A wide variety of designs are created from drywall. When designing all kinds of boxes, it is often necessary to bend sheets at an angle of 90 °. A drywall cutter will help you perform this and other operations with high quality.

How to bend drywall at a right angle?

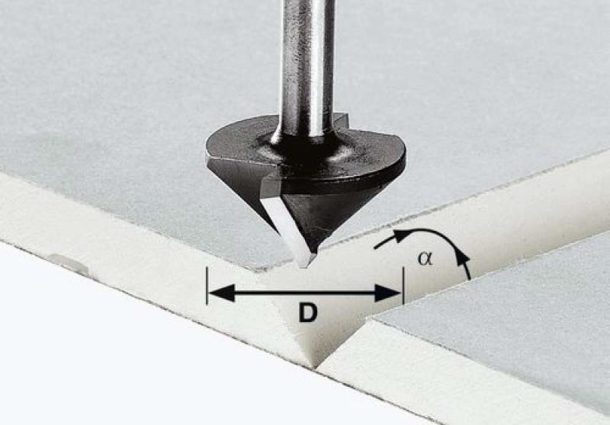

To carry out this operation, for example, in the manufacture of a box for placing the backlight, a V-shaped groove is made in the GKL. At the same time, the layer of cardboard on the back side remains intact. Therefore, for example, with sheets 12 mm thick, the maximum depth of the groove (where the top of the right angle passes) is 10 mm.

After such processing, the GKL is easy to bend at an angle of 90 ° and glue with mounting foam. Get a smooth and reliable connection.

Milling reduces drywall consumption and improves the quality of the outer or inner rib. To process such an element, much less effort will be required than with an "overlap" connection.

A series of videos on GKL milling

Tool Requirements

To form a groove, you will need a special device - a milling cutter for gypsum boards. It is not necessary to purchase an expensive professional model if the master is not constantly processing drywall and he needs it for personal needs. You can get by with a budget option, especially since the requirements for the router are not so strict:

- The power of the device is not less than 1 kW.

- The unit must be equipped with a dust extractor. Otherwise, in a matter of minutes after the start of work, the entire room will be filled with plaster dust.

A disk device is suitable for creating straight grooves and cutting GKL. The shaped milling cutter has great functionality, it can be used to make grooves of any shape, as well as holes.

Types of cutters

Milling cutters for a shaped device perform different tasks.

- A V-shaped fillet groove cutter is needed to obtain a right angle. This is the most popular type when working with GKL.

- A straight slot cutter is used to create slots and holes (point and complex shapes) at a 90 degree angle.° to the drywall plane.

- The T-grooving cutter is used like a straight cutter, but it can be used to drill large diameter pin holes.

- Grooving fillet U-shaped cutter is needed for grooves with a rounded bottom and various holes.

- Edge - to create chamfers along the edge of the sheet.

A high-quality European instrument can cost a decent amount: $45-70 per unit. Chinese-made products have a lower price, but are far from always of high quality. However, professionals claim that recently on the market you can find Chinese products of acceptable quality.

When choosing a cutter, pay attention to the diameter of its shank: it must fit your router. A cutting tool with an 8mm shank will not fit a device rated for 6mm.

Cutters can be sold individually or in sets. For beginners, masters recommend buying a kit at a budget price to start. This will allow you to learn how to handle the router, as well as use it for other types of work. And then supplement the kit by buying the necessary tools one by one.

Accessories

Drywall milling is carried out only on a flat and hard surface, excluding the slightest deflection of the sheet. Professionals prefer to use workbenches, often specially made for this purpose. But you can do without them, performing the operation on a flat floor surface or a stack of drywall sheets.

The V-shaped cutter used to select the groove we need is a curved tool.Therefore, to obtain even fold lines, one cannot do without the use of special guide rails or various templates. They are made from improvised materials: it can be plywood or a metal profile. To obtain an even cut, the router rests against a template that can be fixed to drywall with self-tapping screws.

Another option: the template has an emphasis on a special side of the workbench. But if you need to create several rectangular corners on a drywall sheet, which is not uncommon, then each fold line will require its own template.

GKL milling and fixing a right angle

The operation of forming a groove to obtain an angle of 90 degrees is quite simple:

- A sheet of drywall is placed on the work surface.

- The template is fixed. Its value is selected in such a way that the cutter is at the required distance from the edge of the sheet after the tool rests against the template.

Beginning craftsmen usually use the flat edge of the router to slide along the template. Professionals prefer to use a semicircular. This is explained simply: in this position, the tool, even if it turns a little along the axis, will still go in a straight line. If you rest the flat edge of the device against the template, any deviation will cause a curvature of the cut.

- Milling in progress. The tool is guided and guided smoothly, without jerks.

- Gypsum dust must be carefully removed from the resulting furrow.

- Mounting foam is applied to the V-shaped groove with a gun. It is not scary if a certain amount of it protrudes: the excess is easily cut off.

- A right angle is formed. Before the foam hardens, it is recommended to fix it with masking tape, and the entire drywall construction put on the butt.

Thus, using a V-shaped cutter, you can form a right angle from drywall without much effort.