Beltep is a good and inexpensive mineral insulation

Basalt mineral wool from this manufacturer is available in two packages: rolls or slabs and is considered a good solution for creating multilayer thermal insulation systems. The high assessment of Beltep basalt wool is confirmed by reviews from construction forums and from individuals.

Among the advantages of Beltep mineral wool insulation:

- fire safety;

- environmental friendliness;

- vapor permeability;

- resistance to deformation;

- acoustic comfort;

- a large selection of materials by density;

- low hygroscopicity;

- affordable price.

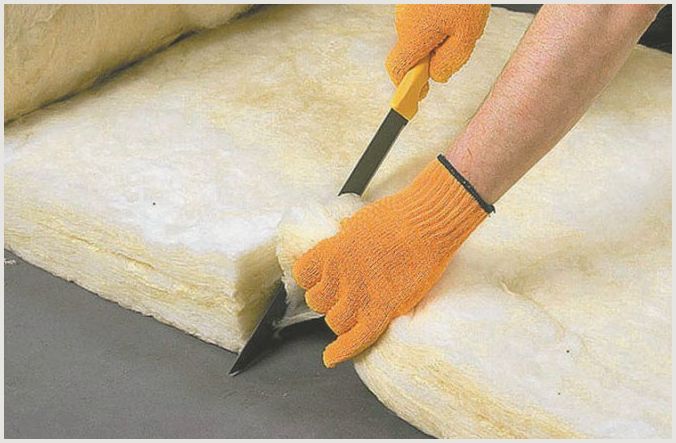

In addition, the material is highly rigid, dimensionally stable, easy to cut and install. When compared with European manufacturers, BelTep is inferior to them in some parameters, but when there is a choice between it and many Russian brands, they often buy mineral wool from a Belarusian company. So we can say that BelTep basalt wool is the best competitor to many similar offers.

: 9.5 points out of 10

: “I tried Beltep mineral wool in my work. The density is good, it does not bend, it stands clearly between the rafters, without falling out.

Optimum application of each type of thermal insulation

Depending on the purpose and design features, certain options for thermal insulation are appropriate. So, for example, in low-rise brick houses, as well as in three-layer concrete panels, it is better to use mineral stone wool as the middle heat-insulating layer.

Also, the insulator will be appropriate for thermal insulation in wooden houses, where it is important to use "breathable" materials. In addition, to keep warm with the help of mineral wool will turn out:

- in attics and pitched roofs;

- in attics and ceilings;

- in rooms with very hot appliances and the risk of fire;

- in pipeline systems and heating mains;

- frame structures of any type.

Expanded polystyrene plates are used for insulation and sound insulation:

- in brick and block structures to eliminate the risk of dew point;

- foundations and underground engineering structures in contact with wet soil;

- horizontal part of foundations with a layer of waterproofing under operating conditions at low temperatures;

- floors and areas between floors with a concrete screed;

- roofs of non-ventilated type with a layer of waterproofing;

- freezers, isothermal vans and refrigerators.

Having studied the characteristics of expanded polystyrene and mineral stone wool as heaters, certain conclusions can be drawn. In terms of thermal conductivity, foam plastic is definitely better in all respects, while only stone wool can compete for the title of a material that removes moisture and steam. However, in a humid environment, foam plastic retains its functionality better than mineral wool, although it is not able to remove moisture to the outside.

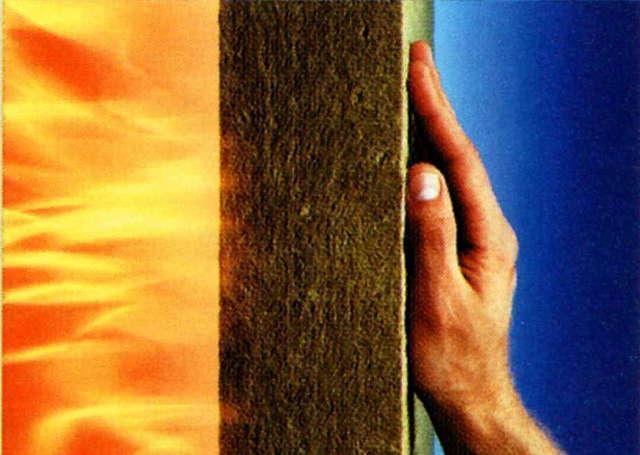

In terms of fire safety, both materials are dangerous, while polystyrene foam as a heater is always a risk of ignition, while mineral heat insulators burn and melt only at the highest temperatures and the inclusion of additional synthetic components. High-quality basalt wool with the most natural composition is able to withstand temperatures up to 1000 degrees Celsius.

Mineral wool weighs more than foam, so it is more difficult to install. Expanded polystyrene is lighter, more convenient to cut and simply attached to the surface. The disadvantage of the latter is the joints and possible cold bridges, which are excluded when choosing in favor of mineral wool.

One way or another, you need to choose expanded polystyrene or stone mineral wool for insulation from trusted manufacturers, taking into account the purpose of the structure.High-quality foam plastic is plates with uniform polyhedrons, securely fixed to each other, while low-quality insulation is easy to distinguish by balls interlocked with each other.

Mineral heaters should have relatively high density indicators, a special arrangement of fibers that excludes increased friability of the material, indicating a low level of quality.

Mineral wool for thermal insulation characteristics and features

The main difference between mineral wool insulation and stone wool insulation is a more affordable price. It is this fact that often becomes decisive in the course of choosing an insulator among the assortment on the market. The low price of mineral wool in comparison with basalt slabs is associated with the peculiarities of the production process.

Another difference can be considered the compactness of the slabs, which will require an order of magnitude less space than basalt counterparts. Against the background of a small mass, the plates have:

- low level of thermal conductivity;

- low density;

- resistance to ignition;

- resistance to chemical and biological media.

In thermal insulation based on mineral wool, corrosion processes do not progress, but in terms of resistance to high temperatures, the insulation loses to stone wool, as it is able to withstand temperatures of no more than +400 degrees Celsius. This is due to the length of the fibers - it is longer than the length of the basalt wool fibers, which suggests an excellent degree of elasticity.

It is possible to insulate with mineral or fiberglass wool surfaces with an irregular shape and an uneven surface layer.

With regard to the ability to absorb noise, mineral heaters are ahead of basalt ones. But with regard to strength and service life, here insulators lose to a large extent due to the inability to withstand shrinkage due to crystallization.

Material density

The most important characteristic for heaters is density. The most popular types of insulation have a density of 35, 50 and 90 mm. This parameter affects the destination, the load on the insulation, installation methods. The first two options are suitable for a private house or cottage, they are used for thermal insulation of walls, floors, roofs and ceilings. Here the material is not subjected to heavy loads.

Consider the difference between 35 mm and 50 mm thermal insulators. Shrinkage of 50 mm products is much less; after installation, the dimensions of the material remain slightly larger. As for the 30 mm insulation, it only fits 3 meters without a jumper, and 50 mm - 5 meters. If we consider 90 mm insulation, then it is used to create a layer of thermal insulation in industrial buildings: large factories and plants, where it is laid over the entire surface of the building. Dowels are used for fastening.

Basalt wool is considered an excellent option for thermal insulation of rooms. It is safe, environmentally friendly, non-flammable and of high quality. The material protects buildings from winter frost and summer heat, providing excellent thermal and sound insulation!

Scope of application of basalt stone wool

Due to the fact that stone wool is a natural non-combustible and durable material (since 95% consists of natural stone), it has been widely used in construction since the beginning of the 20th century.

Due to its excellent properties, which are to reduce heat energy losses during the cold period of time, and to reduce the ingress of heat energy into the building in summer, stone wool is widely used in the following areas:

- When insulating the facades of buildings with subsequent plastering or installation of siding or profile sheets.

- When warming the room from the inside (balconies, loggias, external walls, etc.).

- When erecting partitions from plasterboard sheets in apartments, industrial or office buildings for soundproofing.

- When insulating the base of the floor, followed by pouring the screed.

- For soundproofing a "floating floor".

- When installing a roof or insulating attic floors.

- For fire protection of engineering structures and networks (this material is able to withstand temperatures up to 700 C).

Types and scope of basalt fibers

Equipment for the production of mineral wool allows the production of the following types of stone (basalt) fiber:

- Microfine fibers for the manufacture of fine filters for air or liquid medium with fiber diameters less than 0.6 µm.

- Ultra-thin stone fibers are used in fine filters for air, gas or liquid media, or in the manufacture of ultra-light sound and heat insulating materials with fiber diameters ranging from 0.6 to 1 micron.

- Superthin (microcrystalline) basalt fibers are used for the manufacture of heat and sound insulating hydrophobized products (mats or rolls), various bundles and filters. This type of fiber is considered the most popular, because thanks to a special heat treatment, the resulting microcrystals are able to withstand temperatures up to 200 C higher than the previous types of fibers. Also, super-thin microfiber (diameter from 1 to 3 microns) does not shrink during operation, which significantly increases the range of application of this material.

- Fine mineral-based fibers are random structures with a fiber diameter ranging from 9 to 15 µm. The length of individual fibers ranges from 3 to 2000 mm. This material is widely used in coarse filters, as well as in the production of mineral insulation for industrial needs.

- Thickened stone fibers are in most cases used as the main filtration systems of drainage systems. The thickness of this type of fiber ranges from 15 to 25 microns, and the length is from 5 to 1500 mm.

- Thick fibrous structures are randomly arranged fibers with a diameter of 25 to 150 microns and a length of one fiber from 0.05 to 3 m. Due to this, the resulting material can withstand enormous tensile loads up to 650 MPa.

- Coarse fibers - dispersed fibrous mass of fibrous structures with a thickness of 150 to 500 microns. This type of insulation can be used as a reinforced layer using special binders.

Explanatory Dictionary Dahl

a

b

v

G

d

e

well

h

and

th

To

l

m

n

O

P

R

With

T

at

f

X

c

h

sh

SCH

uh

Yu

I am

stone

STONE, made of stone or generally related to stone. Stone house, stone or brick. Stone breaking, prilom, mine. Stone forest, rocky. Stone sheep, wild sheep, arkar, argali, Ovis ammon, on Ustyurt; Kamchatka, Ovis nivicola. -flax, mountain flax, amiant, asbestos. - onion or garlic, wild garlic, Allium altaicum. - honey, Transcaucasian wild bees build honeycombs in the rocks, where it is completely candied for years; the hardened parts of the honeycomb in the hives are also called that. - marl, hardened friable. - brain, clay earth, packed in clods. - fracture. saxifrage, Sahifraga plant. - ivy, plant. Antirrhinum asarina, undergrowth. Stone cockerel, hoopoe, potato? Stone hazel grouse, Sib. gray partridge. Stone linden, shrub Rhillirea latifolia. Stone rose, shrub Cistus. Coal, rock coal, fossil, there are various types: anthracite, lignite, brown, etc. Stone disease, the formation of stones in the entrails, esp. in the kidneys or bladder. - clay, flask, shale. -mint. plant Mellisa calamintha. - sedge, plant. Carex saxatillis. - parsley, plant. Bubon galbanum. - gerbil, grate, plant. Arenaria saxatilis. - dew, paw, rock rezuha, shifting grass, plants. Androsace villos. - resin, tar, oil, mountain resin, various types of fossil resinous substances, asphalt, oil, etc. A mixture of alum with vitriol, which spreads like oil, is also called stone oil. - salt, non-digestible, kitchen salt in rocks and layers. Stone seed, plant. Lthospermum offic. The righteous Judge is a stone fence. Stone builds the one who can. Like a stone wall, hope. To live behind someone, as behind a stone wall. They wanted iron prosvir from the stone priest! From the works of the righteous do not make stone chambers. The stone sea spins around, the white hare lies down beside it, is it good for the whole world? millstone and flour. Stony, stony, full of stones, strewn with stones.Stony, stony, to a lesser extent. Kamezhnik, mason or kamenets m. rocky place, or collected. pile of stones. Bricklayer m. Handyman, engaged in masonry, construction of wild stone or brick; | stonemason, craftsman, engaged in rough cutting, dressing of simple stones, for construction, burial grounds, millstones, etc. | The name of the mountain Altaians, schismatics; they are Bukhtarma, Bukhtarma yasachniks. Well, Kamenshets mason's wife; | seller of dressed stones. Kamenshchikov, -shchitsyn, belonging to him or her; masonry, characteristic of them. Kameshnik m. small pebbles, pebbles. Kamenik or kamenitsa, Kamenka w. hard. kostenika, drupe, plant Rubus saxatilis. | Kamenitsa any stone structure, esp. with a vault, a tent, a sepulchre. Well, Kamenka vyat. stove, sauna stove. Kamenka arch. generally oven; sib. the oven is temporary, from a savage, not brick; | a bath stove, a heap of wild stone, cobblestone on the stove, on which steam is supplied; the same oven in a barn; | eagle connection, crossing of two or more stone ridges, ridges; mountain node. | Southern a five-brick trap for sparrows. | Bird Motacilla ocnanthe. | Crushed stone, highway, stoned road. | Tver. a stone wall built without clay or lime, in the villages. | Yellow arsenic ore, yellow arsenic, avripigment, operament, rapiment. Water that on the stone! dialect drunkard. Kamenushka psk. heater, brick oven, sauna stove. | Kamch. a species of sea ducks that are found in the cliffs. Kamenka psk. a river along a rocky bed, in the south it is also a heater. Kamenyaga Chernomorsk (komyaga?) salted, a chest of 2 soots. long and 2 ars. the width and depth where the fish is salted, on gangs, under the yoke of stone. Stone cf. psk. a word that turned into the name of many border tracts, but initially, it seems, meant a line, a boundary marked by a stone. To petrify, to petrify, to turn to stone.

Knauf makes everything

Knauf is a manufacturer that has proven time and again that it can provide the construction market with the best deals. Thermal insulation is no exception. Knauf offers good quality mineral wool based on basalt fiber as well as glass fiber composition. The first option is widely used for technical insulation, in construction and in the production of complex equipment. Fiberglass insulation is produced for a specialized purpose (TEPLOKnauf), which is confirmed by its names:

- HEATWALL;

- HEAT stove;

- HEAT-roofing;

- Acoustic partition;

- THERMAL roll.

Most of the mineral wool sold by the manufacturer belongs to the Knauf Insulation series. There are no poisonous phenol-formaldehyde resins in the production of this product. The Knauf Insulation and TEPLOKnauf thermal insulation lines are designed for the construction of residential buildings by individuals and construction organizations.

Disadvantage: high price

: 9.9 points out of 10

: “You rarely hear a bad word about Knauf. So the material is really excellent.”

Material properties and their impact on health

Doctors say that particles released into the air after aging and destruction min. cotton wool in the course of a very long operation or non-compliance with the rules of use, they constantly settle in the lungs of people who are in the zone of their distribution, causing lung diseases, and over time, the formation of oncology.

How harmful mineral wool is - in most cases it depends on the size and shape of the mineral fibers. It is believed that the most dangerous are fibers up to 3 microns thick and more than 5 microns long.

It worsens the situation and the ability of the material to absorb moisture. Heat insulator operation based on min. cotton wool in regions with a very high level of moisture and temperature fluctuations leads to an early loss of their insulating qualities, and then damage to the structure of the fibers, some of which will make their way into the interior of the room, poisoning the air.

Recent studies have only confirmed the fact that under the influence of difficult weather conditions, heat insulators based on min. cotton wool lose weight. The longer a material lasts, subjected to everyday tests of moisture, wind and temperatures, the faster it loses its original functionality.

Another problem is the environment suitable for settling rodents, fungi and mold inside the heat insulator made of min. cotton wool. Such a neighborhood will cause significant harm to health, disrupt the peace and comfort of home.

Mineral wool manufacturers rely on the fact that the material belongs to a non-combustible group, considering this an indisputable plus. But in reality, it turns out that this quality itself will cause irreparable damage to health.

The flammable formaldehyde-based resins and a number of binders included are not only harmful, they will not be able to resist the flame, as well as substances used to reduce moisture absorption. Practice shows that mineral wool heat insulators burn even better than straw, and oxygen flows between the fibers of the material additionally feed the flame.

How important are the above factors and should they be taken into account when choosing a heat insulator? Everyone has the right to make their own decision. It remains to be emphasized that by performing selection in favor of min. cotton wool for insulation, you do not need to save on quality. Products must be certified, tested, from a company with a proven characteristic. A very significant point is the observance of installation rules with the use of protection and operation means - with the timely replacement of the heat insulator as it wears out.

In which case is it better to use one or another type of mineral wool

When the differences between stone wool and mineral wool made of fiberglass are clear, it is possible to determine for which application which is best suited:

1. It is better to fill the attic ceiling or the floors of the upper floors of a private wooden house with rolled glass mineral wool with a density of 11-15 kg / m3, which will not create unnecessary loads on the structure.

2. Indoor walls can also be insulated with a glassy density of 11-15 kg/m3, but in slabs that facilitate installation and increase the strength of placement.

3. To insulate the roof slopes, it is best to use basalt slabs with a density of 100 - 120 kg / m3.

4. In places with high humidity (building facade, sauna walls), it is better to use stone wool with a density of 20 kg / m3, which is more resistant to water absorption. For installation it is more convenient to choose plates.

5. When a small building does not involve thick solid walls (construction trailer, garage), it is better to use mineral stone wool with a density of 150 kg / m3.

6. Where it is necessary to take care not only of insulation, but also to create an obstacle to the spread of a possible fire, it is recommended to use basalt slabs with a density of 200 kg / m3 or special foil

Having thoroughly studied all the types and characteristics of mineral wool, you can begin to choose for a particular place of operation. Before buying, it is worth considering the width of the rolls or plates in order to avoid trimming the edges and speed up installation.

Shrinkage susceptibility

Shrinkage means slipping or caking of the insulation after some time. If the tendency of the material to shrink is high, then voids without insulation may form and the thermal insulation of the building will deteriorate.

Here, the difference between basalt wool and fiberglass mineral wool lies in the improved structure of the first. Part of the basalt wool fibers is located vertically, which prevents it from caking throughout the entire service life. What can not be said about glass wool, which, if properly installed, can last for a long period, but will still shrink over time.Most of all, glass wool embedded in horizontal structures undergoes shrinkage, where, in addition to caking, material slippage can occur.