The most budgetary and high-quality linoleum

| Texture | Details |

|---|---|

| Web width: 1.5, 2, 2.5, 3, 3.5 and 4 meters Wear resistance: 21 class Thickness: 3mm Protective layer: 1.5 mm Price per sq. m. from 190 rubles |

Linoleum classification

Linoleum is divided into types and depending on its wear resistance. Guided by manufacturing technology, manufacturers cover the image, which is previously applied to the PVC base, with a protective layer on top. The wear resistance of the material depends on the thickness of this layer. The thicker the "shield", the more expensive the coating.

Low wear resistance household linoleum is usually laid in residential premises;

The semi-commercial type material belongs to the average level of wear resistance, which is why it is laid in rooms with medium traffic: hallways, kitchens, offices. One is quite hard, which is why there are no traces of heavy pieces of furniture and other objects on the surface.

Commercial linoleum is endowed with increased wear resistance. For this reason, it is laid in industrial premises, as well as in areas with high traffic.

However, please note that these are just general guidelines. In your apartment or house, you may prefer any kind of linoleum. And yet, when choosing a flooring, do not forget about its purpose and the load that it can withstand.

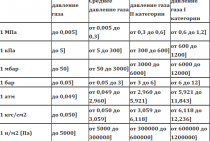

Linoleum classes

On a wooden floor, you can lay different types of linoleum. Wood is a material with excellent sound and cold transmission. Therefore, the PVC coating must have excellent heat and sound insulation properties.

Preparing the foundation

In order for linoleum to last for a long time and there are no problems during installation, you should carefully prepare the rough surface. Any flaw or defect in the paving substrate will degrade the appearance of the finish. And it can even lead to a rupture of the material in this place.

The coating is laid close to the walls, so the old skirting boards are first removed, which can be returned to their place after the work is completed.

Sometimes new linoleum is laid on top of the old one. But this is only possible if the old material that was glued to the floor is in perfect condition. If this is not the case, then the old coating must be removed, and then only a new one should be laid.

A primer must be applied to a concrete even base before coating is laid.

Before laying linoleum on a wooden floor with your own hands, it is pre-leveled with plywood.

Floor covering also requires preliminary preparation. It is laid out on the surface of the floor, and left for a while to make it possible to even out all the creases and kinks. Only then can you start cutting the material.

This floor covering is unpretentious in application, it requires only a flat surface for laying.

Varieties of floor coverings for an apartment

Flooring is an object on which it directly depends on how comfortable it will be in one place or another in the apartment. Therefore, the choice of flooring for an apartment is a very important and crucial step in any repair.

Among the variety of modern building materials for flooring, there are several main varieties.

The most requested are:

- carpet;

- linoleum;

- parquet board;

- laminated panels;

- tile;

- bulk polymeric floors with 3D effect.

It should be noted that each of these coatings has its own operating conditions under which the floor will last as long as possible. Therefore, when determining what is better to lay on the floor, it is worth considering the advantages and disadvantages of one or another type of coating, so as not to make a mistake with the choice.

Best Answers

Andrey Barmin:

Dear Marina!! !Cheaper and more practical...especially for a bedroom... of course, linoleum... in general, laminate flooring in apartments.... I don’t accept ... taking care of it anymore, God forbid the flood and the star of the laminate ... yes, all the divorces, specks, dust, everything will be visible on it ... and it’s cold ... and sonorous ... in short, beautiful linoleum is uniquely and forever ... .GOOD LUCK! ! !Linoleum lasts longer than laminate and can be washed like a ship's deck. True, it is difficult to buy a small piece. But if you managed to do this, feel free to lay commercial linoleum anywhere - in an apartment, in an office, in a country house. And twenty-five years you will not have problems with sex. But keep in mind that linoleum requires a better base - without joints and seams. Laminate flooring does not require perfect leveling of the floor.

Another thing is if you are not sure that you will live (or work) in this room for a long time, and are generally prone to a change of scenery. Then lay down the laminate. But the laminate can only be washed with a well-wrung out cloth or wiped with special protective compounds recommended by manufacturers. Moreover, remember that this is not a natural parquet. This is a fundamentally different type of flooring. Which, if properly installed, will last you 10 to 20 years.

Marina:

linoleum, it costs less and its installation is easier and cheaper

Irishka:

Linoleum

User deleted:

Linoleum is cheaper, but laminate is better

Journey through life:

Linoleum is cheaper. Although it is possible and och. buy expensive lenolium and very cheap laminate.

James Bond:

But laminate would be better

Andrey Enyutin:

about the same. if you have at least a little moisture, put linoleum, maybe the laminate will rise. in addition, the laminate is colder to the touch: ((

Admin:

but laminate is cool and linoleum is ordinary

Nailya Yusupova:

cheaper linoleum, but more practical laminate

Yurchik ...:

Of course, linoleum is cheaper, but laminate is better, it is more beautiful and sliding, but it is expensive !!!!

Evgeny Rodionov:

lenolium is cheaper laminate is a little more expensive you can handle the installation yourself

Larissa:

And best of all linoleum with a pattern under the laminate

Svetlana Borzenkova:

Lay linoleum. The choice is now wide, both in color, price, and quality. More practical.

Natalya Tramway:

Linole. It is cheaper, and the work is cheaper. And easier.

Gorynych:

Linoleum is longer because it needs to mature. I replaced lenolium with laminate and everyone is happy Beautiful, warm and durable

Olga Dmitrieva:

For the bedroom, I won’t even consider linoleum. You know, it’s better to pay a little more, but to save your health. I’m thinking that I don’t even want for the kitchen, I’ll lay laminate or tile ....

Methods for applying protective equipment

There are two ways to treat wood with protective equipment:

- Surface treatment. This method allows you to save all the decorative properties of the tree and at the same time protect it from various influences. This operation is carried out in any private construction, from the finishing of wooden beams in houses and ending with any wooden buildings.

- Deep processing. The implementation of deep staining is possible only in production, where there are special industrial devices. The essence of this treatment is the penetration of the product deep into the wood fibers, which ensures high-quality protection of the entire part.

Why is underlayment placed under linoleum?

What is a standard linoleum underlay? This is a special material used for insulation that prevents the floor covering from coming into contact with the subfloor.

It performs the following functions:

floor leveling

Often the floor is uneven, whether it is a concrete screed or a wooden surface. Irregularities can do a disservice - the linoleum laid on such a floor wears out very quickly, and its overall service life becomes much less.

Warming

In some cases, this is also an important factor.

If a cold basement is located under the floor level, which is not heated, and the linoleum does not have a layer of insulation, then the substrate can play its role.

Soundproofing

Underlayment can help if you're having trouble with this, which often happens in cheap new builds or older homes.

Sounds that reach you from below can be absorbed by the substrate, which greatly increases the comfort of living in an apartment.

When is it needed?

There are three main cases when a substrate is indispensable:

- Cold floor in the room.

If you have a cold basement under the room, then you need a substrate, because what you should not save on is health.

In this case, it is worth using a warm jute-based substrate, or from its mixture with wool and linen. It will keep you warm and protect your feet from drafts.

- Uneven subfloor.

A perfectly flat floor is rare, while microscopic differences will not cause much harm to linoleum, but if they are noticeable, the substrate will help straighten them.

An even base is a prerequisite for the long life of your PVC coating, while during its entire life it will please the eye with a smooth surface.

- Using linoleum without a base.

Such a single-layer material is much cheaper, but the floor will turn out cold. The substrate will help to eliminate this shortcoming.

When can linoleum be laid without a backing?

If you are laying linoleum on top of linoleum or other old flooring, you will not need an underlayment. The main thing in this case is to carefully check this coating for defects, cracks and other shortcomings.

The second case is the use of linoleum, which already incorporates a jute substrate or a foam base. Such a material is multilayered and consists of several components, the lower of which replaces the substrate, providing sound and heat insulating properties.

Main types

What is the best underlayment for linoleum?

Most often, the following materials are placed under linoleum:

Jute based

Moisture passes freely through it, while the substrate does not get wet.

Of the minuses of the jute substrate under the linoleum, it is worth noting not the best soundproofing properties.

Cork

The use of a cork underlay under linoleum is the best insulation and soundproofing component. This is a completely natural material, consisting of crushed tree bark. Cork backing for laminate flooring is widely used.

Among the shortcomings can be noted the high cost.

Based on flax

Such a substrate provides natural air circulation between the floor covering and linoleum.

As a result, it is possible to avoid excess moisture and the appearance of fungus. Insulating properties, like those of jute material, are not the highest.

Combined variant

The combination of jute, wool and linen allows the underlay not only to successfully resist moisture, but also to make the floor warm, while noticeably muffling any sound.

Of the minuses, it is worth noting its higher cost.

Underlay made of sheet material: plywood, OSB or fiberboard

Such sheets are used to level the wooden floor and serve as an excellent substrate in this case.

Of the minuses - such a substrate is poorly resistant to water, with high humidity it gets wet and loses its properties.

Multilayer insulation

Also, the substrate for linoleum on a concrete floor is also used as part of multilayer insulation. Very convenient, for example, film underfloor heating, it will maintain a constant floor temperature at 26-30˚C, which will not allow the coating to melt.

When to apply mastic and glue

When self-laying linoleum in non-residential rooms, even small ones, it is better to glue it. In living rooms, glue or mastic is used only on large areas (more than 25 m2), after preparing the base of the floor. Before applying the glue, linoleum is rolled from both sides to the middle into a roll.

The choice of mastic and glue on the market is presented in a wide variety. It remains only to choose the right glue for a certain type.

The container indicates how thick the adhesive layer should be on the floor surface. It is usually applied with a notched trowel. The higher the height of the teeth, the greater the thickness of the adhesive can be applied. Apply correctly from the middle to the walls.

After applying the adhesive mass, the roll is gradually rolled out. At the same time, a roller is passed along the surface of the linoleum to remove air between the floor and the coating. Such actions improve the quality of the connection with the base of the floor due to the uniform distribution of the adhesive.

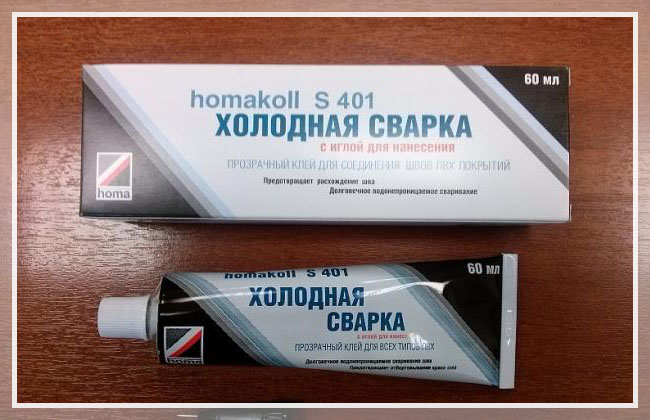

If you cannot do without seams when laying linoleum, then you can connect them by cold or hot welding.

Cold welding does not require special training and tools, so it can be used in everyday life. To connect the seams, you only need glue. For a new, only laid coating, glue A is taken, and to eliminate defects on the old coating, a thicker adhesive C is chosen.

To ensure a strong and durable connection, hot welding of the joints is used. This requires the availability of appropriate equipment: a welding torch, a compressor and rods for filling joints. The molten rod from the flame of the burner is placed in the joint between two sheets of coating. This method is applied 24 hours after laying the coating.

Floor paint treatment

Paint applied to the floor can greatly extend its service life by protecting the wood from various biological influences. You can even apply paint on a surface that has already been painted - just treat the surface with an antiseptic.

When it comes to how you can cover the floor in a wooden house without sacrificing safety, then water-dispersion paints are by far the best choice, since they do not contain solvents, withstand moisture well and adhere well to the surface.

In the case when the humidity regularly increases in the room (for example, in the kitchen or in the bathroom), it is worth using moisture-resistant acrylic paints. Alkyd solutions are best for parquet flooring.

The market for protective products for wooden floors today is not short of materials - everything is available, and choosing the best option remains the biggest problem. In order to know exactly what is better to cover the floor in a wooden house, it is worth considering all the factors in detail, and making a choice based on the conclusions.

Types of bases for linoleum

Now consider all the possible bases on which you can mount such a floor covering.

Concrete

The ideal is a concrete base, leveled using a special leveling mixture, concrete screed or "floating floor". That it is actually the best substrate for linoleum.

Before laying the coating on the concrete screed, it must be allowed to dry completely. The drying time depends on the room temperature, humidity and ventilation efficiency.But according to the norms, the period of drying and hardening of the concrete screed cannot be less than 30 days.

You can check whether the screed contains moisture very simply with a simple piece of plastic wrap. At night, you just need to put it on a screed and secure it with tape. If in the morning it turns out that the film is dry, then you can proceed with the installation. In this case, the base must first be thoroughly cleaned of dust.

In no case should a concrete base be leveled by laying sheets of plywood or other wood material on it. They absorb moisture and deform, therefore, on this basis, linoleum will quickly lose its performance characteristics.

Wood

The wooden floor is also a good base, but if it has cracks, bumps, nail marks or other flaws, then plywood 8-12 mm thick is pre-mounted on top of it. It is she who will perform the function of an insulating and leveling material.

In the event that the floorboards are well preserved, then the use of plywood is not required. Minor irregularities and microcracks are eliminated with a special putty.

Linoleum

Provided that the old linoleum is firmly attached to the base, has no bumps, torn spots and deformations, a new coating can be laid on it. Before this, the base must be degreased and glue applied to it.

In other circumstances, the old coating must be removed. You can read more in the article.

Ceramic tile

In this case, we are talking about the ideal basis for linoleum. If the tile has moved away, the tile joints have cracked or deformed, then before installing the linoleum, all defects are eliminated with the help of a leveling compound.

When it is completely dry, everything is cleaned with sandpaper, and the dust is removed. On this basis, the floor covering will serve for a long time and regularly.

Based on the above information, we can safely say that neither cork, nor jute, nor linen, nor felt materials, which are presented in a wide range on the market, are absolutely irrelevant. They are designed to level the base and insulate it.

But, firstly, all bases, according to the rules and norms, are pre-leveled, and, secondly, domestic-type linoleum in its design is based on a fabric, jute and polyvinyl chloride base, that is, it is insulated.

An exception is a coating without a base, which needs a substrate as additional insulation. Moreover, it should have increased strength and rigidity.

Installation

Laying linoleum on a wooden floor is considered the most profitable and economical way to repair. The material has a low price and a long service life. In addition, installation is quite simple, even when starting work for the first time, the master will be able to lay the coating on his own.

Ease of installation, however, requires knowledge of some of the nuances in the work, which we will discuss below.

Surface preparation

To lay linoleum you need to have a flat base. The level is used for verification. The protrusions found are removed with a grinder.

The presence of large flaws, potholes on the surface can be removed using plywood, fiberboard or chipboard flooring on a wooden floor under linoleum. Fastening sheets to the floor is carried out with nails or self-tapping screws.

After the plywood is laid under the linoleum on the wooden floor, it is necessary to close up all the seams and recesses for the screws. Otherwise, even linoleum with a foamed base will not be able to hide the irregularities present.

At the end, the base of the floor is cleaned of dirt, debris and dust.

Which mounting method to choose

There are several ways to glue linoleum to a wooden floor. The easiest way is to lay the coating without the use of glue. This method can only be used for rooms with an area of \u200b\u200bnot more than 20 m2.For a larger area, this method of fastening is not suitable, due to the possible appearance of waves and folds on the surface.

The next mounting option is double-sided tape. In this case, the adhesive tape is applied to the base of the floor in the form of a grid, and linoleum is laid out on it. This method is good because the coating is well attached to the floor, which prolongs its service life, and if necessary, it can be easily removed.

The last method of fastening is based on the use of an adhesive mixture or glue for linoleum. This method is used for large areas. Flooring in this way is very laborious, and it is quite difficult to dismantle the coating.

Laying

After you managed to level the wooden floor under the linoleum, you can begin the laying process. Flooring should only be done indoors at room temperature, after a few days of bedding and leveling. After that, once again smooth the coating well from the middle to the edges. Depending on the method of fastening, the flooring will have its own characteristics. Laying on a wooden floor (steps 1-3)

When attaching linoleum without glue or with adhesive tape, the material is fixed around the perimeter. When laying without glue, the remaining coating around the perimeter is removed with a sharp knife, and fixed in the doorway with a rail. When laying on adhesive tape, the tape is glued in the form of a grid without removing the protective coating. We bend half of the linoleum into the second part. Then the protective layer is removed from the adhesive tape, and the coating is laid, smoothing it from the center to the walls. We do the same with the second part. After that, the plinth is installed.

When fixing the flooring with glue, half of the sheet is folded, and the glue is applied to the floor with a spatula. After application, you need to withstand at least half an hour, and then bend it and carefully align it. We do the same with the second half of the coating. Laying on a wooden floor (stages 4-6)

The laying process is accompanied by constant leveling of the coating. This can be done immediately with your hands, and then go through a special roller to remove the remaining air inside.

Linoleum flooring should be carried out carefully, because the defects that have arisen during the work will be difficult to eliminate.

In a large room, the flooring is made from several sheets. The joints of the two pieces must be glued together. The strips overlap about 10 cm

It is very important that the pattern matches. We cut both strips in the middle of the overlap

This will make it possible to get a good joint. It is best to glue two strips using cold welding. Masking tape is glued along the seam. The glue is applied along the joint of the strip, so that the penetration into the seam is up to 2-3 mm. Do not remove excess glue, but leave to evaporate. After welding the seam, the masking tape is removed. Having completed the work on fixing the linoleum, you can proceed to the installation of the baseboard and the installation of rails in the doorways.

Knowing all the nuances that may arise in the process, laying linoleum with your own hands will not be difficult. Laying on a wooden floor (steps 7-9)

Which self-leveling floor is better

Where does a good renovation begin? From the floors! It is necessary to clearly understand what floors will be in an apartment or house, because the floor is the foundation of the entire dwelling.

Self-leveling floors are becoming more and more popular. Self-leveling compounds are used for the self-leveling floor, that is, it is very easy to install and good to use. Many people wonder what kind of self-leveling floors are best for an apartment, because there are several types of them? The most convenient option for an apartment can be a finishing self-leveling floor. However, there are several types of them - polyurethane, epoxy and epoxy-urethane. And what in this case is the finishing self-leveling floor better? What is better to choose self-leveling floors - a question for a particular person, the approach here is purely individual.This may depend on where you are going to install this floor, as well as how much money you have.

Features of self-leveling floors

Self-leveling floors have advantages over conventional coatings:

- they do not shrink;

- they do not need expansion joints;

- they themselves are aligned to a horizontally flat surface;

- the coating can withstand heavy physical exertion;

- the floor hardens quickly;

- the coating of the finishing self-leveling floor is completely environmentally friendly.

The finishing self-leveling floor is an ideal solution for an apartment, however, if you plan to put parquet or linoleum on top of such a floor. tile or laminate. a cheaper version is suitable for you - cement or gypsum-based screed. It quickly hardens and levels the floor, but does not have a beautiful finish so that only a self-leveling floor can be left. On top you will have to put another coating. This type of self-leveling floor is ideal for rooms where you first need to level the floor.

Any person can put a self-leveling floor, using the instructions on the package, so you can save on the construction team. The finish floor looks great - no worse than tiles, it is very convenient to wash it and you don’t have to worry that cracks will appear in the field and you will have to change it.

With the help of such a cabinet, it is easy to revive the interior, bring lightness and originality into it. We will talk about the features of wardrobes with sandblasted patterns in the article.

Today, the ceiling is a full-fledged detail of a modern interior, so its design should not be neglected. We will talk about the options for a modern ceiling in the article.

Such designs look stylish and elegant, besides, they are easy to install. We will talk about the features of single-level stretch ceilings in the article.

Due to their versatility, originality and durability, such coatings are incredibly popular today. In the article we will find out which self-leveling floor is better to choose.

Parameters influencing the choice

Tile kitchen floor

The floors in the kitchens differ from others by some requirements, including such as:

- Wear resistance, because the kitchen is the most visited place, so the flooring must be resistant to wear, abrasion, and various loads. Otherwise, it won't last long.

- Ease of care: the coating must be resistant to high levels of moisture, easy to clean from various contaminants.

- Durability: The kitchen floor should also be strong and durable. And it should last at least ten years.

In addition, the appearance of the coating should be taken into account. For example, large-format elements can optically reduce the already small rooms, and a glossy finish, on the contrary, expand the smallest and cramped kitchen. It is best if either plain, dim elements or contrasting ones are used for the floor. Warm shades will give comfort, cold ones will create a strict atmosphere.

When choosing a coating, you should also pay attention to its safety, environmental friendliness, and hygiene.

Is it possible to install underfloor heating in the kitchen?

When installing a floor in the kitchen, you must immediately decide whether an additional heating system is needed. It depends on the thermal insulation of both the base itself and the floor covering.

Underfloor heating can be installed for ceramic or porcelain tiles, laminate, parquet. But for cork floors, this is not necessary, since they themselves are quite warm.

When installing such underfloor heating in kitchens, it is necessary to ensure reliable waterproofing, on which a cement screed is laid.

Epoxy floors

A great option for those who are puzzled by the question of which self-leveling self-leveling floor to choose for their apartment. Epoxy coating is considered absolutely safe, since it is based on an inert substance that does not enter into any reactions.

These floors are easy to keep clean.They are not afraid of dust or dirt, mold never appears on them, and they do not rot. Even a very thin coating can last at least 40 years, not to mention thicker epoxy coatings.

Many are interested in which self-leveling floor to choose for an apartment, in terms of the fact that each room has its own purpose. Indeed, it does not make sense to fill the entire apartment with one compound, but a cheaper option is suitable for living rooms or children's rooms - this is a polyurethane coating.

This approach will save you a lot of money. There is another option and not expensive - this is a cement self-leveling floor, which is better for the owner of the apartment (read: “How to make a cement-based self-leveling floor with your own hands“).

Before deciding which self-leveling floor finish is better, you need to pay attention to:

- the purpose of the future coverage;

- the number of preparatory stages;

- load on future coverage;

- individual coverage requirements.

Having received answers to such questions, you can safely move on to another question - which company's self-leveling floor is better.

What to lay on the floor in the kitchen requirements for flooring

Of course, when we decide which flooring is better to choose in the kitchen, we first talk about comfort. And only then we think about ensuring that the floor we have chosen lasts as long as possible. What does it depend on?

That's right, from what the product was made of, and what are the properties of these materials. Plus, don't discount the appearance of the floor. Because kitchen design can either win or, on the contrary, lose.

What properties do manufacturers give their kitchen flooring? So they must:

- be resistant to wear;

- do not absorb moisture;

- be easy to clean and clean;

- not be subjected to mechanical stress;

- react normally to cleaning agents;

- be beautiful on the outside.

It is important to remember that each type of floor covering has its own additional conditions (such as, say, requirements for increased aesthetics, etc.). After all, someone may be limited to the practicality of the solution, someone may not have enough money

Seems like the requirements are not enough? Are there materials that fully correspond to them? You choose what will be the flooring in the kitchen? Let's look at the possible flooring options for the kitchen:

- Ceramic tile

- Cork flooring

- natural wood

- Laminate

- Polymer self-leveling floor

- Porcelain stoneware

- Linoleum

Preliminary preparation

Any floor surface on which the material will be laid must be carefully prepared (this applies to all materials without exception). Between the concrete base and the linoleum, there must be a specific layer that simultaneously absorbs noise and is a heat-insulating layer.

The stages of preparing the floor surface can be deduced into a sequence of actions:

- Preliminarily, the surface level is assessed, the absence or presence of irregularities, cracks is assessed. If defects are present, they must be repaired without fail.

- Next, the concrete surface is cleaned of dust, debris and other foreign elements, which in the future can also cause cracks on the linoleum surface or lead to irregularities.

- After the above preliminary steps, a material with thermal insulation properties is laid on the concrete. An additional layer can be a heater. This will not only make the floor warmer, but also significantly increase the life of the linoleum.

Agree that these tips are really simple, but allow you to lay linoleum, taking into account the necessary requirements.

What is it for, what types are there

The substrate excludes a possibility of contact of material with a floor. It serves for:

- Compensation for irregularities in the base.If the base has defects, they will be reflected in the coating. All depressions, cracks and tubercles will be drawn on its surface. Subsequently, this will lead to destruction. The material under it, by compensating for small irregularities, will protect the linoleum from premature wear.

- Soundproofing. This is especially helpful in apartment buildings, where noise from the lower floors is perfectly audible.

- Thermal insulation. In rooms located on the first floors, the floors are always cold. The same applies to apartments under which non-residential premises are located. Floors in houses arranged on the ground also need additional insulation. In this case, this is an excellent heater.

There are several types of insulating materials

jute

The jute backing consists of fibers of plant origin. This is a unique material made from natural jute fibers. It contains a flame retardant that prevents rotting and burning. It is able to absorb and remove moisture over time without getting wet.

Cork

This species consists of crushed tree bark. The process of its production eliminates the use of synthetic substances. However, it has the best heat and sound insulation performance.

Cork material, in addition to the high price, has another significant drawback. Due to its low rigidity, its surface bends under heavy furniture. And this leads to deformation of linoleum.

linen

The linen underlay retains natural ventilation between the floor and the floor covering. And this prevents the appearance of moisture and fungus. Since linen is used in the manufacture of this material, it is an absolutely natural product.

During the production process, the material is treated with flame retardants, which do not allow insects to start and prevent decay.

Not sure what to use to keep the room warm and dry? Use a backing that contains equal proportions of linen, jute and wool. It has additional wear resistance and thermal insulation properties.

Foamed

Regarding this type, experts have long come to the conclusion that it is not suitable for linoleum. It quickly rumples and loses its shape, without fulfilling its functions.

Video: what should be the basis for laying flooring

In order to unequivocally answer the question on the basis, it is necessary to know exactly the technical characteristics of a properly arranged floor base, designed just for the installation of linoleum. So the base should be:

- durable;

- as hard as possible;

- absolutely dry;

- smooth - smooth differences of 2-7 mm are acceptable;

- without oil and grease stains;

- no traces of old paint.