Finishing plasterboard surfaces at a considerable height, such as ceilings, is quite difficult. Plasterboard sheets have a considerable weight and size, holding them even together for a long time is extremely inconvenient and tiring. Professionals have long found a solution to this problem using purchased lifting mechanisms. But what if you don't want to spend money on them? Possessing some skills, it is quite possible to make a drywall lift with your own hands.

Lift functions

The main purpose of the lift for drywall is to deliver and hold a drywall sheet at the desired height during installation. This allows not only to greatly facilitate the work, but also makes it possible to install drywall alone.

Naturally, craftsmen quickly adapted the lift to perform other related tasks:

- By attaching a laser level to the drywall lift, you can better mark up and avoid mistakes. The level is fixed with clamps, and then rises to the required height. Such a device provides an ideal marking of the ceiling and corners of the room.

- It is indispensable for assembling a frame for drywall profiles in hard-to-reach places. The device allows you to fix the profiles at the time of their fastening.

- The lift will greatly facilitate the installation of not only drywall, but also any massive suspended equipment: air conditioners, chandeliers or air ducts.

Varieties

According to the area of \u200b\u200buse, GCR lifts can be:

- wall;

- ceiling;

- universal.

They differ in the location of the plane of the table on which the drywall is attached.

The most practical is a universal lift, the working surface of which can change the level of inclination.

The industry offers many types of these devices, but they are not cheap. Usually they are purchased by construction teams specializing in the installation of drywall structures. But they often prefer to make lifts on their own.

Ready-made manual drywall sheet lifters

If there is no opportunity or desire to make the device yourself, then you can buy it. In terms of price-quality ratio, craftsmen prefer the Premos brand gypsum board lifter.

According to the device, it does not differ much from a conventional rack and pinion car jack, but it is this simplicity that ensures the reliability of its mechanisms. Together with a fairly affordable price, this allowed him to occupy a fairly solid niche in the lift market.

The Premos device allows lifting and fixing various building elements weighing up to 100 kg. The telescopic pole provides a lifting height of up to 3.3 m, while the retractable pole allows you to increase it to 4.5 m.

When working at a height of more than 3 m, the lifting operation is carried out as follows:

- By turning the handle, the telescopic rod is slightly extended.

- Then, with a rail, they rest against the sliding support, pushing it to the required height. For convenience, near the holes for fixing the retractable support, the final height of the table is indicated.

- Fixation is carried out with any hardware inserted into the hole, but many prefer to use a steel pin on the chain.

Do-it-yourself lift

Finished products do not always suit craftsmen, and extra costs do not add to their popularity. The device for fastening drywall "Premos" will cost about 15 thousand rubles.Therefore, many people prefer to make a drywall lift with their own hands, and they take drawings from various Internet resources or design the device themselves.

What should be remembered when making a lift yourself?

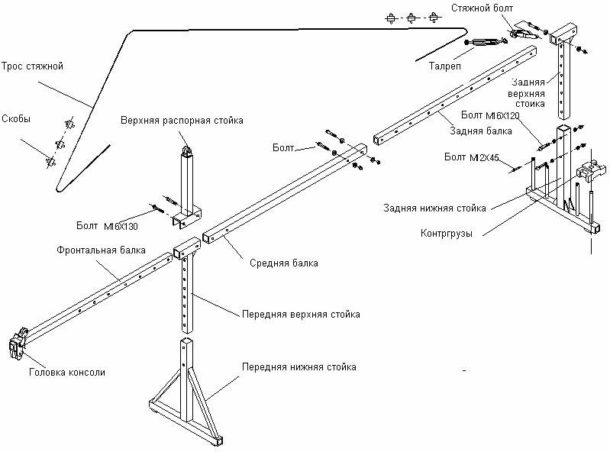

There are four constituent elements, the presence of which in the design is mandatory:

- A chassis or tripod that forms the base. Better on wheels equipped with a locking mechanism. This will make it easier to install the device in the desired location.

- Telescopic stand. It can be made from pipes or squares of various sections, nested into each other according to the principle of a nesting doll. The extension in this case is carried out due to the system of rollers and a special cable.

- Spacer table on which drywall or other lifted elements will be fixed.

It is better if the table has a rotation function: this will not only facilitate the loading of drywall, but also make the device universal.

- A winch, due to which the extension of the telescopic rack of the device will be carried out. May be manual or electric.

The most advanced masters even supply the lift with remote controls.

Important nuances

Some points to consider:

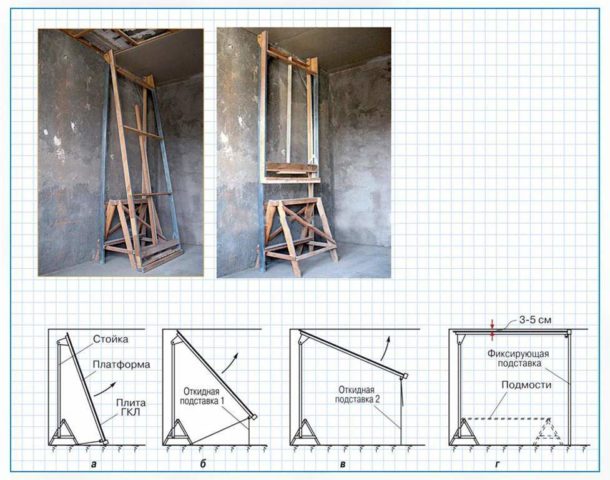

- Regardless of the material, whether it is metal or wood, racks and other parts that are under severe stress must be provided with “kerchiefs” or other elements that give rigidity and strength.

- The folding design of the lift is preferable: it is easier to transport it, and it will take up much less space during storage.

- In addition to the locking device available on the winch or rack and pinion, it is imperative to provide an additional device that securely fixes the work table in the raised position. Otherwise, there is a risk of the device collapsing under load, which could result in serious injury. What you definitely shouldn’t save on is your own safety.