Types of carbon systems

Carbon fiber underfloor heating is laid as the main heating in small rooms, or as additional heating in separate cold areas of an apartment or a private house. Thermal film, sheets with a continuous application of a carbon mixture, and rods are used as heating devices. What are the characteristics of systems?

- Thermal film is produced in rolls. It is thin, no more than 0.42 mm thick. The material is made of polypropylene. The carbon mixture is applied between the film layers in horizontal or vertical stripes. The spray method is used. A heating element made of copper and silver runs along the upper and lower edges. Electrical wires are connected to it. Depending on the floor surface, a material with a power of 100 to 220 W / m2 is chosen. The thermal film is placed in a room with the correct configuration. It can be cut into strips only according to a special marking, which does not allow violating the integrity of the carbon layer.

- Carbon fiber underfloor heating with a continuous application of the mixture has the same properties as the thermal film. A distinctive feature is that there are no markings on the sheets. You can cut out any circuit, so the system is used to heat rooms with non-standard geometry. It is possible to install stationary furniture on the sheets without fear that the heating element will be clamped, which can lead to overheating and shutdown of the system.

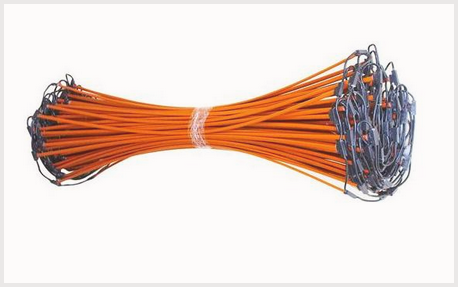

- Carbon rods increase the floor heating surface. They are assembled in a contour with a step of 10 cm; connected by copper wire, which is insulated with a plastic coating. This coating withstands high temperatures over 100 0C. The system is produced in rolls. During installation, the tape is not cut. Make an incision in the wire, turn the roll in the right direction, continuing the laying.

For space heating, it is proposed to use a rod system from Unimat; Korea manufacturer. Heating works from a network of 220 V. The maximum temperature of a heating rod is 60 0C. Average energy consumption 24 W per 1 lin. m.

During installation, it is recommended to use a reflective screen on a lavsan basis. As a control unit, a thermostat from Kaleo is installed. The technical data sheet describes the power of the system depending on the conditions of the room and on the nature of the finish coating.

Why carbon fiber heated floor is better than others

Carbon heated floor is more often used for heating houses. Such a heating system has such advantages.

Self-regulation

Carbon floors independently control the temperature and reduce energy consumption. In such a situation, the homeowner does not need to buy expensive electrical equipment.

As the temperature rises, the distance between the parts of the heating elements increases, and the heating of the room becomes less - an increase in resistance occurs. As a result, the carbon floor reduces the consumption of electrical energy.

When the temperature drops, everything happens exactly the opposite.

Reliability and safety of solid floor technology

The infrared carbon warm floor never overheats, so it keeps the parquet, laminate and other floor coverings safe and sound.

The infrared radiation of the heated floor does not have any side effects.

The scope of use of such infrared floors is expanding every year. They are installed in spas, modern saunas and other places.

Profitability of imported options

The carbon floor has a power of 116 watts per linear meter.

When the adhesive layer or screed is heated, under which such a heating system is placed, the power consumption decreases - and it becomes equal to 87 watts per 1 linear meter.Carbon underfloor heating is considered one of the most effective.

Properties of film CTP

The film carbon warm floor heats up quickly and evenly. It can function continuously for quite a long time, is very durable, is not afraid of mechanical stress and is not subject to corrosion.

Due to lamination in a special film, the possibility of water and steam getting on the contacts is completely excluded. The film is also fireproof and has a high melting point (120 degrees).

A significant advantage is the mobility of the film QFT. It can be easily dismantled and taken with you when moving, used on walls, sloping surfaces and heated in certain areas of the apartment.

Absolute noiselessness, the ability to ionize the air and hygiene allows you to install film carbon warm floor in medical institutions.

Film carbon warm floor

Film carbon electric underfloor heating got its

the name from the appearance - films. Although the actual heating element

the carbon-graphite mixture protrudes, which is located between the two layers

dense polymer. The polymer film withstands temperatures up to 120 °C, which

allows us to talk about reliable protection of the heating element. In this way,

The three-layer structure of the film provides good heating and ease of installation. A

5 protective layers applied from each

sides of the film.

Heating carbon film underfloor heatingFilm carbon fiber underfloor heating

The peculiarity of the film carbon floor is that it does not

needs a screed. To mount the system, it is enough to lay

film under the floor covering.

Note. The film floor is mounted on

prepared base, directly under the finished floor covering. At

installation of the system, the use of foil insulation is prohibited.

Scope of use of carbon film floor

Continuous carbon film underfloor heating can be laid under any

flooring. The exception is:

- carpet (due to poor thermal conductivity);

- tiles (due to the need to perform wet work).

The wooden floor can be laid on the film, but with some

restrictions due to the specifics of the wood itself (its ability to

crack). Therefore, the temperature of the heating element must not exceed

28°C. The same conditions must be observed when laying the film under the laminate.

Please note that we are talking about the temperature of the

heating element, not the front surface of the floor. After all, part of the heat

spent on underfloor heating

Film carbon fiber floor heating - the pros and cons

Advantages

temperature resistance;

high heating rate and uniform heating

the entire surface of the coating;

the ability to integrate with the "smart home" system;

strength;

resistance to moisture and corrosion;

spark resistance;

environmental friendliness;

neutralization of unpleasant odors;

ease of installation;

mobility. The film can be mounted not only on the floor, but

and on walls and ceilings. True, in the case of ceiling mounting, the efficiency

decreases. If necessary, the film floor can be disassembled and moved or

move to another room. Also, its use does not create difficulties in

moving furniture;

in case of damage to one section of the floor, the rest continue

operate in an unchanging mode;

the small thickness of the film does not reduce the height of the room. So

Thus, when mounting the film, there is no need to make a step between

heated and unheated zone (room). And don't raise the floor

screed, as is the case with other types of floor heating systems;

relatively low retail price - 350-900 rubles/sq.m.;

energy savings (up to 30% compared to cable

floor heating system).

Flaws:

lack of resistance to mechanical stress.

Directly with the heating film must be handled carefully during installation,

so as not to break it;

significant cost of a set of equipment.

Specifications of carbon floor

Characteristics and properties depend on the manufacturer. Analysis

several systems will provide averaged data:

- roll width - 500-1000 mm;

- length - 50,000 mm;

- heating film thickness - 0.23-0.47 mm;

- power per 1 sq.m. films - 25-35 W / m;

- the maximum surface temperature of the film is 33 °C.

The best manufacturers of carbon (film) floor:

- CalorIQue LLC is a trademark of CalorIQue (USA);

- Devi (Devi) - trademark Devi (Denmark);

- Ensto Electrification is a trademark of Ensto (Finland,

Estonia); - K-Technologies is a trade mark of Caleo (Russia);

- RexVa is a trademark of XICA (South Korea);

- Sangwoon Trade Co is a trademark of Ace Floor (South Korea).

Reviews about these manufacturers are mostly positive.

Users confirm that carbon floors work without problems during

at least five years, note the absence of extraneous sounds during operation

(crackling, etc.) and smell.

Preparatory work before installation

Before you start installing underfloor heating, make sure you have all the materials you need:

- Lots of carbon mats. During the calculation, it must be taken into account that the coating is allowed to be cut and laid in any desired direction.

- Floor temperature sensor.

- Required number of UTH thermostats. It must be remembered that they are selected with indispensable consideration of the power consumed by the film floor system.

- Temperature sensor responsible for activating the "overheating protection" mode.

- Heat reflective material for the substrate. Allows for more advantageous use of the system by reflecting downward heat radiation.

Before laying down underfloor heating need to prepare the surface

Important: A specialized coating based on polypropylene or lavsan film is used as a substrate. It is absolutely forbidden to use aluminum-based foil, which can provoke a short circuit and system failure.

Where can carbon flooring be used?

Underfloor heating rod carbon flooring is one of the varieties of infrared structures that can be put under the laminate for example. It is a stationary intelligent heating system based on infrared floor heating mats. Each of them consists of thin carbon rods placed in parallel, which are interconnected by a hermetically insulated power cable.

Experts say that there are almost no restrictions on the use of such a floor. The system can be used for heating:

- loggias, covered terraces, balconies;

- apartments;

- premises for production needs;

- private country houses and houses;

- hotels and motels.

Underfloor heating is considered a good replacement for conventional heating radiators. All a decent number of developers are showing interest in it and are going to collect it in their own apartments or offices. But before purchasing the material, you should familiarize yourself with the good qualities that it has in front of similar options:

- Relatively light weight and, as a rule, a small load on the floors.

- The most economical energy consumption.

- Possibility of mounting on large areas.

- No need to install large and heavy heating appliances and, on this basis, equip a separate area for them.

- Possibility of installation under all kinds of flooring.

- Ability to work during the life of the structure.

- Explosion and fire safety.

- Can be installed in rooms with high humidity.

- If necessary, it can be turned off without harm to the properties of operation even at low temperatures.

- Not exposed to corrosive processes.

- No electromagnetic radiation.

- Fast heating.

- The presence of a special self-regulation system that protects the system from burnout even in the event of a defect in the screed. Moreover, thanks to it, heavy furniture can be installed on top of the mounted floor.

The practical infrared heated carbon floor has the only drawback: the mats can only stand in a thin screed or in a layer of tile adhesive. Similarly, a stationary system is obtained, which, with all the desire, cannot be dismantled.

Infrared carbon floor consists of rods interconnected by a power cable

Installation of infrared, film, rod carbon, electric heating installation under a tile, a board

Before installing the core underfloor heating under the tiles, the master installs the carbon core mat.

New generation materials are used for laying carbon flooring

When laying the mat, several standard fixtures and materials are used. The mat is installed under the adhesive layer or under the screed. Installers cut the mat in multiples of 10 cm in length. The length of 1 strip is 25 m.

In order to install an infrared rod underfloor heating under the tile, you need the following materials:

- Heat insulating underlay. It increases the performance of the carbon mat and reduces heat loss;

- Connecting kit - 4 heat shrink pipes and 2 sleeves;

- Heat shrink insulation - 2 thick-walled carbon tubes for each mat strip;

- Thermostat, on which a temperature sensor for the floor is installed;

- Corrugated tube. It is used when installing a temperature sensor for the floor;

- Connecting wire that has double insulation.

When installing a carbon mat, installers perform the following actions:

- free the base of the floor from debris and level it;

- calculate the installation area of the mat;

- choose a place to install the thermostat. In such a situation, a groove is made in the floor and a sensor is installed in it in a pipe covered with corrugation;

- further, a heat-reflecting material is placed on the floor surface and attached to the base of the floor - with tile adhesive or adhesive tape.

In such a situation, the roll is rolled out from the place where the thermostat will stand;

- further, the strip is cut into several parts and rotated 180 degrees;

- then the strips are attached with adhesive tape to the heat-reflecting material and docked together;

When laying a heated carbon floor, the carbon rods must not be allowed to cross each other:

- then the strips of the mat are interconnected with special wires for installation. At the same time, in the cut places of the mat, the wires are stripped of insulation;

- then a sleeve is placed on the wire, which is located in a heat-shrinkable pipe, and clamped with crimping pliers;

- further, remove the insulating material from the connecting wire and put a heat-shrinkable pipe;

- then, the power wire of the mat is connected with a sleeve to the connecting one;

- further, a sleeve is placed with a building hair dryer;

- then, the heat-shrinkable pipe is moved to the connection and fixed with a stroyfen.

As a result, all the strips of the mat are connected;

- then, with an end kit, installers isolate the ends of the wires;

- then, a heat-shrinkable pipe is placed on the wires, seated with a stroyfen and crimped with tongs;

- further, 1 strip of the mat is attached to the thermostat using a special connecting kit - according to the instructions that are attached to such a tool;

- then, holes are made in the heat-reflecting material for a strong connection to the floor;

- then, the temperature sensor is inserted with a probe into the pipe covered with corrugation;

- further, a plug is placed on the pipe;

- then, the pipe is placed in a groove along the carbon rods;

- then, the thermostat is mounted in the wall and the heating system is checked for 15 minutes. Also, the strength of the joints is checked.

Next, the carbon mat is covered on top with a screed or adhesive solution.

WATCH VIDEO

The screed is poured onto the rods of the heated floor. Installation of tiles is also done on a heated floor - while using tile adhesive.

The thickness of the screed or adhesive layer together with the tiles is at least 2 cm.

The adhesive layer, the screed dry for at least 1 month. Turn on the heating system only 30 days after laying the floor. Carbon fiber underfloor heating is expensive, but very high quality.

Film floor installation

All carbon systems are laid on a flat surface. The base is recommended to be leveled. Differences of 1 mm per 1 linear meter are allowed. m. Thermal film and rods heat the entire surface around: not only the floor covering, but also the lower base, the foundation. In order for warm air to pass upwards, thermal insulation and a reflective screen are laid on the base. In the future, the installation of a thermal film is carried out.

On the floor, the boundaries of the "warm floor" are marked. From the wall and furniture, the film is placed at a distance of at least 5 cm. The gap between the strips is 2 cm

Pay attention to the width of the roll. If the width is 50 cm, then the length of the tape should not exceed 13 m

The larger the width of the roll, the smaller the allowable length of the tape will be: width 80 cm - length 10 m; width 100 cm - length 7 m. It is recommended to pre-mark the film and divide it into separate tapes.

There is space for a thermostat on the wall. Make a hole into which a plastic cup is inserted. It will contain the entire electrical part of the system and the control unit. The control panel is left on the wall surface.

Thermal film tapes are laid according to the marking. They are connected with adhesive tape.

Contacts are connected to each sheet. The terminals are installed in the area of the copper and silver bus. Strengthen the terminals with pliers.

Install wiring; connect terminals. The connection scheme is parallel.

The joints are isolated with bituminous tape. Insulation covers the places of cuts in the area of \u200b\u200bmetal tires. So that the joints do not stand out on the surface and do not experience a large load from the floor cladding, a recess is made for them in the substrate or in the reflective screen.

A temperature sensor is installed on one of the tapes. A distance of 60 cm is maintained from the wall to the sensor, and 10 cm from the edge of the film. A niche is cut out under the sensor in the substrate.

All wires are led into a corrugated tube, which is connected to a thermostat. For the pipe, a groove is made in the floor and in the wall, which is then sealed with mortar.

The system is being tested. With a positive result, the carbon floor is covered with a substrate and a laminate is laid.

To lay the tiles, use tile adhesive.

Types of carbon floors

Currently, the carbon floor has two types, these are rod mats and film. Each model has common advantages over other systems, but they also have their own differences. Therefore, in order to make the right choice, it is worth considering them in more detail.

Rod mats

This model of electric floors is produced in rolls, with the following standards: width - 83 centimeters, length up to 25 meters, thickness no more than 3.5 millimeters. The kit includes a thermostat and a temperature sensor. For core mats, the power consumption depends on the heating temperature, on average it ranges from 110 to 180 watts per linear meter. Power consumption per linear meter is no more than 50 watts per hour, powered by a power supply not exceeding 220 volts. This type of underfloor heating can be combined with any type of flooring, but the ideal solution would be to lay a carbon fiber underfloor heating under the tiles.

Installation of core mats

Due to the fact that manufacturers have done most of the work, the installation of a carbon fiber underfloor heating is carried out several times faster than devices made from electrical cables. Installation of cable models is quite painstaking. Since before fixing the elements, it is necessary to lay the cable, with a correctly maintained distance. If we consider that such work will be required for more than one meter, then we can assume that it will take a fairly large amount of time. In the carbon rod warm floor, the distance between the rods is already taken into account, so for installation it will be enough to spread the mat on the floor surface and fix it with construction tape or glue. Where it is required to deploy the mat, it will be necessary to remove the rods from the mesh, cut the mesh along the marked lines and lay it parallel to the first strip at a distance of 6 cm, carefully making sure that the cables do not touch each other. After the laying is completed, a concrete screed is poured in a thin layer.

Infrared film

The film carbonic heat-insulated floor consists of a continuous layer. Its elements are connected by soldering, due to which such fastening is more reliable than clipping. Carbon film can be cut into strips of different sizes, in any direction. There are currently two types of infrared film:

- Normal. Such a film consists of one or two layers of polypropylene, on which a layer of carbon-graphite mixture is applied in stripes.

- Solid. This film has great protection against overheating, as it consists of 13 layers, where on each side there are 5 security layers and 3 working layers between them. Such a film is made of pure carbon fiber, so its price is much higher than that of a conventional film.

Both of these carbon floor films are absolutely safe, as they can withstand temperatures up to 120 degrees. But if a continuous film can be laid under overall furniture and electrical equipment, it is strictly forbidden to use the usual one in these places, for the reasons that the effect of thermal locking may occur.

Mounting infrared film

A feature of film floors is that during their installation there is no need to pour a concrete screed. In order to mount them, it will be enough to spread the film on a clean base of the room, and then lay the floor covering. But here it is worth noting that the film floor heating is not combined with carpet and tiles. Since in the first case there will be insufficient thermal conductivity, and tiles require a concrete screed. Wood flooring also has its limitations. To avoid the formation of cracks when the wood dries out, film floors should not exceed a temperature of 28 degrees. The ideal option would be to place a warm floor under a laminate or linoleum.

How to install a rod floor

The rods are placed on the prepared surface. It is leveled, covered with insulation, equipped with a substrate with a reflective screen. You should not make blanks, cut the roll into tapes. The roll is rolled out along the marked contour of the room.

If you need to make a turn, then cut the wire from one edge, move the roll 180 degrees. After laying, the mats are fixed to the substrate with adhesive tape. Carbon rods should not intersect, find each other. Carry out the connection of the contour of the carbon underfloor heating.

- For connection, a VVGnG mounting wire is used: it comes with the heating system.

- The edges of the wires are stripped of insulation: the film is removed by 7 mm. A sleeve is put on the bare edges: it is fixed with pliers. The connection is closed with a shrink film.

- The film is treated with a building dryer.

Connect the entire circuit in a similar way. The instructions have a connection diagram for all elements. The temperature sensor is placed at a distance of 20 cm from the border of the mat.For him, a hole is made in the substrate.

All electrical wires are placed in a corrugated tube, which is fixed in the floor and on the wall. It brings all the electrics to the thermostat. For the corrugation, a groove is made, which is sealed with a solution of concrete.

It is necessary to equip a screed that will connect the base of the floor and the heating system. To do this, holes of 7 * 15 cm in size are made on the substrate. They are staggered. Fill the floor surface with tile adhesive or concrete screed.

Any cladding surface is suitable for carbon flooring. When finishing, certain rules must be observed. Equip a substrate for a hard coating or lay fiberboard sheets for a soft decorative material. When connecting the heating system to the mains, a parallel circuit is used. It is indicated in the instructions for the equipment.

What is the best electric underfloor heating? The purpose of the main types of electric floor heating

- header

- What is the best electric underfloor heating? The purpose of the main types of electric floor heating

- header

- How much does a warm floor eat? all honestly without cheating!!!

- header

- Energy-saving underfloor heating. Benefits, connection, verification of work.