The window sill is an important element of the interior. It completes the window opening, serves as a shelf and even a seat. Consider the best window sills for plastic windows, the rules for choosing them.

Often the window sill bears the main decorative load. Especially if the room is small or there are lush flowers, books, vases, photographs on the window sill.

Appointment of window sills

To choose a good window sill, you need to take into account its properties and technical characteristics. This element of the interior performs several useful functions at once:

- Protective. A properly installed window sill provides additional protection against the penetration of cold and moisture into the room.

- Functional. In small rooms (kitchen, bathroom, bedroom), this element can serve as a table or work surface. In the office on the window sill there are often books, folders with documents. And in living rooms, it is sometimes used as a bench.

- Binder. The product can complement the space of the table, serve as a transitional element between pieces of furniture.

- Decorative. With a good choice of colors and materials, the window sill becomes a decoration of the room.

Types of window sills

Window sills are:

- plastic;

- wooden;

- composite;

- from natural or artificial stone.

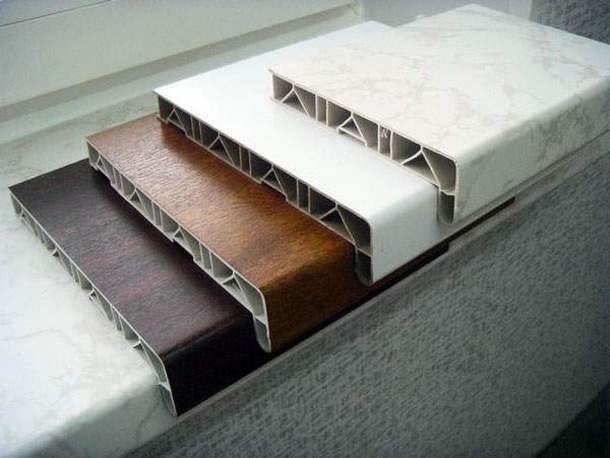

Plastic

When replacing wooden windows with PVC frames with double glazing owners often choose a plastic window sill. When you weigh all the pros and cons, this seems like a very reasonable choice.

| Advantages | Flaws |

| Identical technical characteristics with the window material (chemical composition, coefficients of expansion and resistance to temperature influences).

Environmental friendliness. High-quality models do not contain formaldehyde, lead stabilizers, which makes them safe for humans and completely recyclable. Same care: one PVC cleaner can be used during cleaning. Light weight. Price range: 80–540 rubles/p. m with a web thickness of 100 mm. Acrylic coating makes the window sill more resistant to heat and minor damage. Strength provided by a system of internal ribs. Aesthetics: harmonious combination with the material of the double-glazed window. Laminate coating can imitate wood or stone. Single service life (30–50 years)

|

Restrictions on the ability to withstand the load.

The absence of an acrylic coating impairs high temperature resistance. Risk of deformation under mechanical or thermal stress. Cheap models contain formaldehyde, the fumes of which are harmful to health. Matte models have rough surfaces that accumulate dirt and dust |

Experts advise choosing models of plastic window sills with a price of 250 rubles / p. m with a web thickness of 150 mm. The technology of their production excludes the addition of additives harmful to humans.

Parameters affecting the price:

- The cost of the pigment included in the product. Titanium oxide is used for the production of expensive models. This pigment maintains the whiteness of the window sill for 10 years. Cheaper models easily absorb dust, acquiring a yellowish tint, colored ones fade over time, creating a unkempt effect.

- Coating quality. Brands Moller, Danke use compounds that prevent mechanical damage (scratches, abrasion) and deformation when exposed to high temperatures.

- Danke

- Moeller

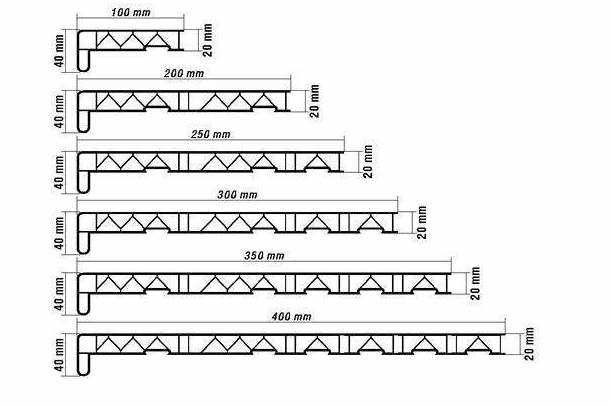

A standard PVC sheet for the manufacture of a window sill has the following dimensions:

- Length - 4050–6000 mm.

- Width - 100-600 mm with a step of 50 mm. A product with dimensions of 600-1000 mm with a step of 100 mm is considered wide.

- Thickness - 18–22 mm. With an increase in this parameter, strength and resistance to mechanical stress increase.

Cloths of this length are purchased by construction companies and firms. For specific projects, installers independently cut window sills of the required dimensions. It is possible to produce PVC sheets according to individual orders for old-plan houses or country cottages.

Composite (MDF, chipboard)

Well-pressed chipboards form the basis of chipboard window sills. As a rule, they are covered with a thick laminating film. It gives resistance to chemical agents, temperature and mechanical influences. Any colors and textures, inserts, inserts can be used.

Fibreboards, firmly bonded with safer and more environmentally friendly compounds (lignin, paraffin), form the basis of MDF window sills. They are 2 times more resistant to mechanical stress than chipboard products. In addition, MDF boards are moisture resistant, they can be installed in the bathroom.

The surface is laminated or covered with a thin natural wood veneer, which makes them look like wood.

Window sills of the German brand Verzalit have excellent characteristics (long service life, moisture resistance, strength, resistance to household chemicals). They are made from wood shavings pressed under high pressure with polymer resins.

Wooden

Beautiful window sills made of a solid array of dried wood testify to the good taste of the owner. They are made from:

- pines, larches (price - 2500–2800 rubles / m²);

- oak, ash, beech (price - from 4500 rubles / m² with a web thickness of 40 mm);

- elite breeds (ebony, mahogany).

A solid array can be replaced by separate bars, tightly glued together.

But such products need regular maintenance. Before the manufacture of window sills, the array is impregnated with an antiseptic to prevent destruction. The texture and color of natural wood are preserved thanks to a layer of oil (mastic, varnish). And this surface layer needs to be updated (once every 1–1.5 years).

On sale you can find wooden window sills with the following dimensions:

- The length of the canvas is from 15 cm, the width is up to 1 m.

- The length of the canvas is from 70 cm, the width is up to 3 m.

Made of artificial stone

Very durable, resistant to all types of influences (mechanical, chemical, biological), have absolute moisture resistance, fire resistance. They are based on mineral fillers and polymer resins.

Dyes create a rich color range, you can give the product any shape, which opens up scope for design solutions. On such a hard surface, you can securely fix / install any device (fan, vise). And the scratches that appear are easily eliminated by grinding.

There are also disadvantages. Only specialists can mount products. For reliable fastening of such models, brackets that can withstand heavy loads are required. And the high price (3,500–8,000 rubles/p. m.) does not allow classifying the products in the budget segment of products.

There are 2 options for window sills made of artificial stone:

- Made from acrylic composite. The finely dispersed filler of marble, granite or quartz chips is compacted and bound with an acrylic mixture. In the manufacture of hardeners, pigments and other substances are added to the bulk. Additives increase the hardness and toughness of the material. New properties reduce the chance of chipping.

- From quartz stone. Quartz chips, which make up 90–95% of the mass of the product, are bound with polyester resins. The technological process involves the addition of mineral coloring pigments (iron compounds, red lead, ocher). Such a window sill is heavier and denser, but the risk of chipping increases.

From natural stone

Granite, marble or onyx are used for natural stone window sills. Such plates are well polished, have a beautiful texture and intricate pattern. But due to difficulties in production (possible internal voids in the stone), they are not cheap (up to 4,000 rubles / item).m with a web thickness of 20–30 mm).

Window sills made of natural stone are not resistant to surface damage: they are easily scratched. And the deep scratches that stand out on the stone are extremely difficult to remove. It will take 2-4 people to transport and install the stove.

Which window sills are better: glossy or matte?

When choosing between a glossy or matte plastic finish, you need to remember the main features of these surfaces. The regularity of cleaning and the general appearance will depend on them.

- Texture. Shiny glossy surfaces reflect light well, creating the illusion of an intense light flux and increasing the illumination of the apartment.

- Resistance to aggressive influences. Matte surfaces turn yellow from prolonged exposure to direct sunlight, the chemical agents of detergents destroy the stove over time.

- Aesthetics. Any contamination or mechanical damage (scratch) is clearly visible on the glossy finish. The rough matte surface lasts a long time without cleaning.

- Care: wipe the glossy window sill with a damp soft cloth. For matte surfaces, you can not do without detergents.

- Compatibility with slopes. If the slopes are made of glossy plastic sandwich panels, the same glossy window sill will look good with them.

- Glossy marbled

- Glossy wood effect

- Bright glossy

Window sill and condensation on the windows: where is the connection?

Dense wooden window sills accumulate moisture and, even if all installation rules are followed, can provoke condensation. But the stone ones will play the role of a kind of heater: they will warm up themselves and contribute to the uniform heating of the window opening.

Condensation can form on windows if the window sill is too wide. Avoid the effect of "weeping" windows can be done in two ways:

- The window sill should not overlap more than half the width of the radiator located under the window. Warm air currents will be able to rise up to the glass without obstacles.

- With a large width of the window sill, gratings cut into it will become the exit, which will direct warm air flows to the double-glazed window.