Bark beetle is a species decorative plaster, which got its interesting name due to the textured surface pattern, reminiscent of the furrows left in the wood by the wood-boring beetle. Despite the fact that the bark beetle is more often used for exterior decoration of buildings, it can increasingly be found in the interior of apartments. Depending on the application technology, the walls covered with this textured material can look completely different. We will learn how to apply bark beetle decorative plaster and give it a beautiful and unique texture.

Types of bark beetle

The unusual furrowed relief of the bark beetle is obtained due to the presence of a filler in the mixture in the form of fine marble chips or gravel with a granule size of 1 to 3 mm.

Depending on the binder component, the plaster can be mineral, acrylic, silicate, silicone or hybrid. The mineral mixture is sold in dry form and requires self-preparation, polymer types of plaster are a liquid ready-made mixture packaged in buckets.

Polymer plasters are durable and resistant to dirt and mechanical damage, have lower consumption and can be tinted, however, are several times more expensive than the mineral mixture.

Approximate consumption of material

Consumption of bark beetle plaster averages from 2.4 to 4 kg per 1 m. sq. and depends on several indicators:

- base material;

- filler grain size;

- thickness of the finishing layer;

- application technology.

Consider the difference in plaster consumption per 1m2 using the example of different types of products of the popular Ceresit brand.

Polymer cement or mineral plasters

- Ceresit ST-35 (grain size - 2 mm) - up to 2.8 kg per 1 m2;

- ST-35 (grain size - 2.5 mm) - up to 3.5 kg per 1 m2;

- ST-35 (grain size - 3.5 mm) - up to 4.9 kg per 1 m2;

- Ceresit CT-36 (grain size - 2 mm) - from 2 to 5 kg per 1 m2, depending on the method of application.

Acrylic

- ST-63 (grain 3 mm) - up to 4.5 kg per 1 m. sq.;

- ST-64 (grain 2 mm) - from 2.7 to 3 kg per 1 m. sq.

silicate

- ST-73 and ST-75 (2 mm) - up to 3 kg per 1 m. sq.;

- ST-73 and ST-75 (3 mm) - up to 4.5 kg per 1m. sq.

Silicone

- CT-75 (2mm) - up to 3 kg per 1m. sq.;

- CT-75 (3mm) - 4.5 kg per 1m. sq.

Silicate-silicone

- ST-175 (2 mm) - up to 3 kg per 1 m. sq.

It is difficult to determine the exact amount of the mixture that will be spent on finishing; when buying, you can rely on the data indicated by the manufacturer, adding 5-10% to this value. On practice plaster consumption per 1m2 may differ from the figure declared by the manufacturer, since the packaging indicates the recommended consumption for a leveled surface. Any irregularities on the walls entail an increase in material consumption. In addition, it is quite difficult to make a uniform layer over the entire surface of the walls without many years of experience.

Material consumption is also dependent on the preliminary preparation of surfaces. In order to be able to get by with less plaster, before applying it, in addition to a special primer with quartz sand, which increases adhesion, you must additionally use a deep penetration acrylic primer.

Preparatory work

The best basis for decorative plaster is walls leveled with ordinary lighthouse plasters. Make sure that there are no sinks and depressions on the surface, and also check the walls with the rule - if you find more than 2 depressions per 2 meters, the surface will have to be plastered with a leveling mixture. If the walls are even, before applying the plaster, do the following:

- Remains of old finishes, dirt and dust are removed from the walls.

- If there are cracks, they must be expanded and sealed with cement mortar.

- Nails, screws and dowels are removed, holes are also sealed with cement.

- Surface primed two types of compositions: the first layer is made with a deep penetration primer, which strengthens the surface and reduces the absorbency of the base material. The second coat requires a primer with quartz sand.

Tip: we recommend using primer and decorative plaster from the same manufacturer.If you chose bark beetle plaster from Ceresit, then for two layers of primer, CT-17 and CT-16 compositions are suitable for you.

Tools and materials

Do-it-yourself decorative bark beetle plastering is done with a minimum set of tools. You will need:

- stainless steel spatulas 10 and 30 cm wide;

- plastic grater or trowel;

- dry mix or ready-made bark beetle composition;

- construction mixer or drill with a nozzle;

- container with warm water;

- clean cloth.

Applying plaster to the wall

The technology for applying the plaster mixture is simple: the mass is applied to the wall, starting from the bottom corner of the wall, and distributed over the surface with movements from the bottom up. The application of decorative bark beetle plaster is carried out large spatula or a trowel, the excess is removed with a small spatula.

The spatula must be placed at an angle of 60 degrees to the surface. The most important thing at this stage is to achieve a layer of the desired thickness, which will correspond to the size of the filler granules, too thick a layer will not allow the bark beetle texture to appear. If grooves or scratches begin to appear on the surface after the leveling motion, the required thickness has been reached.

Creating an invoice

The most responsible and creative stage in the work is the creation of a textured surface, which manifests itself due to the movement of marble chips during grinding. You can start rubbing after the layer of plaster dries a little. The texture creation technology is as follows: a plastic float or trowel is applied to the wall and pressed lightly. The movements of the grater should be uniform and repetitive, their nature depends on what kind of pattern you want to get.

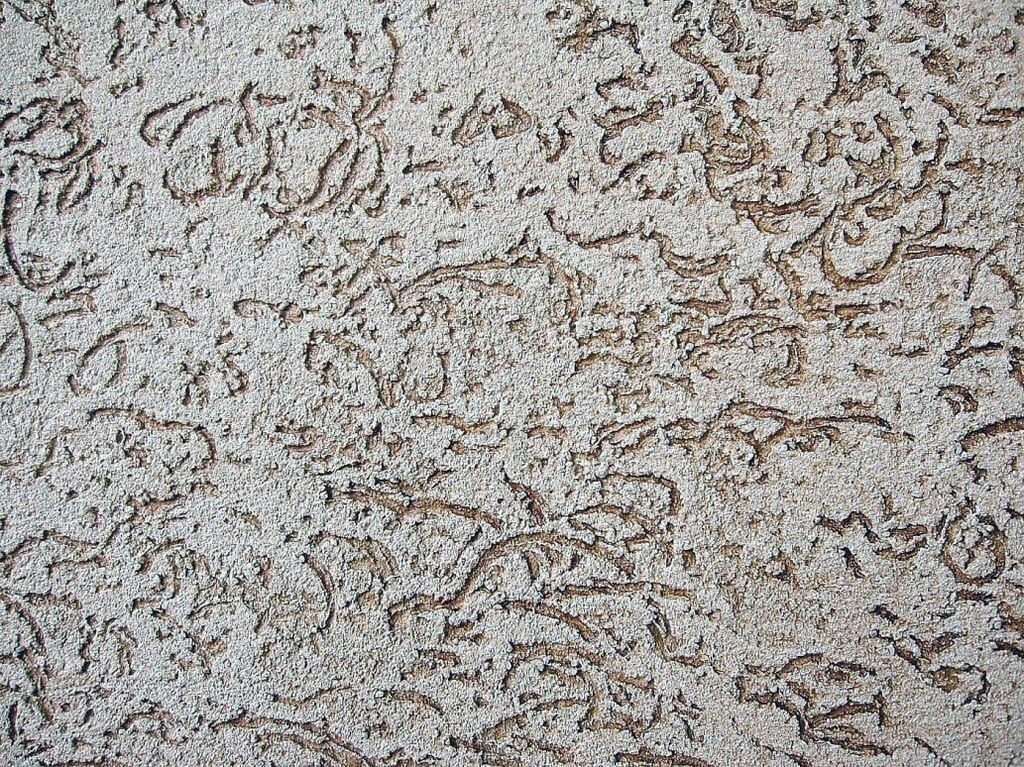

- The classic pattern of bug-eaten wood can be obtained by uneven circular and arcuate movements of the grater in different directions.

- The "Rain" pattern is obtained by rubbing the plaster with long continuous movements from top to bottom vertically or diagonally.

- "Travertine" - an imitation of the surface of a stone - is done with short jerky movements in different directions.

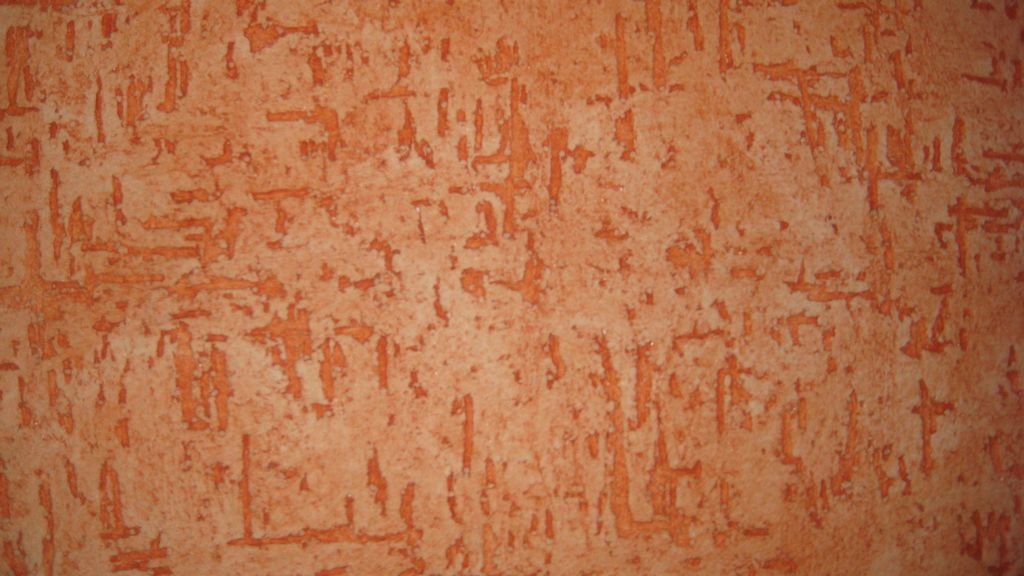

- The "Lamb" pattern can be made in circular motions of small amplitude.

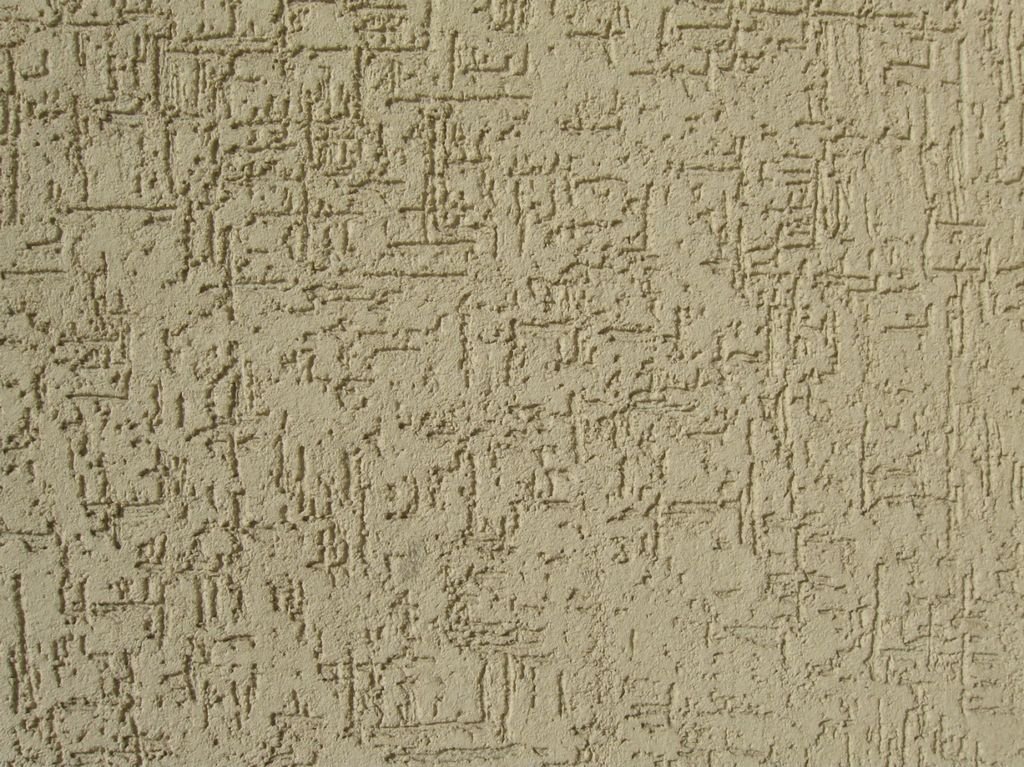

- The woven pattern is created by alternating movements from bottom to top and from left to right. Vertical strokes are made long, horizontal movements are performed with quick short strokes.

After the plaster dries, the wall can be further processed with sandpaper, paying special attention to the joints.

Painting plaster

The finished liquid mixture can be tinted before application, however, most experts agree that it is better to paint the walls after plastering is completed. You can start painting a day after applying the bark beetle.

Tip: to get a darker shade of grooves, you can paint the wall in a dark color, and after the layer has dried with a semi-dry roller, apply a paint of a lighter shade.

Additional protection can be provided by applying varnish. Glossy varnish will create a glow effect, matte - will preserve the impression of a tree eaten by bark beetle.