Sealing involves the use of the following materials:

- sealing cord;

- rags;

- silicone sealant.

Use a silicone thinner to remove old sealant.

When using polysulfide, silicone, acrylic, butyl sealants, cavities and seams are not only cleaned, but also dried. Experts do not recommend using soapy water or detergents for this purpose, as they can impair adhesion.

Old sealants and other contaminants from concrete and stone surfaces are removed with a wire brush, if necessary, special cleaning and dissolving compounds are used. Metal, plastic and glass are wiped with a solvent or an alcohol-containing liquid, the remnants of which are wiped dry with a napkin. To protect the areas adjacent to the sealed seam from contamination, an adhesive tape is used, which is removed immediately after completion of work.

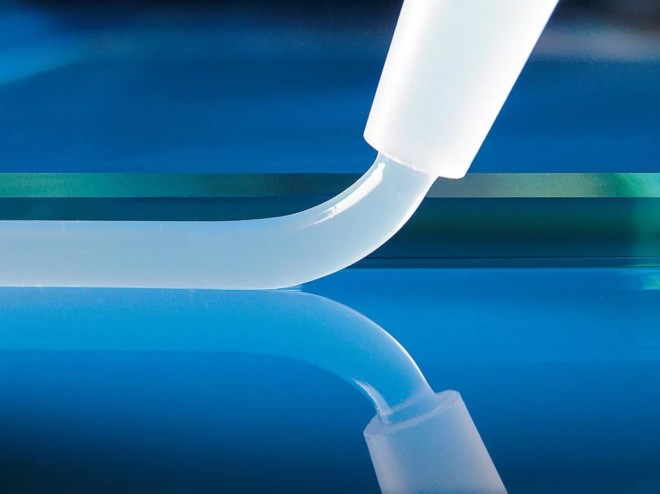

The surface to be treated must not be too cold or hot. The optimum temperature range is within 5-40°C. It is recommended to heat the tube with sealant to room temperature. The extrusion method is determined by the type of packaging. The sealant comes out of the tip after squeezing the tube.To form a beautiful seam and remove excess material, use a spatula dipped in water. It is necessary to carry out the procedure without delay, since a film appears on the surface of the sealant quite quickly, within 5-30 minutes, depending on the composition. The average curing rate of the material is 2-4 mm per day at a humidity of 50% and a temperature of 20°C.

How to seal

In order for the do-it-yourself sealing process to be carried out correctly, you should use special equipment, which is most often supplied with a sealant. We are talking about the so-called gun, into which a capsule with sealant is inserted, and the force is transmitted from the trigger through a special design to the piston. This allows the sealing mass to be applied in an even layer without breaks along the entire butt length. But before doing this, you need to degrease the surface, completely and very carefully clean it of particles of dirt and dust, in order to ensure a reliable connection of the silicone to the edges of the degreased surface. It will not be superfluous to apply an antifungal composition in order to exclude any formation of fungus or mold at all.

The following factors influence the speed of hardening:

- thickness of the applied sealant;

- temperature;

- moisture level in the room where the work is carried out.

Given the last two factors, you should not use the bathroom for some time so as not to increase the humidity and temperature in it before work. When it was possible to seal the necessary area, experts do not recommend using the shower for some time. As stated, a silicone-based sealant is the ideal solution for protecting joints during installation of a shower enclosure. It is easier to manage than with acrylic sealant, and its properties will be better. And the affordable price indicates that it is better to choose just this type of sealant.

If you go directly to the sealing process, then silicone shower enclosures should be either during assembly (each connection), or after installation is completed (all joints that have formed). It is necessary to carefully apply the sealant to places that have already been sealed with cords or rubberized gaskets. It is necessary to process the joints in such a way that the places where the parts are attached to the structure with screws or bolts are on the outside of the sealant strip.

Sealing should be carried out according to the manufacturer's instructions.

, which clearly and step by step describes the whole process. And at each stage, silicone must be applied to all joints and joints.

Seam processing should be carried out as carefully and very carefully as possible. The substance must not come into contact with the inside of the shower box, bathtub or drip tray. For any corner, a small amount of sealant will be enough. If you are unsure that you can carefully silicone, then some places, and especially those that are next to the sealing line, can be pasted over with masking tape. This will protect them from accidental contact with sealant.

When all work is completed, the adhesive tape can be easily removed.

If suddenly you accidentally stained some unprotected place, then the fresh composition can be removed with a piece of cloth. Once the sealant dries, it will be nearly impossible to remove without damaging the surface.

When all joints inside the shower cabin are treated with silicone or other sealant, and the structure is fully assembled and fixed with all fasteners, it is imperative to conduct a general inspection of the shower cabin from the outside. You should carefully inspect it for the presence of excess sealant from the outside.

If such excesses are found, they should be carefully wiped off with a rag or piece of cloth.

Next, you need to give the sealant time to dry.

As a rule, the drying time is indicated on the tube. When it is completely dry, then you need to check the structure for leaks. To do this, simply close the drain and draw water into the pan or onto the floor to a certain level, and then drain it. During the collection of water, it will be possible to understand whether the shower stall is flowing in the most important places. If such a leak is found, then in order to eliminate it, it will be necessary to replace all the already applied sealant with a new one. It would be pointless to use sealant precisely in places of leakage, since it will not be a single tenacious mass. This solution is temporary. But sooner or later, a leak will appear in this place again.

Working with sealant

For sealing, you need to use some materials:

To properly seal the tray and shower, you need to prepare all the necessary surfaces. Clean them from old coating layers, dirty spots, dust, and you also need to degrease the parts.

It is necessary to perform these procedures when sealing is to be carried out. In order to remove the old sealant, it is better to use a special solvent designed to work with silicone.

From concrete and stone surfaces, the old sealant is best removed using a wire brush. If necessary, you can use special cleaning and dissolving compounds.

Metal, plastic and glass surfaces are treated with a solvent or alcohol-containing liquid, then wiped with a dry cloth. To protect the areas that touch the sealing seam from dirt, adhesive tapes can be used, which can be removed after all procedures have been completed.

The surface to be treated shortly should be of medium temperature. This range is from 5 to 40 °C. The sealing tube is heated to room temperature.

How to squeeze out the composition is described on the package. Silicone or other sealant appears at the end of the tube as soon as the tube is squeezed. In order to form a beautiful seam and remove unnecessary strokes, you can use a wet spatula (soak in water).

This work requires a quick reaction, otherwise the film on the sealant appears in 5 minutes (this factor depends on the constituents of the material).

On average, a small layer of material (from 2 to 4 mm) hardens in a day if the temperature is 20 ° C and the humidity is 50%.

Types of sealants

Joints are treated with special compounds called sealants.

There are two types of sealants on the market:

- with silicone base

- with acrylic base.

Acrylic-based sealants are completely unsuitable for rooms with a high moisture content. The fact is that acrylic decomposes under the influence of water, and when it dries, it begins to crack and slowly collapse. Manufacturers are trying to introduce moisture-resistant substances into the composition, but even this does little to save the situation.

Silicone sealants are considered the best option for working in high humidity conditions. They are not afraid of water, qualitatively close up holes. It is because of these properties that specialists prefer sealant. True, you still need to be able to choose a quality product.

The main task of the sealant is to reliably protect against leaks. Therefore, do not try to profit somehow when buying it - you can buy an inexpensive sealant, but not of high quality. He will soon lose all his useful properties and work will have to start from the very beginning.

To determine a quality product, you must carefully study the information indicated on the label. A good sealant in its composition should have forty-five percent of a hydrophobic substance and exactly the same amount of silicone rubber. The composition should also contain a plasticizer.When choosing, preference should be given to products from manufacturers that have long established themselves.

The need for sealing showers

The versatility of some models of shower cabins allows not only to use it for its intended purpose. These may include: audio players, massage systems, dryers and other functions.

But, one thing remains the same - this is the design of shower cabins. Those have a tray for draining water and a body that is made of glass or plastic. Expensive models can be installed permanently, separately from the bathroom walls. Their body is closed. But often the price of such cabins is expensive. Therefore, coal cases that are attached to the walls are popular.

The installation of shower boxes is not difficult. The main thing is to take the necessary measures to protect the building materials on the floor and on the walls in the bathroom.

There may be gaps between the pallet and the adjacent tile. Flowing down the wall, the water will spill under the pallet itself, spreading into puddles.

Such consequences, in addition to inconvenience, carry great harm to the integrity of the installed coatings in the room. And with frequent and voluminous leakage, there is a risk that the liquid will penetrate lower to the floor and create problems for neighbors. Yes, and the cabin itself can suffer. In the most inaccessible places for processing, it can form:

- fungus;

- zail;

- water stagnation.

All this gives rise to the formation of putrefactive processes, which are not only dangerous to the health of the inhabitants of the house, but can also significantly reduce the life of the device.

You can protect yourself from possible problems. And it will be easy to do if you know how to seal. The main thing is to get a high-quality sealant for shower cabins, and grease all the joints of the device with the bathroom with it. This building material has several important properties that are necessary for the harmless use of this box.

These include: moisture resistance, elasticity, the possibility of gluing surfaces, as well as an antifungal effect. A whole range of positive aspects can be obtained with the right choice of sealant. But, it remains only to figure out what factors you need to be guided by when buying.

Types of sealants

The sealing process is carried out by using special tools called sealants. They are produced as a high density paste, which is applied to the seams at the joints of various surfaces. The specified substance consists of polymers having an adhesive base. When they dry, they simply fill the space and glue the surfaces together.

Today, two types of sealant can be used:

- based on silicone;

- acrylic.

The latter are almost impossible to use in bathrooms and showers due to the high humidity in these places. And acrylic under its action simply begins to decompose, in the process of drying it simply cracks and slowly collapses. It is for this reason that various substances are added to acrylic pastes that are resistant to water. But even so, acrylic is not as durable as silicone.

Silicone is considered the best solution currently on the market for two reasons:

it calmly reacts to the effects of water, and also reliably covers all holes and openings. Therefore, most craftsmen believe that it is better to use silicone sealant in the described case. But it also needs to be able to choose. The main purpose of this composition is to create a reliable barrier to prevent moisture penetration. Considering that the consequences of its penetration can then result in serious expenses, it is better not to save on sealant from the very beginning.The fact is that some low-quality compositions of this type can quickly lose their waterproofing properties, and after a while the work will have to be done again.

To determine whether the sealant is of high quality before the moment of its purchase and subsequent use, it is necessary to familiarize yourself with the composition indicated on the label. The best option for a shower cabin will be an option that contains at least 45 percent of a hydrophobic type filler, 45 percent of silicone-based rubber, a plasticizer, as well as various kinds of additives: thixotropic agents, catalyzate and fungicides. It is best to choose sealants from well-known manufacturers whose products have already shown their high quality when creating seams and sealing such areas.

How to seal a shower

In order to seal the cabin with your own hands and with high quality, it is better to use a special device. The device is shaped like a gun and a sealant is inserted into it. The gun will greatly facilitate the process of squeezing the mass. The sealant will lay down evenly and continuously.

Before starting to apply silicone, the surfaces must be treated with a degreasing agent, as well as remove dust and possible dirt. It also does not hurt to carry out the treatment with a composition that protects against the formation of mold.

Usually the sealant dries in a day, but various factors can affect this:

- the thickness of the applied composition;

- room temperature;

- humidity in the room.

Based on the last two points, it would be better to refrain from visiting the bathroom for a while, so as not to inadvertently increase the moisture content in it and not raise the temperature. After processing, it is better not to use the booth for a certain period of time. As already mentioned, the silicone type of sealant is the best option for such work. And the availability of its price contributes to the choice of it.

Starting work on sealing joints, processing must be done immediately upon connection, or immediately after installation. Carefully apply the composition to places with sealing cords and gaskets. The joints are processed so that the places with fasteners remain outside the sealant strip.

During the work, you should follow the recommendations given in the manufacturer's instructions. At each stage of assembly, all joints and connections are necessarily treated with sealant.

Particular attention should be paid to the processing of seams. Make sure that the composition does not get on the inner sides of the surfaces.

It is enough to apply a small amount of the substance. If there is no certainty that it will be possible to carefully carry out the processing, then masking tape can be applied to some areas.

After the work is completed, the adhesive tape can be removed. Excess sealant should be removed with a piece of cloth. The main thing is not to wait for it to dry.

After processing all joints and final assembly of the cabin, a thorough external inspection should be carried out. Excess sealant must be removed.

After finishing work, you must wait until the sealant is completely dry. After that, you should check how well the work was done. Just close the drain and draw water into the shower tray and drain it. During this procedure, it will be easy to determine if there are leaks.

If a leak is detected, then the sealant should be completely replaced in this place. It makes no sense to apply a new layer of substance on top of the existing one. Well, he will not grapple, and in any case, the leak will form again.

If there is no pallet in the cabin, then for complete sealing it is necessary to process the seams between the tiles with a special grout. The grout will allow the seams to repel water, just like tiles do.

What to focus on when choosing a sealant

There is a lot of information and information about how to seal a shower cabin. Often, everything happens according to the same scheme, partially modified. The question of which sealant is suitable for sealing a shower cabin is more significant and significant. After all, the durability of the entire structure depends on the right choice.

The first thing to focus on is the composition of the substance. The product container contains a list of all components contained in it.

If the pallet material is acrylic, then acrylic sealant will be the best. For metal baths, a silicone product is suitable. And the more of this component in the composition, the faster it will dry and bind the surfaces stronger.

Sealant color

Transparent sealant is universal

It is selected for the materials to be glued. Transparent sealant is more versatile.

Water resistance

It is this factor that determines the possibility of using sealant in the bathroom, where a high level of humidity is constantly maintained.

Bacteriological resistance

Due to the constant exposure to moisture, mold can form in the cracks. A product with such a mark prevents its occurrence.

Presence of additives

The fewer foreign elements in the composition of the product, the better.

It is rare to find quality sealant cheaply. The price always matches the quality. Inexpensive material will not be able to effectively perform its basic functions, especially over time.

By focusing on a sealant with the right composition, color, resistance to mold growth and a minimum amount of additives, you can be sure that this is exactly what you need to seal the shower enclosure.

Peculiarities

After installing the cabin in a small bathroom, there is still space for some furniture, a washing machine, and so on. And the sealing of the shower stall is the most important element in protecting the room from moisture and its excess and, as a result, dampness in the room. The severity of the problem in this case is due to the fact that the booth is a prefabricated structure. Namely, through the cracks between its parts, moisture with steam gets out and increases humidity.

Moreover, this causes the formation and extremely rapid spread of fungi, mold, and other harmful microorganisms in the bathroom, and then in the apartment. Their spores, which are released into the air, cause allergies, diseases of the respiratory tract, lungs, and so on. In addition, dampness can attract various creatures: cockroaches, rats, insects, woodlice and the like, which are carriers of dangerous infectious diseases. That is why it is strongly recommended that after installation it is imperative to seal and waterproof the shower cabin.

If we talk about the most common places for leaks, then most often these are butt joints. This is the weakest point in any shower stall. Another reason may be the cabin design itself. In a large number of models, small thresholds are installed through which water simply spills. Another reason for a water spill may be the poor quality of the drain mechanism or the connection of its elements. In this case, water simply accumulates under the shower. As a rule, it is enough to either tighten the fasteners, or replace the system itself. Another fairly common cause of shower stall leaks is a crack in the shower tray.

Types of sealants

It is by no means easy to choose compositions for insulating seams due to the presence of a huge number of different preparations on sale. You need to carefully study the information on the labels, delve into the essence of the manufacturer's recommendations, consult with the seller or manager offering the product, and only after that make a purchase decision.

The quality of the sealant for the shower cabin, the correctness of its application depends on the sanitary condition of the bathroom, the serviceability of the equipment, and the well-being of the residents.

Effective isolation of risk zones is provided by polymer compositions based on:

- silicone;

- acrylic polymers;

- polyurethanes.

All types of products are a viscous paste-like mass, which, when squeezed out of the tube, fills the entire space of the gap, gluing the contacting surfaces.

https://youtube.com/watch?v=Xwn5wPKTn88

Polyurethanes

Composites based on polyurethanes act aggressively on the skin and mucous membranes of the respiratory system, and you can work with them only in a protective mask and gloves. Moderate performance, combined with the danger of contact, has led to the fact that now polyurethane products cannot compete with more advanced formulations and are gradually losing popularity.

Acrylic polymers

Polyacrylic compounds for sealing have a favorable ratio of consumer properties and price, which increases their attractiveness to the buyer. They are well fixed on materials due to high adhesion rates, withstand any temperature, and can be top-coated with paint, putty or varnish. The desire to purchase acrylic sealants is hindered by their not the highest resistance to mechanical deformation, the tendency of many modifications of preparations to be exposed to water.

For example, if you seal the tray with polyacrylic, and then allow an overweight person to take a shower, who may well want to give himself a hydromassage, then there is no guarantee that the seams between the lower container and the walls will not crack.

If bathers with significant weight are not expected, another misfortune may cause concern. Even composites with the addition of moisture-proofing substances do not withstand prolonged contact with water and slowly decompose, and the prospect of restoring the seams in the near future does not please anyone.

Silicone compounds

The leading positions in the ranking of sealing products for shower cabins are consistently occupied by silicones, the consumer characteristics of which make the buyer forget even about relatively high prices.

There are several types of silicone compositions that differ in the structural features of the base substances, the presence of additives.

Composites containing antifungal additives that increase the viscosity of the mass upon drying, plasticizers, pigments that create a pleasant decorative appearance of the seams make it possible to effectively silicone the shower cabin.

Despite the importance of the functions performed by the additionally introduced components, the best qualities are those with the maximum concentration of silicone and the minimum concentrations of everything else.

Advantages and disadvantages of silicone sealants

Having opted for this type of substance, the masters proceed from the generally accepted opinion. However, in addition to the above qualities, silicone seals have others.

The disadvantages that silicone has include the destructive effect on polycarbonate and polyacryl. The structure of these materials has microcracks, once in which the substance bursts them, causing the expansion of cracks.

Therefore, when choosing equipment for washing, you need to pay attention to the composition of the materials from which it is made.

And silicone seals are not compatible with paints. Therefore, for colored showers, it is necessary to select compositions that are invisible from the outside.

In addition, the silicone composition, due to its specificity, cannot be rubbed into the joints, like acrylic, and removing excess is also very problematic. Therefore, you need to work with it carefully, having a special tool and observing the application technology.

As for the pluses, in addition to durability and high tightness, silicone has high elasticity.Therefore, changes in the physical volume of the cabin elements associated with sudden temperature changes will not affect it.

In addition, silicone has water-repellent properties, so even leaked moisture will not affect it destructively. Temperature fluctuations do not affect it either.