Many people, having started to make repairs, immediately face the problem of uneven walls. This is especially true for those who live in old buildings. The most budget option for leveling the surface is plastering. If you decide to do it yourself, you should find out what tools for plastering walls you may need.

Long gone are the days when a plasterer could get by with a trowel, a bucket and a trowel. New building materials and technologies appear, and with them new tools. A modern master must have at hand an arsenal of various devices that will help to achieve an absolutely even surface of the wall.

The surface, with cement-sand mortar applied to it, becomes stronger by 25-30%. Thanks to plastering, you can hide various defects and prepare it for wallpapering or painting. Finishing work is carried out in 2 stages. First, the surface is prepared for applying the solution, and then performed directly wall plastering.

Necessary tool for preparatory work

The quality of work depends entirely on the availability of all the necessary tools. In the process of preparatory work, you will need:

- Hatchet or plaster hammer with pick. It is used to beat protruding parts from the working surface. Also, with a hammer with a pick, notches are made on it to increase the area of adhesion of the solution to the surface.

- Maklovitsa. Usual brush, only large size. She is comfortable primer deep penetration. The primer strengthens the top layer of the surface and increases adhesion.

- Plumb. They hang walls with them and find out how evenly the surface is plastered. With the help of a plumb line, the threads are pulled horizontally, vertically and diagonally. This allows you to determine the exact location of the beacons in the same plane.

- Rack level. With it, you can set beacons in a horizontal plane, for example, on the top of a slope or on a ceiling.

- Laser level. This device was invented for more "advanced" plasterers who value their time. It is easy to operate, significantly speeds up and improves the process of marking and installing beacons.

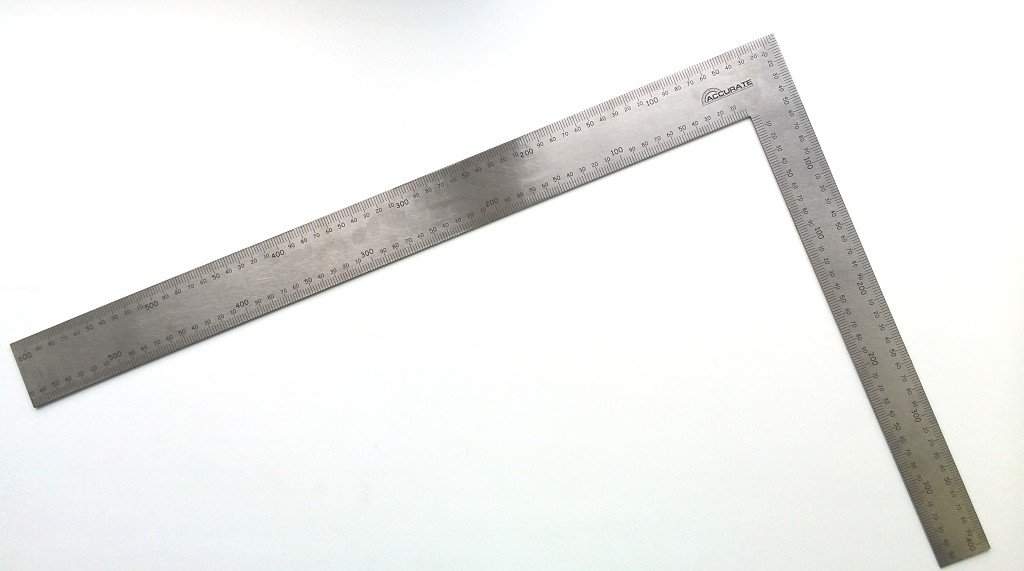

- Square. With this device, you can set slope and corner beacons. May be wood or metal.

- Nylon thread. It is necessary for the correct installation of beacons.

Wall plastering tools

And what may be needed to perform direct finishing work? Let's make a list of tools.

- Ladle, up to 1 liter. It is very convenient to use in the process of throwing a solution of different consistency on the work surface. They can measure the required volume of plaster mixtures for the preparation of the solution. A bucket can also throw a solution between the beacons.

- Bucket. It should be a volume of 10-20 liters.

- Plaster spatula. She throws the solution in those places where its quantity is not enough.

- Plaster trowel (falcon). May be metal or wood. It has dimensions of 400×400 mm, with a handle that is perpendicular to the base. The trowel serves to bring a small amount of mortar when correcting inaccuracies in plastering. Most often it is used in tandem with a spatula. This trowel is best chosen according to the individual preferences of the master. So that the hands do not get tired during the work processes, the weight of the trowel must be acceptable. The trowel may be different for each type of plaster.

- spatula. Not everyone is comfortable using a spatula and trowel. Therefore, in your arsenal, just in case, you should have 2 spatulas: one large and the other smaller.Kraftool is a leading manufacturer of spatulas.

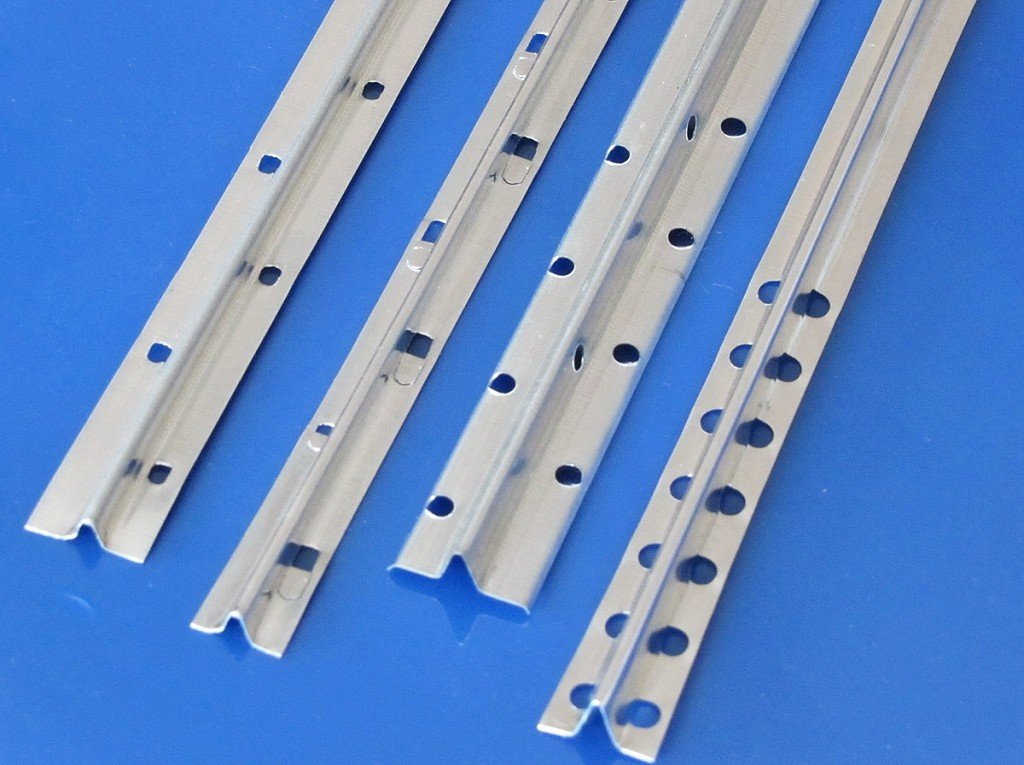

- Lighthouses. Act as guides to create a perfectly flat plane. They are made of galvanized steel. After plastering, the beacons should be removed from the plaster after it has set.

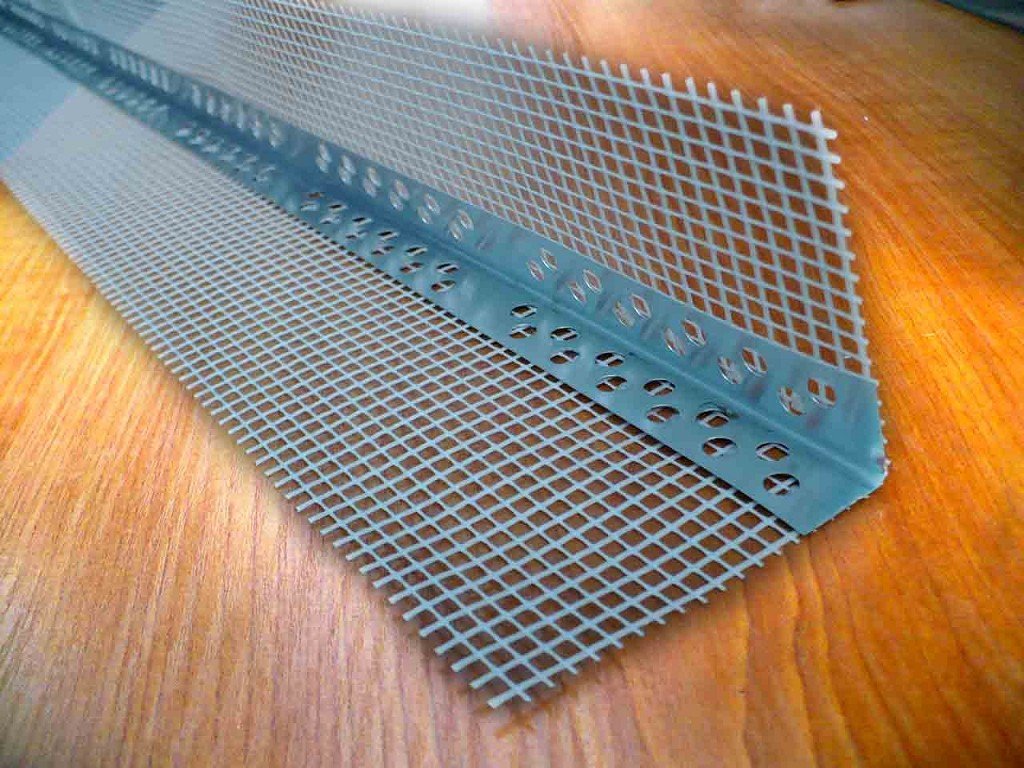

- Stucco corners. Will be needed for forming external corners.

- Rule. It is a wooden or aluminum rail. Serves for alignment on beacons of the thrown solution. It is used for lining the inner corner. The length of the rule can be different: from 0.5 m to 3 m. Working with the tool is quite simple. It is enough, after applying the bulk of the solution to the surface, to install it on adjacent beacons with both ends and stretch it from bottom to top. In this case, the excess solution will remain on the surface of the rule. So you will immediately see all the problem areas where it needs to be added more.

- Poluterok. It looks like a polished long rail, the length of which is 400-800 mm, the width is not more than 150 mm, with a handle. Using this rail, the plasterer will be able to finish the surface leveling. It can be performed only when the solution has already been dehydrated, but has not completely solidified. By making circular rotations with the fixture, you can achieve a perfectly flat surface.

- Steel ironer. This tool performs "iron" to seal the surface layer of the plaster. It is a polished metal plate with a handle. The trowel is installed at an angle on the surface of the plaster and is carried out with effort on it. It turns out that under such action the surface layer is compacted and after drying it is not destroyed.

- Cotton gloves. Hands must be protected from contact with the solution, so it is recommended to have 2-3 pairs of gloves.

- Construction mixer. Needed for mixing small volumes of mortar mechanically.

- Plastering machine. May be needed if large-scale construction work is coming. It is enough to connect the supply of running water to the apparatus and pour the dry mixture into it. The machine mixes the solution and delivers it through the hose. It is better to work with three: one person pours the mixture, the other applies the finished solution from the hose to the surface between the beacons, and the third level it with a rule.

Mixtures for plastering

Special attention should be paid to plaster mixtures. In the modern construction market, you can find a wide variety of mixtures for performing different types of plastering work. They can be gypsum, cement, heat-insulating, decorative and protective.

The most famous is Knauf's Rotband plaster mix. It can be safely called the standard among all existing mixtures. The composition is excellent for leveling all surfaces. Can be used in bathrooms as well as on concrete.

For plastering by machine excellent plaster mixture "MP-75" from "Knauf". It is intended for indoor use only. Has good indicators of wear resistance and durability.

Decorative mixtures are used for finishing surfaces outside and inside the building. They improve the aesthetic and decorative qualities of the surface. There are textural, structural and Venetian. Walls plastered with such plaster do not require special care. The plaster has excellent water-repellent properties, so if necessary it can be washed with a detergent. It is best to use a soft cloth or sponge for cleaning. Metal scrapers and hard brushes should be avoided.