The place of radiators in the heating system

The use of radiators in residential heating plays a key role today. Not all residential properties, especially apartments in multi-storey buildings, can be converted to underfloor heating. Therefore, the main work on heating the internal living spaces is performed by radiators or the good old and well-known to us, batteries.

Radiators transfer thermal energy from the coolant to the surrounding space. Heat transfer is carried out due to the large heating surface of the heating device. In modern models, there are a number of technical improvements, thanks to which it has become possible to connect in a variety of ways and with any wiring scheme.

in old cast-iron and steel batteries there was only one upper and one lower branch pipe, through which hot water is supplied and the return flow is carried out.

In modern models, in addition to the main supply and output pipes, there are built-in air vents. This battery design has radically changed the quality of the functionality of the heating system. If there are air pockets in the heating devices, it is enough to open the bleed valve and bleed the air.

In many respects, thanks to modern models of heating batteries, it has become possible to choose the most convenient connection scheme, to install heating devices in those places in the living room in which they are most effective. The quality of the heating water circuit depends on the correct piping. The process is necessary if you are using a pipeline made of polypropylene pipes.

Important! In the presence of metal risers, the strapping is made from other consumables. It can be metal copper pipes or metal-plastic

The use of polypropylene pipes in this case is strictly prohibited.

The reason for the incompatibility of metal pipes with polypropylene products is the presence of a threaded connection. Given the fact that propylene pipes have a high coefficient of thermal expansion, when a hot coolant is supplied, the threaded connection will lose its tightness and stability. Therefore, if you want to connect a heating radiator made of polypropylene pipes, try to use fittings, adapters and couplings made of similar materials.

take into account the difference in diameters of pipes made of different materials

Radiator connection diagrams

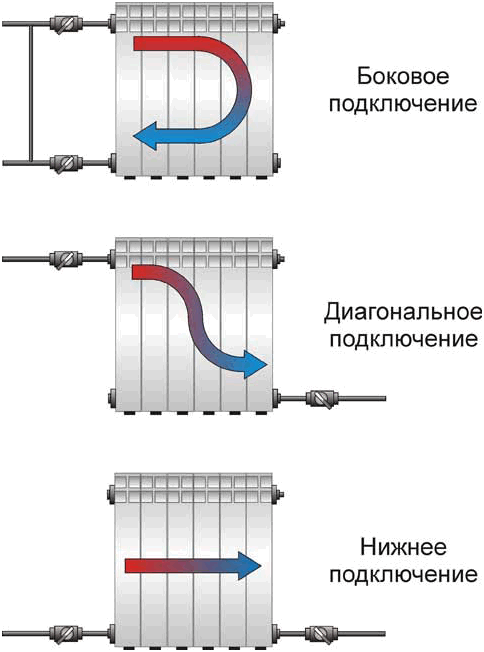

How well the radiators will heat up depends on how the coolant is supplied to them. There are more and less effective options.

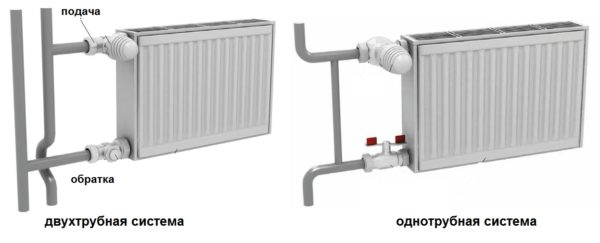

Radiators with bottom connection

All heating radiators have two types of connection - side and bottom. There can be no discrepancies with the lower connection. There are only two pipes - inlet and outlet. Accordingly, on the one hand, a coolant is supplied to the radiator, on the other hand it is discharged.

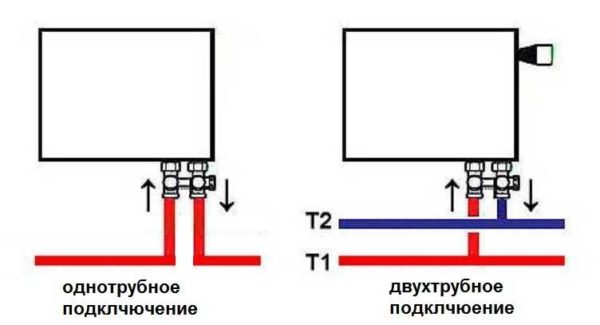

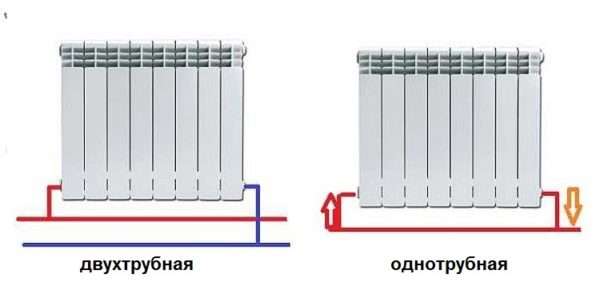

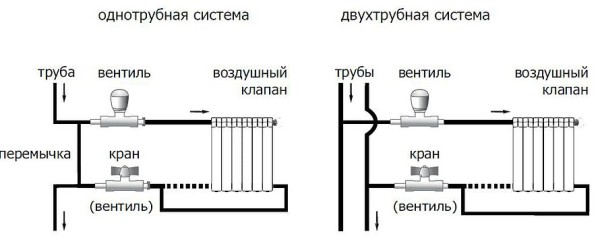

Lower connection of heating radiators with one-pipe and two-pipe heating systems

Specifically, where to connect the supply, and where the return is written in the installation instructions, which must be available.

Radiators with side connection

With a lateral connection, there are much more options: here the supply and return pipelines can be connected to two pipes, respectively, there are four options.

Option number 1. Diagonal connection

Such a connection of heating radiators is considered the most effective, it is taken as a standard, and this is how manufacturers test their heaters and the data in the passport for thermal power - for such an eyeliner.All other connection types are less efficient at dissipating heat.

Diagonal connection diagram for heating radiators with a two-pipe and one-pipe system

This is because when the batteries are connected diagonally, the hot coolant is supplied to the upper inlet on one side, passes through the entire radiator and exits from the opposite, lower side.

Option number 2. Unilateral

As the name implies, pipelines are connected on one side - supply from above, return - from below. This option is convenient when the riser passes to the side of the heater, which is often the case in apartments, because this type of connection usually prevails. When the coolant is supplied from below, such a scheme is used infrequently - it is not very convenient to arrange pipes.

Lateral connection for two-pipe and one-pipe systems

With this connection of radiators, the heating efficiency is only slightly lower - by 2%. But this is only if there are few sections in the radiators - no more than 10. With a longer battery, its farthest edge will not heat up well or even remain cold. In panel radiators, to solve the problem, flow extensions are installed - tubes that bring the coolant a little further than the middle. The same devices can be installed in aluminum or bimetallic radiators, while improving heat transfer.

Option number 3. Bottom or saddle connection

Of all the options, the saddle connection of heating radiators is the most inefficient. Losses are approximately 12-14%. But this option is the most inconspicuous - the pipes are usually laid on the floor or under it, and this method is the most optimal in terms of aesthetics. And so that the losses do not affect the temperature in the room, you can take a radiator a little more powerful than required.

Saddle connection of heating radiators

In systems with natural circulation, this type of connection should not be done, but if there is a pump, it works well. In some cases, even worse than the side. Just at some speed of movement of the coolant, vortex flows arise, the entire surface heats up, and heat transfer increases. These phenomena have not yet been fully studied, therefore it is still impossible to predict the behavior of the coolant.

Heating in the house

At the first stage, you should decide on the types of radiators and options for their connection, since buildings should be prepared in advance for the selected type of heating. A modern space heating system includes several components.

These include:

Do-it-yourself polypropylene heating wiring without a soldering iron

You can find their different options in large numbers in our markets.

The general instructions for installing batteries look like this:

- first choose a place to place them;

- bring pipes to them;

- connect them together;

- make a test run, and if everything is in order, turn on the heating at full power.

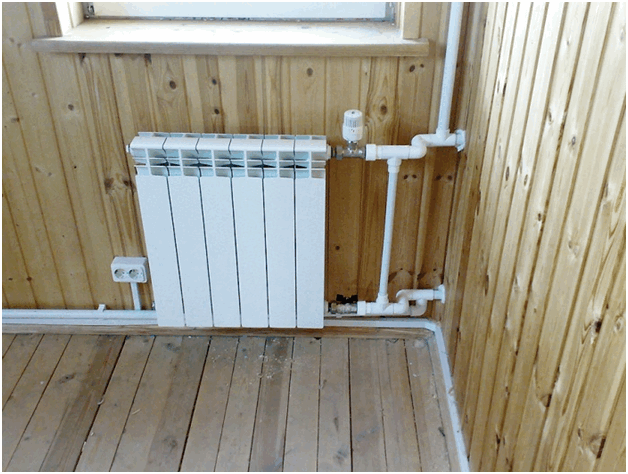

How to install heating radiators with polypropylene pipes with a jumper for quick shutdown

Tying with polypropylene pipes

Piping of radiators can be carried out using a variety of pipes, but experts recommend using polypropylene. Ball valves for strapping are also bought in polypropylene, they can be straight and angled, this option is the simplest and most inexpensive. Brass fittings are more expensive, and installation is more difficult.

Polypropylene strapping is performed as follows:

- the coupling with the union nut is inserted into the multiflex, which is easily connected to any outlet;

- the pipes themselves are attached to the walls at a convenient height, they should not fit snugly against the surface, it is better to leave a gap of 2-3 cm. The pipes are fixed with special brackets, which are fixed to the wall with nails or self-tapping screws.

Polypropylene strapping to radiators can also be carried out when pipes are laid into the wall, in which case they come to the surface only at the connection points.

Piping of radiators can be carried out using a variety of pipes, but experts recommend using polypropylene.

Fasteners for batteries can be very different, most often it is a pin connection, which is fixed on the wall surface. Corner brackets can also be used, which also allow you to hang radiators at the required height. For panel batteries, fasteners are supplied in the kit, for sectional batteries, you need to buy separately. Usually, two brackets or pins are enough for one section.

The connection of cranes is carried out in this way:

- the crane is disassembled, a fitting and a union nut are screwed into the radiator;

- the nut is tightly tightened with a special wrench.

As you can see, this process is extremely simple. To perform such work, you only need to purchase a special plumbing key for American women, without which it is unlikely that you can simply install a tap.

The following materials and tools are required for battery installation and piping:

- a set of special keys;

- seals for threaded connections;

- tow and thread paste;

- thread for carving.

Features of connecting radiators

Installation of heating differs in some features:

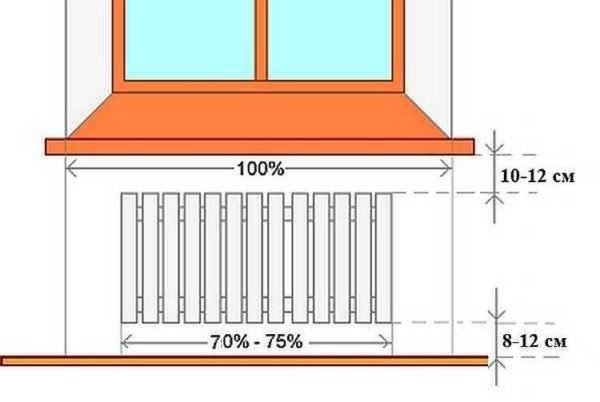

- It is necessary to observe the distance from the radiator to the window sill of 100 mm. If the gap between the batteries and the bottom of the window sill is different, then the heat flow is disturbed, the effect of the heating system will be low.

- From the floor surface to the battery, the distance should be 120-150 mm, otherwise a sharp temperature drop occurs.

- In order for the heat transfer of the equipment to be correct, the distance from the wall must be at least 20 mm.

At the same time, we take into account that the installation method and the efficiency of heating radiators are greatly influenced by the installation method: under the window sill in the open form, the efficiency of the heating system is maximum - 96-97%, in a niche in the open form - up to 93%, in a partially closed form - 88-93 %, fully closed - 75-80%.

The heating radiator can be installed using a variety of methods, its piping is carried out with metal, polyethylene, polypropylene pipes

It is important during installation to correctly position not only the pipes, but also the batteries themselves, to connect in accordance with all recommendations and standards. In this case, the heating system will work very efficiently and will not require repairs.

Share this helpful article:

Types of heating systems

The amount of heat that a heating radiator will radiate depends not least on the type of heating system and the type of connection chosen. To choose the best option, you must first understand what kind of heating systems are and how they differ.

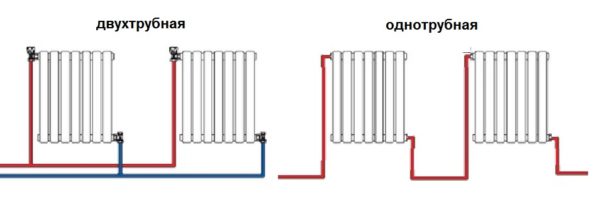

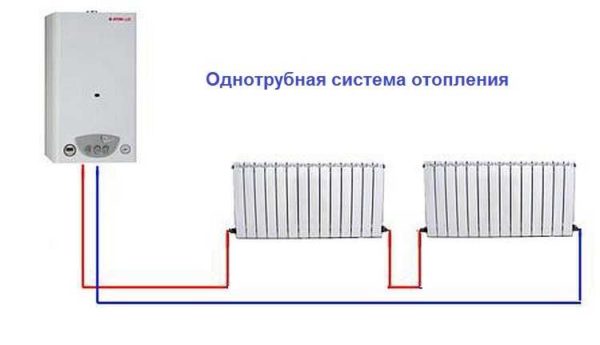

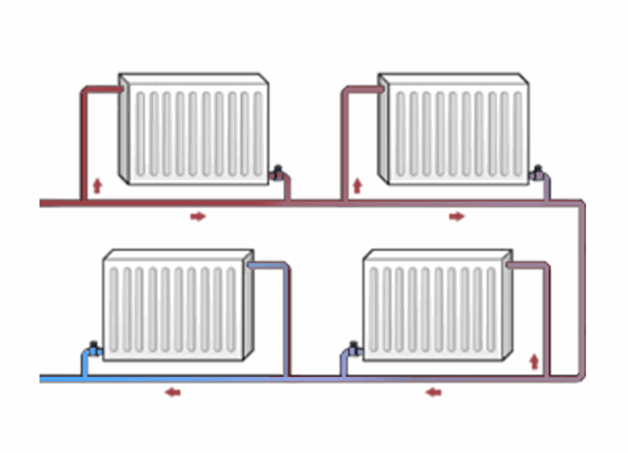

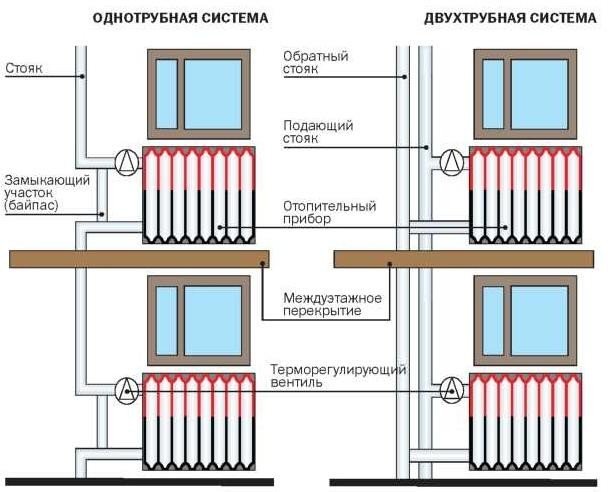

Single pipe

A single-pipe heating system is the most economical option in terms of installation costs. Therefore, it is this type of wiring that is preferred in multi-storey buildings, although in private such a system is far from uncommon. With this scheme, the radiators are connected in series to the main and the coolant first passes through one heating part, then enters the second one, and so on. The output of the last radiator is connected to the input of the heating boiler or to the riser in high-rise buildings.

Example of a one-pipe system

The disadvantage of this wiring method is the impossibility of adjusting the heat transfer of radiators. By installing a regulator on any of the radiators, you will regulate the rest of the system. The second significant drawback is the different temperature of the coolant on different radiators. Those that are closer to the boiler heat up very well, those that are further away become colder. This is a consequence of the series connection of heating radiators.

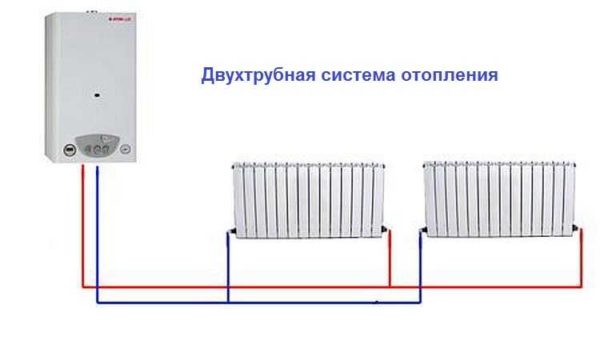

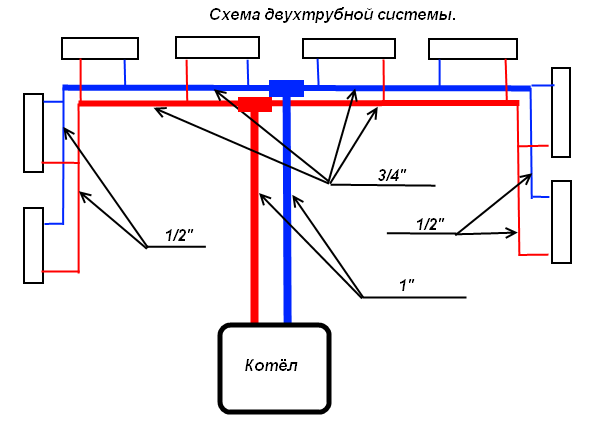

Two-pipe wiring

A two-pipe heating system is distinguished by the fact that it has two pipelines - supply and return.Each radiator is connected to both, that is, it turns out that all radiators are connected to the system in parallel. This is good in that a coolant of the same temperature enters the inlet of each of them. The second positive point is that you can install a thermostat on each of the radiators and use it to change the amount of heat that it emits.

The disadvantage of such a system is that the number of pipes when distributing the system is almost twice as large. But the system can be easily balanced.

What can be the binding of polypropylene pipes

The piping for a home heating system can be very different. The thing is that the consumer is always trying to reduce the amount of consumables, while trying to equip radiators in all heated rooms.

It should be said right away that these are relics of the past. Unlike expensive metal pipes, polypropylene consumables are much cheaper and easier to install. therefore, saving on the length of the pipeline is not worth it. Choose the type of strapping that will bring the most benefit in your case. The only factors that may influence the choice of type of strapping are the following factors:

- what heating scheme is used (one-pipe system or two-pipe);

- what type of radiator connection you have chosen (diagonal, side or bottom).

As a rule, when using any heating scheme: one-pipe or two-pipe, any type of connection for heating radiators can be used.

according to experts, the laying of the pipeline is necessary to minimize the number of bends. A smooth highway remains resistant to hydrodynamic loads. The pipeline will reduce the number of zones in which air can accumulate.

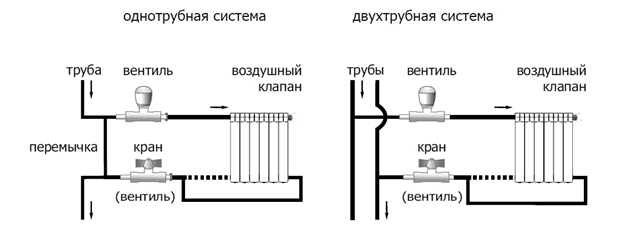

For tying a single-circuit and double-circuit heating system using polypropylene pipes, there are some peculiarities.

- usually in such a system a serial connection of radiators is used;

- a bypass is always mounted in front of the battery, connecting the supply pipe and the return pipe. During normal operation of the heating system, the bypass is not activated. During preventive maintenance or in the event of an emergency, the water supply to the radiator is stopped. The coolant circulates freely through the bypass.

- both parallel and series connection of batteries is used;

- both radiator pipes are connected to different pipes. The upper one is connected to the supply pipe, the lower branch pipe is connected to the return. Usually in two pipe systems there is a parallel connection of radiators, so the installation of bypasses is not required.

Tying polypropylene pipes with radiators is carried out in two ways: by soldering and using fittings. Installation of radiators and their connection is carried out using a soldering iron and plumbing keys for an American.

Advantages and disadvantages of one-pipe and two-pipe heating systems

The main difference between the two heating schemes is that the two-pipe connection system is more efficient in operation due to the parallel arrangement of two pipes, one of which supplies the heated coolant to the radiator, and the other drains the cooled liquid.

The scheme of a single-pipe system is a series-type wiring, in connection with which the first connected radiator receives the maximum amount of thermal energy, and each subsequent one heats up less and less.

However, efficiency is an important, but not the only criterion that you need to rely on when deciding to choose one or another scheme. Consider all the pros and cons of both options.

Single pipe heating system

- ease of design and installation;

- savings in materials due to the installation of only one line;

- natural circulation of the coolant, possible due to high pressure.

- complex calculation of thermal and hydraulic parameters of the network;

- the difficulty of eliminating errors made in the design;

- all elements of the network are interdependent; if one section of the network fails, the entire circuit stops working;

- the number of radiators on one riser is limited;

- adjustment of the flow of coolant into a separate battery is impossible;

- high coefficient of heat loss.

Two-pipe heating system

- the ability to install a thermostat on each radiator;

- independence of the network elements;

- the possibility of inserting additional batteries into an already assembled line;

- ease of elimination of errors made at the design stage;

- to increase the volume of coolant in heating devices, it is not necessary to add additional sections;

- no restrictions on the length of the contour along the length;

- the coolant with the desired temperature is supplied throughout the entire ring of the pipeline, regardless of the heating parameters.

- complex connection scheme compared to single-pipe;

- higher consumption of materials;

- installation requires a lot of time and labor.

Thus, a two-pipe heating system is preferable in all respects. Why do the owners of apartments and houses refuse it in favor of a one-pipe scheme? Most likely, this is due to the high cost of the installation and the high consumption of materials necessary for laying two highways at once. However, one should take into account the fact that a two-pipe system involves the use of pipes of a smaller diameter, which are cheaper, so the total cost of arranging a two-pipe option will not be much more than a single-pipe one.

The owners of apartments in new buildings are lucky: in new houses, in contrast to residential buildings of Soviet development, a more efficient two-pipe heating system is increasingly being used.

Choosing a place and method of installing a radiator

The options for connecting heating radiators depend on the general heating scheme in the house, the design features of the heaters and the method of laying pipes. The following methods of connecting heating radiators are common:

- Lateral (unilateral). The inlet and outlet pipes are connected on the same side, while the supply is located at the top. The standard method for multi-storey buildings, when the supply is from the riser pipe. In terms of efficiency, this method is not inferior to the diagonal one.

- Lower. In this way, bimetallic radiators with a bottom connection or a steel radiator with a bottom connection are connected. The supply and return pipes are connected from below on the left or right side of the device and connected through the lower radiator connection unit with union nuts and shut-off valves. The union nut is screwed onto the lower radiator pipe. The advantage of this method is the location of the main pipes hidden in the floor, and heating radiators with a bottom connection harmoniously fit into the interior and can be installed in narrow niches.

- Diagonal. The coolant enters through the upper inlet, and the return is connected from the opposite side to the lower outlet. The optimal type of connection that provides uniform heating of the entire battery area. In this way, correctly connect the heating battery, the length of which exceeds 1 meter. Heat loss does not exceed 2%.

- Saddle. The supply and return are connected to the bottom holes located on opposite sides. It is used mainly in single-pipe systems when no other method is possible. Heat losses as a result of poor circulation of the coolant in the upper part of the device reach 15%.

https://youtube.com/watch?v=olrD9qxCAhM

WATCH VIDEO

When choosing a place for installation, several factors are taken into account to ensure the correct operation of heating devices. Installation is carried out in the places least protected from the penetration of cold air, under window openings. It is recommended to install a battery under each window. The minimum distance from the wall is 3-5 cm, from the floor and window sill - 10-15 cm.With smaller gaps, convection worsens and battery power drops.

Typical mistakes when choosing an installation location:

- Space for installation of control valves is not taken into account.

- A small distance to the floor and window sill prevents proper air circulation, as a result of which heat transfer decreases and the room does not warm up to the set temperature.

- Instead of several batteries located under each window and creating a thermal curtain, one long radiator is chosen.

- Installation of decorative grilles, panels that prevent the normal spread of heat.

Coolant circulation methods

The circulation of the coolant through pipelines occurs in a natural or forced way. The natural (gravitational) method does not involve the use of additional equipment. The coolant moves due to a change in the characteristics of the liquid as a result of heating. The hot coolant entering the battery, cooling down, acquires a greater density and mass, after which it falls down, and a hotter coolant enters in its place. Cold water from the return flows by gravity into the boiler and displaces the already heated liquid. For normal operation, the pipeline is installed at a slope of at least 0.5 cm per linear meter.

Scheme of coolant circulation in the system using pumping equipment

For forced supply of coolant, the installation of one or more circulation pumps is mandatory. The pump is installed on the return pipe in front of the boiler. The operation of heating in this case depends on the electrical supply, however, it has significant advantages:

- The use of pipes of small diameter is allowed.

- The main is installed in any position, vertically or horizontally.

- Less coolant required.

Video instruction with advice from a specialist

Hello! I have such problems with heat: 1) In the corner apartment in the children's room, there are two supply and return pipes. On the supply side, the fire pipe on the return line is several times colder. Radiators connected to the return is correct or not. Can I connect more radiators to the supply and run them over a cold street wall? 2) The toilet has no radiator and pipe at all, although the wall is also cold (street). 3) In the bedroom there is only a pipe (return) a radiator battery is connected to it, and through the wall in our kitchen there is a supply. Is it possible somehow to combine two rooms and install in two rooms with pipe-supply?

In our 9-storey building, the heating system is built like this: one pipe on the supply goes from bottom to top. Radiators are connected to it on all floors in parallel with jumpers. The coolant enters the radiator from below, and the upper outlet from the radiator is connected to the same pipe. Only part of the radiator warms up. How to connect the radiator correctly so that it warms up completely?

Good afternoon. The nine-story building has a two-pipe heating system in every room. In one room, the heating supply pipe goes up past all the radiators. Accordingly, all radiators from the ninth floor are connected to the return line, and on the second floor my battery is generally almost cold. Tell me if this connection is natural, or is it just a locksmith's mistake?

Hello! Can you please tell me how correct your data is in determining an effective method for connecting a radiator? And what sources can you refer to to obtain the above data? Thank you all in advance!

Embed the valve into the jumper (which is not entirely legal if there are valves on the radiator) or reconnect the radiator in a diagonal pattern. On propylene - it is elementary and fast, compact and quite aesthetically pleasing. The top tie-in (exit) is transferred instead of the top stub opposite. Do not forget that the thread direction of the plugs is mutually opposite.

Obviously, you have a single-pipe heating system in your house, in which some rooms are connected to the pressure line, while other rooms sit on the back. This is a moronic Soviet system - the return water is already cold and cannot heat the room. But for installing additional batteries, you can be fined, because. such alteration of the project is not allowed

Connecting a heating radiator to polypropylene pipes selection of radiators, valves and fittings

Please note: when heated to 95 degrees, the maximum allowable pressure is reduced to 6-7 kgf / cm. It is not difficult for a person who is familiar with the operating modes of various heating systems firsthand: it is not difficult to draw conclusions from the figures given: polypropylene should be used only in autonomous heating circuits

It is not difficult for a person who is familiar with the operating modes of various heating systems firsthand: it is not difficult to draw conclusions from the above figures: polypropylene should be used only in autonomous heating circuits.

Why? After all, the standard parameters of the central heating (4 - 6 kgf / cm2, 50 - 95C) seem to fit into the typical characteristics of polypropylene?

Yes, because the actual operating conditions of the central heating system sometimes differ from those provided for by GOSTs and SNiPs.

- At extremely low outdoor temperatures, the operation of the elevator assembly without a nozzle, with a muffled suction, is practiced. In this mode, the heating medium enters the heating system from the supply line of the heating main, having a temperature of up to 150C.

- In case of water hammer (occurring, in particular, when the circuit is filled too fast) at the front of the water flow, the pressure can reach 25–30 kgf/cm2.

Polypropylene is clearly not designed for such pressure.

In addition, it is useful to know a few more things about polypropylene.

Significant elongation during heating makes it necessary to lay long straight sections of bottling and piping with the use of compensators - pipe bends. avoiding its deformation on straight sections.

Elongation can be reduced when using reinforced pipes.

They are characterized by a lower coefficient of thermal expansion:

- 3 mm / 1 rpm / 50C for pipes reinforced with fiber (chopped fiberglass);

- 1.5 mm/1 lm/50C for aluminum foil reinforced polypropylene.

An important point: when connecting to the fitting, the aluminum foil in the welding area must be stripped. Otherwise, pipe delamination is possible due to electrochemical corrosion of aluminum.

Material selection

The popularity that polypropylene pipes have won. associated with a number of their positive qualities:

- The price for them is much lower than for metal counterparts.

- High durability, due to the fact that the plastic does not rust, moreover, it practically does not deposit sediment.

- Doesn't need painting.

However, it should be borne in mind that not all types of polypropylene pipes are suitable for heating systems. The fact is that they must necessarily have a reinforcing layer that prevents significant thermal expansion of the pipeline.

Reinforced polypropylene pipe

Moreover, it is desirable that the reinforcing layer be aluminum, since fiberglass reinforcement leads to saturation of the coolant with oxygen. This, in turn, causes rusting of the metal surfaces of boilers and other elements of heat supply. Pipes that have aluminum reinforcement and are suitable for heating systems are marked with PN25.

Note! When choosing pipes, attention should be paid to the uniformity of their wall thickness. To do this, you need to look at their cut.

As for the diameter, the optimal parameter is 25 mm.

In this case, it is also necessary to purchase fittings, which include:

Scheme of one-pipe and two-pipe connection of radiators

Where to put radiators

Traditionally, heating radiators are placed under the windows and this is no coincidence. The upward flow of warm air cuts off the cold air that comes from the windows.In addition, warm air heats the windows, preventing condensation from forming on them. Only for this it is necessary that the radiator occupies at least 70% of the width of the window opening. Only in this way the window will not fog up. Therefore, when choosing the power of radiators, select it so that the width of the entire heating battery is not less than the specified value.

How to place a radiator under a window

In addition, it is necessary to correctly choose the height of the radiator and the place for its placement under the window. It must be placed so that the distance to the floor is in the region of 8-12 cm. If lowered, it will be inconvenient to clean, if raised higher, the feet will be cold. The distance to the window sill is also regulated - it should be 10-12 cm. In this case, warm air will freely go around the barrier - the window sill - and rise along the window glass.

And the last distance that must be maintained when connecting heating radiators is the distance to the wall. It should be 3-5 cm. In this case, ascending currents of warm air will rise along the rear wall of the radiator, the heating rate of the room will improve.

We connect the heating radiator to polypropylene pipes

In the private sector, in the houses of the old housing stock and in new buildings, work is currently underway to re-equip heating systems. Old heating equipment, steel and cast iron radiators are replaced with new appliances. Modern industry produces bimetallic, steel heating devices with improved parameters and characteristics. Accordingly, in parallel, the old steel pipelines through which the coolant circulates are replaced with new consumables. Today, polypropylene pipes take the first positions in the creation of a heating circuit.

Accordingly, in view of such a large-scale modernization of heating systems, reasonable questions arise. How is the distribution of the water circuit made of polypropylene at home carried out? How does the connection of a heating system radiator to polypropylene reinforced pipes look like? We will understand in detail and consider what constitutes the connection of polypropylene consumables to heating sources in detail.

Conclusion

Working with polypropylene pipes is not particularly difficult. Previously, any installation of the heating system has a ready-made scheme and thermal calculations. With the help of the drawn up scheme, you will be able not only to calculate the required number of pipes for your heating circuit, but also to correctly place the heating devices in the house.

The use of polypropylene pipes at home allows you to reinstall the radiator at any time. The presence of appropriate shut-off valves will ensure that you turn the radiators on and off at any time. However, during the installation process, certain rules and instructions should be followed.

- avoid using a combination of individual pipe fragments made of different materials during installation.

- Excessively long piping without the proper number of fasteners can sag over time. This applies to small heated objects, where there is a powerful autonomous boiler, respectively, the water in the pipeline has a high temperature.

When installing, try not to overheat the pipe, fittings and couplings. Overheating leads to poor soldering quality. Molten polypropylene boils, obscuring the internal passage of the pipe.

The main condition for the durability and quality of the pipeline of the heating system is the strength of the connections and the correct piping. Feel free to install taps and valves in front of each radiator. By installing an automation system and adjusting the heating mode, with the help of taps you can mechanically turn on and off the heating in the room.

Oleg Borisenko (Site Expert).

Indeed, the configuration of the room may require a combined connection of radiators. If the design of the radiator allows, then several radiators can be mounted in one circuit by connecting them in different ways - side, diagonal, bottom. Modern threaded fittings, as a rule, are high-quality products with consistent thread parameters. However, to ensure the tightness of threaded connections, various seals are used that differ in characteristics. The sealing material must be selected depending on the design features of the heating system and its location (concealed, open), since sealants can be designed to adjust (tighten) threaded joints, or they can be a one-time use that does not allow deformation after curing. Select a sealant for sealing threaded connections will help the material of this article: https://znatoktepla.ru/truby/vybor-universalnogo-i-zharoprochnogo-germetika-dlya-trub-otolpeniya.html

- Do-it-yourself project and calculation of a brick fireplace

- How to lay and insulate heating pipes in the ground?

- Why do you need a plinth for heating pipes?

- Choosing ribbed registers, radiators and heating pipes

- How to hide a heating pipe?