I want to level the partitions in the apartment with drywall, but it's a pity to lose precious centimeters, which are already lacking? Install drywall on unframed walls. This method is even simpler - you do not have to bother with mounting the profile. It saves space and creates equally perfect surfaces. Even without rich experience in repair, this task can be handled on your own.

Benefits of leveling plasterboard walls without a frame

This method of mounting the GKL sheet:

- Economical on materials.

- Takes less time.

- Produces less debris and dirt.

- Installation and decoration is completely done by hand, so you can feel like a pro.

Via GKL (plasterboard sheet) you can level any wall: brick, concrete, wood.

For mounting GKL sheets on the wall, it is necessary to purchase special adhesives. The most popular of them are the Knauf and Volma mixtures. You can also mix gypsum putty with a small amount of PVA glue.

The essence of the frameless method of fastening the GKL sheet

Installation of drywall on walls without a frame is carried out using a special composition. They glue the sheet to the base surface. The joints are puttied and reinforced with tape. After priming, the wall is ready for finishing - wallpaper, decorative plates are glued on it, or painting is done at your discretion.

Since the sheets themselves have a small thickness, the total area of the room hardly suffers. They are convenient to use when leveling the walls of small rooms: a bathroom, a pantry, a loggia, and in other places where every centimeter of space is important.

Preparation of walls for gluing drywall sheets

Before you start installing drywall without a frame, you must clean the wall from the old finish.

- Wallpaper is easier to remove with a spatula, after wetting them with water using a sponge or spray gun. An excellent soaking effect is obtained by using a steam generator.

It is difficult to remove paint from a concrete wall, but it is necessary, otherwise the composition for gluing the GKL will either not stick to it or tear it off the base. As a result, the sheet will not hold.

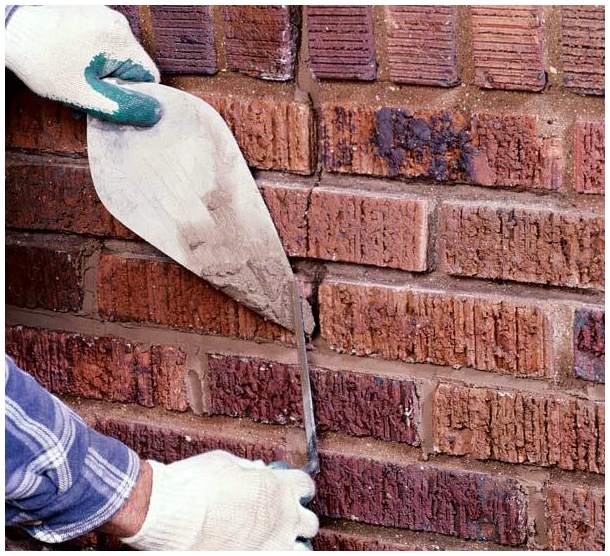

- Old plaster is tapped to detect hidden delaminations. Remove damaged and suspicious parts to a solid base.

If the layer of plaster is thick all over the wall, it makes sense to remove it entirely with a perforator or hammer with a chisel. This will help to further save centimeters of usable space.

Additional wall treatment

Proper wall treatment before attaching drywall sheets to a wall without a frame is extremely important.

- Inspect the wall itself - repair cracks, fill holes from old communications, throw mortar at the places where large pieces of plaster fell out.

- If necessary, punch recesses for sockets, switches and wiring. Wires and junction boxes must be installed.

The insulation of the latest generation of wires allows you not to pack them in a fireproof corrugation, so you just need to attach them to the wall with clamps.

- Remove debris, brush or vacuum dust from the walls and floor.

- In order for the adhesive to adhere firmly to the surface of the wall, it is evenly primed. In areas with fresh plaster, the primer is absorbed more strongly, so here it is applied in two or even three layers.

When mounted under sheets of gypsum plasterboard, a poorly ventilated air gap remains. In rooms with high humidity, optimal conditions are created there for the development of various kinds of rot and fungus. Treating the base wall with an antiseptic will help to avoid this danger.

- Since the GKL sheet has large (2500 x 1200 mm) dimensions, free up a suitable flat area on the floor to work with it.

It is possible to mount the GKL only when the wall is completely dry, after all the procedures performed.

Technology of frameless installation of drywall sheets

Before gluing drywall to the wall, you need to set the overall level. With the help of the assembly rule and the plumb line, the vertical deviations of the surface are measured. On the floor and ceiling, a line of alignment of the wall in length is marked.

The GKL sheet is cut immediately to the entire wall. To reduce the amount of work, it is better to buy sheets according to the height of the room or more. Then you do not have to adjust and putty horizontal joints.

GKL can be attached to the walls in two ways.

Attaching the sheet to the adhesive

The fastening technology will differ slightly depending on the degree of curvature of the walls.

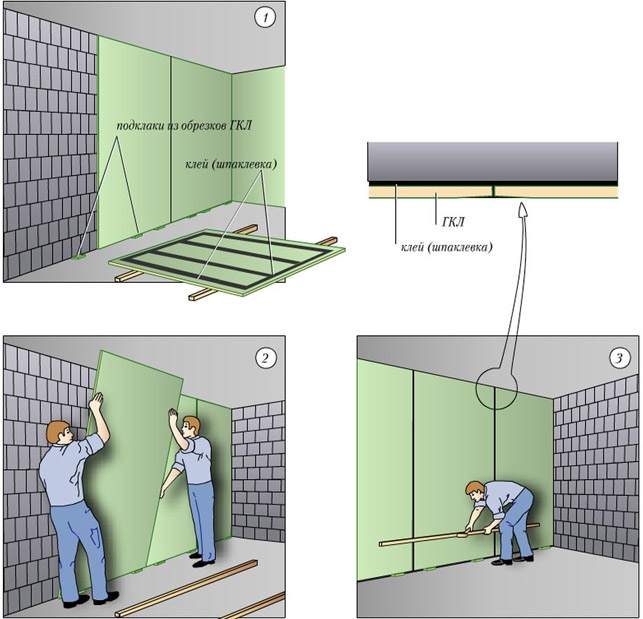

If the differences on the wall are less than 4 mm, then the adhesive composition is evenly applied to the perimeter of the GKL sheet using a notched trowel. The sheet is installed in the chosen place, pressed and leveled, applying the rule to the surface and tapping it with a rubber mallet, not forgetting to check it with a building level.

Important! The adhesive solution sets quickly. Experimentally find out how much volume you need to dilute in order to have time to work it out in one go.

A wall with a level difference of up to 2 cm will require a thicker adhesive. It is applied to the surface of the drywall sheet with cakes about 5 cm high at a distance of 30 cm from each other. Installation is carried out in the same way as described above.

If the wall has differences of 4 cm or more, additional work is to be done. In the recesses, it is necessary to stick additional beacons from GKL scraps. There is another method: fill the right place with mounting foam, and after it dries, cut it off at a general level.

In the future, the adhesive composition is applied to the dried beacons and directly to the wall. The sheet is pressed against the adhesive and aligned in all directions.

Fastening the sheet to the wall on mounting foam

Sheathing walls in this way is more laborious, but it will provide greater reliability of fastening, regardless of the curvature of the surface.

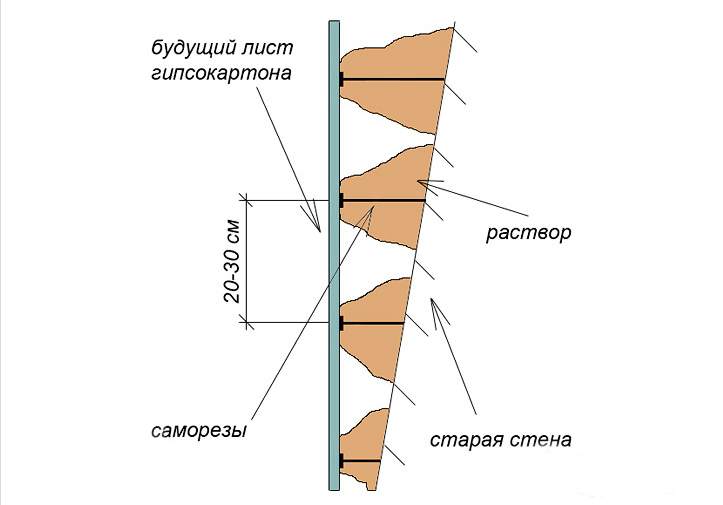

- GKL sheet is pressed against the wall. At its corners, and in 4-6 more places, holes are drilled in the wall, making marks. The sheet is pushed aside, and the resulting marks are drilled and dowels are driven into them.

- On the sheet, stepping back from the holes by 10–15 centimeters, pieces of a shock absorber (foamed rubber, foam rubber) are glued. This distance is necessary for the free expansion of the foam. The thickness of the sponge depends on the differences on the wall. Ideally, they should be the same.

- The sheet is attached to the wall. Screws with wide caps or a washer are screwed into the dowels. They also regulate the level, creating a flat surface. Similarly, the installation of the remaining sheets is carried out.

- After control by the rule, a hole is drilled near each self-tapping screw. The tube for pumping mounting foam should enter it without effort. Foam is pumped through the hole into the cavity. It should form a cushion between the wall and the sheet. The amount of foam is determined empirically in advance. After the foam hardens, the screws are removed.

Regardless of how the GKL was attached, holes and joints are rubbed with putty. After drying, sandpaper smooths out all the roughness, bringing the wall into perfect condition.

Do not rush to start decorating the wall with decorative materials. The adhesive base sets quickly, but it will take at least a day to dry completely.

A few words about safety

Working with GKL generates a lot of dust. Inhaling it will not add health to anyone, so it is better to protect yourself with a respirator.You should also take care that dust does not penetrate into the living quarters by curtaining the openings with a damp cloth.

As you can see, sticking drywall to the wall with your own hands is not such a difficult task. To do this, it is not necessary to invite the master of the corresponding profile. It is enough to have patience, a little bit of experience, and you will succeed.