Taking a bath is never compared to a regular shower, because it is the perfect way to feel relaxed after a busy day and even get healthier. Modern plumbing industry offers an impressive selection of bathtubs, including - acrylic, quartz, artificial stone, steel and cast iron. But ageless classics are cast iron bathtubs. Consider the question: how to install a cast-iron bath.

The reason for the love for such material is not at all that someone is too lazy to change the Soviet bath for a modern one, made from innovative materials. In fact, such a font is valuable in that it optimally distributes heat, which, moreover, lasts for a long time. However, such an element of plumbing has its own characteristics, which make its correct installation rather problematic. What is the specificity of this work?

Preparing for installation

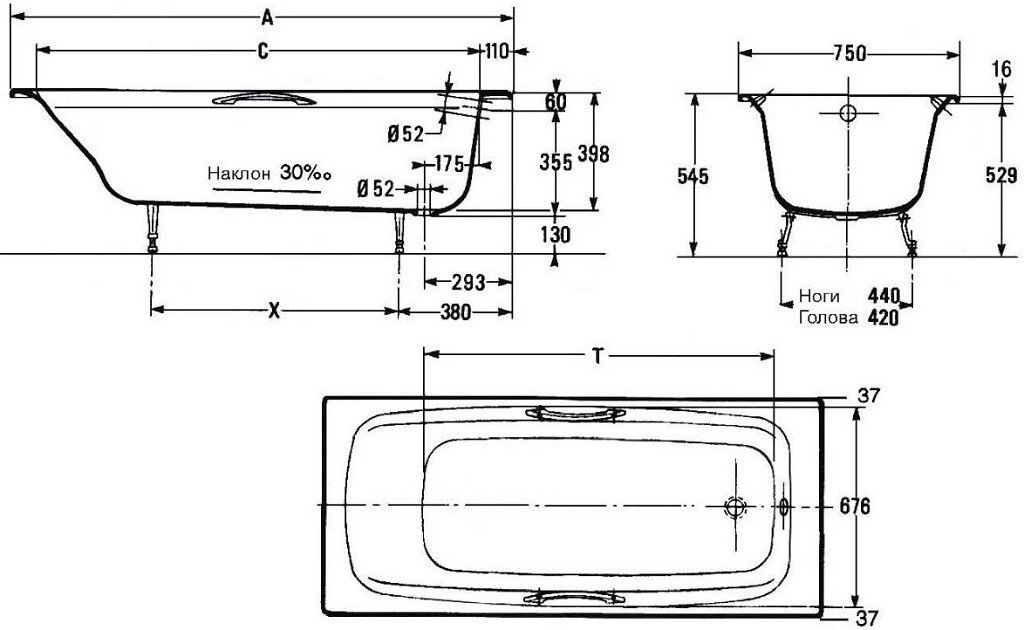

Before starting the installation, the key is to measure the dimensions of the bathtub and the dimensions of the room so that they match each other. All indicators to be measured can be seen in the figure below.

How to properly take a bath

The main problem with the self-assembly of a plumbing fixture is that cast iron products are quite large in weight - from 100 kilograms or more, in connection with this, transportation and installation should be carried out together. That is how many people are required to lift and carry a cast-iron bath, and three loaders will only interfere with each other when the product is transported.

If there is no elevator in the house, this device should be raised to the desired floor with drain holes in the direction opposite to the direction of movement. The product is brought into the bathroom in a vertical position for a more convenient location, because this is how it takes up a minimum of space in the room, freeing up space for movers to maneuver. It is better to close the jamb and the threshold in the process with a soft material so as not to damage the new bathtub.

Tip: in order not to damage the walls of the bathroom itself when skidding, they also need to be protected, for this a tarpaulin, cardboard, rolled insulation material, etc. will come off.

Finishing the room before installation

The key point before installation is the correct preparation of the room for such a large-sized object. Firstly, the bathroom must have a concrete screed, which is covered with thick ceramic tiles on top. In case of low strength of the floor and the impossibility of strengthening or replacing it, it is advised to put steel plates under the legs, the minimum width of which is 5 cm, and the thickness is not less than 0.5 cm.

Wall decoration is also an important issue due to the difficulty of moving the bath. You can go two ways. Firstly, tile the whole room before the bath is brought into it. Secondly, lay the tiles only above the bathroom, as if “drown” its upper part into the wall. This allows you to reduce the gap between the wall and the sides of the bath, achieving a decrease in the volume of leaking water. Such a finish is made only after the installation of the bathroom, which is pre-covered with some kind of protective coating to protect it from tile adhesive.

The room should be provided with moisture insulation, otherwise spilled water can cause serious trouble to you and the residents of the apartment below.

An example installation diagram can be seen in the following diagram.

Features of mounting a cast-iron bathtub on legs

First you need to turn off the water in the apartment and, in addition, by opening the taps, remove it from the system. After making the bath, it is laid sideways, turning the bottom towards the wall, against which it will then be installed. The distance to the wall should be approximately 70 cm. Then they begin to mount the first pair of legs.

Tip: it is better to fix the height adjustment screws on the bath supports before installation, while the nuts should be positioned relative to the legs from the floor.

Installation of bath supports

Legs can be mounted in two ways:

- Fastening with wedges. The supports are put on special mounts on the bottom and fixed there by driving in the wedges included in the package. This should be done extremely painstakingly, without any extra effort. As a result, the bath supports must be fastened so that the elements fit together with maximum density and do not move under any physical impact.

- Fastening with screws. The legs are fixed in the grooves with the screws included in the package. As in the first method, the main thing is not to over-tighten the bolts, otherwise you can damage the bath itself and break the threads. The only thing left after that is to put the device on the brickwork. After fastening, the supports must be stationary.

Tip: To avoid excessive force when tightening the bolts, a torque wrench can be used.

To secure the rear supports, the cast iron product is turned over, setting it in the way it should be when using it. Then they put one end on the floor, for example, a board with a length of 60 cm (or another object that acts as a stand), after which the edge of the bath without legs is placed on it. The main thing at the same time is that the lifting height allows you to conveniently mount the product supports.

It is highly desirable when installing a safety net by another person in order to avoid pressing down with a cast-iron "colossus". The rear legs are installed in the same way as the front legs. If the floor in the room has a smooth surface, it is advisable to put gaskets. It is better to pour polymer glue into them and under them. These measures are necessary so that the bath is securely fixed in one place.

Tilting the bath and fixing it against the wall

When tilting a cast iron bath, please note that the manufacturer has already provided the necessary slope towards the drain. You only need to adjust the sides of the product horizontally using a level. The level should be taken as long as possible so that the measurements are most accurate. The adjustment must be done very carefully, since the legs fixed on the wedges can change their position. The rigidity of the cast iron bath determines that the location is adjusted only on those sides that are adjacent to the walls.

The distance from the wall to the bath during installation must be at least 1 mm. After the final installation, it can be pushed completely against the wall by tapping on the supports adjacent to these walls. After that, the existing gaps are sealed with a special sealant. Moreover, it is advisable to buy a special sealant for additional fixation of the bath to the wall and a separate silicone sealant to seal the seams from above. If the walls differ in curvature and the gap between them and the bathroom is very large, you can seal it with a special skirting board, also covered with a layer of silicone-based sealant.

Tip: the bath should be at least 4-5 cm from the bottom row of tiles to facilitate its removal during dismantling.

Sewer connection

At the final stage, connect the bath to sewer system. It is best to use plastic components for this, as they are easy to operate and most practical. They can be bought separately, although sometimes they are included in the package. The lower drain hole is connected to the siphon, and the upper one is connected to the overflow drain, which also leads to the siphon. With the help of pipes, the siphon pipe is connected to the sewer drain. All communications are connected to the bath with rubber gaskets. Such a cast-iron product must be grounded, and this work should be entrusted to qualified electricians.