Power calculation

When designing a future floor heating system, you need to calculate the required number of mats and distribute them in an optimal way. The core heat-insulated floor has in a complete set all elements, necessary for installation. But in some models, additional elements for installation may be required.

When calculating, you need to pay attention to two factors:

- type of heating. The heating system can be either main or additional;

- heated area. It is necessary to take into account the area in order to mount heating that can provide an optimal comfortable temperature.

These two facts will affect the power of the system chosen. There are two categories of carbon rod underfloor heating on the market:

- power up to 160 W/m2;

- power up to 220 W/m2.

The higher the design temperature, the more power the system needs to use.

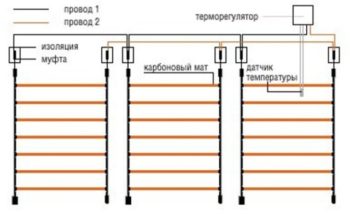

When designing the location of the mats, they can be oriented in any way. But, according to the advice of experts, it is better to build them along the longest wall. The connecting contacts must point towards the thermostat. So you can achieve a minimum number of cuts in the heating cloth, reducing the length of the installation wires from the thermostat.

What underfloor heating to choose for a private house and apartment

The choice of underfloor heating system is carried out taking into account such factors as:

the size of the room, in particular floor area and height;

type of heating. Whether the underfloor heating system will be the main source of heating or additional, will have a significant impact on its capacity.

What to look for when choosing underfloor heating

indoor environment. All underfloor heating systems, except for infrared rods, are very sensitive to overheating, which means that they cannot be mounted under furniture and heavy household appliances. The minimum height is 350 mm. Often this leads to the fact that one part of the floor is significantly warmer than the other. Uneven heating (temperature fluctuations) negatively affects the wooden flooring (floor board, solid board, parquet);

wall height. It should be borne in mind that some underfloor heating systems are mounted exclusively in the screed. This statement is true for a water-heated floor, rod and electric with a heating cable or mats. The higher the height of the heating element (pipe diameter or cable section), the thicker the screed will be. If the height of the walls does not allow raising the floor by 70-100 mm, then film warm floors should be considered;

maintainability of the system. The coupler thoroughly closes access to the elements of the system, which creates additional problems in the event of a malfunction, i.e. cannot be quickly repaired. Even to identify the place of failure without dismantling the floor is problematic;

work speed. The speed of work is understood as the performance of all types of work: from design to fine surface finishing. Despite the fact that the core floor is mounted within a few hours, it is not recommended to turn it on until the screed is completely dry, and some manufacturers (for example, Kaleo) set a limit of 28 days. The water floor is also mounted for a long time, which is associated with the specifics of the pipe layout and also requires complete solidification of the screed. The best option from the point of view of "operation immediately after installation" would be a film infrared heat-insulated floor.

type of finished flooring. In many ways, the final choice is determined by the answer to the question, which warm floor is better for tiles, or which warm floor is better for laminate.Indeed, in one case, the use of glue is required, and not all systems are suitable for this, and in the other, it is necessary to take into account the tendency of wood to deform and the presence of harmful substances in the composition of materials (it is possible to release, for example, formaldehyde when heated).

As you can see, there are many factors that influence the final choice of a warm floor system, the most complete consideration of which will help you make the right choice.

Tags:FloorWarm floorHeating

Which underfloor heating is better comparative characteristic

The table summarizes the main parameters for comparative analysis.

| Indicator | water floor | electric floor | |||

|---|---|---|---|---|---|

| Cable | Cable in mats | Film | Rod | ||

| Heating type | Convection | thermal radiation | |||

| Warm-up time, min. | 30-60 | 20-30 | 20-30 | 5-10 | 10-15 |

| Overheat resistance | – | + | + | + | – |

| Add. equipment | boiler | – | – | – | – |

| Installation restrictions | |||||

| - on the balcony / loggia | – | + | + | – | – |

| - in a private house / in the country | + | + | + | + | + |

| - in the apartment | - (requires permission) | + | + | + | + |

| Power per 1 sq.m. | Depends on boiler power | 180-220W | 180-220W | 25-45W | 25-50W |

| Food/fuel | Gas, solid fuel, electricity | Electricity | |||

| Mounting method | Wet work | Wet work | Wet work | Dry works | Wet work |

| Can be dismantled and reused | – | – | – | + | – |

| Installation restrictions | Cannot be installed under furniture or other low-standing objects | ||||

| Installation in a large room | + | (due to the cost of electricity) | |||

| – | – | – | – | ||

| System inertia | high | average | average | high | low |

| Possibility to adjust the temperature | – | + | + | + | + |

| Repairability | – | – | – | + | – |

| The entire floor needs to be removed. | Easier due to the absence of screed | Dismantling | |||

| Influence on the height of the walls | up to 150 mm | 50-80 mm | 30-50 mm | 5-10 mm | 20-30 mm |

| The weight of the underfloor heating system per 1 sq.m. area | 200 kg | 30 kg | 30 kg | 2 kg | 30 kg |

| Mounting speed | 4-7 days | 1-2 days | 1 day | 1 day | 1 day |

| Time to Operation | 7 days | 7 days | 7 days | 1 day | 28 days |

| Initial investment | low | low | medium | high | very high |

| Operating costs | high | very high | very high | high | medium |

| Economical compared to radiator heating | up to 25% | up to 50% | up to 50% | up to 70% | up to 80% |

| Installation in a room with high humidity (in the bathroom, in the bath) | + | Possibly with reservations | Not recommended | + | |

| Floor Compatibility | |||||

| – natural wood (floor board, parquet) | – | – | – | – | + |

| – laminate | + | + | + | + | + |

| – linoleum | + | + | + | + | + |

| – tiles / porcelain stoneware | + | + | + | + | + |

| – carpet | + | – | – | + | + |

| Radiation | No | electromagnetic | infrared | ||

| Popular / well-known brands | – | – | Devi, Teplolux | CalorIQue, Devi, K-Techno-logies (ТМ Caleo) | K-Techno-logies (TM Unimat), Felix (TM Excel) |

| Price, rub/sq.m (medium range) | 200-500 | 400-900 | 700-2000 | 1350-1700 | 1500-2685 |

| Estimated service life, years | 10 | 15-20 | 15-20 | up to 50 | up to 50 |

The material was prepared for the site www.moydomik.net

Carbon rod underfloor heating

Infrared carbon underfloor heating is one of the types of electric underfloor heating that has positive features. Rod elements heat the flooring with infrared radiation.

Under the action of infrared waves, the elements of furniture and flooring are heated, and not the air in the room. Thanks to this, comfortable conditions are created.

Infrared rod carbon warm floor has carbon threads in its structure, which are connected to each other by a multi-core cable. It turns out a flexible mat that is easy to lay out, and the heating elements already have an optimal pitch, which allows you to effectively warm up the floor covering without the formation of cold spots, the so-called "thermal zebra".

There are also film carbon warm a floor that has special strips rather than rods as heating elements.

This unique technology for creating comfortable conditions is gaining popularity. At the same time, installation is easy, which you can do yourself.

Rod carbon underfloor heating

Today, core floors (infrared mats) are the most

new and most progressive type of warm floors. for the system's ability to

self-regulation, it is often called the “smart floor” system. Carbon fiber construction

rod flooring is more complex than film flooring. Though

here carbon fiber also acts as a heating element, it has

another configuration.

Rod carbon warm floorInstalled rod warm floor

Rod carbon floor heating element –

rod filled with carbon-polymer filler. Rod connection

occurs using a stranded copper wire (thickness 2.5 mm) with

additional protective insulating sheath made of polyester and polyethylene.

Scope of use of the core floor

Due to its enhanced performance

the core floor can be used in a living room, in a bathroom, on a loggia,

in the room, in the winter garden, in the gym, in office buildings, warehouses, as an element

anti-icing systems.

The core floor can be laid on any type of flooring, without

exceptions. It is ideally combined with such fastidious material as

natural wood, parquet or laminated board. And in view of the fact that

a rod carbon floor is mounted on a thin layer of screed, such an electric

floor heating system, it is the only one suitable for installation under

tiles or porcelain stoneware. In addition to the possibility of installation, the rod system

allows you to save on work, if you use glue instead of a screed

mortar and direct tiling.

Rod carbon underfloor heating - pros and cons

Advantages:

resistance of the elements of the core floor to the impact

aggressive media and mechanical loads;

the estimated life of the system is 50 years;

parallel connection system that provides

maintaining performance in case of damage to the heating mat;

high rate of heat transfer;

efficient heating (the most economical system with the most

high efficiency);

uniform and fast heating of the room;

thanks to infrared radiation eliminates unpleasant

smells;

fire safety (the presence of silver in the rod is not

allows the system to ignite);

no electromagnetic radiation;

light weight (no load on floors);

can be used in rooms with a high level

humidity;

relative ease of installation;

the ability to install heavy objects of any area on the floor

(particularly furniture and household appliances). The system will adjust the floor temperature to

different places on your own.

the presence of self-regulation protects the floor from overheating.

heating of large areas is possible.

If you figure it out, then acquiring a rod infrared carbon

floor - the user buys a floor heating system that significantly

outperforms systems of similar purpose in its characteristics.

Flaws:

installation is carried out only with pouring the screed. It's "wet"

work and lack of mobility. Unlike the film system, you cannot pick up

with you when moving;

high cost (retail price - 1500-2685 rubles / sq.m.)

Technical characteristics of the core underfloor heating

General characteristics are slightly different depending on

manufacturer, but the analysis of different systems makes it possible to bring average

data:

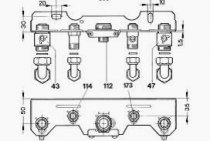

- roll width - 830 mm;

- length - 25000 mm;

- mat thickness - 3-3.5 mm;

- power per 1 sq.m. mat - 125 W / m. (stem temperature 60

°C) – 170 W/m. (stem temperature 20 °C); - power consumption per 1 r.m. - 20-50 W;

- the maximum surface temperature is 60 °C.

The best manufacturers of core underfloor heating

- K-Technologies - trademarks GTMat, Unimat, RHE (Russia);

- GH Systems - trademarks of HOTmat (South Korea);

- SamMyungTech LTD is a trademark of EcoOndol (South Korea);

- GT is a trademark of GT (South Korea);

- Felix is a trademark of Excel (South Korea).

Conclusion

Reviews of those users who have already installed the system

infrared carbon warm floor, allow us to assert that it is worthy

an alternative to existing systems, both in terms of operational properties and

and in terms of heating efficiency. The installation of a rod floor allows

Reduce space heating costs by up to 50%.

Tags: Floor Warm floor Heating

Morphological analysis of the word Sterzhnevoy

Lemma: Rod

Part of speech:

Adjective

singular, masculine, animate, inanimate, nominative

Adjective

inanimate, masculine, singular, accusative

Adjective

feminine, singular, animate, inanimate, genitive

Adjective

feminine, singular, inanimate, dative, animate

Adjective

animate, instrumental, inanimate, feminine, singular

Adjective

singular, feminine, prepositional, inanimate, animate

Expressions and words closest in meaning

Total found 78 similar words

overriding

leader, chief

Senior

adult, chief

guiding

leading, leading

Finite

main, final

first class

best, high quality

prevailed

chief, reigning

Best

best, optimized

Title

first

selective

best, high quality

Radical

root, active

Aboriginal

eternal, condo

Important

up-to-date, up-to-date

Elitist

the best, choice

Medullary

central

Best

highest, Kazovy

fateful

most important, most important

dominant

leading, dominant

Dominant

dominating, dominating

Dominant

dominant, dominant

single node

nodal

Great

delightful, delightful

cornerstone

general, main

Elementary

original, inferior

Supreme

general, suzerain

Aboriginal

indigenous, aboriginal

first class

cool, awesome

The most important

chief, cardinal

Significant

topical, important

Initial

original, primary

priority

combat, priority

Basic

basic, basic

Authentic

main, original

Enviable

bad, good

Pervenky

first

Premier

first

Early

early, untimely

dominant

dominating, dominating

fundamental

basic

Fundamental

constitutive, fundamental

Debut

first

Decisive

main, closing

Signal

two-signal, aircraft signal

Basal

basic

Excellent

enviable, splendid

Substantial

substantial, basic

Leading

lead, pilot

Combat

active, abusive

first class

best, first class

Trunk

main, airline

essential

central, essential

Rootstock

horse, native

born

indigenous, natural

Hereditary

indigenous, hereditary

primordial

root, eternal

two-node

nodal

constitutive

fundamental, defining

Trial

exemplary, exemplary

Elementary

ingenuous, natural

Median

median, mean

General

supreme, chief

preeminent

dominating, dominating

Middle

central, middle

Higher

pain, apex

Note

first

Minicentral

central

Elite

the best, choice

Cardinal

general, chief

Kondovy

original, durable

Significant

significant, concrete

Fundamental

main, durable

Substantial

substantive, basic

Capital

general, profound

Good

benevolent, impeccable

parade

main, tinsel

Key

electric key, main

multinode

nodal, five-nodal

largest

maximum, ultimate

Head

chief, leading

Mounting Features

The installation technology will consist of several stages. Each of them is important in order to ensure the best efficiency of the heating system and the use of a minimum amount of electricity.

Before installing a carbon rod floor, you need to familiarize yourself with the safety precautions when working with electrical appliances:

- all stages of work should be carried out only with the electricity turned off;

- do not overlap the rods, because this will lead to damage to the mats;

- do not operate the floor until the screed is completely dry. Including you can not turn on the system itself, so as not to cause an accelerated drying process, which adversely affects the strength of the screed;

- you can not use self-tapping screws and other screw-in fasteners on the floor, because the probability of hitting the rods is very high;

- when flooding the flooring, you need to turn off the system from the electricity supply until it dries completely. At the same time, it is impossible to use a warm floor as a means for drying.

Equipment

The minimum set should include the following items:

- mat with carbon rods;

- connecting wires;

- end connecting elements;

- installation instructions.

In addition to the kit you will have to buy:

- corrugated pipe;

- thermostat;

- temperature sensor;

- heat-insulating material (preferably foil);

- bituminous insulation;

- Scotch.

Foundation preparation

The base should be level, but not necessarily perfect. Small deviations in height are allowed, not exceeding 3 mm. If the defects exceed this value, it is necessary to do leveling work.

To install the thermostat, you need to punch the wall in order to covertly install the connecting wires in the corrugated pipe. The height of the thermostat should be at the level of 0.9–1.7 meters. In the same way, a ditch is made for laying the temperature sensor.

Substrate heat-insulating layer

The use of a heat-insulating layer will improve the efficiency of the system. In this case, the insulation must be brought to the walls in order to block the loss of heat through the side surfaces.

How to lay a rod electric carbon underfloor heating

Installation is easy and simple. It is necessary to roll out a roll on which the rods already have an optimal pitch. If necessary, the mats are cut. Neighboring mats should be 5-7 cm apart from each other. It is desirable that one mat be less than 25 meters long. To prevent the mats from moving, they are fixed with tape.

Connecting to a thermostat

For the correct connection of wires from core mats, it is better to use the instructions. If there is no confidence in this, then it is better to entrust this stage of work to the masters.

Mounting the temperature sensor

The temperature sensor is placed in a corrugated pipe, which will allow, if necessary, to replace a faulty sensor. A special ditch is prepared for laying the corrugated pipe. It is advisable to plug the laid corrugated pipe from the open side on the floor so that the solution does not get on the sensor during concrete pouring. The sensor contact is connected to a special connector on the thermostat.

Test run

After all the wires are connected, electricity is supplied to the heating mat. A functional check is necessary to check the correct connections and the reliability of the contacts. The time of the first test run of the system should not exceed 15 minutes.

Filling the screed

On top of carbon mats, it is recommended to make a screed from dry adhesive mixtures. In this case, the thickness of the screed layer should be 2-3 cm. At a minimum height, the installation of carbon mats will not greatly affect the height of the room.

https://youtube.com/watch?v=qasfwsItpgQ

Installation of carbon fiber underfloor heating

Laying a warm floor under the tile is very simple, but if you need to install a thermostat, in this case you will have to seek help from a specialist.

The beginning of installation work is the preparation of the floor surface. If there are gaps, depressions, irregularities on the base of the room, it must be leveled with a concrete screed, and then proceed with the phased laying of the core floor:

- Determine the location of the thermostat.

- For the sensor, make a groove under the thermostat in the floor.

- Heat-reflecting material is laid on the floor, keeping a distance of 5 cm from the walls, with the foil side up. Then, in order to exclude its mobility, all elements are fixed to the base of the room with building tape or glue, while making sure that the carbon rods do not cross.

- Infrared mats are laid on a heat-insulating layer and fixed with adhesive tape. If necessary, the core "carpet" is cut along the marked lines, turned over and laid along the first strip, keeping a distance of 6 cm between them.

- A special sensor with a corrugated pipe is installed in a groove in the floor.

- A thermostat is installed in a pre-prepared place. Next, the mats are wired to it.

- After all the work has been completed, it is necessary to check the operation of the system.

Filling the solution in this case is not required, the tiles are glued directly to the mats. If, nevertheless, the core mats will be used under another floor covering, then they must be filled with a solution, no more than 3 cm thick.

Having become acquainted with the device of a rod infrared warm floor and its principle of operation, it can be confidently attributed to the best heating systems. But do not forget that the efficiency in heat supply directly depends on the correct installation. Therefore, if you doubt your abilities, it is better to invite a specialist to lay warm mats.

Subgroup electric cable underfloor heating

Cable underfloor heating in a coil (in a bay, per meter)

Floor heating cable systems are quite popular among manufacturers. And many of them offer to buy a ready-made kit. Among the leaders in the market are Devi (Denmark), Caleo (South Korea), Teplolux (Russia). The price for a set varies from 10,000 to 37,000 rubles. depending on the heating power, length and type of cable.

The packaging also affects the cost. There are options that include only the cable, regulator and sensor, and some even contain a tool for installation. You can reduce the acquisition cost if you complete the system separately. For example, the price of a DEVIflex cable (100 W) is 3,850 rubles / 10 m.p., a thermostat with a sensor will cost 6,670 rubles.

Pros: relative cheapness, well suited for use under tiles;

Cons: the complexity of calculation and installation, the height of the room is reduced by 50-100 mm.

We recommend a detailed description -

Cable underfloor heating in mats

It is advisable to choose this option for those who plan to carry out the installation themselves. The price on the example of Devimat is from 4,950 to 22,750 rubles. The cost is affected by the area of the mat, its power, the type of heating cable used.

Pros: thinner cable, ease of calculation, mats are easy to lay out (the mesh on which the cable is attached can be cut) and mounted, a constant distance between the turns of the cable is maintained, there is no need to fill the screed, due to the thickness of the warm floor, the ceiling height is reduced by 10-30 mm ;

Cons: higher cost of mats (by 25-30% compared to the cable system).

What is carbon underfloor heating?

Consider one of the new systems of electrical infrared

heating - carbon warm floor (carbon, carbon fiber). This

progressive floor heating system, the action of which is based on the use of

far infrared radiation. The distinguishing feature of this range is

absence of electromagnetic radiation and "live" space heating.

Infrared radiation is harmless to human health, and in medicine in general

used for medicinal purposes.

Carbon and carbon underfloor heating - what's the difference?

Carbon is the international name for all composite

materials based on carbon nanostructure and

various binders. Thus, what is known

domestic consumer as carbon, and carbon is one and the same substance.

Those. film carbon floor and film carbon floor are the same

system.

Manufacturers offer two types of carbon floor systems:

- film carbon fiber floor heating (solid);

- rod carbon warm floor.

There are two more types of carbon floors on the market:

Bimetallic underfloor heating

Bimetallic warm floor Heating system based on bimetallic film.

A distinctive characteristic of the carbon film is the patented two-layer

connection (top layer of copper alloy and additives, and the bottom layer of aluminum alloy with

additives). The heating plates emit infrared waves.

Such a warm floor is laid only in a “dry” way, in a screed or in tile adhesive

forbidden.

Amorphous warm floor (ANT)

Amorphous underfloor heating (ANT) Israeli company Advanced Heating Technologies (AHT) Ltd has developed a new technology - underfloor heating based on amorphous metal tape. The main feature is fire safety, because. floors do not heat up above 35 °C (for example, cable floors can heat up to 60-70 °C). Made in the form of thin heating mats. The heating element is made of amorphous metal (ultra-thin tape, 30 microns thick). A warm floor on an amorphous tape can be installed under all floor coverings (tiles, parquet, laminate, linoleum and carpet).