Natural lighting of apartments: panoramic windows, fully glazed facades of buildings - these are the trends in the development of modern architecture. To create a comfortable environment and save on utility bills, features such as energy efficiency and solar protection are important.

What is multifunctional glass?

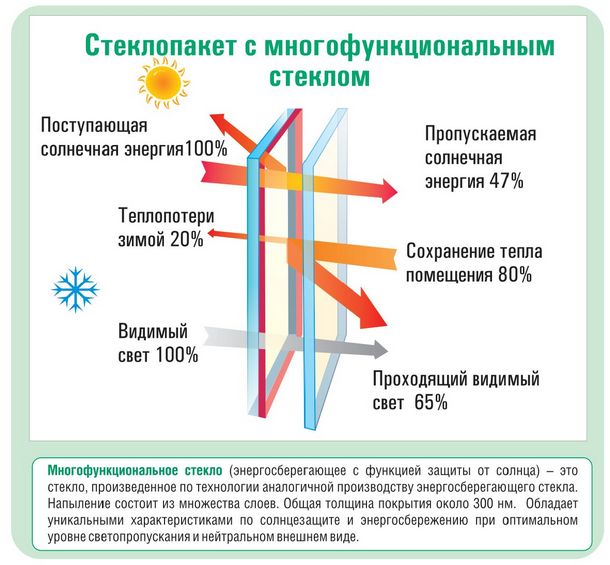

It is a material capable of selectively transmitting infrared heat waves. The multifunctional coating does not let in heat radiation from the street in summer, saving it from overheating, and accumulates heat radiated by heating devices indoors in winter. The material owes its qualities to the thinnest metal films formed by vacuum magnetron sputtering.

glass structure

The spraying is applied crosswise, forming five separate layers, different in purpose and composition:

- the degree of specularity, the shade of the surface, and the ability to transmit light depend on the first and last layer. Layers are formed from oxides and nitrides;

- in the middle - a functional layer of silver with chromium, reflecting heat waves;

- on both sides, the functional coating is protected from chemical and mechanical effects by protective layers. They are also involved in the absorption and reflection of infrared radiation.

For added protection, the coated side of the glass is placed inside the double-glazed window. Its tightness prevents chemical destruction of deposited metal films.

Multifunctional glasses are completed with double-glazed windows of all configurations, even single-chamber ones. Increased efficiency allows the use of less glass: the overall weight of the structure is reduced, and the hinges and fittings last longer.

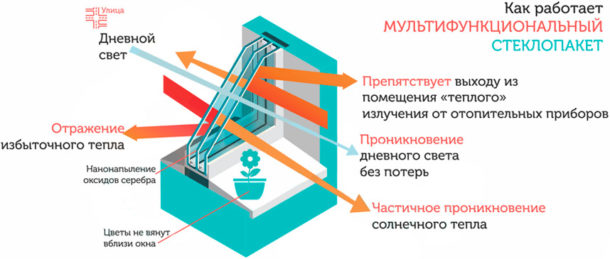

How does multifunctional glass work?

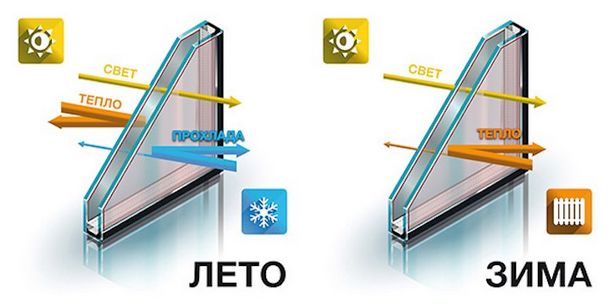

Metal spraying serves as a thermal mirror: it reflects thermal radiation, passing light waves. Thanks to this, the heat generated by the heating devices is retained in the room, and the heating from the sun's rays is reduced.

Types of energy-saving glasses

These are glasses with a transparent metal film on the surface, consisting of metal oxides. It serves as a kind of "mirror" that reflects infrared heat waves. There are three types of such coverage:

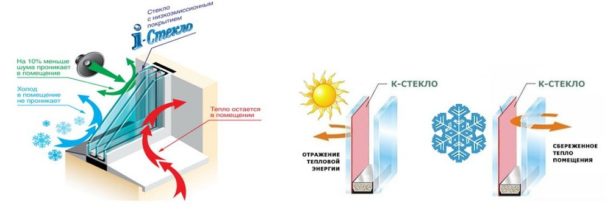

- Solid or K-glasses. They are used in double-glazed windows, as well as with single glazing. The metal coating is applied by pyrolysis at the manufacturing stage. In terms of heat-saving characteristics, it is inferior to other types, it is used mainly for glazing offices, industrial and administrative buildings.

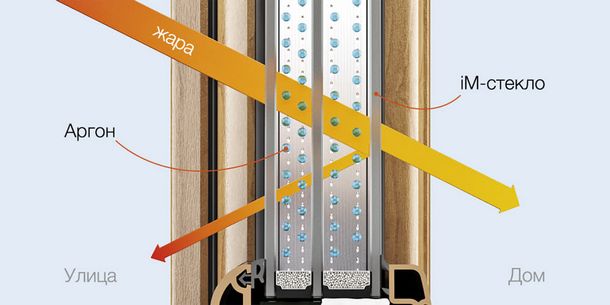

- I-glass with a soft coating is used exclusively in double-glazed windows. Their tightness protects the silver layer and the protective film of titanium oxide from destruction. An inert gas, most often argon, pumped into the glass unit increases the thermal insulation properties of the structure.

- Multifunctional or iM glasses. This soft-coated variety is distinguished by the number of metallic films applied: there are at least five of them versus two for ordinary i-glass. Accordingly, the characteristics of the material are improved: thermal insulation, as well as operational properties.

The difference between i-glass and multifunctional: is it worth overpaying?

The difference lies in the number of layers and the functions performed by them:

- The main task of i-glasses is thermal insulation, while the light transmission coefficient is quite high. The multifunctional coating also performs the role of sun protection. At the same time, the material has not only a dimming, but also a mirror effect.

- Multifunctional glass, unlike its counterpart with a soft coating, is more durable and resistant to mechanical stress. Less "capricious" in processing and operation: it is hardened, bent. This allows you to make frames of the desired configuration.

- The number of layers increases the thermal insulation characteristics of the material: protective layers are also involved in the reflection of infrared radiation. Therefore, other things being equal, multifunctional glass retains heat better than its “i-brother”.

- A wide choice of color scale of a surface, an opportunity to carry out its lamination.

Thus, the difference in price is more than compensated by the superiority of the multi-layer coating in comfort, durability and ease of use.

Difference between generations of multifunctional glasses

Since its inception, the multifunctional coating has been continuously improved. The second generation of this material with a double coating of silver has already appeared on the market. In this case, the layers are applied crosswise, which increases the strength and durability of the coating. Other features have also been improved:

- The heat transfer coefficient decreased from 1.1-1.3 W˟m2/K to 1.0.

- Light transmission improved from 66% to 75%, which is close to 88% for conventional glass.

- Specularity decreased from 26% to 13%.

Ability to transmit solar heat

The main "highlight" of multifunctional glass is sun protection. Incredibly, an air conditioner running in summer consumes twice as much electricity as it is spent on heating a room in winter!

The level of sun protection is characterized by the SF indicator - the percentage of transmitted solar energy. The lower this figure, the higher the level of protection from the sun.

Silver coating reflects up to 68% of the thermal energy of the sun's rays falling on it. The effect is comparable to lowered blinds or tightly closed curtains. But at the same time, the natural lighting of the room does not suffer, which is important for people and indoor plants.

To maintain the optimum temperature, it is enough to ventilate the room at night and close the windows tightly in the late morning, before the onset of heat. The coolness will remain in the room for the whole day. People and plants behind multifunctional glass are reliably protected from ultraviolet radiation, furniture and interior items will not fade under its influence.

Multifunctional windows in summer and winter

A multilayer silver coating protects the room from heat and cold, depending on the time of year:

- In winter, it does not release infrared heat waves generated by heating devices into the street. Up to 78% of heat is retained and heating costs are reduced.

- In the summer, it does not let the heat from the street into the room. More than 60% of the thermal component of the sun's rays is reflected, and the cost of air conditioning is reduced.

Where are glass with multifunctional coating used?

The scope of their application is residential, office and industrial premises. Where there is air conditioning in summer and heating in winter. The high price of the material will pay off within three years due to energy savings.

Particularly relevant is the installation of double-glazed windows with multifunctional glass for rooms where natural light and sun protection are required: building facades, living rooms and children's rooms, attics, winter gardens. They are indispensable in cafes, restaurants or shops with glazed facades, where it is impossible to use solar shades, blinds or other devices that protect from the sun.

Comparison of double-glazed windows with ordinary and multifunctional glass

According to the parameters that form the microclimate of the room, ordinary glass is almost two times inferior:

| Ordinary glass | iM-spraying | |

| Heat transfer resistance coefficient, ˚C˟m2/W (percentage of stored heat) | 0,45 | 0,73 |

| Emission factor | 0,83 | 0,13 |

| Share of transmitted solar energy | 72% | 40% |

| Light transmission | 76% | 66% |

| Noise isolation | 31 dB | 31 dB |

energy saving

The high cost of metal-coated glass more than pays off in the process of its use:

- Air conditioning costs in the summer are reduced by two to three times. In many residential areas, the air conditioner will not need to be turned on at all if you use a reasonable mode of natural ventilation of the rooms.

- Heating costs in winter are 50-60% less due to reduced heat loss through windows.

Advantages and disadvantages

Advantages:

- The most cost-effective type of glazing for the consumer.

- Excellent thermal insulation and sun protection.

- Good soundproofing.

- Lack of "cold" radiation, condensate and fogging of glasses.

- Preservation of natural light in the rooms.

- Resistance to mechanical damage, impact resistance, safety.

- A wide range of colors of glass, the possibility of lamination and tinting.

- Privacy of the room due to the mirror effect.

The main disadvantage is the high cost. And also it should be taken into account that in winter the sun-protection properties of glazing will slightly reduce the natural heating of the room by the rays of the sun. Double-glazed windows with multifunctional glasses are recommended to be installed in those rooms where air conditioning costs are significant.

Production of iM double-glazed windows

The main difference is in the glass making process. The sheets pass through the conveyor through the magnetron chambers, in which the deposition layers are formed. For example, Pilkington Suncool's second-generation Double Silver multiglass uses 22 such chambers.

Multifunctional glasses are installed in a double-glazed window by spraying inside, protecting the metal layer from chemical destruction by air, as well as from physical damage. Additional protection and thermal insulation is provided by an inert gas, most often argon, pumped between the panes.

IM-spraying is effective even in single-chamber double-glazed windows, but two-chamber ones are most widely used. Designs with three and four chambers retain heat better, but retain a lot of light - the room can become dark, uncomfortable. Therefore, they are installed in the northern regions.

According to the installation features, operating rules, a double-glazed window with multifunctional glass does not differ from a conventional one.

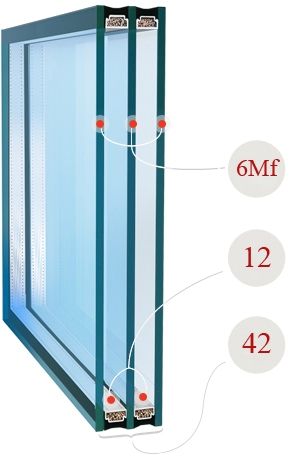

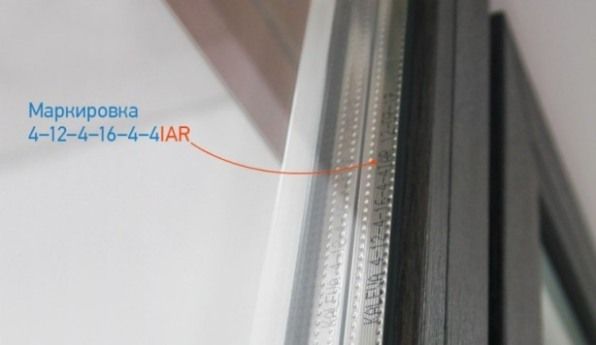

What is indicated in the iM-glass unit formula?

It's easy to decipher. Through hyphens, the thickness of the glasses and the width of the spacers in the double-glazed window are indicated. The formula starts with the outer glass and ends with the inner one.

For example: 4-14-4-14-4 - double-glazed window, glass thickness 4 mm, chamber thickness - 14 mm.

The brands of glass used in double-glazed windows are indicated by special symbols:

- M1 - ordinary glass. Some manufacturers indicate only the thickness, omitting this abbreviation. Therefore, if there are no letters after the numbers, ordinary transparent glass is meant.

- Mf - multifunctional. In a double-glazed window, it is always installed first from the outside. It may also be referred to by the letters "iM", brand names of manufacturers, or abbreviations. For example, SunCool, GuSolar, DS, Sunergy and others.

- And - energy efficient with a soft coating. Alternative designations: letter "i", names ClimaGard N, Top N+, ClimaGuard N.

- "s" - sunscreen. Or by brand names: SunGuard Solar, Stopsol Supersilver and others.

- A - self-cleaning (Active Clear).

Designations for filling chambers:

- There is no designation - air.

- Ar - argon is used.

- Xe - xenon.

- Kr is krypton.

- Sf is sulfur hexafluoride.

Designations of special elements of cameras:

- There is no designation - the usual aluminum frame.

- TP - thermal break, a special warm spacer.

- Brand designations of manufacturers.

Examples of decoding the double-glazed window formula:

- 4s-10Ar-4-10Ar-4i is a double-glazed window filled with argon, with one sun protection layer, one energy saving layer.

- 4Mf-12Ar-4M1 is a single-chamber double-glazed window with one multifunctional and one ordinary glass 4 mm thick, with a chamber 12 mm wide filled with argon.

- 4 DS Clear Diamond-10 TSS -4M1 -10 TSS -4M1 - double-glazed window, with self-cleaning multifunctional Double Silver glass 4 mm thick, two ordinary glasses of 4 mm each and two chambers, 12 mm wide, equipped with a proprietary TSS thermal break system.

Comparison of different double-glazed windows

| A type | Formula | Light transmission coefficient, % | Heat transfer resistance coefficient, С˟m2/W | Soundproofing, dB | UV transmission, % | Solar factor, SF |

| Ordinary single chamber | 4-16-4 | 82 | 0,32 | 24 | 53 | 78 |

| Conventional two-chamber | 4-10-4-10-4 | 72 | 0,47 | 36 | 43 | 71 |

| Energy-saving single-chamber | 4-16-4i | 76 | 0,57 | 30 | 35 | 65 |

| Energy-saving two-chamber | 4-10-4-10-4i | 68 | 0,72 | 36 | 25 | 59 |

| Multifunctional single chamber | 4Mf-16-4 | 71 | 0,6 | 30 | 13 | 38 |

| Multifunctional two-chamber | 4MF-10-4-10-4 | 68 | 0,75 | 38 | 11 | 35 |

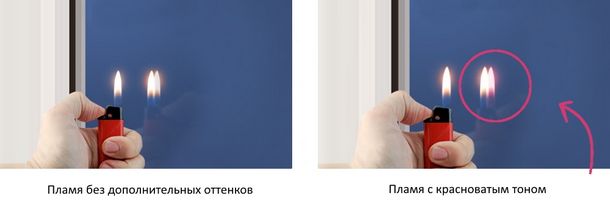

How to distinguish a double-glazed window with a multifunctional coating?

- The most reliable way is to label the double-glazed window. A special sticker is attached to the glass.

- By the presence of a mirror layer.

- In color - greenish or blue tint.

- The optical detector will indicate the metal deposition, focusing on the electrical resistance of the surface.

- A “folk” test with a lighter: if you bring a flame source to a metal-coated glass, then one of the reflections will differ in color. It will take on a reddish or crimson hue.

Durability and operation

The multifunctional coating is located inside the sealed double-glazed window and will last until it is depressurized. The approximate life of the window is 15-20 years, until the argon evaporates from the chamber. After that, the metal coating will oxidize and collapse.

With high-quality assembly, careful operation and periodic pumping of argon, the service life of an iM-glass unit is practically unlimited.

Unlike i-glass, multifunctional glass can be tempered and bent. It is more resistant to mechanical stress, less traumatic.

Coefficient U and its value

It is measured in watts per square meter multiplied by degrees Celsius. Assesses the thermal insulation qualities of individual parts of the house, including window openings. With the improvement of thermal insulation - decreases:

| U (W/(m2WITH) | |

| single glass | 5,6 |

| Ordinary double glazing | 2,8 |

| Single-chamber double-glazed window with iM-glasses | 1,1-1,4 |

GOST for multifunctional glass

The manufacture of glass with metal coating is controlled by GOST 31364-2014, which states:

- Glass parameters, dimensions, permissible deviations from them.

- Specifications: coefficients of absorption, reflection, light transmission, resistance to heat transfer; coating resistance, permissible surface and edge defects, energy saving class.

- Ways and methods of quality control.

- Requirements for marking, transportation and storage of sheets.

Effect on plants

Green spaces are comfortable behind iM-coated double-glazed windows:

- Overheating by direct sunlight is excluded.

- No cold radiation - plants will not freeze even on the windowsill.

- A sufficient amount of ultraviolet radiation and illumination for the development of plants and photosynthesis processes is provided by the high light transmission of glass.

Manufacturers of multifunctional glasses

- American company GUARDIAN - brands SunGuard, ClimaGuard. Founded in 1932, it has offices in 22 countries on five continents. The company has two factories in Russia - production in Rostov and Ryazan.

- The English company Pilkington - Suncool, Eclipse Advantage, Life Glass series. It has been operating since 1826. Representative offices in 130 countries. Marriage is extremely rare, each case is considered by management as a real emergency.

- Japanese manufacturer AGC - brands Sunergy, Stopray, Energy. There are two plants of the company in Russia (in the Moscow and Nizhny Novgorod regions). A network of distributors from Kaliningrad to Irkutsk.

Technical characteristics of some samples of products of three leading companies are presented in the table.

| Glass brand | Light transmission, % | Direct transmission of energy, % | Solar factor, % | Heat transfer coefficient, W/m2*TO |

| Guardian SunGuard SNX60 Ultra | 13 | 28 | 29 | 1 |

| Guardian ClimaGuard Solar | 67 | 43 | 43 | 1 |

| AGC Sunergy Gray | 34 | 30 | 42 | 4,1 |

| AGC Stopray Vision-60T | 59 | 33 | 37 | 1 |

| Pilkington Suncool 70/40 | 71 | 39 | 43 | 1,1 |

| Pilkington Eclipse Advantage Clear | 61 | 50 | 55 | 1,6 |

- The Swiss company Glas Trösch - Comfort SILVERSTAR ZERO glass. Founded in 1905, it has more than 60 enterprises in Western and Eastern Europe. The strictest quality control.

- Russian "Salavatsteklo" - brand MUKTICOMFORT. The plant was founded in 1962, the largest glass manufacturer in Russia. Representations in 20 countries of the world.

There is a huge variety of models of multifunctional glass, differing in their properties and qualities.In order for new windows to serve as long and efficiently as possible, the choice must be taken as carefully as possible. Compare the characteristics of models from leading manufacturers, identify their advantages and choose the appropriate option for your conditions.