How much does infrared floor heating consume

It is almost impossible to calculate exactly how much each floor in kW consumes electricity, since: there is a film with different power, each building has its own energy losses, depending on the quality of insulation, the number of window openings, etc. You will also need to take into account that the real consumption will be somewhat different from the maximum electricity costs, as the actual mats will operate approximately 70% of the time. What needs to be taken into account in the calculations:

- total heated area. Heating costs are taken at the rate of 70-80% of the area of the room. Taking into account the peculiarities of installation and operation of mats, a fully insulated room will require laying a film on only 70% of the area.

- The presence of a thermostat - a device that allows you to automatically regulate the heating of the room. Installing a temperature sensor reduces power consumption.

- The maximum power consumption at the time of starting the heating system.

- Good thermal insulation of the building.

If we take a house of 50 m², a film with a power of 160 W and a heat-insulating layer of 1.2 cm - electricity consumption is about 0.5 kW per hour. As a result, the daily electricity consumption of infrared film underfloor heating will be 12.6 kW.

How to reduce electricity costs when using underfloor heating film

-

Power selection

For comfortable floor heating in city apartments, a film with a capacity of 150 W / m2 is sufficient. Film underfloor heating is installed in those places where heating is needed.

For the main heating and comfortable floor heating, film underfloor heating with a power of 220 W / m2 is used, for example, Marpe Normal GSM thermal film. At the same time, you should follow the recommendations of manufacturers for the installation of heating systems on the first floors, in country houses and balconies using continuous carbon films (for example, Marpe Black Heat), which have additional layers of moisture protection. The coverage area is about 70% of the total area of the premises.

-

Room insulation

When using infrared underfloor heating as the main heating in a country house, the ventilation of the room will be of great importance. If all the generated heat escapes through the slots, the film will work longer to maintain the required temperature and, accordingly, the amount of electricity consumed is much higher.

To save energy, it is necessary to use heaters to reduce heat loss. Double and triple glazing as well as tight-fitting doors avoid large amounts of heat loss.

-

It should be borne in mind that different types of flooring have their own thermal conductivity.

-

Using a thermal insulation layer

When installing infrared floor heating in both country houses and apartment buildings, it is recommended to use a heat-insulating substrate. It is made of chemically cross-linked rigid polyethylene foam with a closed porous structure a few millimeters thick and a non-metallized reflective layer. Such a substrate not only protects the film from condensation and short circuits, but also allows you to direct all the heat into the room, excluding heating of the interfloor overlap, while saving up to 40% of electricity compared to cable heating systems.

For full-fledged heating of the room, it is enough to cover about 70% of the floor area of the room. Installation of heating elements under furniture and household appliances is not only impractical in terms of energy consumption, but also undesirable due to the possibility of damage to the flooring or overheating of the film.

-

Using programmable thermostats

A significant reduction in energy consumption will ensure the use of programmable thermostats for each room. This will allow you to adjust the temperature in each room individually, depending on the day of the week and time of day.

If non-programmable thermostats are aimed at maintaining the set temperature, turning off the heating when the desired value is reached and turning it on when the temperature drops, then the programmable ones are able to regulate it depending on the time or turn off the heating altogether. By reducing the heating temperature by 1 °C, approximately 4% of electricity is saved. The use of a programmable thermostat, compared to a conventional one, saves up to 30% of electricity.

By following these recommendations, you can significantly save on energy costs and keep the heat in the house when using underfloor heating film.

Energy consumption of infrared film underfloor heating

It will be a shame when, in the event of a warranty case, you will not find someone to contact. If the site has only a contact phone number and a minimum of information about the trading organization, there are no bank details, pickup points, then you should at least think a little.

The price of the product

In modern Russia, the Age of market conditions and fierce competition has come, in which everyone from the manufacturer to the consumer participates. The price of a film underfloor heating directly depends on its quality and brand.

To date, the price of a film underfloor heating ranges from 550 rubles. up to 1000 rubles for striped and from 1200 to 1750 thousand per square meter for continuous thermal film.

With a large availability of various brands and fierce competition between manufacturers, everyone strives to make their product more accessible, but everyone has their own limits, crossing which economic feasibility is lost.

It is possible to reduce the cost of goods only through the use of lower-quality materials in the production, but even that is not infinite. For example, if in the production of a protective layer of a thermal film, instead of components made in Korea, materials made in India are used, then the difference in price will be about 100 rubles, but, accordingly, will entail a decrease in the quality of the goods.

You can, of course, get a discount from a trading company, but for this you need to buy in bulk.

Installation of film underfloor heating

This is a very significant topic for conversation. Buying thermal film is half the battle, you need to correctly calculate what related products you will need, thermal insulation must have a special reflective layer, how to properly connect the ground layer without which you cannot operate electric underfloor heating, what is the best way to connect heating strips and what material to use when installing under soft coatings. By getting answers to these questions on the site or in a conversation with a representative of a trading organization, you will form the right opinion about the seller and the degree of trust in the brand.

conclusions

The conclusions are simple. Search by getting information and drawing conclusions on your own, or relying on the opinion of experts, but remember the rules:

- Buying cheap goods you save on quality.

- When buying an expensive product, you overpay for the brand, but you get confidence.

- If the seller praises only his own product and blames others, then this is the opinion of an interested person, whose opinion should be treated with a degree of skepticism.

- When buying a product, talk about the installation of a film underfloor heating, be sure to take detailed instructions and a phone number on which you can get advice.

When using the materials of the article, an active link to the article is required!

Return to list

The advantages of infrared floor heating indicated by the manufacturer

All manufacturers of this innovative product present it as something high-tech, with a lot of advantages and devoid of disadvantages. Among the indisputable advantages of the heating system, it is worth highlighting:

- Profitability. Thermal conductivity of carbon in comparison with analogues presented on the market is much higher. Thanks to this, the infrared heating system is highly efficient with less energy consumption. For example: 1.5-2 sq.m. films, depending on its width, will “pull” a day approximately like a light bulb. Yes, and the consumed electricity is spent only to replenish the heat losses of the heated room. As a percentage, energy savings are about 20%. Today, this factor is especially relevant against the backdrop of a limited limit on energy resources.

IR film connection

- Ease of installation and the ability to "grow" the system. In comparison with analogues, the same electric or water heated floor, the installation of an infrared system does not require casting on a concrete floor. The installation of the system can be completed in just 2-3 hours. If necessary, you can always dismantle and even "grow" the system to cover a larger area.

- High system reliability. High-strength carbon fiber, which is the material for the manufacture of heating plates, is resistant to influences of various nature. The manufacturer's warranty for this system averages about 10 years. The surface temperature can be conveniently adjusted using a thermostat. It limits the heating of the film, preventing its overheating and destruction, and thereby optimizing the operation of the heating system according to the specified modes.

Installation of the infrared floor is very simple

- Environmental friendliness. Infrared rays, acting like solar heat, kill pathogenic bacteria, thereby reducing the likelihood of developing allergies in residents of the house. The effect of radiation resembles the work of aeroin generators used in medicine. By deodorizing polluted air, they help to get rid of unpleasant odors in the apartment. This is especially true for pet owners whose pets like to leave “tags” on their territory.

- Versatility of application. Infrared heating film can be installed not only on the floor, but also on the ceiling and walls, insulate curved surfaces without fear of deforming the material. There is a wide range of this innovative product on the market today. The key to the reliability and durability of the system is the right choice of heating film for infrared floor heating.

Recommendations for choosing material in the video:

There is a common myth about the ionization of a room heated using an infrared "warm floor" system with anions (negatively charged ions). During the heating process, the film does emit a small percentage of anions, but the laid tile or laminate acts as an obstacle in their path.

Where can I get a qualified review of the film warm field

Yes, as usual! Only good friends who have experienced it for themselves, or compile it on their own, and this requires information from several sources. Sources can be information posted on the websites of manufacturers and their official dealers. Articles on this topic, where there are no positive reviews about only one brand and negative about all others. In conversations with company representatives and sellers in order to find out individual characteristics. Feel free to ask sales managers about the difference between their film flooring and competing ones.

Look at the characteristics, the materials from which it is made, feel, finally, because even by touch you can reveal the differences, when one thermal film is even seemingly made soundly, has inscriptions about the trademark, manufacturer, certificates, markup by footage, and the other is all transparent and flimsy and it is clear that in its manufacture they obviously saved on materials.

Feedback Tepletto infrared film heat-insulated floor Met all our expectations, provided even and comfortable heat.

27.09.2013

Review recommend:52

Advantages:

Affordable price range, easy installation.

Flaws:

It is not recommended to put heavy furniture on those places where mats are laid.

The Tepletto infrared film heat-insulated floor produced by South Korea was first used in 2012 in her house, in the living room of 38 sq. m. Prior to this, the temperature in this room, given our climatic conditions, could not be provided at a comfortable level in the cold season. What they just didn’t use: various additional sources of heating with a decent amount of electricity. Then the idea of arranging underfloor heating for additional heating appeared. Since all the construction and finishing work in the house had already been completed, only ultra-thin infrared warm floors with dry installation, without screed, were suitable for installing underfloor heating. From a large number of proposals, Tepletto infrared film warm floor was chosen. We installed it under the laminate. The installation itself was so simple that we managed it ourselves. Laying mats, assembly of the entire structure was quick. The thermostats for it were offered different from simple, just turn it on and off, and up to an adjustable touch. We have chosen an adjustable one, where you can not only set the desired temperature, but also choose the heating time.

What should I pay attention to when choosing such a thermal film

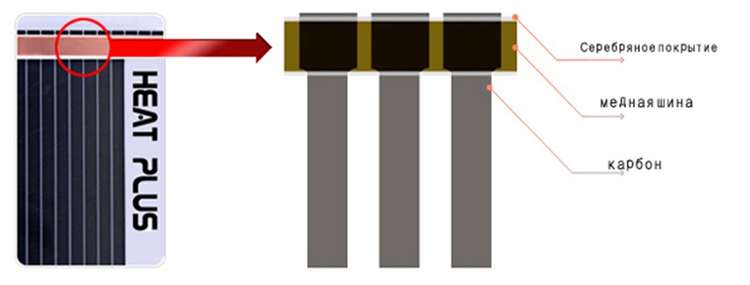

Carbon strip width

The width of the carbon strips must be at least 20 mm and located as close to each other as possible. The uniform distribution of heat over the warm floor depends on this.

Copper bars

Copper busbars must also be at least 20 mm wide and withstand current sufficient to heat the thermal film. If the tires are narrow or thin, they may heat up and burn out. The maximum length of the heating strip depends on the cross section of the copper bus.

Resistance between copper bar and carbon layer. The lower the resistance, the lower the losses during the passage of current and the less the possibility of an electric arc (sparking). Reducing the resistance between the tire and carbon is achieved by using a silver paste.

The foundation

In the manufacture of thermal films, the carbon layer is applied to the base only in continuous films. In striped thermal films, the element that maintains the shape of the heating element is the solder between the insulating layers.

Protective layers

Various materials can be used as a protective layer, for example, lavsan, polyester, polyethylene terephthalate (PET) and other insulating materials. The price of a film underfloor heating directly depends on the choice of material in the manufacture and the number of protective layers.

Manufacturer

The more the trading company discloses information about the plant where the products are manufactured, the more confident you will feel and know where to turn for advice or in the event of a warranty case. The manufacturer's website always lists companies that are official dealers in Russia and are responsible for product quality.

It is also important to know when the plant was built, because the more modern it is, the more it meets the requirements for compliance with the quality of products.

Salesman

It is desirable that the seller is responsible for the sold goods and issues all the necessary documents and warranty certificates.

Installation and useful tips

The surface of the base is leveled with specialized compounds. Irregularities or sharp drops can disable individual sections.

Leveling the surface of the base screed

If the base is made of boards, it is recommended to level the horizon with fiberboard or plywood. In case of strong drops, the surface is cut with fully electric jointers, or the places of the highest drops with a hand tool.

- Thermal film;

- Connecting wire;

- Connection terminals;

- insulating material.

Completing set of required materials

One of the external versions of the thermostat

Depending on the floor covering, other components are selected.

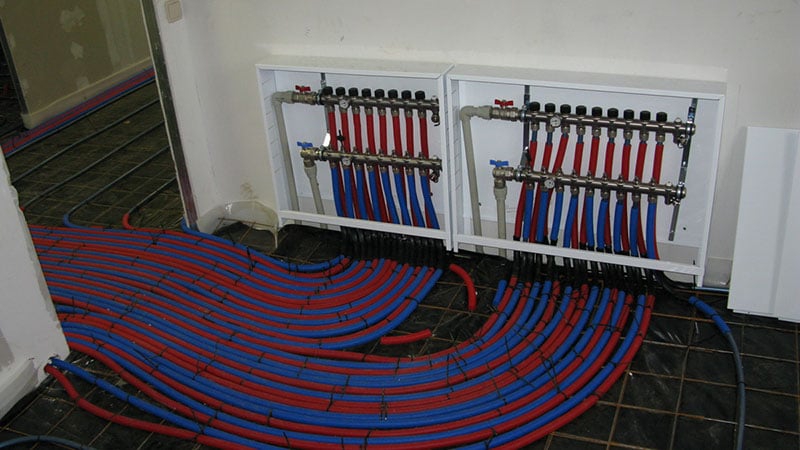

Features of the water floor heating system for ceramic cladding

To figure out how to properly make a warm floor under a tile, you need to study the principle of its operation and know the nuances for installing the structure.

Features of the operation of a water heated floor are the circulation of heated water through pipes made of metal-plastic or brass, laid under the floor finish. The system is powered by central or autonomous heating. The cost, installation and energy consumption of this type of floor heating is much cheaper when compared with electrical counterparts.

But there is an unpleasant nuance - in high-rise buildings built in the sixties, the installation of water-heated floors is not possible. Since their overlap may not withstand the additional load. In addition, obtaining permission to redevelop the heating system in high-rise buildings is quite difficult.

Next, a metallized reflective screen is lined. This is a composite material made of polypropylene fiber and a metallized film, which has the properties of reflecting thermal radiation and waterproofing. The film must be tightly fixed on the damper tape with adhesive tape.

In the process of laying a water-heated floor, all pipes are connected to a distribution manifold

At the next stage, pipes are laid. It is necessary to use special tubes mounted to the grid. In this case, the distance from the walls should be at least ten centimeters.

In the process of laying pipes, you should pay attention to the fact that they are placed strictly along the guides available on a special grid. After the adjustment relay and thermometer are mounted

At the end of the installation process, the structure is covered with a layer of cement screed.

Types of infrared film underfloor heating

- Film infrared heat-insulated floor. The essence of this system is that the heating element is a fiber laid between two layers of a polymer film. The heating film is flexible, durable, wear-resistant, and also a good dielectric.

- Rod infrared heat-insulated floor. The peculiarity of the system is that the function of the heating element is performed by carbon rods connected by a wire.

This is the most innovative of the systems, allowing to reduce heating costs by 60% (compared to other systems). Only their high price hinders the widespread use of carbon rod floors.

This is interesting: Device for sharpening drills - we describe all the nuances

House heating costs with infrared floor

Further calculations can be made by taking the average cost of electricity in the region (the price may vary depending on the location of the house). Having made a simple calculation of power consumption up to 50 m², we can come to the following results:

- Power consumption per month - 378 kW.

- For the heating season, 4 months - 1512 kW.

Next, we calculate the cost of electricity. The average cost per 1 kW in Moscow is 4 rubles. 50 kop. It turns out that you will have to pay approximately 6804 rubles for the heating season, with a long winter and late spring 9072. As a result, serious savings on heating are obtained. Of course, these results can only be achieved under all the conditions listed in the previous subheading. If you plan to use an IR system heating, as the main source of heating the building, a film with a power of 240-400 watts is required.Accordingly, the energy consumption of underfloor heating with infrared radiation will increase by about a third, in rare cases twice.

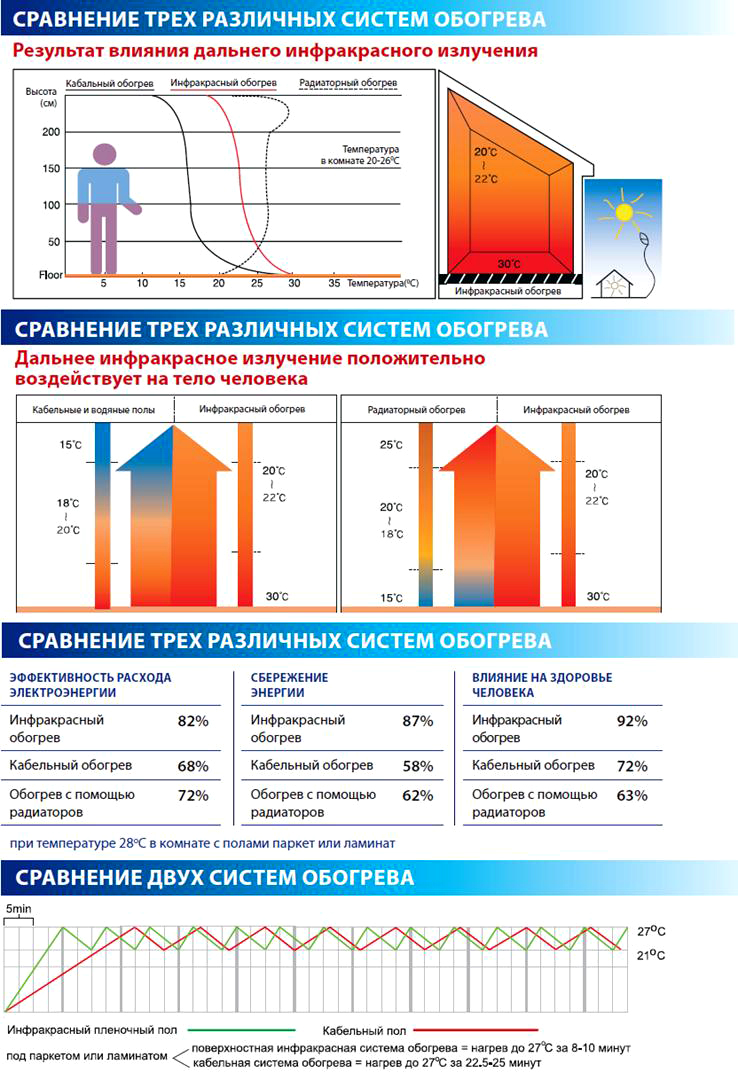

Beneficial or not heating from infrared floor

As it was shown, the energy consumption for infrared carbon underfloor heating is not so large as to categorically refuse to use an infrared heating system. Add to this a few more economic benefits from their use:

- Low operating costs. You can do the laying of the floor yourself, unlike gas equipment, when connecting, no permits and approvals are required, payment for the manufacture of projects, etc. Repair does not require large economic costs.

- The operating energy consumption per m² is lower than that of a similar system in which floor heating is carried out using cable heating. For a quick calculation of energy costs when using IR film underfloor heating, there are special tables. With their help, you can calculate the approximate cost of heating.

- Fast installation. It will take approximately 1 hour to carry out laying work by specialists (floor insulation and installation of a heating system). Subject to the use of linoleum as a floor covering.

How much power the floor consumes in Watts can be found in the technical documentation. If necessary, all calculations and the layout scheme will be performed by consultants of the company selling the film. Infrared floors are one of the most economical heating systems, which makes them the main competitors of gas and solid fuel heating.

How much electricity does a warm floor take?

As for installation under the tile. Here, many consumers have questions: will the tile stay on the film floor, will the seams crack? There is only one answer: with proper installation, the tile will hold as well as on a conventional screed. By correct installation, we mean, firstly, the use of fiberglass reinforcing mesh, and secondly, the mesh must be nailed to the primary floor with impact dowels over the entire area. Also, the tile must be fastened with a special glue for warm floors and the size of the adhesive layer must be at least 15mm. Many buyers have a question: if there are too many pluses in the product description, then what could be the minuses, which sellers usually prefer to remain silent about? In our opinion, the film floor system has the disadvantage of a large number of hidden contacts, unlike, for example, a cable floor.

Therefore, it is very important to test the performance of the system before laying the flooring and to control the work of the tile, laminate or other flooring laying masters. Contact between the heating film and the wire is recommended by different sellers in different ways: most often, contact is provided by a special connector, which is crimped with a flat press

There is also the option of soldering the film with a wire. In principle, both options provide reliable contact between the heating film and the wire. And, probably, the complexity or, even more correctly, a poor and inaccurate description of the installation of the film under the tile, which can lead to laying errors and peeling of the tile, and, accordingly, to customer dissatisfaction, can also be attributed to the system's shortcomings. Otherwise, we see only positive aspects when choosing a film infrared floor for any room. An interesting feature and, of course, the advantage of IR heating film is that it can be used not only to create a floor heating system. It can also be mounted on walls, ceilings, on any curved surfaces, without fear of deforming it. The field of application of infrared heating film is truly enormous, and sometimes customers themselves come up with ways to use its unique properties: flexibility, uniformity and speed of heating, safety. So, for example, our customers have used the film for heating containers with honey, heating equipment for the production of window sills, printing equipment, the bottom of artificial reservoirs, creating greenhouses, etc. We hope that you will appreciate this modern and practical material! We wish you happy shopping!

Underfloor heating classifications

There are two main types of underfloor heating:

- Water;

- Electric.

The electric floor has 3 types:

Single core cable. The whole system consists of a one-piece cable without a bonding substrate and joints;

Self-planning "pattern", a budget option

Electric mats:

Carbon. This is a two-core system connected by conductors;

Cable. This is a one-piece cable system fixed to a fixing substrate;

Laying cable mats under tiles

Infrared electric thermal film.

Example of laying a film floor

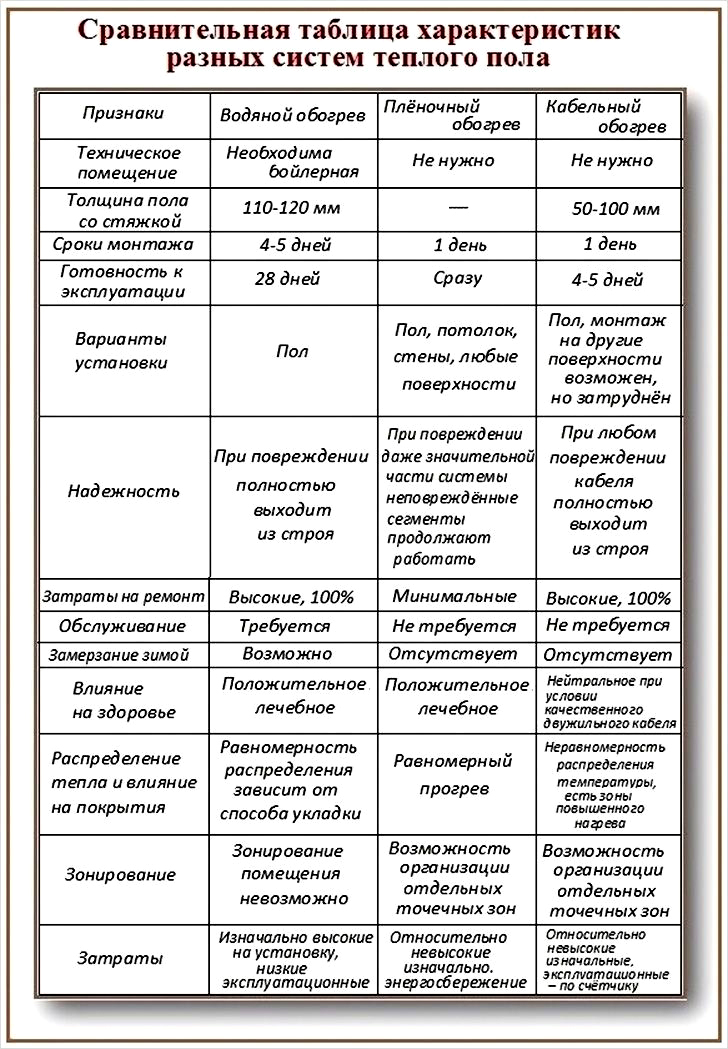

Comparison of functional characteristics

You can compare all classifications of underfloor heating in different areas: installation time, financial costs, electricity consumption, heat distribution, etc.

Table comparing the functionality of water and electric heating systems

Table of heat distribution in the room and the effect of infrared radiation on humans

Note! It is not recommended to lay the film floor under the tiled floor, since the liquid adhesive or screed in this case does not have sufficient contact area with the base and the surface will “float” and subsequently crack. Also, alkaline compounds in tile adhesive can disrupt the integrity of the protective film.

A suitable option for installation under a tile is a cable underfloor heating. Wiring diagrams for underfloor heating in a private house. Before starting work, you should study the possible laying and connection schemes. A special publication of our portal will help you.

Advantages of film material

The unconditional advantages of a film floor over a cable analogue or a water-heated floor are:

- Easy installation process;

- Since there is no screed, the height of the room remains practically unchanged;

- Failed sections do not interfere with the further operation of the entire system. Damaged elements are easily replaced without dismantling the entire system;

- Since the surface of the film floor heats up everywhere, it will not be difficult to find the area with damaged sections.

Positive aspects of the film sample

The electricity consumption of a film underfloor heating depends on the power and, as a rule, has the same characteristics as a cable floor. Reviews of power consumption are easy to find on the net.

Underfloor heating electric, electricity consumption per 1m2

With regard to connecting to the mains, if a large area is covered, then it is better to bring it to a separate machine, you need to consult an electrician. The floor is heated instantly, after 5-6 minutes. the floor is already warm. The programming mode was chosen: in the morning from 6-8 o'clock, in the evening from 17 to 21 o'clock and this is quite enough. With this mode of use, the power consumption is small, there was no significant increase in the bill. Tepletto infrared film warm floor met all our expectations.

| Usage time: | 1 year |

| Year of manufacture/purchase: | 2012 |

| General impression: | Met all our expectations, provided even and comfortable warmth. |

| My mark: | |

| Recommend to friends: | Where is it more profitable to buy |

Infrared film underfloor heating is a distributed heating of a room in which the heat source is a carbon (hydrocarbon) thermal film. Infrared thermal film belongs to the electric heating method and shares its niche with cable underfloor heating, but not competing, but complementing each other. Cable floors are mounted in a coupler and under a tile, and a film heat-insulated floor under dry floor coverings, such as a laminate, linoleum, a carpet.

In general, everything is clear and it would seem that there is nothing difficult in choosing a warm floor, BUT, before making their choice, the consumer wants to find reviews about warm floors, and here the fun begins. There are an endless number of sites on the Internet dedicated to this topic and even more articles and comments about underfloor heating.