Selection of heating pipes

Having orientated which heating boiler will heat the water in your house, you can choose pipes for heating radiators and the system as a whole. Traditional materials for heating pipes:

- steel;

- copper;

- plastic.

Quite expensive and requiring the invitation of professionals for welding, steel or copper pipes are increasingly being replaced in practice with metal-plastic or polypropylene pipes.

Metal-plastic pipes

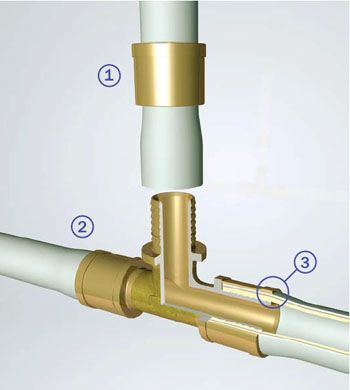

The connection and installation of metal-plastic pipes can be performed using compression and press fittings.

To make a connection using compression fittings and the subsequent connection of heating pipes, you will need:

- spanners;

- expander;

- springs for bending pipes.

The main disadvantages of connections on compression fittings are:

- their relatively high cost;

- fragility of rubber gaskets under the influence of high temperatures;

- periodic "simple" heating pipes in the summer, which also does not have a very favorable effect on the durability of rubber parts.

As a result, the need for preventive work to tighten the connections may occur every five years or more often.

Rules for connecting metal-plastic pipes using a press fitting

Reliable non-separable connection on press fittings allows installation of heating with plastic pipes, hiding them directly in the walls. These pipes will last without replacement for many years if the temperature of the heating water flowing through them does not exceed 80°C.

The disadvantage of using this type of connection can only be called the need to purchase special equipment for installation

Polypropylene pipes

Recently, a leading place among suitable water and heat supply equipment has been occupied by a pipe for a heating boiler made of polypropylene. The use of polypropylene is due to the fact that it is very durable, is not afraid of defrosting the system, and has a very affordable price.

Polypropylene pipes can be bent quite evenly (unlike metal-plastic). They will last a long time if all the rules of operation are observed.

Their only drawback is the need to use a special tool for welding.

There are the following features of the connection of pipes made of polypropylene by welding:

- It is more convenient to weld polypropylene pipes together with a partner. The main condition for the high-quality connection of plastic pipes is the choice of the correct heating time so as not to overheat them, and precise fixation, which does not allow shifts and displacements along the axis for the first few seconds after connecting the heated parts.

- Welding and installation of heating pipes is carried out at positive ambient temperatures - above +5 °C. When working in winter, it is necessary to create a "heat zone" where polypropylene pipes are welded.

For high-quality work on soldering polypropylene pipes, it is necessary to comply with all the requirements of the instructions attached to the device.

It would be a good idea to do a few trial welds on individual short lengths of pipe using inexpensive couplings to get at least some initial skill in handling the welding set.

Connection of metal-plastic heating pipes

For metal-plastic pipes, similar connection methods can be used, with the exception of threaded ones. Since their principle of operation was described above, it makes no sense to repeat.

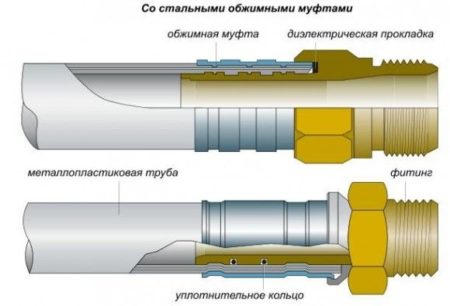

A fundamentally new version of the connection is represented by press fittings. They are divided into crimping and pressing or slip-on.

Crimp press fittings

The sleeve that compresses the pipe can be fixed directly to the body or located separately. This type of work is carried out with the help of special pliers. The tool has a removable head, which is selected based on the diameter of the sleeve.

Heating wiring without pipe welding by crimping a press fitting is performed as follows:

- Cut the pipe using a pipe cutter.

- Clean up the cut.

- Apply a gauge to eliminate out-of-roundness that occurs after trimming with a tool.

- Put on the compression ring.

- Put a dielectric gasket and a sealing ring on the fitting, then press the element into the inner cavity of the pipe.

- Crimp using pliers.

If the work is done correctly, on the inside of the sleeve, two strips will be clearly visible where the compression has occurred. These zones should not coincide with the locations of the gaskets, otherwise they will be destroyed over time, which will significantly reduce the service life of the connection (5-10 years instead of 20-30).

sliding fitting

The difference of this connection option is that the ring is not compressed, but pulled onto the pipe. To do the job, you will need a special press, not tongs.

Connection instruction:

- Cut the pipe and put a metal ring on it.

- Expand the end of the part with an expander.

- Insert the fitting up to the stop.

- Push the coupling with the jaws of the press and press on the fitting.

You can see how the sliding fitting is mounted on this video:

https://youtube.com/watch?v=KKjkMvK5HZ4

The recommendations presented in the article will help you repair or install heating pipes without welding. The most commonly used option is compression fittings, which do not require prior preparation and the use of special tools.

Advantages and disadvantages of each method

Thread

Advantages:

- reliability;

- ease of assembly, the possibility of disassembly;

- low cost.

Flaws:

- stress in the thread cavities, increases the fatigue of the material, reducing its strength;

- the need to use locking means to prevent unscrewing the working element.

flanges

Advantages:

simplicity and convenience of reusable connection and disconnection.

Negative properties:

- high labor intensity in manufacturing, therefore, the price is high;

- during long-term operation, a decrease in the place of its connection, loss of tightness.

gluing

The advantages of this method include its not a laborious process that does not require great skills and effort.

But waiting for gluing sometimes reaches three days, which is not always convenient.

This type of connection cannot be attributed to reliable methods.

Welding

Advantages:

- reliability;

- durability;

- tightness;

- the ability to connect parts of any shape.

Flaws:

- occurrence of residual stresses;

- the possibility of changing the geometry;

- risk of destruction under vibration and shock loads.

Trumpet

Compared to all types, socket pipes have the advantage of low cost, small axial and lateral movements of the pipe, which is very useful in case of temperature changes and soil shrinkage.

The negative indicator lies in the difficulty of the connection connector and insufficient reliability at elevated pressure.

Pressing

A common positive factor is the excellent self-centering of the joined parts, a stable state under shock loads. Simplicity and not laborious process.

Not amenable to reverse disassembly or displacement of each other. Here are a few disadvantages of this method.

Ductile iron and fittings made from it

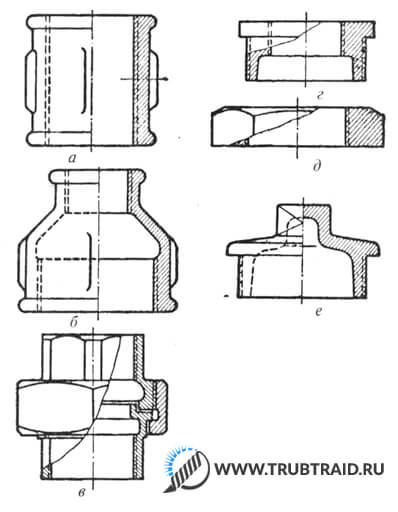

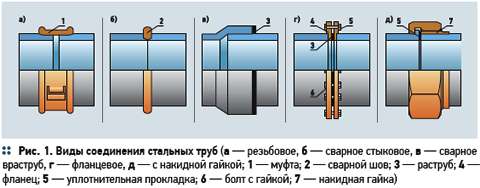

The most common ductile iron parts for connecting steel pipes and other pipeline parts are: A) straight couplings B) transition couplings C) connecting nuts D) futorki E) locknuts E) plugs.

For absolute sealing of the system with a threaded connection, it is necessary to use seals, for example, gaskets. In addition to them, with other types of fastening, additional parts are used. If it is necessary to use the articulation of the elements of the line using flanges, that is, without a coupling, then in addition to the gaskets, bolts are also needed.

When connecting risers at an angle, ductile iron fittings are used: straight and transitional elbows, tees, crosses.

The cast iron coupling has a low collar around the entire perimeter of the butt circumference, which serves to increase the strength of the part, in contrast to the steel counterpart, which does not have such an element.

The quality of connections depends not so much on the methods of sealing, materials, but on the master and the quality of his work. If he is responsible, accurate, has elementary plumbing knowledge, skills in working with a wrench or pipe wrench, then you cannot find a better specialist. Subject to the elementary rules for the installation of pipeline systems, the pipeline will function for many years. This can be confirmed by anyone who has at least once been involved in the installation of a pipeline system, even the shortest and simplest.

Try it yourself, experiment and see that you are the best specialist in the installation of pipeline systems using the threaded method of connecting line elements.

Detailed description of each method

Threaded

They can be done in several ways, the most common is squeezing.

The following tools will help you do this:

- Pipe wrench.

- Coupling with internal thread.

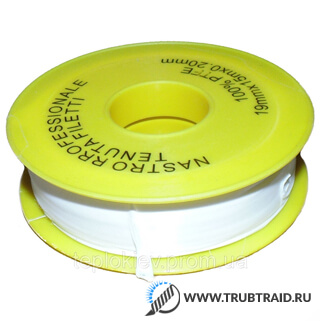

- Seals for sealing. Maybe: hemp rope, FUM tape or sealant.

- Lock-nut.

Two pipes have an external thread. We put sealant on them. One thread is longer than the other. Where there are more turns, the nut is screwed on, to the end. Then the clutch. Then we wind it on the second part, twisting the campaign with the first. When the coupling stops winding, we support it with a lock nut

We tighten the keys, carefully, no matter what the clutch bursts

flanges

For a flange joint you will need:

- two flanges;

- paronite gasket;

- bolts, washers, nuts;

- keys;

- manual arc welding;

- level.

Flanges need to be welded. Avoid displacement, they must be in the same plane.

We catch with the help of the horizontal level. We fasten two bolts into the upper holes. We put the part on the edge of the tube, so that the bolts are at the top. We put a level on them and catch the position of the bubble between the strips in the middle. When caught, we make a tack welding at the top point. The horizontal plane is ready.

We rearrange the level, in a vertical position, leaning it against the flange mirror. We catch the level by slightly adjusting the lower end of the flange, which is not yet tacked. Having established the vertical, put the second tack. And then two more getting four uniform sections.

Then the welder welds the flange on both sides. Similarly, manipulations are performed with the second pipe.

gluing

This method is rarely used in metal parts. The process itself does not require a special skill from a person, but it takes a very long time.

This job requires:

- glue. BF-2 or 88N or EDP;

- tassel.

Before gluing the parts, first apply the first layer on their surfaces and allow to dry. This layer will be the bonding layer. Each glue has a drying time in the instructions. Then the second layer is smeared and the parts are placed under the press for a day or even more. It all depends on the glue.

After cleaning the seam from the smudge of glue.

Welding

The welding process is used in almost all joints of metal pipes.

In order to obtain a seam, such welding methods are used as:

Gas welding is used to obtain permanent joints in pipes of small diameter with a minimum thickness.

The gas welding station consists of:

- oxygen cylinder;

- acetylene;

- rubber hoses;

- burners.

Contact welding is rarely used. More this method has proven itself in working with plastic pipes.

The most common way to obtain permanent joints is electric arc welding, is divided into:

- manual

- semi-automatic in shielding gases

During the construction of pipelines, connections are obtained only by welding

An important part is the preparation of the joint for welding

The pipe must be connected to another:

- without fractures and displacements;

- the joint must be cleaned;

- make a chamfer;

- set a gap of 1-3 mm.

Necessary equipment for welding:

- electrodes;

- power source (transformer or rectifier);

- cable;

- personal protective equipment for the welder overalls, gloves, brushes.

Butt soldering of polyethylene pipes and with the help of an electric coupling

Trumpet

This type of connection has been widely used in cast iron pipes for the oil and gas industry, housing and communal services. One of the simplest options for one-piece joints.

The main process for obtaining a joint is to close the gap between the socket and the surface of the conical pipe. For this, cement material is used.

To seal the socket, cement grade 300-400 is used, which is thoroughly mixed with water in proportion nine parts cement to one part water. The bell is filled with cement mortar using a scoop and minted with chasing until the latter begins to rebound from the cement.

Pressing

This method of obtaining a one-piece seam has become necessary for small-diameter non-ferrous metal joints. Conventional electric arc welding is not capable of welding such metals in terms of its technical parameters, therefore, in this case, they found a different approach.

To join such thin-walled non-ferrous metal pipes, press fittings with compression sleeves are used. They perform crimping in the inner part of the pipe, and the outer seals provide the joint with tightness.

Advantages and disadvantages of a hidden scheme for laying heating pipes

As for the advantages, it is one, but significant - aesthetic beauty. With hidden laying of heating pipes in the wall or floor, they do not violate the interior of the room

This is important for rooms with panoramic glazing, floor-to-ceiling windows, etc. Decor is also important in rooms with massive furniture, you don’t have to think about damaging products from heat from the pipe

But the hidden scheme has more disadvantages:

- Do-it-yourself hidden installation of heating pipes is a difficult task. To reliably hide the outline, you must comply with regulatory requirements.

- Significant heat loss. Before the coolant warms up the house, it must first heat the screed or wall, then the finish, only then the heat enters the room.

- Increasing the cost of work. To hide the contours, you need to buy pipes made of steel or with reinforcement, sleeves, insulation, insulating materials - all this will require investments.

Before starting work, all the nuances are determined - access to the key nodes of the highway, laying out, taking into account the load on the floor, wall. Also, the optimal cross-sectional size for the circulation of the coolant is calculated without increasing the linear expansion property of the pipes.

And one more important nuance, on which the performance of the circuit depends on hidden laying out, is the correct slope of the heating pipes. The standard slope is 0.5 cm for each meter of the highway. You can reduce the readings to 0.2 cm, but only if a good pump is integrated into the system and the circuit is selected with the correct diameter of the inner tunnel.

Features of pipes for hidden installation

Which pipes are best suited for laying out a hidden type - this question is most often asked by the owners of private houses

Professionals recommend paying attention to metal-plastic pipes with reinforcement. Plastic parts deteriorate under the influence of UV rays, so they are well suited for installation in a screed, wall thickness

As for steel products, they are more difficult to bend, therefore, more fittings must be used on turning sections. The increased number of connectors increases the risk of leakage. It turns out that PP pipes with reinforcement are the best option for hidden installation of a heating system.

Options for laying out the heating pipeline in the house

There are two types of installation - open and hidden. An open network is installed along the bottom of the walls, a closed network can be recessed into the floor screed. The choice of method depends on the requirements of the owner, the skill of the master. Subject to the laying technology, the network performance parameters do not decrease.

But there are some nuances that need to be addressed first:

- The layout technique depends on the material of the pipes for the circuit. For example, steel elements have a minimum thermal expansion. This property allows, without much risk, to recess the contour into the screed, to wall it into the walls. The risk of leakage due to deformation or rupture is minimal. The metal-plastic circuit has a significant linear expansion, so it is better not to hide such pipes in the walls and floor.

- High-quality insulation of the pipeline will reduce heat loss. The winding will prevent the risk of breaking the walls of the circuit in the event of a strong linear expansion.

Most often, masters choose an open version of the calculation. But only in the case when we are not talking about the contours of the warm floor.

Hidden styling

The pipeline is laid out in the walls, floor or rises to the ceiling with arrangement behind a suspended or hemmed finish. It is most convenient to engage in hidden laying work during a major overhaul or at the construction stage of an object.

Features of the formation of contours of a hidden type:

- the minimum number of joints, turns, bends - such networks are less at risk of deformation, leakage;

- availability of connection zones for inspection, preventive maintenance;

- old heating pipes cannot be hidden in the floor screed.

In order not to forget all the details of the arrangement, it is recommended to draw up a detailed technical plan for the heating system. Such a scheme will help to quickly find the main shutdown node if the heating pipes in the floor screed are leaking.

Open layout

Laying heating pipes in an open way is the easiest and most affordable option for a home master. It does not matter the complexity of the circuit or the number of turns - with the right selection of the section, performance does not decrease.

Additional benefits of an open network include:

- Low cost of work. Due to the absence of additional sleeves and other elements, the costs will not be so impressive.

- The ability to quickly update, repair. All the details remain in sight, the restoration will not take much time.

How and how to seal pipe joints

Types of seals, sealing methods

To prevent leakage of the working medium of the pipeline, it is necessary to seal the pipe twists with high quality.

When threading steel pipes, the following are used as seals:

- gasket. This method of sealing a threaded joint requires relatively thick pipe end cuts. The presence of even pipe ends can never provide tightness. When using a rubber or plastic gasket, this problem is successfully solved. This option is ideal in the case of articulation with a union nut;

- winding. Linen strands, polymer threads, FUM tapes in combination with hardening sealants, paints, pastes can serve as materials.

When installing plastic risers, a sealing method is used based on the deformation properties of the material. The essence of this method is that a plastic pipe with an external thread is screwed into a riser with an internal thread. Plastic during deformation contributes to the excellent filling of the intermediate space, eliminating the appearance of gaps.

When it comes to pipeline structures with high pressure, cylindrical threaded pipe connections are not entirely appropriate here. In such cases, a conical type connection is used. The principle of connection is that when screwing in, a tight pressing of the pipes is observed until such a measure until the gap completely disappears.

Sealing materials

To make the joint impermeable, the following are used as sealants:

- flax (tow);

- asbestos;

- FUM tape;

- natural drying oil;

- white;

- minium;

- graphite lubricant, etc.

A reliable seal when twisting steel pipes on a thread is a linen strand impregnated with red lead or whitewash. This connection is easy to install, reliable in terms of sealing. The sealant has been used for a very long time, does not lose its popularity even today, despite the appearance of artificial analogues.

For those who have little experience in the installation of fittings and pipes, we suggest that in no case use flax without paint. At first, the joint will not let moisture through. But a few months will pass, the flax fibers will get wet and begin to decompose. Therefore, the quality of all connections will deteriorate, and after another month or two, water will seep at the junction.

Many people use FUM tape, which is in no way inferior to the old traditional materials - tow with paint.

Sometimes there is no tightness at the junction of the risers. To eliminate this defect, it is necessary to replace the sealing material, and clean the threaded section from dirt and sealant residues. After that, wind the linen thread, FUM tape or other sealant again, assemble the structure.

Pastes, sealants of chemical origin are used as additional sealants, which will help strengthen this section of the pipeline.

Rules for choosing the diameter of pipes for heating

The size of the section affects the circulation rate of the coolant. If the diameter is chosen incorrectly, the transport of the heated liquid will be slow, the devices will heat up unevenly. Fluid flow rate standards 0.4–0.6 m/s. Reduction of movement to 0.2 m/s. will provoke stagnation of water, air congestion is formed. Subject to the circulation of the coolant at a speed of 0.7 m / s. energy consumption increases, noise is heard. The optimal parameter for the speed of water movement in the system is 0.3–0.7 m/s. From this calculation, choose the diameter of the pipe for heating.

Recommendations of specialists in the selection of products:

- if no more than 2 radiators are connected in the network, the section size is up to 16 mm;

- when integrating 1 battery with a power of 7 kW or several radiators with a capacity of up to 2 kW (in total, the total power should not exceed 7 kW) - the allowable circuit cross section is 20 mm;

- with a total power of a group of radiators in the line of 11 kW, a pipe with a diameter of 25 mm is needed;

- supplying heat to a dead-end wiring, for example, to a distant wing of a house, requires the installation of elements with a cross section of 25 mm;

- parts with a diameter of 32 mm are mounted in a network with 12 batteries with a total power rating of up to 19 kW;

- if the house system has more than 20 radiators, the total power of which is not higher than 30 kW, products with a size of 40 mm will be required.

It is also important to consider the capacity of the pipeline. If the water speed in the line is not more than 0.4 m/s, the polypropylene circuit ensures the transfer of the standard amount of heat

Table of heat energy release depending on the pipe section:

| Thermal energy (kW) | Outer diameter (mm) | Inner diameter (mm) |

|---|---|---|

| 4,1 | 13,2 | 20 |

| 6,3 | 16,6 | 25 |

| 11,5 | 21,2 | 32 |

| 17 | 26,6 | 40 |

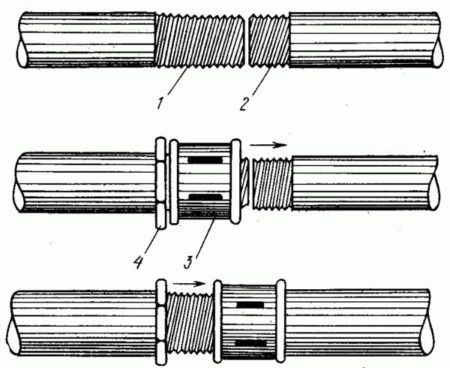

Connection of metal heating pipes without welding

The fastest way to connect without the use of welding is a compression fitting. Nevertheless, we will consider other methods: threaded connection and installation of a repair and installation clip. The latter is used both for docking and for eliminating leaks resulting from metal cracking.

Thread

It will be possible to create a threaded connection only if there is free access to the pipe, i.e. at the initial installation stage. In other cases, threading will be quite problematic or impossible. The procedure itself is carried out according to the following scheme:

- Clean the pipe of paint and rust. If there are metal sagging after previous welding, they should be cut off. The surface to be joined must be clean and smooth.

- Using a file, chamfer the end where the cut was made.

- Take a die of a suitable size, screw the handles into it. Lubricate the cutters with grease or lard.

Install the tool on the pipe, make sure that it is located strictly perpendicular.

Make half a turn of the die clockwise, then a quarter of a turn counterclockwise. Then repeat the movement until the thread is cut.

Now let's figure out how to crash into a heating pipe without welding. To do this, you will need to use a coupling with a nut. It can have three branches to create a wiring. When creating a thread, it should be remembered that on one pipe it should be 2 times longer. Clutch fastening:

- A nut is screwed onto a longer thread, then a coupling.

- A nut is screwed onto the second pipe.

- The parts are matched together, after which the sleeve is twisted from the long thread and partially screwed onto the short one. The element should be approximately in the middle of the cut.

- It remains to screw the nuts on both sides, after wrapping the sealing material (fum-tape, tow) on the threads.

Such a connection is considered strong enough and can last more than one year.

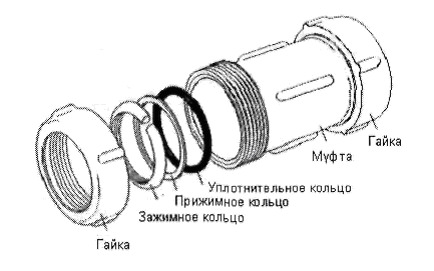

Compression fittings for steel pipes

This type of connection allows heating without welding pipes and threading. At the same time, experts note the high reliability of compression fittings, the leader in the production of which is Gebo. This often causes confusion of concepts - many call these connecting devices after a popular manufacturer (a vivid analogy is the Xerox brand, which has become a household name for copying documents).

Among the advantages of this connection method, one can single out the speed of work, and the absence of the need to use a special tool. All you need are two wheelbrace wrenches to hold and clamp the fitting.

The working procedure is as follows:

- Put the fitting parts on the pipe in the sequence: nut, clamping ring, clamping ring, sealing ring.

Put on the coupling, make sure that all the elements are located correctly and without distortions.

Tighten the nut. One thread should remain visible. If a small leak occurs after the coolant has been supplied, the nut can be tightened.

Do the same for the other side of the fitting.

You can learn more about compression fittings by watching the video:

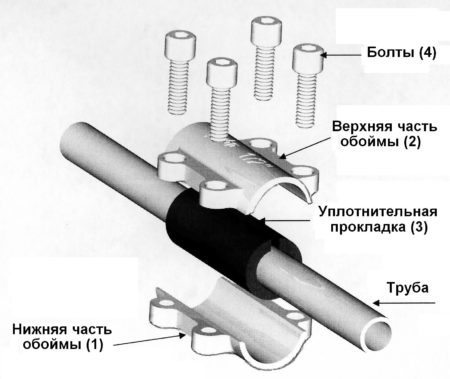

Repair and installation clip

When operating old systems or exceeding pressure, the question often arises of how to seal a heating pipe without welding. For these purposes, a repair and assembly clip is used. It can be made in the form of a coupling or a tee. The outer part of the part is metal with clamping bolts, inside there is a rubber gasket.

The element is often used to urgently fix a leak, but can also be used as a permanent option for connecting water pipes. Instructions for use:

- Clean the pipe fittings from paint and other deposits that may affect future tightness.

- Apply a rubber seal to the joint. Make sure that its cut does not fall into the junction of the upper and lower parts of the clip.

- Lubricate the cut with sealant and, if possible, allow some time to dry.

- Install the parts of the cage, fasten with bolts.

These are all options for creating a strong connection between metal pipes without using a welding machine. Now we will describe several methods for working with metal-plastic parts.