What are jets

Mixture preparation

In the burner, a mixture of gas and air is prepared so that the gas burns with maximum heat output, does not give soot and does not emit carcinogenic waste during combustion. Each burner is designed for a specific mode of operation, a large one consumes more gas than a small one. In order to mixture

turned out to be correct, in each burner there is a jet of the size calculated by the designers. The larger the hole, the more gas will pass through it. The inlet pressure of natural gas is lower than that of bottled gas. Therefore, for each stove, manufacturers have designed two sets of nozzles. One for the main gas pipeline, the other for bottled gas.

Marking

down to a hundredth of a millimetre. This guarantees the necessary throughput. The end of the bolt is marked with a number that indicates its size. Each burner (small, medium, large, oven) has its own number, determined by the manufacturer. In most cases, the threads and sizes of nozzles are similar for products from different companies.

Some manufacturers supply a second set of nozzles with the stove. If you lost it or it was not provided in the kit, do not despair. On the Internet, when requesting a brand, you can find technical

passport of your plate. It contains all the necessary data of nozzles for the main gas pipeline and bottled liquefied gas. For instance, for slabs brand "Hephaestus", nozzles with the following markings are required:

- 45 is small.

- 75 - medium.

- 85, 95 - large or oven.

Jets are sold in gas equipment stores. Picking up and buying the right size or set is very simple.

Main parameters of injectors

The development of gas-balloon equipment provoked the emergence of a huge number of varieties of nozzles. The parameters of the division of dispensers are not several positions, but about ten of the most important divisions. To be more precise, HBO nozzles are classified according to:

- Housing material (metal or plastic);

- Type of metered fuel (propane-butane or methane);

- Working voltage of the coil;

- Working pressure and the maximum possible;

- Opening and closing times (that is, they can be instantaneous, delayed or customizable);

- The electrical resistance of the coil;

- Working temperature range;

- The outer diameter of the outlet fitting;

- valve seat diameter;

- Jets available for calibration.

GR series gas injectors

Unified Technology

Gas injectors of the GR series are unified on the majority of details. This allows us to reduce the cost of our products, provided that the entire design is based on significantly more expensive technologies.

The high technological level and accuracy of manufacturing gas injector parts is a necessary and critical condition for the quality operation of a gas engine and a key factor in the development of the gas engine industry as a whole

The unification of the injector body and the development of a universal rail provide a number of advantages. A single injector of the GR-1000 type was originally developed by order of the STC KAMAZ and corresponds to the fit and all settings of KAMAZ gas engines manufactured from 2011 to 2014.

The body of the gas injector of the GR series is designed for installation in a cylindrical hole in the gas train of the engine with a seal with two rings of equal diameter.This design balances the retracting and pulling out effects of gas pressure inside the rail on the injector, which, in turn, allows you to securely fix the injector in the rail with gas pressure. Additional fixation of the injector in the ramp opening is achieved with a special screw. The described design of the gas injector body allows you to repeatedly remove and install the gas injector into the rail or change one failed injector without dismantling the rail and breaking the tightness of the gas pipelines.

Protective mesh made of polyamide

The use of a protective grid with a mesh size of 0.125 microns at the gas inlet to the injector of the GR series, which is significantly smaller than the armature stroke (0.14 - 0.22 in different models) allows you to protect the dosing mechanism from debris from the gas line of the car.

The use of a protective grid with a mesh size of 0.125 microns at the gas inlet to the injector of the GR series, which is significantly smaller than the armature stroke (0.14 - 0.22 in different models) allows you to protect the dosing mechanism from debris from the gas line of the car.

Technologies and Materials

The GR series injectors have a number of features that were previously difficult to combine together in one product. For example, high performance and large margin of electromagnet strength, strong magnet and low inductance, high performance and short response time, etc.

These and some other properties are combined and embodied thanks to the careful selection of materials, incoming quality control and unique technological discoveries. A gas injector is a product whose design precision must be combined with mass production, long-term performance in an aggressive environment, in a wide range of temperature, pressure and voltage drops. And it all has to be cheap.

Small stroke of the anchor

The GR series injectors use dosing technology, which combines a large injector throughput with a high response speed, a large response pressure range, a long resource and small errors throughout the injector resource. This combination of properties became possible when we abandoned the conventional annular seat, developing the original design of the node ...

Possible malfunctions

Summarizing the story about the device of HBO injectors, it would not be out of place to pay attention to their possible malfunctions. In fact, there are few of the latter, or rather, only three:

- The first option is the nozzles or some of them are out of order. The problem is solved by parsing, cleaning and, if possible, repairing faulty elements. If this approach did not give an effect, then you will have to install new nozzles;

- The second option - there was a malfunction in the system "injectors - control unit". The malfunction can be eliminated by “ringing” the network and setting up the equipment “on a new one”. Often a problem of this nature is solved through an appeal to the HBO master;

- The third option - the nozzles are simply clogged. The easiest way to get rid of this “breakdown” is to remove the dispensers, disassemble them and clean them thoroughly.

Note that on older generations of LPG (up to 3) there may be problems with the confrontation of the car’s mono power systems with gas equipment. It seems possible to solve them by introducing an injector emulator into the HBO system (the most preferable choice is an instance from BRC). On most of the third and all subsequent HBOs, the conflict between mono-power systems and equipment is resolved automatically in the control unit, so such a omission of equipment cannot happen with them.

Any malfunction of the injectors is indirectly manifested by the following symptoms:

- instability of the motor;

- loss in power and dynamics;

- inability to switch to gasoline;

- increased fuel consumption;

- failures in the operation of the engine while driving.

In general, on the issue under consideration today, the most important provisions have been successfully considered. We hope the above material was useful to you. Good luck on the roads!

Purpose and types of jets

The purpose of the gas stove nozzle is to ensure the flow of gas to the burner.At the same time, it also evens out the flame on the burner due to the dosed intake of combustible substance. It is possible to connect gas coming from a gas pipeline or liquefied gas in cylinders to a kitchen tile. Since such substances have different pressures and compositions, different jets will be required. Their main difference is the different diameter of the hole. LPG requires a narrower diameter. Also, the greater the power of the burner, the larger the size of the hole will be.

It happens that, after serving for some time in the kitchen in an apartment, an outdated stove is transported to a summer house or a country house where there is no main gas pipeline or connection to it. And gas in cylinders will be used as a combustible substance. In such a situation, it is necessary not only to connect the cylinder correctly, but also to replace all nozzles.

Connection and setup

After installing nozzles for liquefied gas, which differ from those for natural gas, you can start connecting the cylinder itself.

You can also install the cylinder indoors with a stove, but it is recommended to take it out to a shady place on the street, in a metal box adapted for this purpose. In this case, the distance from the window should be at least 0.5 meters. It is always best to turn off the faucet after cooking.

Connection to the cylinder

The connection to bottled gas is similar for all such equipment, for example, Hephaestus stoves. A reducer is screwed onto the balloon. The gasket must be installed. A fitting is screwed onto the inlet pipe of the plate. It can be included with the unit. Here, too, a gasket is needed. Now a gas hose is connected to the outlet of the reducer and connected to the fitting on the stove. The hose is secured with clamps. If the hose is introduced from the street through a hole in the wall, be sure to place a piece of metal pipe in the hole to avoid chafing the hose.

The requirements for the hose are:

- should be no longer than one and a half meters;

- it is desirable to carefully fix it in order to ensure its immobility as much as possible;

- it should not break and bend;

- it must be a special hose designed for such a gas;

- do not use more than the prescribed period of operation;

- Be sure to check for damage after a while.

After connection, it is necessary to check all elements for leaks. To do this, the gas supply is opened, and all joints are coated with soapy foam. The presence of leakage is eliminated by tightening the nuts, harnesses, replacing gaskets. After replacing the cylinder, such a check must also be performed.

Summing up

To switch to using bottled gas, you will need to replace the jets for gas stoves in all burners and in the oven. This may also be required if there are any problems with the operation of the burners.

Before replacing, be sure to pay attention to the diameters of the jets for gas stoves, as well as their thread pitch. All of them are marked, therefore, knowing the characteristics indicated in the data sheet of your kitchen assistant, it is easy to make the necessary replacement.

In more modern stoves, unscrewing the nozzles is not difficult. In older models, it may be better to contact a service center, as some designs are quite difficult to repair on your own.

How to replace jets yourself

As a rule, nozzles rarely fail, and many do not even suspect that they can be replaced at home. One of the cases where injectors are required to be changed is when changing the type of fuel, as mentioned above. But the need to replace the jets on the gas stove also appears in such cases:

- the color of the flame has changed: yellow and red blotches appear instead of the usual blue color;

- there is soot or uneven combustion;

- there is a hiss, and at the same time the flame is separated from the burner or goes out;

- when the burner is ignited, a pop is heard.

If you are going to fix the problem yourself, then we will consider the whole process step by step.

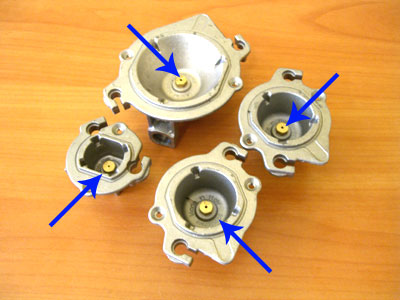

We disassemble the burner

First, of course, you need to shut off the gas supply. In general, working with gas equipment requires special care and compliance with safety regulations. Then remove the grate from the hob. The burners themselves are removed without effort. To replace the jets, in some models of gas units, you will need to unscrew the top panel of the hob. But more often, a nozzle is visible right under the burner.

If you have an older model of equipment, and the jet is located in the body, you will have to disassemble it. In this case, you need to unscrew the bolts at the corners of the hob. There may be other assembly options where the panel will have to be pry off to separate from the main body. In this case, of course, it is better to look in the documentation for exactly where the required elements are located and how to get to them.

The internal structure may look like this. A pair of parallel metal strips are traverses, on which the burner bodies are attached. The gas supply to the burner is similar for all nodes. The jet itself is located in the burner body, to which the gas pipeline is connected. Through the tip, the fuel is supplied to the nozzle, from where the gas is already supplied to the burner.

We unscrew the jet

To unscrew the jets in a gas stove, you will need an open-end wrench or a tubular wrench, depending on the model. It should be said that in old models of such equipment it can be extremely difficult to get to the nozzle, since it is located in the burner body and it will not be easy to turn it out with a key. It may be necessary to disassemble almost the entire unit. In this case, it is better to remember the sequence of actions and prepare different small containers for the parts that you will take out.

For more modern models, the process should not be difficult. When replacing, the size and thread of the nozzle must be taken into account. Some kitchen appliances are equipped with nozzles for converting to liquefied gas, and all replacement steps are clearly spelled out in the instructions, for example, in the Darina 1A GM 441 002W model. If the kit does not provide for the presence of such parts, it is better to seek advice from the seller of a specialized store. In this case, it is advisable to have old nozzles with you, or at least measurements of the diameter and thread pitch.

Checking the channel

If you did not have the goal of changing the nozzles to use a different fuel, but only to eliminate the combustion problem, then it is quite possible that the hole was simply clogged. And cleaning it will save you from replacing it. You can do this with any thin sharp object, such as an awl or a knitting needle.

It is important that the diameter of the object is not wider than the diameter of the hole. Otherwise, you can deform it, which is unacceptable

For the same reason, cleaning must be done with care.

jet replacement

As already noted, in modern models it is not difficult to get to the nozzle and replace it. In a more difficult situation, it is located in the burner body. And to change it, you have to pull the tip with the jet out of the burner body. To do this, you need to remove the latch, which is located directly under the body and looks like a clothespin. It is worth remembering that when performing such actions, you should not make too much effort so as not to break individual parts.

Assembling the burner

After replacing all the nozzles, you will need to reassemble the burner in the reverse order. After that, you can switch from natural gas to bottled gas. But before that, you need to remember to change the nozzle in the oven.

Burner ready

After the burner is assembled, it's too early to check the flame of the fire. Below we consider the replacement of oven jets in a gas stove with our own hands.

Choice of nozzles

Each gas equipment has its own characteristics, so it is important to select nozzles individually for each generation of LPG. Many motorists raise the question "Which nozzles for HBO are better?"

In the case of gas-balloon equipment, this wording is initially incorrect, because the proverb known to many applies to it: what is good for a Russian is death for a German. Naturally, the saying should be rephrased for gas equipment and understand that for one generation, specific nozzles can be simply ideal, but not able to work with another.

In order to make a competent choice of nozzles, it is enough to adhere to the following points:

- First, find out what generation your gas equipment is. In the selection process, this plays an important role, because each type of HBO has its own nozzle standards. So, for the first generation, the EURO safety standard is applied, for the second - EURO-2, for the third, fourth, fifth and sixth - EURO-3 and higher;

- Second, determine the number of nozzles needed. It should be noted that for HBO generations 1-3, it is permissible to purchase nozzles separately. In the case of older versions of equipment, it is recommended to buy ready-made kits. This approach will help to avoid problems in the further configuration of the equipment;

- Thirdly, check the connection method and other technical features of your HBO regarding injectors;

- And fourthly, when choosing new dispensers, give preference to trusted manufacturers. At the moment, they are deservedly considered Valtek, BRC, Digitronic, Rampa, Barracuda and Lomato. Moreover, the same BRC and Lomato produce their own LPG, so it is quite possible for their owners to avoid difficulties in selecting new nozzles by telling the seller only the model of their equipment.