Use of the safety valve

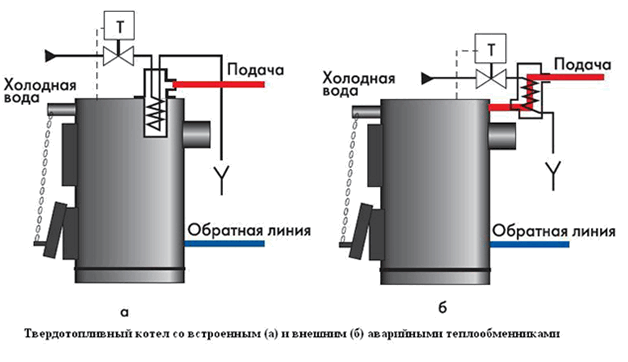

This is not the same as a safety valve. The latter simply relieves pressure in the system, but does not cool it. Another thing is the boiler overheating protection valve, which takes hot water from the system, and instead supplies cold water from the water supply. The device is non-volatile, connected to the supply and return lines, water supply and sewerage.

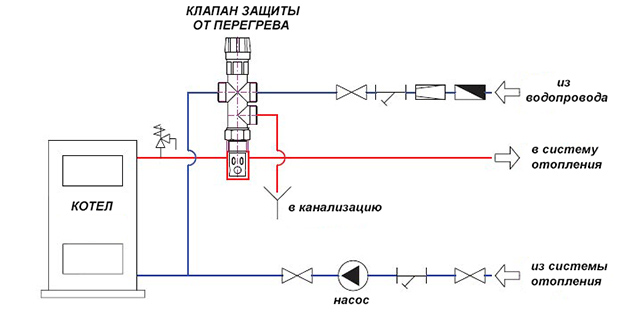

At a coolant temperature above 105 ºС, the valve opens and, due to the pressure in the water supply system of 2-5 bar, hot water is forced out of the heat generator jacket and cold pipelines, after which it goes into the sewer. How the solid fuel boiler protection valve is connected is shown in the diagram:

The disadvantage of this method of protection is that it is unsuitable for systems filled with antifreeze liquid. In addition, the scheme is not applicable in conditions where there is no centralized water supply, because along with a power outage, the water supply from a well or pool will also stop.

What is the danger of condensate for the boiler

When kindling a solid fuel boiler, one has to deal with the fact that the cold coolant washes the walls of the already heated combustion chamber, cools them, which leads to the condensation of water vapor, which is invariably present in the flue gases. Water particles, interacting with flue gases, form acids, which leads to the destruction of the inner surface of the combustion chamber and chimney.

But the negative effect of condensate is not limited to this: particles of soot that settle on the walls dissolve in drops of water. Under the influence of high temperatures, this mixture is sintered, forming a dense and durable crust on the inner surface of the combustion chamber, the presence of which sharply reduces the intensity of heat exchange between the flue gases and the coolant. The efficiency of the boiler drops.

It is not easy to remove the crust, especially if the combustion chamber of the boiler has a complex heat exchange surface.

It is impossible to completely eliminate the formation of condensate in a solid fuel boiler, but the duration of this process can be significantly reduced.

Design

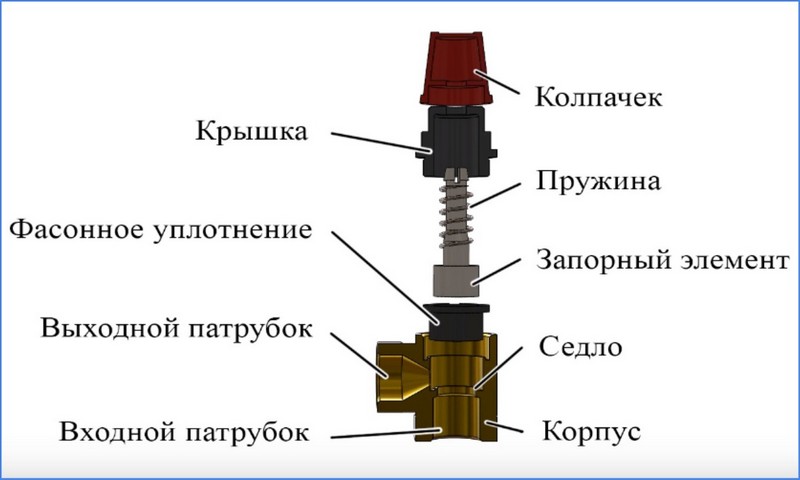

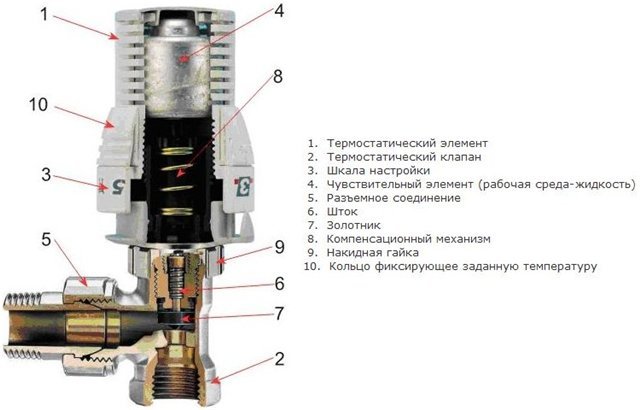

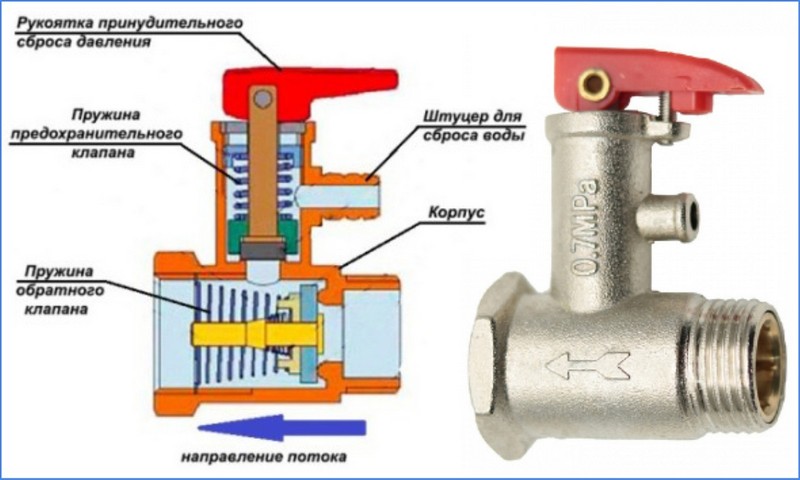

A typical boiler safety valve has a collapsible design and consists of the following main elements:

Frame. Usually made of brass and looks like a tee. On its sides there is a lower inlet threaded hole, a side outlet branch pipe and an upper saddle, on which a shaped seal sits.

Locking group. It is a spring-loaded pulley with a cylindrical (disk) end locking element, on which an elastic rubber seal is put on in the form of a cup (disk).

Lid. A black cap made of heat-resistant polymer is screwed into the upper threaded branch pipe of the brass body, holding the spring-loaded rod in the working position. On the upper faces of the cover there are protrusions along which the upper cap, shaped in the lower part, connected to the locking rod, slides. When rotated through a certain angle, the cap rises along with the stem and opens the side branch pipe - this allows you to use the safety valve for heating always open in manual mode.

Cap. The polymer part, usually red, with a ribbed side surface, is screwed to the hollow stem inside with a screw. The gentle protrusions in the lower part of the cap, when it rotates, fall on the teeth of the cap - the handle rises along with the spring-loaded shutter and opens the side channel, allowing you to relieve pressure manually.

Adjusting washer.The inner wall of the cover has a thread in which the adjustment nut rotates; when lowered, it compresses the spring - thus increasing the valve response threshold. When the nut is turned upwards, the spring is weakened and the set pressure is reduced. For turning, the nut is equipped with a transverse slot in the upper part for a flat screwdriver.

Principle of operation and types of valve actuators

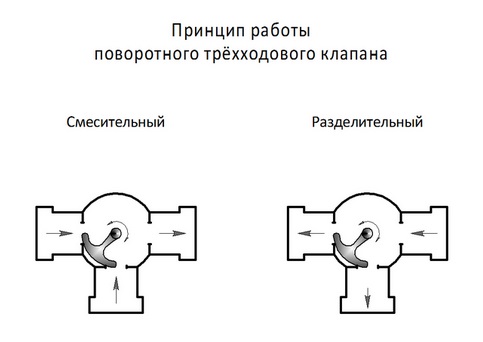

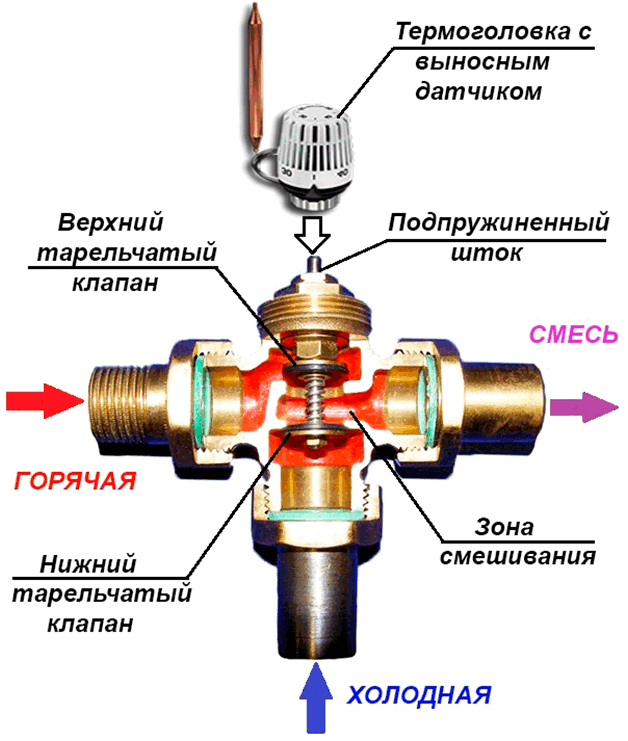

The product is produced in different configurations and with different actuators, but the principle of operation of a three-way valve remains the same: to mix two streams with different temperatures into one, the temperature of which is set by the user or required according to the scheme. The liquid inside the valve flows from one pipe to another until its temperature changes and reaches the set value. Then the drive gradually opens the flow from the third nozzle, keeping the temperature of the leaving water within the set value. On this basis, such a valve is called a three-way valve.

The principle of operation of the three-way valve

Any three-way mixing valve has two inlets and one outlet. The distribution of flows is carried out using a drive, which can be of several types:

- The thermostatic actuator (thermostat) is one of the most popular, it works due to the thermal expansion of the sensing element, as a result of which the valve stem is pressed and the liquid begins to mix.

- The most common type of actuator that is installed in a three-way diverter valve is electric, actuated by a signal from the control unit.

- The valve can be controlled by pressing the rod with the actuator of the thermostatic head. It reacts to the air temperature, which it determines itself or with the help of a remote sensor and a capillary tube. The drive is most often used in underfloor heating systems.

Stationary solid fuel boilers cannot be directly connected to the heating system. One of the reasons is that cold water should not be allowed to enter the boiler jacket until it has warmed up. Otherwise, condensate is released on the walls of the furnace, which, mixing with the ash, forms a strong layer of soot. It prevents free heat exchange, reducing the efficiency of the installation, and it is very difficult to clean off carbon deposits. The second reason is that it is necessary to protect cast-iron furnaces from temperature changes during an unexpected stop of the pump due to a power outage, and then start it. The task is to prevent cold water from entering the hot boiler, which is why a three-way valve is needed. It will make the coolant circulate in a small circle until it heats up, and only then will it begin to mix cold water.

How to choose

Before proceeding with the direct purchase of the valve, you should find out a lot of points regarding the boiler used and the features of the heating system, this will increase the efficiency of the system, otherwise it may lead to a deterioration in regular performance.

The main thing in this matter is to determine the operating parameters of the coolant (this is easy to find out using the available documentation). In addition, it is necessary to take into account the heating consumption and the piping scheme itself.

You can determine the flow rate and temperature of the coolant using project documentation. If there is none, you can use the recommendations that are indicated in the passport of the boiler itself, which is used in the system.

All these parameters are needed in order to choose the right valve (you have to choose purely by capacity).

The drive control system is selected according to the type of heating system and the piping of the boiler itself. The simplest models and options involve the use of a conventional thermostatic valve (although there are exceptions).And, as already mentioned, to ensure the quality of floor heating, you should use a product with a thermostatic head.

If you plan to work with a complex piping system, then manufacturers recommend using a valve with an external control controller.

Be that as it may, any modern heating system must use a three-way valve, which is an important node in the entire system and there is simply nothing to replace it with - an alternative has not been invented.

An exception is the previously used elevator systems, which have not been used for a long time and are considered obsolete (due to their low efficiency and convenience).

Be sure to take into account that there is not only a mixing valve, but also a separating one. The first option considered above implies the possibility of mixing two streams into one, and the second option - a dividing valve, offers the possibility of dividing one stream into two, while adjusting the flow to each of the outlets.

Both of these types of valves can be used in the system. However, mixing is necessary in any case, and separating is rarely used in simple heating systems.

The right choice of valve can be called if the user chooses a purchase not only for throughput, but also for temperature. If the first selection criterion is the main one - without taking it into account, one cannot count on the functionality of the system as a whole, then the second criterion implies the duration of the valve operation - if it is not designed to operate in a system where the temperature is higher than that allowed by the valve itself - the part will wear out faster and will need to be replaced, or will not function at all.

An autonomous heating system is a much more complex mechanism, consisting of a large number of interconnected units and assemblies that perform the corresponding functions. The three-way valve for the boiler in this mechanism plays the role of a mixer in which the temperature of the coolant is adjusted.

This is done so that the pipes are evenly heated and the level of heating in each room is approximately the same. If you do not use the part, it will turn out that the water, when passing through the heat exchanger, will not heat up equally, and as a result, some rooms will receive less heat energy than all other rooms.

Reasons for overheating of a solid fuel boiler

Even at the stage of selection and purchase, it is important to consider the performance characteristics of the heater. Many models that are on sale today have a built-in overheating protection system.

Whether it works or not is another question. However, it is necessary to adhere to certain knowledge and skills, hoping to create an effective and safe autonomous heating system at home.

The reliable operation of the heating unit depends on the operating conditions. With obvious violations of the technological parameters of heating equipment and the abuse of standard safety rules, there is a high probability of an emergency.

It is possible to prevent possible negative consequences even at the stage of installation of a solid fuel boiler. Proper piping of the heater will be the key to your safety and reliable operation of the unit in the future.

Speaking in detail, in each case, the protection system of a solid fuel boiler has its own specifics and features. Each heating system has its pros and cons. For example:

When it comes to solid fuel boilers with natural circulation of the coolant, it is necessary to take care of the safety and performance of the heating equipment even during installation. The pipes in the system are metal.Moreover, the diameter of such pipes must exceed the diameter of the pipes used for laying the circuit with forced circulation of the coolant. Sensors installed on the water circuit will signal a possible overheating of the coolant. The safety valve and expansion tank play the role of a compensator, reducing excess pressure in the system.

A significant disadvantage of the gravitational heating system is the lack of an effective mechanism for adjusting the operating modes of solid fuel boilers.

Great technological opportunities for consumers are provided by those working with forced circulation of the coolant in the system. Already only the presence of the second circuit significantly increases the ability to regulate the heating temperature of the boiler water. The only negative in the operation of such a system is a working pump, which can make it difficult to operate the heating system with its work.

This is due to the fact that when the electricity is turned off, the pump ceases to perform its functions. Stopping the circulation process and the inertia of solid fuel heating boilers can lead to overheating of the heating unit. If the boiler equipment is not equipped, the situation with a power outage is fraught with extremely unpleasant consequences.

Effective protection against overheating of a working solid fuel boiler should be based on the mechanism for removing excess heat generated by the heating device.

What are the ways to protect heating equipment from overheating

Manufacturing companies are trying, in order to increase the consumer attractiveness of their products, to include any guarantees of its safety in the technical passport of boiler equipment. The uninitiated consumer has no idea about the means of protecting the heating boiler from boiling.

There are currently the following ways to ensure the protection of solid fuel units used for autonomous heating systems. The effectiveness of each method is explained by the operating conditions of boiler equipment, and the design features of the units.

In most cases, in the data sheet for the heater, manufacturers recommend using tap water for cooling. In some cases, solid fuel heating boilers are equipped with built-in additional heat exchangers. There are models of boilers with remote heat exchangers. A safety valve is used to prevent overheating. The safety valve is designed only to relieve excessive pressure in the system, while the safety valve opens the access of tap water when the boiler overheats.

Exceeding the coolant temperature of 100 0C creates an overpressure that opens the valve. Under the action of tap water, which is supplied under a pressure of 2-5 bar, hot water is forced out of the circuit by cold water.

The first aspect that causes controversy about tap water cooling is the lack of electricity to run the pump. The expansion tank does not have enough water to cool the boiler.

The second aspect that this method of cooling dismisses is associated with the use of antifreeze as a coolant. In the event of an emergency, up to 150 liters of antifreeze will go down the drain along with the incoming cold water. Is this protection worth it?

The presence of a UPS will make it possible to maintain the operation of a circulating pump in a critical situation, with the help of which the coolant will evenly diverge through the pipeline without having time to overheat. As long as the battery capacity is sufficient, the uninterruptible power supply guarantees the operation of the pump.During this time, the boiler should not have time to heat up to critical parameters, the automation will work, starting the water through the spare, emergency circuit.

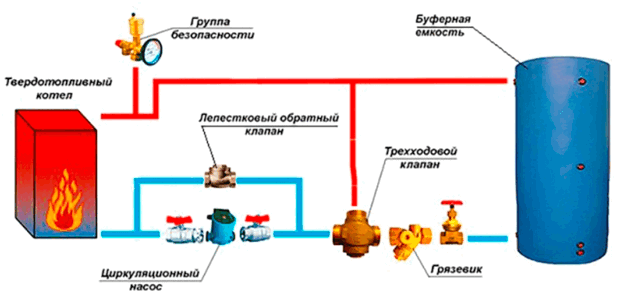

Another way out of a critical situation would be to install an emergency circuit in the piping of a solid fuel unit. The shutdown of the pump can be duplicated by the operation of a spare circuit with natural circulation of the coolant. The role of the emergency circuit is not to provide heating for residential premises, but only to be able to remove excess heat energy in an emergency.

Such a scheme for organizing the protection of the heating unit from overheating is reliable, simple and convenient in operation. You will not need any special funds for its equipment and installation. The only conditions for such protection to work are:

- the presence of an expansion tank or storage tank in the system;

- the use of a check valve only petal type;

- the pipes of the second circuit must be of a larger diameter than the conventional heating circuit.

How to install

When installing a safety drain valve, the following rules must be observed:

- Usually, the pressure relief valve in the heating system is placed in the domestic circuit in a single copy. Its main placement points are directly above an electric, solid fuel, gas boiler on its outlet pipe or next to a horizontally located pipeline. If this is not possible for technical reasons, the main condition for correct installation is installation in the supply line up to the first shut-off valve.

- The outlet side pipe is usually connected to a sewer or drainage system, if it is technically difficult or the volume of coolant in the circuit is low, you can use a flexible connection, which is lowered into a container of a suitable volume.

- The liquid must be drained with a jet break through a funnel or a hydraulic seal to ensure the system's operability when the sewer is clogged.

- When installing in a pipeline, use a tee with a lower outlet of a suitable diameter, its standard value is 1/2, 3/4, 1 and 2 inches. The diameter of the pipeline leading to the valve must not be smaller than that of the system.

Valve types

So, in more detail about the two existing types of valves, you can read below:

- 1. The three-way thermostatic valve for the boiler is an automatic model. It will maintain the set temperature level without additional human intervention. At the same time, the most functional models are equipped with an additional security system that blocks the movement of the coolant if there is no circulation through one of the incoming pipes. Thus, the batteries will not boil over.

- 2. The three-way thermostatic mixing valve for the boiler can be equipped with both automatic and manual control. The fundamental difference will be the need to regularly check the status of the system so that it does not overheat. Today, mechanical devices have already been practically abandoned, as they have been replaced by more advanced units.

Varieties

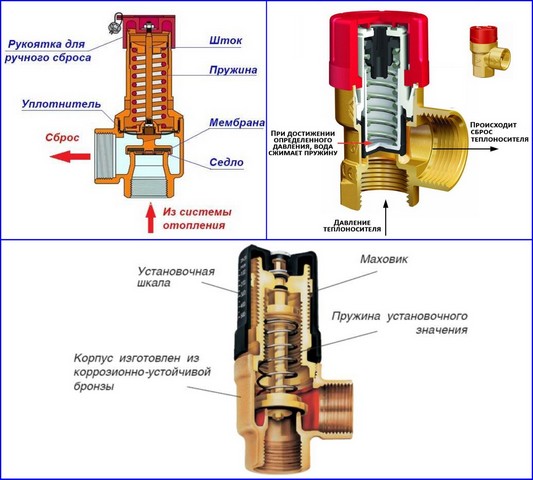

Existing types of valves are able to work with boiler equipment from leading foreign (Vaillant, Baxi, Ariston, Navien, Viessmann) and domestic (Nevalux) manufacturers on gas, liquid and solid fuels in situations where automatic control over the operation of the system due to the type of fuel is difficult or violated when the automation fails. Depending on the design and principle of operation, safety valves are divided into the following groups:

- According to the purpose of the equipment in which they are installed:

- For heating boilers of the above design, they are often supplied on fittings in the form of a tee, in which a pressure gauge is additionally installed to check the pressure and a vent valve.

- For hot water boilers, there is a flag for draining water in the design.

- Tanks and vessels under pressure.

- Pressure pipelines.

- According to the principle of operation of the clamping mechanism:

- From a spring, the clamping force of which is regulated by an external or internal nut (its operation is discussed above).

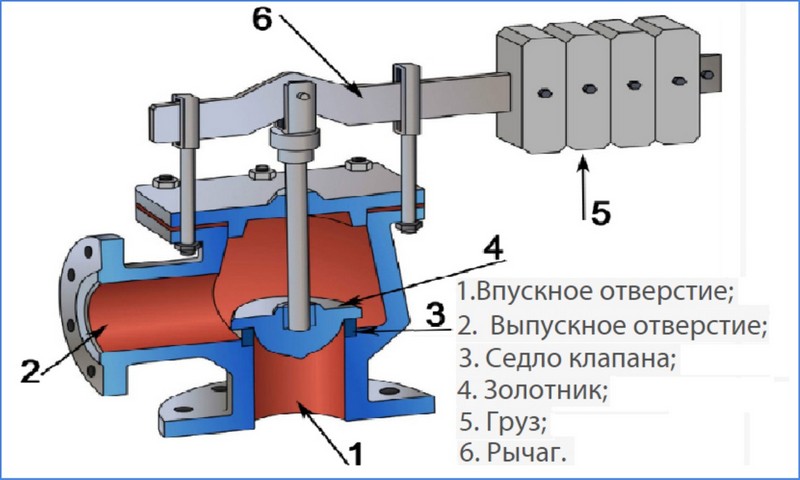

- Lever-load, used in industrial heating systems designed to discharge large volumes of water, their response threshold can be adjusted by suspended loads. They are suspended on a handle connected to the shut-off spool by the principle of a lever.

- Locking mechanism actuation speeds:

- Proportional (low-lift spring) - hermetic constipation rises in proportion to the pressure and is linearly related to its increase, while the drain hole gradually opens slightly and closes in the same way with a decrease in the volume of the coolant. The advantage of the design is the absence of water hammer in various modes of movement of the shut-off valve.

- Two-position (full-lift lever-cargo) - operate in the open-closed positions. When the pressure exceeds the response threshold, the outlet opens completely and the excess volume of the coolant is bled off. After the pressure in the system normalizes, the outlet is completely blocked, the main design flaw is the presence of water hammer.

- By adjustment:

- Non-adjustable (with caps of different colors).

- Adjustable with screws.

- According to the design of the spring compression adjusting elements with:

- Internal washer, the principle of operation of which was discussed above.

- External screw, nut, models are used in domestic and municipal heating systems with large volumes of coolant.

- With a handle, a similar adjustment system is used in flanged industrial valves; when the handle is fully raised, one-time water can be drained.

Kau stroen thermostatic valve

Thermostatic valves are of two types:

-

mixing

- flow A entering the valve is distributed to flow B and flow AB -

distributive

- flow A entering the valve is divided into 2 flows

The mixing valve is installed on the return pipeline and the diverting valve is installed on the supply pipeline. The valve is controlled by a thermal head with a thermoflask.

The thermoflask with the help of a special sleeve is attached to the surface of the return pipeline in close proximity to the heating boiler. Inside the flask is a working fluid, the temperature of which is equal to the temperature of the coolant before entering the boiler. If the temperature of the coolant rises, the working fluid increases in volume, and, conversely, when the temperature of the coolant decreases, the volume of the working fluid decreases. Expanding or contracting, the working fluid presses on the stem, closing or opening the thermostatic valve.

Using the thermal head, you can set a certain temperature, above (below) which the heating medium will not be heated. How to set the temperature by choosing the operating modes of the thermal head is described in detail in the instructions for it.

Another feature of the thermostatic valve is that it reduces the flow of coolant to the boiler, but never shuts it off and does not open it completely, protecting the boiler from overheating and boiling. The valve is fully closed only when the boiler is started.

Thermal mixing valve design and operating principle

Like most parts and structural elements of a solid fuel boiler, a three-way or similar one has a simple and understandable design. It consists of:

- main body;

- spring-loaded rod;

- two dampers, poppet type;

- thermostatic element (head with fixed positions).

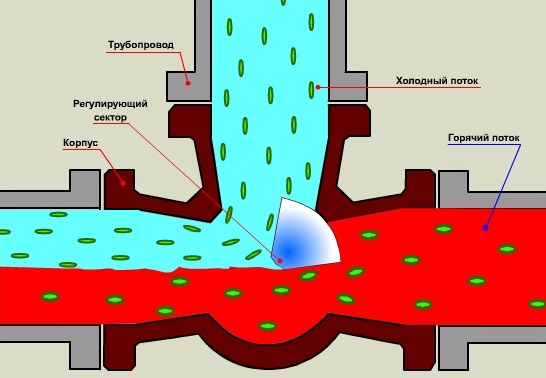

The diagram shows in detail the mechanism in section, where and how its main elements are located.

Looking at the design of the device is not a pipe to understand the principle of operation. Let's take a closer look at the ongoing processes.

In the normal mode of operation of the heating system, the main dampers, arranged linearly, are in the open position. Insufficiently hot water passes freely freely from the boiler to the heating circuit.

The thermostatic head, equipped with a temperature-sensitive liquid sensor, is in the standard position. In the event of an emergency situation, for example: from the side of the boiler, a coolant begins to flow into the system, the temperature of which exceeds the specified parameters. The temperature control sensor is activated, which drives the stem. The operating mechanism closes the main straight-through passage, simultaneously opening a passage from the side through which cold water enters. As a result of mixing water of different temperatures, the temperature equalizes to the established norm. The coolant, already at normal temperature, leaves the device through the pipe into the heating system. The adjustment of the thermostatic head of the device is determined by the degree of pressure of the bellows with expanding liquid on the stem. Accordingly determines the sensitivity of the device.

The moment of operation of the device is determined by adjusting the head, set to a certain temperature.

If the water continues to heat up as a result of the actions taken, the device shuts off the main incoming flow, opening the access of cold water from the third branch pipe. The stem in this case is in its lowest position. Water from the third branch pipe is already mixed with the main flow. When the temperature of the coolant changes in the direction of decrease, the rod under the action of the sensor reduces the pressure, opening access to hot water.

In order to achieve the correct operation of the entire mechanism, it is necessary to strictly comply with the requirements for its installation. can be installed in the right-hand or left-hand version, both on the return and on the supply circuit. During operation, the device does not require any maintenance.

Why is the valve leaking?

The pressure relief valve in the heating system can leak for various reasons. In some situations, this is an acceptable natural process, in other cases, a leak indicates a malfunction of the device.

Leaking safety valve can be caused by the following reasons:

- Damage to the sealed rubber cup, disk as a result of repeated use. If during the repair the replacement part cannot be found on sale or it is not included in the package, you will have to change the device completely.

- In spring types, the opening of the side drain pipe occurs gradually; at boundary pressure values \u200b\u200band short-term jumps, the valve may partially operate and drip, which does not indicate a malfunction.

- Leakage can be caused by incorrect settings or malfunctions of the expansion tank - damage to its membrane, air escaping through a depressurized housing or a damaged nipple. In this case, sudden pressure surges are possible as a result of hydraulic shocks, causing periodic short-term leakage of the coolant through the safety valve.

- The cause of leakage in some adjustable valves is the seepage of liquid along the stem through the top during operation.

- If a backpressure is created on the outlet pipe above the instrument's trip threshold, a leak will also occur.

The safety valve of steam boilers is designed to protect them from excess pressure in the system caused by various factors, and is an indispensable element in the operation of this type of equipment. On sale there is a wide range of safety devices from Chinese, domestic and European manufacturers, which are characterized by relatively low cost.When buying, it is rational to choose a protective group from several devices, which additionally includes a pressure gauge and an air bleed valve.

Water dripping from safety valve. What to do

Accumulative water heaters today are in increasing demand among our compatriots. These units allow them to simply effectively solve many economic problems, but sometimes it happens that the device itself becomes the source of the problem.

One of the most common problems we face is water leakage. If water drips from the safety valve, then the cause must be determined as soon as possible, because in some cases this process should not be considered a malfunction. That is why there is no need to rush into the decision to call a water heater repair specialist.

Possible causes of malfunction

The causes of water leakage from the valve can be:

- Valve failure;

- Incorrectly set pressure difference in the system;

- Other reasons, in particular, water may leak from the valve, but this will not be considered a breakdown.

The first two reasons involve the repair of the unit.

Troubleshooting

Gas water heaters should be tested first. It is necessary to determine in what situation water flows out.

If you noticed that water flows out during the heating of water, then most likely your unit is fully functional. The fact is that when heated, the water expands, respectively, the pressure of the liquid on the walls of the tank increases

When the pressure exceeds the norm, the valve gets rid of excess water. The solution to this problem can be to attach a rubber hose and bring it to the sewer or a container of the required size.

If the water heater's safety valve is letting cold water through, it's most likely because the water pressure is too high. The solution to this problem is to install a reducer to normalize the pressure in the water supply network. To do this, you need to contact a qualified specialist. Also, you can’t do without the help of a professional if you are inclined to conclude that the cause of the water leak is a malfunction of the valve itself.

Thus, the first step to solving water heater leak problems is to determine the cause of the leak and determine the nature of the problem. Remember that it is always safer to turn to a professional for help than to repair complex equipment yourself, because inept repairs can lead to a more complex malfunction.

Nominal diameter and adjustment

The cross section of the safety valve must be equal to or greater than the cross section of the pipe on which it is installed. Otherwise, the hydraulic resistance of the device will be too large, as a result of which the operation of the system will be disrupted.

The adjustment of the safety valve of the heating system depends on the type of clamping mechanism. In spring devices there is a cap, the rotation of which sets the pre-compression of the spring. These products are characterized by a high adjustment accuracy of +/- 0.2 atm.

Lever-weight valves are adjusted with less accuracy. To do this, you need to move the load along the lever or increase its mass.

Rice. 3. Independent ITP connection scheme with pressure maintenance device

Such a scheme is somewhat more expensive than a dependent one, but at the same time it protects in-house heating devices from low-quality coolant coming from the central network. If it is necessary, in addition to heating, to provide centralized hot water supply, then one or more heat exchangers are additionally installed. Depending on the ratio of the load on heating and hot water, single-stage and two-stage schemes for connecting water heaters are used.

Examples and payback

In Ukraine, modern automated heat points with an independent connection scheme are offered by the Austrian company Herz.

Herz ITPs operate at a temperature of network water in the primary circuit (district heating) of 110–140°C / 65–80°C. At the same time, the temperature in the house heating system is maintained at 90–55°C / 70–45°C. The nominal pressure in the primary circuit is up to 16 bar. The working pressure in the secondary circuit is from 2 to 10 bar. To maintain the pressure in the system, a diaphragm expansion tank is used or, in the case of systems with a capacity of more than 300 kW, a pressure maintenance unit. The coolant is circulated by highly efficient frequency-controlled pumps.

In the configuration of the ITP, schemes are implemented based on a two-way valve or a combi-valve - a flow controller with an electric drive, and a plate or brazed heat exchanger. Weather-dependent regulation of the coolant temperature, temperature settings are carried out by the controller. In this case, it is possible to organize remote access and control of equipment via a GPRS modem. To account for heat consumption, the use of an ultrasonic flow meter with a calculator is provided.

In addition to ITP for multi-storey buildings, apartment heating points are also used. They allow the consumer to individually regulate the operation of the heating and hot water systems, and provide convenient accounting for energy consumption. For example, the Herz DeLuxe substation is designed for a maximum operating temperature of 90°C, a maximum operating pressure of 10 bar and a hot water flow rate of up to 15 l/min. Such heat points are installed directly on each consumer (apartment). Options are offered for open or hidden installation in the wall, as well as with a mixing unit for low-temperature panel radiant heating, for example: warm walls, warm floors (Fig. 4).

Rice. 4. Compact apartment heating unit Herz Bregenz

The payback time for investments in IHS in building retrofits is between 1 and 5 years and depends on the equipment used, the size of the building and the type of system. At the same time, it is worth remembering that the installation of individual heat points is an important and necessary step, but not the only one on the way to the energy efficiency of a residential building heating system. The greatest effect is achieved in conjunction with the balancing of the heating system and the installation of thermostatic valves on heating appliances.

Viewed: 5 337

The basic principle of boiler protection against condensate

To protect the solid fuel boiler from the formation of condensate, it is necessary to exclude the situation in which this process is possible. To do this, do not allow cold coolant to enter the boiler. The return temperature must be 20 degrees less than the supply temperature. In this case, the supply temperature must be at least 60 C.

The easiest way is to heat a small amount of coolant in the boiler to the nominal temperature, create a small heating circuit for its movement and gradually mix the rest of the cold coolant with hot water.

The idea is simple, but it can be implemented in various ways. For example, some manufacturers offer to purchase a ready-made mixing unit, the cost of which can be 25 000

and more rubles. For example, the FAR company (Italy) offers similar equipment for 28500 rubles

, and the company Laddomat

sells a mixing unit for 25500 rubles

.

A more economical, but at the same time no less effective way to protect a solid fuel boiler from condensate is to control the temperature of the coolant entering the boiler using a thermostatic valve with a thermal head.

Principle of operation

The valve that protects the boiler has a simple device and works on a principle that is understandable even to a schoolboy.The device consists of a straight fitting with a 90 degree outlet and a spring-loaded hermetic seal that closes the side passage. When the pressure in the system increases from overheating, exceeding the clamping force of the spring holding the valve in a fixed position, it rises and opens the side hole.

Excess liquid begins to pour out from the side and is sent to a container, drainage or sewer system. After bleeding off part of the coolant, the pressure in the system and on the valve weakens, the spring puts it in place, blocking the side pipe.