Types of pipe connections without welding, what are the pros and cons

Reasons for threadless and non-welded connections

Variety of fittings

Advantages of crimp type fittings

Ways to correctly connect tubular products without threading or welding

flange connection

Couplings Gebo for joining pipes

Docking profiled pipe without threading and welding

Carrying out any work related to the laying of pipelines for various purposes is inevitably associated with the need to connect them.

As you know, threaded connection and welding are considered the best methods of coupling, although they are not acceptable and feasible in all cases.

In this article we will talk about how to connect pipes without welding and threading, what kind of fixtures are used, and what to look for when working.

Other ways of threadless pipe connection

Pipe connections without welding and threads are also now available. To do this, use one of several devices:

- a special clutch that can be purchased at a store or made independently;

- Gebo fitting;

- flange.

Connecting pipes with a coupling

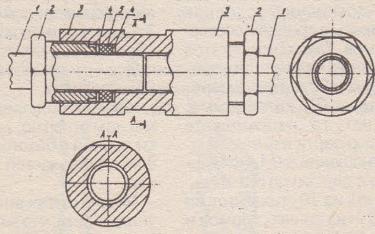

The connection of metal pipes without welding and threading can be realized using a special coupling.

Such a fitting consists of the following elements:

- housing (3), which is best made of cast iron or high strength steel;

- two nuts (2) located at opposite ends of the coupling. If the fitting is made by hand, then brass or bronze is used for the production of nuts;

- 4 metal washers (4) installed inside the coupling;

- rubber gaskets (5) used to seal the joint.

Connecting fitting device

The diameter of nuts, washers and gaskets must match the diameter of the pipes to be connected.

To install the clutch, you will need:

- insert the pipe ends (1) through the nuts (2) to the middle of the coupling. The pipes must also pass through the washers (4) and gaskets (5);

- the nuts are tightened to the stop, while squeezing the gaskets. The connection is quite strong and durable.

Connecting pipes with a Gebo fitting

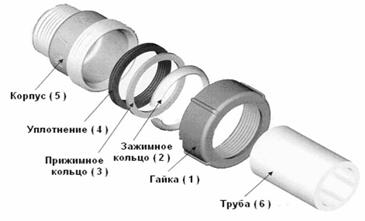

To connect pipes without welding and Gebo threads with a fitting made of plastic, you will need:

- purchase the required item. The Gebo fitting consists of:

- corps;

- sealing rings;

- clamping rings;

- clamping rings;

- nuts.

The device of a special fitting for joining pipes

- carefully put the coupling in the unscrewed state on the ends of the pipes requiring connection;

- fix the joint with nuts.

To obtain a more reliable connection, the nuts can be tightened with wrenches.

Gebo fittings are available for plastic and metal pipes. Couplings for PVC pipes are also made of plastic. Accordingly, fittings for metal pipes are made from metal.

Gebo fitting for metal pipes

The connection of metal pipes without a thread with a Gebo-coupling occurs in a manner similar to the above described method. Before joining the pipe, it is recommended to clean it.

Gebo fittings allow you to make the pipe joint as airtight and aesthetic as possible.

Ready-made connections are not subject to temperature changes and pipe vibrations. Couplings can be applied to all types of pipelines.

flange connection

A flange is a product designed for joining pipes and installing additional equipment on a pipeline.

The flange consists of several mounting bolts with nuts located around the perimeter of a metal or plastic surface. The sealing ring is located in the middle.

Fitting used for joining pipes

A large number of different flanges are currently being produced. Joint elements may differ:

- by diameter (corresponding to the diameter of the pipes);

- shape: square, round, rectangular and so on;

- according to the material of manufacture: plastic, metal. Metal products can be made of stainless steel, copper, brass;

- by destination: for pipes conducting cold and hot water, gas, aggressive substances and so on.

It is required to choose a flange based on the parameters and characteristics of the pipeline.

Using a flange, you can connect a metal pipe to a plastic one without a thread. To connect pipes, you must:

- install flange parts at the ends of the pipes to be joined. For reliability, you can resort to the welding method (how to do this is described above);

- put a sealing ring;

- fix the connection with fixing bolts.

Particular attention must be paid to the installation of the sealing ring. It must be clearly fixed between the pipes, otherwise the joint will not be reliable.

It is not difficult to connect pipes without the use of threaded elements. Before choosing a method for joining pipes, it is necessary to determine their diameter and the type of material from which they are made. Some methods require special equipment and initial use skills, others can be performed by novice craftsmen.

Pipe connection

V

one image (main view) of the node

pipe connection with a cut in place

connections. The node consists of a terminal

part of the pipe and one of the connecting

elements (fittings). Execution example

task is shown in fig. 12.

Rice.

12. Pipe connection

Pipe connections widely

used in the installation of pipelines

communications: water and gas supply,

heating, sewerage, etc. This type

connection refers to fastening with

using pipe threads (at pressure in

networks no more than 25 atmospheres). For the reason that,

that the pipeline can be dialed by

corresponding calculations from various

pipe diameters and in different directions,

then you have to use to connect

various fittings (fittings):

elbows, tees, couplings, crosses.

If the pipeline

does not change direction in a separate section,

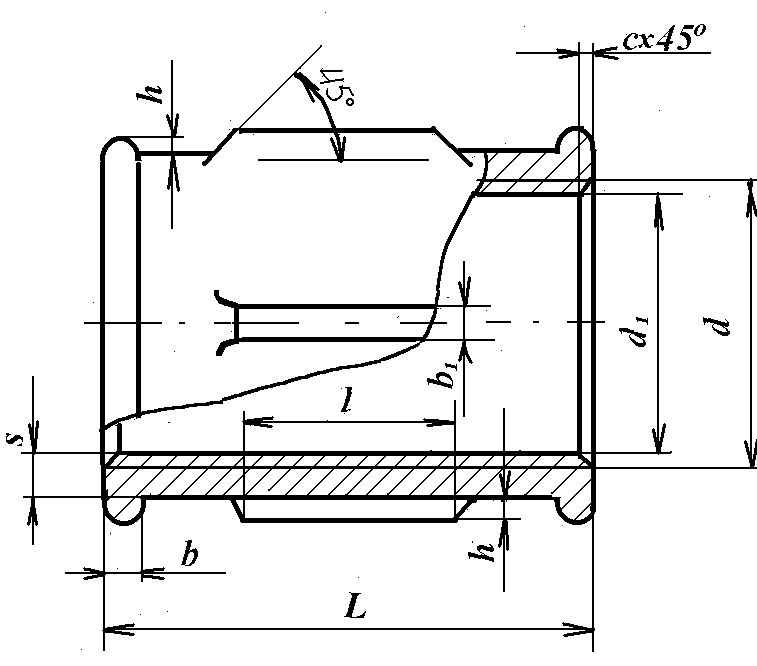

then the pipes are connected by couplings (Fig. 13). On the

rice. 14 shows a square that allows

connect pipes of the same diameter

right angle.

Rice.

14. Square

Rice. 13. Clutch

Tees

(Fig. 15) are used when

pipeline forks.

Rice.

15. Tee

Job Options

taken from the table. 3.

table

3

|

Option |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

|

Coupling GOST 8955-59 |

square GOST 8946-59 |

Tee GOST 8948-59 |

|||||||||||

|

Conditional pass |

8 |

10 |

15 |

20 |

25 |

32 |

40 |

20 |

15 |

20 |

25 |

32 |

40 |

Pipe cylindrical

thread, as opposed to metric threads,

has an isosceles profile

a triangle with an apex angle of 55º.

The profile of these threads is indicated by the sign

g,

and after the designation of the profile is affixed

conditional size. Conditional this size

called because it shows

pipe inner diameter

(in inches) for which it is designed

this carving. One inch is about

25.4 mm.

Inner diameter

pipes (clear diameter) are called

conditional passage and in reference tables

denoted by Dy (mm).

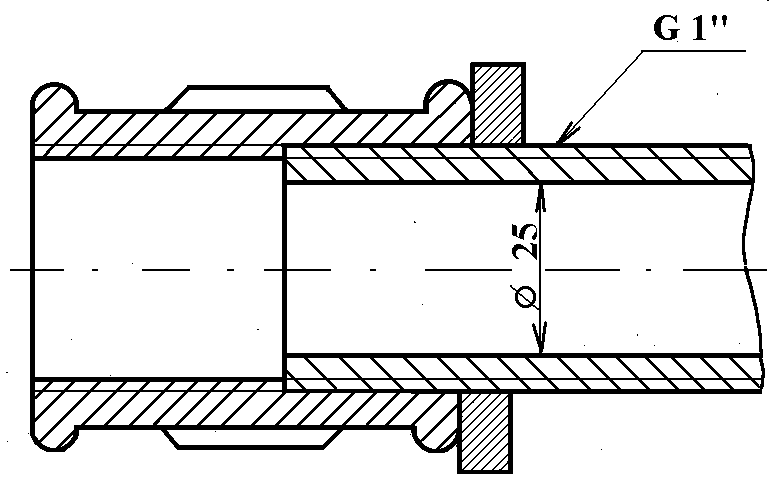

Pipe designations

threads are applied above the flange of the leader line. As an example

thread marked G

one". This means that the inner diameter

pipe is equal to one inch and corresponds to

conditional pass Dу25,4mm.

Designations of pipe threads are applied

no matter on the outside diameter

pipes are threaded or on the inside.

Thus, if the thread is given on

outer diameter of the pipe, then this diameter

will not be equal to 25.4 mm, but will be equal to

33.25 mm.

Depending on the

the selected option the dimensions required

for making drawings of fittings,

are taken from the tables: for couplings - tab. 4;

for elbows and tees - tab. 5.

Table 4

|

Conditional passage DAt, |

Thread |

d |

d1 |

L |

l |

S |

h |

b |

b1 |

c |

|

8 |

G |

13,16 |

11,45 |

27 |

7 |

3,5 |

2 |

3 |

2 |

1 |

|

10 |

G |

16,66 |

14,95 |

30 |

8 |

3,5 |

2 |

3 |

2 |

1 |

|

15 |

G |

20,96 |

18,63 |

36 |

9 |

4,2 |

2 |

3,5 |

2 |

1,6 |

|

20 |

G |

26,44 |

24,12 |

39 |

10,5 |

4,4 |

2,5 |

4 |

2 |

1,6 |

|

25 |

G |

33,25 |

30,29 |

45 |

11 |

5,2 |

2,5 |

4 |

2,5 |

1,6 |

|

32 |

G |

41,91 |

38,95 |

50 |

13 |

5,4 |

3 |

4 |

2,5 |

1,6 |

|

40 |

G1½ |

47,80 |

44,85 |

55 |

15 |

5,8 |

3 |

4 |

3 |

1,6 |

table

5

|

Conditional passage DAt, |

Thread |

d |

d1 |

L |

l |

s |

s1 |

h |

b |

c |

R≈ |

|

8 |

G¼˝ |

13,16 |

11,45 |

21 |

9 |

2,5 |

3,5 |

2 |

3 |

1 |

12 |

|

10 |

G⅜˝ |

16,66 |

14,95 |

25 |

10 |

2,5 |

3,5 |

2 |

3 |

1 |

15 |

|

15 |

G½˝ |

20,96 |

18,63 |

28 |

12 |

2,8 |

4,2 |

2 |

3,5 |

1,6 |

16 |

|

20 |

G¾˝ |

26,44 |

24,12 |

33 |

13 |

3 |

4,4 |

2,5 |

4 |

1,6 |

20 |

|

25 |

G 1˝ |

33,25 |

30,29 |

38 |

15 |

3,3 |

5,2 |

2,5 |

4 |

1,6 |

23 |

|

32 |

G |

41,91 |

38,95 |

45 |

17 |

3,6 |

5,4 |

3 |

4 |

1,6 |

28 |

|

40 |

G1½ |

47,80 |

44,85 |

50 |

19 |

4 |

5,8 |

3 |

4 |

1,6 |

31 |

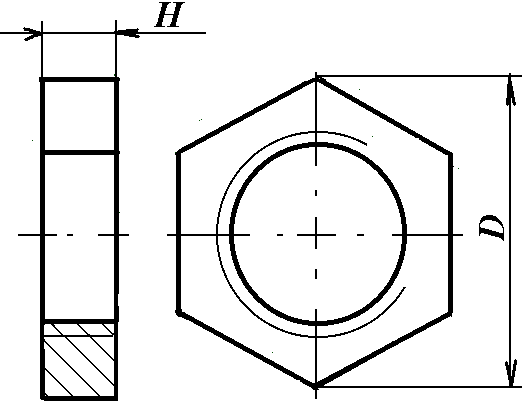

When connected

pipes with a tee or coupling into a knot

includes locknut GOST 8961-59 (Fig. 16).

The elbow is screwed on to the full length lO

threaded part of the pipe (to failure), and

locknut is not installed. Locknut dimensions

are given in table. 6.

Rice.

16. Locknut

|

Conditional passage, mm |

6 |

10 |

15 |

20 |

25 |

32 |

40 |

|

H |

7 |

7,5 |

8 |

9 |

10 |

11 |

12 |

|

D |

25,4 |

28 |

36,9 |

41,6 |

53,1 |

63,5 |

69,3 |

Example

performance of the task is shown in fig. 17.

Rice. 17. Example

completion of task number 2

What is carving and its types

A thread is a groove of a special shape and size, spirally applied to the inner or outer surface of a pipe or metal rod. Can be applied to cylindrical or conical surfaces. It is characterized and differs from each other by the shape of the groove, the height / depth of the relief and the distance between the turns - the pitch. In order to connect two parts, they must have the same or compatible threads, and one part must be with an external thread, the other with an internal thread of the same type and size.

In general, threads are divided into fastening and running. Running gears are used in machine elements and provide movement. We are more interested in those that are used in everyday life and that we encounter in the process of repair and construction. It's just a fastener. About her, in fact, we will talk.

Types of thread in the direction of the turns and surface

It is also worth knowing that in the direction of applying the turns, the threads are right and left, and on the surface on which they are applied - cylindrical and conical.

Thread types

The pipe thread has its own profile, which gives tightness. It serves for non-welded connection of metal pipes in pipelines, installation of various kinds of fittings, connection of devices. Recently, a threaded connection has also been used on some types of plastic pipes, but there is a different approach - it is cast, although the essence is the same.

Three types of pipe thread and their differences

There are three main types of carving:

Metric. You can distinguish by the sharp tops of the turns and grooves. The shape is a triangle with 60° angles. It is called so because its parameters are indicated in millimeters, and these are units of the metric system. Standardized by GOST 9150-81.

Inch. It is also a triangle at its base, but with a vertex of 55°. It is present on the details of imported production. As you can see, the difference between metric and conical threads is in the corners.

Trubnaya. It differs from the metric one with a slightly smaller angle - 55 °, and with the inch one it has the same angle. The main difference is that the edges are rounded.

And this is fundamentally important. Can be applied to a cylinder (pipe), and then the word "cylindrical" is added to the name

Standardized by GOST 6357-81. When cutting on a cone, it is called a pipe conical thread.

What is the carving. These are connecting - for connecting parts

The types of threads that can be on imported fittings and components may also come in handy. This is a Whitworth thread, which is designated BSW if it has a coarse pitch and BSF if it has a fine pitch. It was this standard that was taken as the basis for the development of pipe threads in the USSR. So Whitworth threads and pipe threads made to the standard are compatible.

Types of threads and their areas of application

There are other profiles, but they are running and very specific. Not needed under normal circumstances. For general development, let's say that there are also rectangular and trapezoidal shapes.

Where is which one used

Now about where what type of thread is used. Metric is applied to anchors, bolts, studs, nuts and other fasteners. Applied to a cylindrical surface does not provide tightness, therefore it is not the best choice for pipelines. However, it is used, and for tightness they “sit down” on a winding - tow or fum tape.In addition to plumbing, it is used in the assembly of frames from round pipes on a threaded connection.

What is the thread: profiles and standards

The picture changes when a metric thread is applied to a conical surface. Such a connection has a high degree of tightness. It is the metric conical thread that is applied to the covers, used in industrial pipelines, for transporting gases and liquids that emit volatile substances. In everyday life, the use of conical threads is limited, since special equipment is required for its application.

It is easy to guess that pipe threads are used in pipelines. Thanks to the smooth lines of the profile, even without additional sealing, the connection is tight. It is this type that is applied to the squeegees, corners, tees, and other devices that are used in the assembly of plumbing, heating and sewerage.