Polypropylene pipes reinforced with aluminum are much superior in their characteristics to metal counterparts. Therefore, when installing a plumbing or heating system, most people opt for plastic products. Such popularity is quite understandable. Plastic pipes do not spoil the appearance of the premises, they are easy to maintain and install. Reinforced products serve much longer than ordinary plastic, while retaining all technical parameters. There are two ways to reinforce plastic pipes: aluminum or fiberglass. Let's look at both options.

General characteristics

Polypropylene products, regardless of the method of reinforcement, have the following technical features:

- Increased strength and rigidity compared to conventional plastic. Accordingly, during installation, long pieces of the pipeline can be launched without using additional fasteners.

- Reduced linear expansion of products. For ordinary plastic, this figure is 10 millimeters per meter, at a temperature of 70 degrees Celsius. When using reinforcement, the expansion rate can be reduced by a factor of 10, only 1 mm per meter of pipeline.

- Increased resistance to high temperature and corrosion. For reinforced products, temperature drops from -10 to +90 degrees are not terrible.

- Due to the high strength and wear resistance, it is possible to lay a monolithic water supply in the apartment, thereby eliminating the possibility of leaks.

- Reinforcement practically does not affect the total weight of the structure.

Reinforcement with aluminum

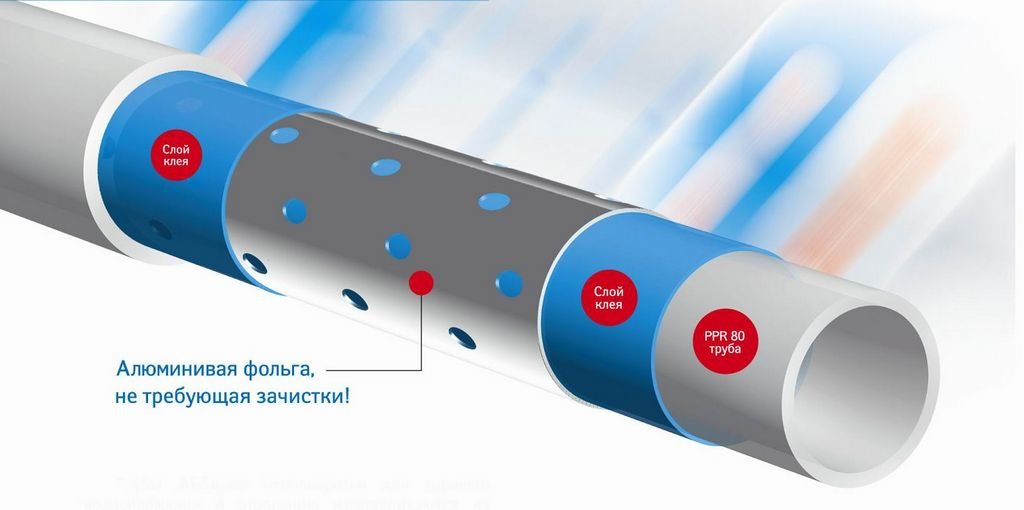

These products can be recognized among analogues by marking - PPR-AL-PPR. It is possible that you will come across the label PPR-AL-PEX. These are also pipes reinforced with aluminum, only the inner layer is made not of plastic, but of ethylene. It should be noted that there are several ways to reinforce aluminum.

- At first, smooth foil was used for this, which had to be glued with a special adhesive. Subsequently, this method of reinforcement was abandoned. The slightest violation of manufacturing technology, and the pipe began to delaminate. Smooth foil began to be replaced by perforated one, which made the design more reliable.

- In addition, it is interesting to consider the method of connecting the foil. On some products, the reinforcement is overlapped. A thickening appears at the junction of the foil, and in order not to violate the overall geometry, manufacturers have to reduce the surface layer. This negatively affects the service life and technical characteristics of such products.

- Reinforced pipes look much more profitable, where aluminum foil is joined end-to-end. These products are able to better withstand temperature and pressure. A laser is used to reinforce polypropylene in this way.

Despite the clear advantages of reinforced pipes, there are some disadvantages. For example, a rather time-consuming connection process. When using fittings, the edges must be cleaned. For this, a special device is used - a shaver. This tool is not cheap, but you cannot do without it when installing aluminum-reinforced pipes. If this process is neglected, moisture will get between the layers of the product. As a result, leaks will occur, and the service life of the heating system will decrease accordingly.

fiberglass reinforcement

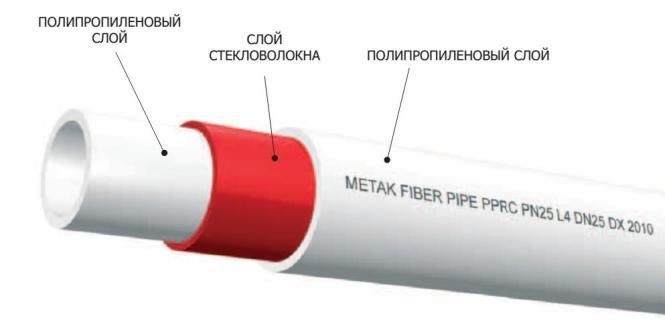

According to its technical characteristics, this option is not inferior to previous products. The use of fiberglass made it possible to strengthen the pipe without losing elasticity. Pipes reinforced with fiberglass are more convenient in terms of installation. They do not need additional stripping, which greatly simplifies the workflow.Among the shortcomings, it can be noted that it is unlikely that it will be possible to save on fastenings of fiberglass pipes. If too long sections are left, the pipeline will sag during operation.

Fiberglass reinforced pipes can be recognized by the marking PPR-FB-PPR. Products are a three-layer structure, where the outer and inner layers are made of plastic, in the middle there is a layer of fiberglass.

Manufacturers of fiberglass pipes claim that the service life of their products is about 50 years. In most cases, this is true.

Nuances when choosing

After reading the information and comparing the characteristics of reinforced pipes, many probably had a question: what kind of reinforcement should be preferred? Fiberglass products look the most advantageous. They are more convenient to install, which will save time during work. In addition, the manufacturing technology of such pipes looks more reliable: fiberglass is simply fused between layers of plastic. Given that these products have good elasticity, they can be bent, minimizing the number of fittings.

When choosing products, pay attention to the maximum allowable pressure that the pipe can withstand. On polypropylene pipes, this parameter is indicated by the letters PN. The best option for installing a heating system in an apartment is PN 25. Pay attention to the temperature limit.

When choosing, we recommend that you pay attention to the products of German or Czech manufacturers. They hold the palm in this market segment. But you have to pay for quality. From budget options, Turkish or domestic reinforced pipes can be distinguished.