To protect the floor slabs from moisture, the apartment needs waterproofing of the floor before the screed. This precaution will avoid many unpleasant situations. For example, to protect neighbors from below from leaks in the event of a water pipe break. For residents of the lower floors, waterproofing the screed will protect the floor from cracks and possible destruction. The fact is that concrete has a porous structure and has the ability to absorb and accumulate moisture. Therefore, a long stay in a humid environment will eventually lead to destruction. screeds. If your apartment is not located on the ground floor, the waterproofing layer can not be laid in all rooms, but only where there is high humidity, such as bathrooms, toilets and kitchens. In construction, two types of waterproofing are mainly used. Let's consider each of them in more detail.

Waterproofing under the screed with roll materials

A film that protects the screed from moisture and steam is well suited for apartment buildings. This material reliably protects floors from both internal and external influences.

- Before starting work, the floor in the room is surrounded around the perimeter damper tape. Such a tape can be put on glue or fixed with dowel-nails. The damper tape compensates for the thermal expansion of the screed.

- If the base of the floor needs to be leveled, this is done by smoothing out cracks and irregularities with cement mortar.

- The rolled material is laid on the prepared surface with an overlap on the walls - at least 15 centimeters, and on top of each other with an approach of about 10 cm. If roofing material is used as waterproofing, then it is attached to the base with bituminous mastic. In addition, joints are also smeared with mastic. The film is also overlapped and fastened with a special hair dryer.

- Rolled waterproofing is usually laid in 1-2 layers. After that, the floor screed is performed.

Floor waterproofing before screeding with coating materials

This is a relatively new method of floor waterproofing, which has already gained popularity among builders and finishers. The method of applying coating waterproofing is quite simple: the material is applied with a brush and fills in all the potholes and microcracks. This reliably protects the screed from the penetration of steam and moisture. Usually, the function of coating waterproofing is performed by materials based on bitumen or rubber.

- The base of the floor is thoroughly cleaned of dust and debris. It is recommended to smooth out all sharp protrusions and corners. Particular attention should be paid to stains left by chemicals, solvents and machine oil. The molecules of these substances can react with coating materials, which will lead to the destruction of the waterproofing layer.

- After that, the surface of the base floor is treated with a primer. This material provides more reliable adhesion of the floor to the waterproofing. It is recommended to choose a primer suitable for the mastic used. Ideally, primer and insulation should be from the same manufacturer.

- The primer (primer) is applied with a wide brush in one layer. When smearing, special attention should be paid to the corners, joints of the floor and walls, the area near the water pipes. The primer dries in about 2-3 hours.

- To apply bituminous mastic, a wide roller or brush is used. Waterproofing is laid in several passes, with each subsequent layer being applied only after the previous one has completely dried. Each movement of the roller or brush should go in a different direction. For processing corners and joints, it is recommended to use a thin brush.

- In order for the bituminous waterproofing to dry completely, it is necessary to wait about 48 hours.After that, you can start making a screed.

Important! If reinforcement is provided for the screed, then plastic gaskets must be laid on the waterproofing. Direct contact between reinforcement and bituminous mastic can damage the latter.

Nuances

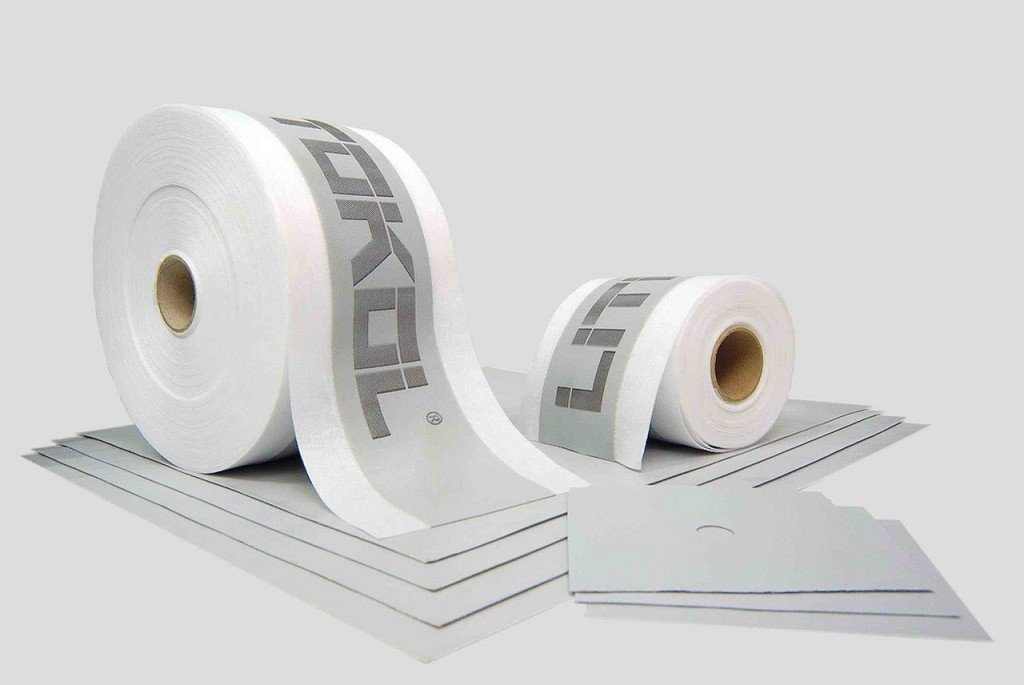

The reliability of the protective layer largely depends on the quality of the butt joints, in particular: wall-floor. The optimal solution would be to use the reinforced tape Litoband from LITOKOL.

This product ensures the tightness of corner and butt joints of the floor-wall, drain and sewer pipes. The tape is not afraid of a humid environment and temperature effects, it is easy to install and safe for health. It should be noted that Litoband tape can be used with any type of waterproofing. This material is used as follows:

- Preliminary preparation of the base of the floor is being done. Works are carried out taking into account the materials used. Examples are given above.

- Then a layer of waterproofing is applied.

- After that, the Litoband 10 or Litoband tape is glued. The digital marking indicates the length of the product. Tape the inside and outside corners first. For this, elements marked AL and AE are used. Then the water pipes and the sewer drain are pasted over. The elements of Litoband S or P will help with this.

- Then glue the joints of the floor with the walls. It should be clarified that the tape is glued with an overlap with a run-in of at least 7 centimeters.

- The tape is applied to the surface with a rubberized layer outward and firmly pressed.

- When the entire room is pasted around the perimeter, a second waterproofing layer is applied.

The LITOKOL company also produces waterproofing mixtures. AQUAMASTER or HIDROFLEKS materials have proven themselves well. It is a synthetic resin based waterproofing.

You can also choose the cement-containing mixture ELASTOCEM MONO. Resin-containing mixtures are ready to use and do not require additional preparation. Waterproofing containing cement must be diluted with water to the desired consistency.

Waterproofing in the apartment can be done combined. For example, if the dwelling is located on the first floor of an apartment building, it is possible to combine roll and coating waterproofing.

People living on higher floors sometimes double waterproofing their bathrooms. One layer is applied to the base of the floor, the other - after the screed is completed - directly under the finish coat. It should be noted that there are other ways to apply a moisture-resistant layer under the screed. For example: the use of bulk mixtures or liquid rubber. This is a more expensive waterproofing and you will have to hire a team of craftsmen to apply it.

The quality of waterproofing directly depends on compliance with the technology of its application and the quality of the selected materials. You can protect the screed from moisture on your own, without resorting to the services of professionals.