It is preferable to warm the room from the outside. In this case, a greater heat-saving effect is achieved, the supporting structures are protected from the effects of the external environment, and the usable area is not reduced. But this is not always possible, especially when it comes to apartment buildings. It is cheaper and more convenient to insulate the walls of the dwelling with drywall and foam from the inside.

Benefits of penoplex

For internal insulation under the GKL, foam, mineral wool or foam plastic can be used. Polyfoam does not have the best thermal conductivity, and mineral wool is hygroscopic, therefore, for this method of thermal insulation, foam is more preferable. This is facilitated by its characteristics:

- Lightweight plates.

- Ease of processing and giving the desired shape, which greatly facilitates installation. For example, if there is a window or battery on the wall, then it is not difficult to cut out a piece of foam plastic of the required size in order to bypass them.

- Good indicators of moisture and vapor barrier.

- Good sound absorbing properties.

- Strength, durability, safety.

There are few disadvantages:

- The material does not tolerate prolonged exposure to the sun. Therefore, it is necessary to follow the rules for its storage.

- During operation, it can be damaged by rodents.

- Quite expensive compared to other materials.

A few nuances that you need to know about when installing insulation under drywall

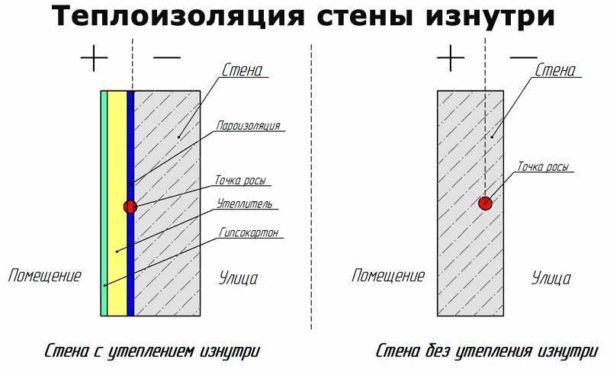

As already mentioned, wall insulation from the inside is not the best solution due to some of the disadvantages of this method. Consider 3 main nuances:

- Dew point offset. It is between the wall and the insulation, so the base can become damp from the inside.

- Reducing the size of the room. Heat insulator, frame, plasterboard occupy part of the internal space.

- Reduction of the permissible load on the floor surface. The insulation may not withstand heavy objects hung on the wall, therefore, if necessary, it is recommended to use anchors.

Necessary materials and tools

For laying insulation under drywall, you will need:

- Directly penoplex itself. For internal wall insulation, products marked "C" with a thickness of up to 30 mm are used.

- Reinforcing mesh, plaster and putty. Suitable for both leveling the base surface and for finishing drywall.

- Deep penetration primer and special for GKL.

- Glue designed for fixing foam.

- Vapor barrier.

For the frame method of mounting drywall, penofol with a foil surface is ideal. It will reflect heat into the room.

- Dowels. The insulation plates are fastened to their dish-shaped variety, and the metal profiles of the frame are fastened to the dowel-nails.

- Guide and rack profile to create a frame.

- Self-tapping screws for metal for fastening elements, direct hangers and other necessary fasteners.

- Silicone sealant.

Tools:

- Drill with a mixer and a container for preparing an adhesive solution.

- Perforator with a drill for drilling holes for dowels, on which we will attach profiles.

- Metal scissors.

- Screwdriver.

- Painting knife.

- Spatulas and graters, sandpaper.

- Roller and brush for applying primer.

- Marking tool: level, plumb line, tape measure, pencil.

Ways of laying penoplex under drywall

There are two mounting options: with and without a frame. You can correctly lay the insulation under the GKL with your own hands in both ways, the main thing is to know their advantages and disadvantages.

- The frameless method is suitable for warming small and even surfaces. Quick, easy installation of insulation and drywall.Disadvantages: inability to level the base surface, low structural strength.

- The frame method is used if the walls are curved or have a significant area. This design is more difficult to build, but it is more reliable.

Foam insulation under drywall without frame

The step by step instructions will be:

- At the first stage, the base surface is prepared: the old coating is removed, cracks and potholes are repaired, and protrusions are knocked down. The wall should be as flat as possible.

- The surface is treated with a deep penetration primer.

- According to the manufacturer's recommendations, a special composition is prepared. If not, you can use tile adhesive.

- The inner part of the insulation board is rolled with a spiked roller. Another option is to brush it with a metal brush. This will ensure good adhesion to the adhesive solution.

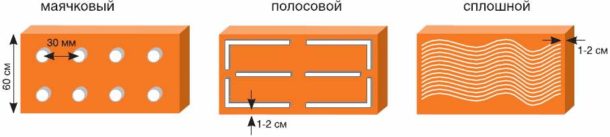

The adhesive is applied to the sheet surface with a notched trowel. It is not necessary to cover the entire slab with the composition: it is enough to coat the perimeter and center, the options are shown in the photo.

- A fragment of insulation is applied to the wall and held for a minute. Be sure to control the correct installation of the building level.

- start gluing foam from below. Rows are recommended to be shifted relative to each other so that the plates are staggered.

For reliability, the penoplex is fixed with dish-shaped dowels: 4 are placed at the edges and one in the center.

- The seams between the plates are filled with silicone sealant, wide gaps can be sealed with mounting foam.

- Drywall is attached to the insulation with glue. The scheme for applying the composition is the same as on foam boards. It is recommended to place a layer of vapor barrier between them.

- After the glue has dried, which will take 24 hours, the drywall is finished. The seams are sealed with putty and sickle mesh, rubbed, after which the entire surface is covered with a double layer of primer.

Insulation with frame

The procedure for choosing this installation method will be as follows:

- The surface of the wall is subjected to minimal processing: poorly adhering elements of the old coating are removed.

- The frame is marked: a strip is drawn on the ceiling, then with the help of a plumb line it is transferred to the floor. These are the guide lines. The location of the vertical posts is marked on the wall in increments of 60 cm.

- The guides are fastened with dowels. Mounting step - 25–30 cm.

- Mounted vertical elements. They are screwed to the guides with metal screws. The deviation is regulated by means of direct suspensions, located every 50–60 cm. The position of the racks is checked with a building level.

- Penoplex is glued to the wall in the same way as with the frameless method. Insulation plates are rolled with a roller with needles, an adhesive solution is applied. Then they are tightly inserted between the vertical posts and pressed for 40-60 seconds.

Advice. Pieces of insulation are placed in the metal profile to prevent heat transfer through the racks. Another option is to fill them with foam.

- Drywall sheets, if necessary, are cut into the desired fragments. GKL docking takes place strictly on the racks. Fixation is carried out with self-tapping screws in increments of 25–30 cm. In order not to damage the surface of the drywall during installation, a special bit is put on the screwdriver, which limits the depth of screw tightening. You can find it in hardware stores.

- Produced seaming with reinforcing tape and putty. After grouting, the entire wall is covered with two layers of a special primer on drywall. The second layer is applied after the first has dried.

Thus, it is quite possible to insulate the walls of the apartment from the inside, using foam plastic and drywall, with your own hands. If everything is done correctly and accurately, then the desired effect will certainly be achieved.You can see the process in detail in the next video. And if you have any questions along the way, ask them in the comments.