One of the most economical and at the same time effective options for space heating in our time is a film underfloor heating. In conditions of constant rise in the cost of heat carriers, as well as electric energy, the use of heating elements with low power is a fully justified solution.

Benefits of underfloor heating

The main advantages of such a warm floor are:

- Environmental Safety. Thermal radiation with a wavelength of 5-20 microns, which is emitted by the elements of such a floor, is absolutely harmless to people, animals and plants.

- Reduced energy costs due to more efficient space heating and low power consumption.

- How to lay? Mounting a film underfloor heating with your own hands is quite realistic, just follow our installation instructions. There is no need to involve specialists for this.

- The use of infrared rays for heating the room does not lead to a decrease in air humidity, which has a positive effect on the health and well-being of people.

- Due to the small thickness of the film, it can be mounted under the facing materials of walls and ceilings, which makes it possible to even more efficiently heat the premises.

- Unlike other options, when laying a film coating, the film can be dismantled and re-laid, for example, when moving. Of course, its dismantling is possible only if floor coverings such as linoleum, laminate or carpet are used.

- The heating film has a long service life - up to 30 years or more.

Design

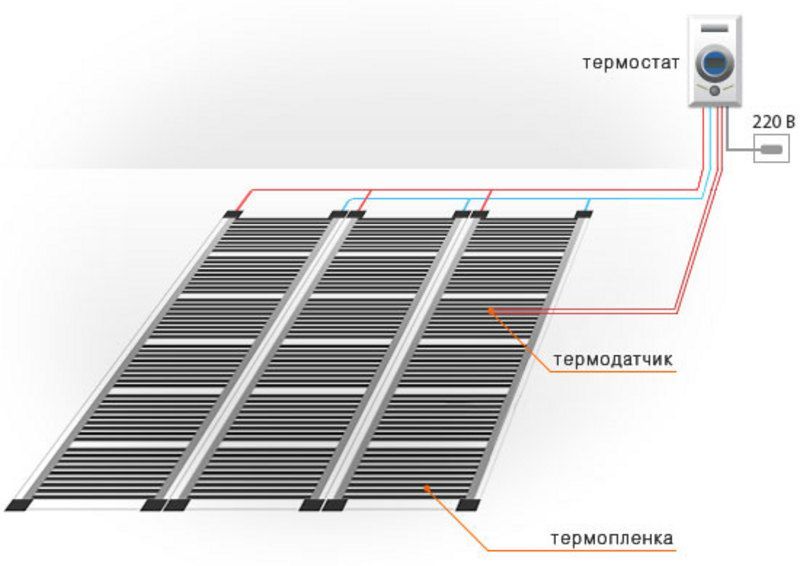

To install a film underfloor heating, you must use the following elements:

- Substrate.

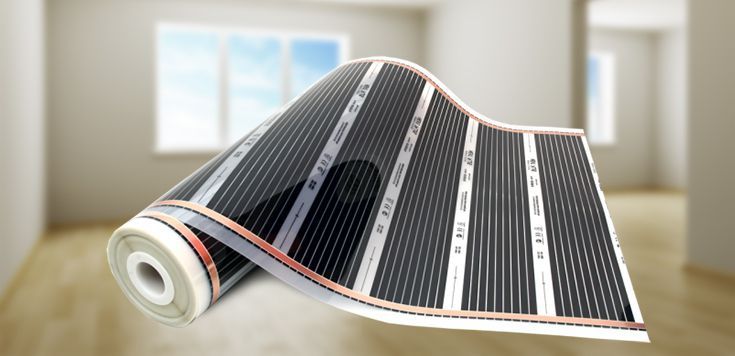

- The film, which consists of a polyester base. As a heating element, strips of carbon paste are used, interconnected by copper jumpers. Before starting work, make sure that the canvas can be cut to your size.

- A temperature sensor is used to determine the temperature of the floor surface.

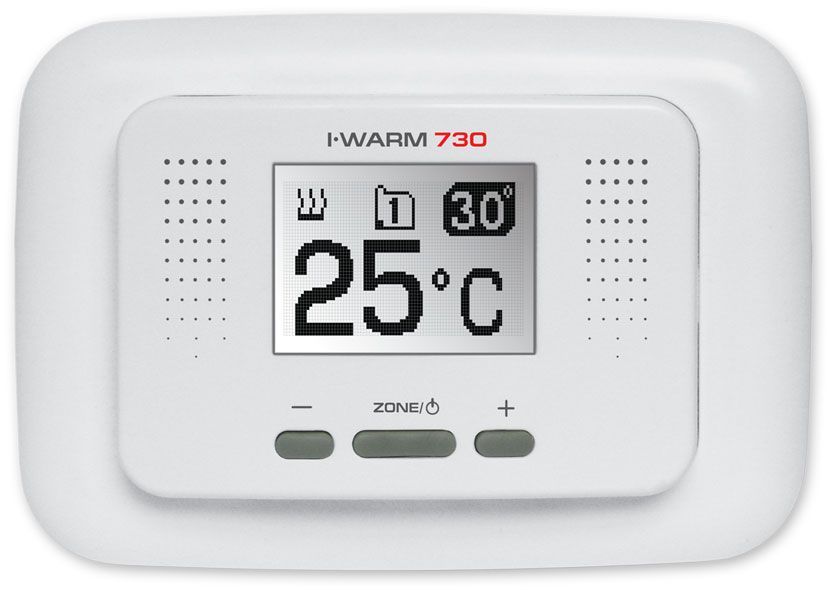

- The operation of the entire heating system is controlled by a thermostat.

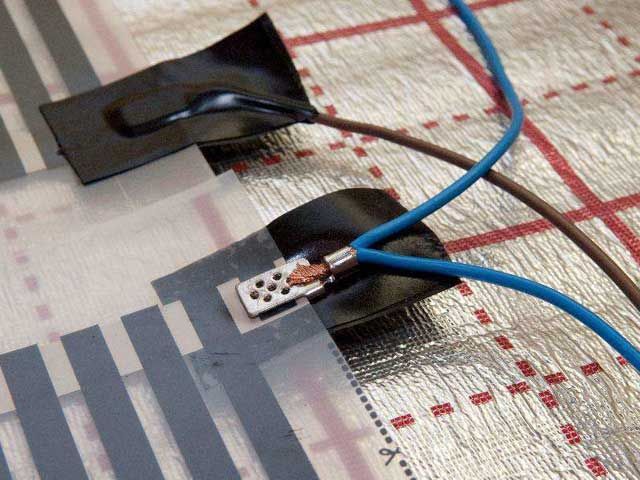

- For connection of electric wires to heating elements of a heat-insulated floor its delivery set includes contact plugs.

Important! Do not connect with soldering tin! Manufacturers prohibit soldering any wire section to the tape floor structure. When soldering is carried out, excessive heating of the conductor rail occurs, which can break the contact in the heating system and lead to its failure. The manufacturer insists on using crimp connectors.

- The electrical connections are insulated with bituminous insulators (see installation instructions).

The principle of operation of this design is extremely simple. When voltage is applied to the terminals of the thermal film, an electric current begins to flow through the carbon elements, which causes the appearance of infrared radiation. The scheme for connecting a film underfloor heating is also very simple: carbon film strips are laid on the base, connected with wires, and you can lay a fine floor covering. But more on that later.

Heating Film Specifications

The main technical characteristics of the film underfloor heating on the market include:

- Power consumed per linear meter of film. Currently, for most of its models, this figure lies in the range of 45-67 watts.

- Melting point (130 C). It should be noted that during operation the surface of the film is heated to a temperature not exceeding 55 C..

- The percentage of infrared radiation in the total frequency spectrum must be at least 95%.

- The length and width of one strip of thermal film (as a rule - 8 X 0.5 m).

- The film thickness is 0.4 mm. This makes it possible to lay a warm floor under any floor covering - laminate, parquet, ceramic tiles, as well as linoleum or carpet. The main thing is to strictly follow the installation instructions and film underfloor heating will delight you with comfort and warmth for many years.

Mounting order

Do-it-yourself installation of a film underfloor heating is carried out in the following order:

- Drawing up a plan for the placement of furniture and household appliances. This takes into account the area of \u200b\u200bthe room and the total power of the entire heating system.

- Marking the area of \u200b\u200bthe room in which it is planned to install heating elements.

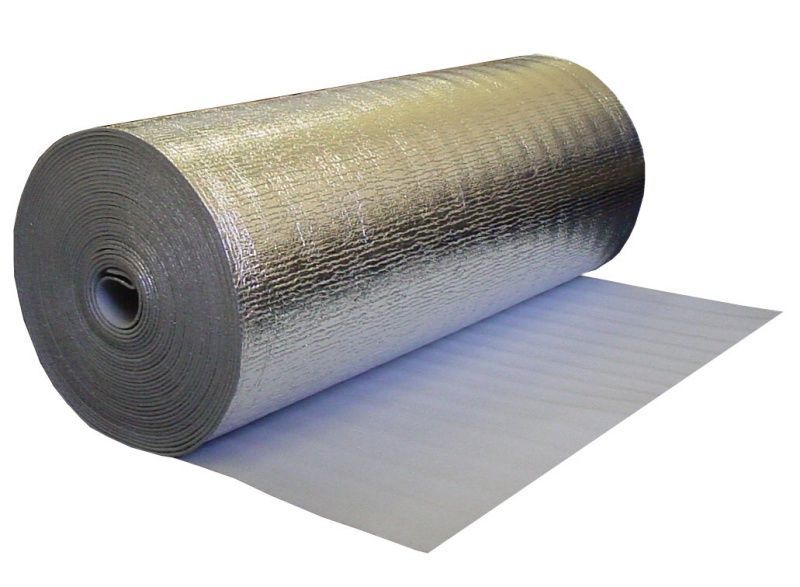

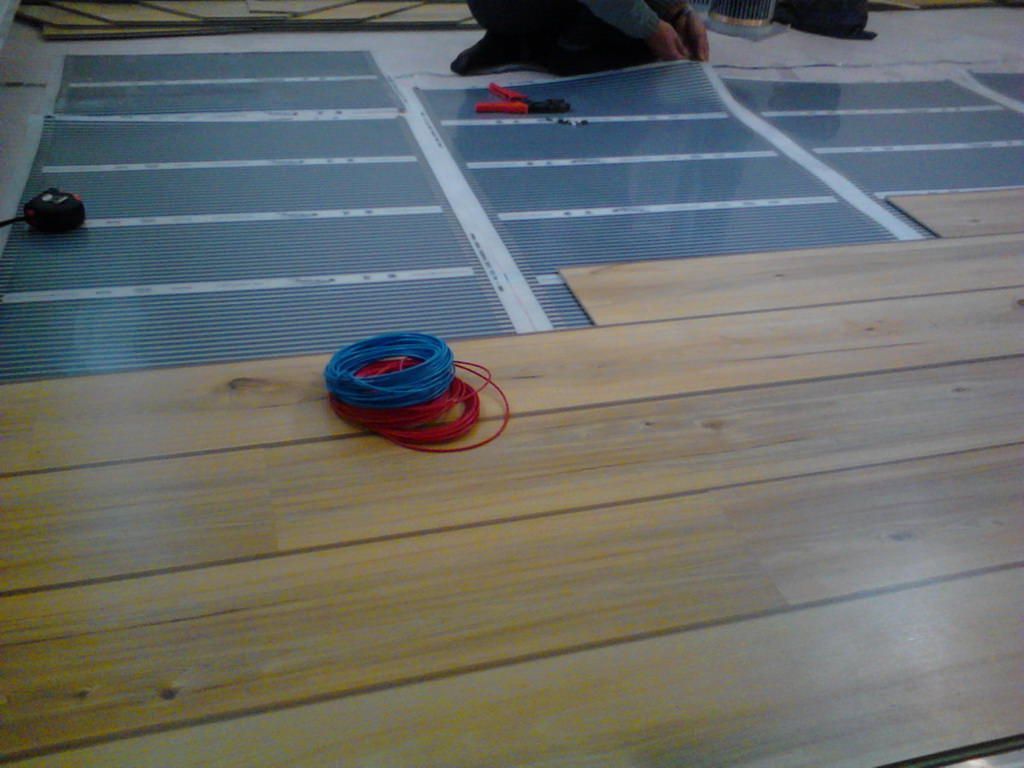

- Laying a heat-insulating substrate that prevents heat from being used to heat interfloor ceilings or a concrete floor base. Foamed polypropylene is used as a substrate, one side of which is covered with a reflective material. The underlay should only be laid on a level, dry and clean subfloor surface.

- In strict accordance with the previously drawn up plan, the installation of a warm film floor is carried out. Its strips are cut to the required size and stacked without overlaps; heat-resistant adhesive tape is used to fasten the strips together. Laying a warm floor closer than 10 cm to the walls is not allowed.

- Installing a thermostat. The installation height of this device is determined for reasons of ease of use, as well as the overall design of the room. The wires connecting the thermostat to the heating elements, as well as to the electrical network of the apartment, are placed in pre-prepared strobes. The installed thermal sensor must be equipped with a corrugation without fail, and be able to be easily replaced if necessary. How to connect the controller to the network and where to connect the temperature sensor and cables from the warm floor is indicated in the installation instructions for the device.

- Connecting the underfloor heating to electricity. For this, wires with a cross section of at least 1.5 mm are used.2, which are clamped with pliers in the terminals of the contacts. The warm floor is connected through the temperature sensor to the thermostat according to the diagram. The temperature sensor is installed between the heating film and the heat-insulating substrate near the location of the thermostat. All connecting wires are recessed into grooves cut in advance in the substrate.

- Functionality check.

- Laying a film layer of protective polyethylene over an infrared film.

- You can install flooring.

Attention! Before laying a warm floor, you should carefully plan the decor of the room. Its laying on the areas that will be occupied by furniture will lead to overheating of the carbon elements and their failure.

Wiring diagram

It should be noted that the connection of all elements of the underfloor heating is carried out in parallel. This is extremely important to ensure the reliable operation of the heating system as a whole, since if one of its elements fails, the rest will continue to work.

Attention! You can cut the film only in specially designed places. On each roll, they are indicated by a dotted line. Otherwise, the integrity of the electrical circuit may be violated.

Laying foil under various types of flooring

Film underfloor heating for laminate should be laid on a perfectly flat surface according to the installation instructions. The maximum allowable floor level difference cannot exceed 1 mm per 2 linear meters.

Important! Film underfloor heating under linoleum or carpet is laid using a plywood or fiberboard substrate between the infrared film and the floor covering.

Installation of a warm floor under ceramic tiles is carried out directly under a concrete screed.

To ensure normal space heating, the area of the warm floor should occupy at least 70% of the total area of the room. When using a warm floor as an additional space heating system, its area can occupy 30% of the room.

Disadvantages of film underfloor heating

The disadvantages of such space heating systems include:

- The complexity of repairing thermal elements in case of their failure. Repair is especially complicated if it is laid under ceramic tiles.

- The possibility of rearranging furniture and household appliances when changing the interior of the premises is significantly narrowed.

Thus, infrared film can be called one of the most successful design options for underfloor heating. With a relatively small power, it combines high efficiency, reliability, as well as ease of installation and operation.

Video instruction

Detailed instructions for installing a film underfloor heating with your own hands, video: