Thermal insulation of brick housing

Brick walls must be insulated without fail, since, in order to reduce heat loss with just a brick box at home, you will need to use a large amount of this material (the increase occurs due to the thickness of the walls).

Moreover, as in the case of other types of buildings (made of wood and foam block), it is desirable to insulate brick walls from the outside.

Overview of suitable materials

- One of the popular options is warm plaster, the thickness of which should be 30 mm. It is attached to a woven mesh, which will provide a good grip. To achieve high efficiency, you need to perform insulation of the ceiling, floor. If the old plaster has begun to crumble, it must be removed so that you can proceed with the installation of a new coating.

- It is undesirable to perform wall insulation with foam plastic from inside a brick housing, because this material is susceptible to combustion, and, in addition, it is not resistant to moisture

- And expanded polystyrene has all the necessary qualities for highly effective thermal insulation. It does not absorb moisture, is characterized by a low coefficient of thermal conductivity and is multi-tasking, as it can also be used to insulate the ceiling, as well as to reduce heat loss when installed outside the house. Styrofoam is attached with glue

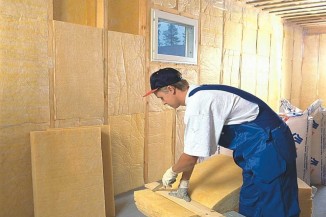

Another option is mineral wool. It is freely used for ceiling insulation, and for thermal insulation of walls, roofs. Such a coating is mounted between the profiles of the crate. You can use metal or wood material to create the frame. To protect the walls from moisture, a film is used. A vapor barrier is also laid on top of the insulation layer.

Causes of moisture

Dew Point Shift Results

In the winter season, with the onset of frost, the walls of our houses freeze through. In a correctly calculated wall thickness, the transition point from minus to plus temperature, it is called the dew point, is located inside the wall and condensation does not occur. That is why they used to build houses with stone walls no less than 80 cm thick. Today, with the use of the latest construction technologies and innovative materials, it has become possible to build houses with thinner walls, but such buildings require the installation of additional heat-insulating structures.

The question arises: from the outside or the inside to carry out insulation?

The issue of exterior finishes disappears when the house is made of timber and does not require exterior finishing. If the house is made of stone, then it will be more competent to make insulation from the facade, but this does not exclude the carrying out of internal work.

There is the only exception - the internal insulation of the walls of an apartment in a multi-storey residential building, where the use of any type of heat-insulating material will not give tangible results.

Finishing and ventilation

Both outside and inside the house, after the work on the insulation of the room has been completed, most likely, it will be necessary to finish all surfaces. Depending on the insulation used, different types of decorative coatings can be used. For example, for cork material, it is not necessary to complete the finish, as it looks quite attractive. The same applies to warm plaster.

Mineral wool coating, expanded polystyrene, polyurethane foam must be covered with decorative material, since unfinished walls, in this case, will look bad. The most common way to “sheathe” walls is drywall.

Considering that multilayer vapor barrier is used for thermal insulation from the inside of the room so that the air in the house does not stagnate, a forced ventilation system is equipped.Since the option of private housing is being considered, it is possible to hide the ventilation duct system before performing insulation and finishing.

Thus, the use of the same materials for the ceiling, walls and floor is allowed, but for each building the most suitable option for installing thermal insulation should be selected.

Installation of insulation in a house from a bar

Considering that wood, of all building materials, is more susceptible to moisture than others, it is very important to protect the walls. Insulation of a timber house from the inside is carried out only after surface preparation

At this stage, the following actions are performed:

- Regardless of whether housing is being built or an already finished building is being modernized, you need to check all wall surfaces for cracks and leaks. In a private house made of wooden beams, all joints must be clogged with jute fiber. If larger gaps have formed over time, then tape tow is used. Then the surfaces are treated with a special composition, due to which the risk of fungus and mold formation is reduced.

- In wooden housing, it is necessary to take care of moisture protection in order to avoid rotting of the house box in the future. For this, a film waterproofing material is fixed before installation.

- Do-it-yourself wall insulation from the inside in wooden housing is carried out by means of a mineral wool coating. This option is the most preferred, as it allows the house to "breathe". It is also used for insulation of the ceiling, floor. Thermal insulation with mineral wool is made between the battens of the crate

- The frame is made of a wooden bar with dimensions 5x5 and 5x10. This is quite enough for reliable fastening of mineral wool. Installation of the crate is better to start from the corners of the room, while using the building level

- The distance between the vertical bars should be somewhat smaller (1-2 cm) than the width of the mineral wool roll. This is due to the fact that this material is elastic, so this trick is used to increase the density. But mineral wool insulation should not be carried out with excessive pressure on the material, due to which it loses its thermal insulation properties.

- Another layer of film coating is fixed on top

If the method of warming wooden housing with mineral wool is chosen, it is better to play it safe and glue the joints of the waterproofing material with construction tape. In addition, the film strips overlap.

Additionally, mineral wool should not be fixed, this can damage the waterproofing layer located under the insulation.

Materials for thermal insulation

Materials for thermal insulation

As a result, several main conclusions can be drawn:

When installing thermal insulation on the inside of the walls of the house, the dew point inevitably moves to the inner surface of the wall. This will happen even with correct calculations of the thickness of the heat insulator. As a result, the service life of the entire thermal insulation structure is reduced.

The thermal insulation structure must necessarily include a vapor barrier membrane. As a result, it is necessary to solve the issue of normalizing the humidity in the room (increase in the cost of heating and ventilation systems).

Insulation inside the room reduces the volume of rooms.

Since the entire structure is installed inside the house, the issue of human safety becomes the most important

It is important to understand which of the heaters best meets this requirement. Materials from natural raw materials are the best choice

Soft slabs or mineral wool rolls, which have high heat-shielding and sound-proofing properties, are well suited. All materials with good vapor permeability and ability to absorb moisture will lose their functional properties over time.

The use of expanded polystyrene or polystyrene, as materials that practically do not absorb moisture, is more beneficial. In this case, it is necessary to consider the hermetic fit of the plates to each other. The main disadvantage of this option is a completely synthetic material, and they will have to breathe.

Today there is a lot of talk about polyurethane foam, which hardens when applied to the surface, and, of course, gives a strong adhesion to the inner surface of the wall. Condensation does not form, but for the work it is necessary to construct technological formwork. This process is quite long, while the wall does not breathe.

There are many wall heaters, there are plenty to choose from, but the decision must be made correctly. People will live, work and breathe in this house.

Lining for interior decoration of a wooden house

Manufacturers offer a variety of options for facing materials for interior decoration. However, to finish a wooden house, they often resort to lining. It allows you to preserve the overall style and atmosphere of a building made of wood. Such material can be used both for exterior decoration and for interior (only the methods of their processing differ). Lining is of various types. Moreover, we are not talking about the tree from which it is made and not about its size. The lining profile, depending on the desire of the customer, can be modified. There are wavy or even design of the material, as well as imitation of timber or logs (block house).

To finish the walls inside a wooden house, lining with a thickness of 15-20 millimeters is used. Its cost is less than that of thicker analogues, but such material fulfills its tasks. You can arrange lining boards in any order: horizontally, vertically, at an angle. Owners of remarkable patience and diligence are able to create whole pictures from lining.

When fixing the lining on the crate or on the walls, do not forget about the possible shrinkage of the house. To compensate for possible changes in wooden walls, leave a gap of 20-40 millimeters near the floor and ceiling.

The better to sheathe the walls in a wooden house inside

A wooden house is the dream of many. And therefore, when it becomes possible to buy it or build it yourself, you want it to please with its warmth and comfort for many decades. And for this, it is necessary to carefully approach the finishing of the structure.

Particular attention needs to be focused on the questions: how can you sheathe the walls in a wooden house inside and how to do it right

Now on the market you can find many offers for the sale of houses and cottages that already have interior decoration. But not all of them can be trusted. It often happens that for the sake of economy, walls are sheathed in violation of all technologies. This will become clear not immediately, but only after a certain period. Therefore, the best option would be self-plating the walls of a wooden house.

In what cases it is impossible to perform insulation on the outside of the walls

It is always best to mount a layer of thermal insulation on the outside, unless there is a clear reason not to. These include:

- Neighborhood of a house with an unheated room, where it is problematic to perform insulation

- A decorative finish was made on the outside of a wooden, brick house or a building made of foam blocks, which is expensive and time-consuming to dismantle

In all other situations, insulation on the outside of the walls will be preferable. The only option that involves high-quality internal thermal insulation, which is laid even at the construction stage, is a frame building.

In other cases, it is better to select materials that are characterized by vapor and waterproofing properties, and are also mounted without seams.

The essence and problems of internal insulation

When insulating a house from the inside, you need to take into account some features.

Most experts really believe that it is worth insulating a house inside only in extreme cases, advising insulation from the outside. What is meant in this case by the word "within"? This refers to the direct coating of the walls of rooms with any materials. And if floors, ceilings and some other areas can be easily insulated, it is with the insulation of walls that a lot of problems arise.

The main difficulty is the transition of the wall surface to the cold zone. Usually, if there is no thermal insulation, the warm air from the room passes through the walls, heating them. If insulation is laid from the inside, air masses will collide with them, not being able to go outside. All walls in this case remain cold, and there is a risk of cracks.

For this reason alone, it is worth considering whether it is necessary to insulate a private house from the inside instead of thermal insulation from the outside. It is logical: why waste money and your strength, if as a result you can get only cracked walls and a cold room? But this is only part of the difficulty. In addition to damage to the insulated surfaces, there is condensate and other troubles that will appear after a minimum time if at least a small mistake is made during the insulation work.

Features of the thermal insulation process

Insulation for walls in private housing, as in the case of any other object, is best laid on the outside. If the thermal insulation is mounted from the inside, then the walls will remain cold, and due to the shift in the dew point, condensation will form on the internal surfaces. This will lead to the constant presence of moisture, which is especially dangerous for a wooden house.

In a situation where the main box of the building is made of brick or other material, for example, foam blocks, it is the thermal insulation that will suffer to a greater extent, especially when it comes to mineral wool insulation. But even under such conditions, it is possible to build the most secure structure that will retain heat in the house.

How to insulate your home

Independent wall insulation

If it is decided to abandon facade insulation, then how to insulate the house from the inside to avoid condensation? After all, it is he who leads to the appearance of fungal formations, the destruction of thermal insulation materials. Each owner needs the entire thermal insulation internal structure to work efficiently and functionally. There are several widely used home insulation technologies.

Insulation of a log or timber house has its own characteristics. The thermal conductivity of wood in comparison with stone is, of course, lower, and wood retains heat well, however, when walls are insulated from the inside, moisture can form between the inner surface of the wall and the surface of the insulation. To avoid this, an air gap is made to blow wood and insulation. Technically, the problem is solved using a frame crate made of wood with a frame width equal to the width of the insulation boards. The crate is mounted at a distance of several centimeters from the wall to provide a ventilation effect.

From the side of the wall, a windproof membrane is pulled onto the frame, which performs a dual function: it protects the air gap from overlapping with the fibers of the heat insulator and limits excess air movement inside the insulation. In this case, it is more expedient to insulate the walls from the inside with natural environmentally friendly materials. There is a wide selection of mineral wool insulation, in Russia the most famous manufacturers are: URSA, ISOVER, ROCKWOOL, KNAUF and others. From the side of the room, the insulation is hermetically covered with a material that provides protection against the penetration of steam into the inner layers of the heat insulator.

The technology for insulating concrete or stone walls is similar to the previous design, but in this case it is necessary to provide for a larger number of technological openings for air to enter.Much more condensate will appear than in the first case, and the air gap must be wide enough for intensive ventilation. In fact, it is necessary to build an additional internal wall.

When carrying out thermal insulation work indoors, it must be understood that natural physical processes will affect the entire structure. This work requires a competent professional solution.