Preparing the floor for laminate

The second important issue in laying the coating is the point of how to prepare the floor for the laminate in the apartment. This material is whimsical in terms of operation and maintenance, so it should be placed on a carefully prepared base. This process includes the elimination of cracks, tubercles, cracks, irregularities. If they are not removed, the coating will be damaged due to the increased load in the places of the remaining defects. Also, the high humidity in the screed, rotten boards, cracks in the concrete base are terrible for the material.

The preparation itself consists of the following steps:

- Dismantling of the old coating. It is not always necessary - parquet, tiled, linoleum or carpet can become the basis for a laminate if their height differences are minimal and amount to 3 mm per square meter. If the differences in level are higher, then the coating is removed as carefully as possible so as not to damage the screed. Rotten and creaking boards are being replaced in the wooden floors.

- Alignment - carried out in accordance with the basis. Concrete floors can be leveled with a self-leveling screed, and wooden floors can be leveled with plywood. Before these processes, you need to clean the base well so that there is no debris or dirt on it. If a screed is carried out, then you need to prepare a homogeneous mixture without lumps.

Do I need to level the floor under the laminate

If there are still doubts about whether it is necessary to spend effort and money on leveling the floor, several features of this coating should be taken into account:

- Laminate under the weight of a person can easily bend. If there are voids under it due to an uneven floor, it may crack over time.

- The locks between the panels may come apart if the floor is uneven. As a result, moisture will get under the laminate and it will deteriorate from the inside.

- Large differences on the surface threaten swelling and cracks.

- Panels may creak.

- The person will feel the instability of the laminate.

As a result, the laminate will not last long and will soon have to be replaced.

To be sure of the need for a surface leveling procedure, you must first perform several manipulations:

- analyze the floor for chips, potholes, obvious irregularities;

- identify concrete "waves";

- determine if there are relief differences in the floor.

If one of the listed signs has been identified, then it is necessary to level the surface.

The need for alignment

The concrete floor under the laminate must be perfectly flat for the following reasons:

- The presence of bulges and depressions on the concrete surface can lead to failure of the interlocks. If the concrete floors are not leveled, this will lead to the formation of gaps at the joints and cracking of the laminate boards.

- The concrete base has a high level of moisture, which is unacceptable for a laminate. Excess moisture gets from the screed through cracks in the concrete floor. To avoid this, you should prepare the concrete base immediately before laying the boards.

- Laying laminate is not possible on a skewed floor or concrete surface with potholes, bumps and cracks. This will worsen the quality of laying and entail a considerable consumption of building material. Installed laminate flooring on a warped subfloor will have a short lifespan.

- The leveling of the concrete floor can be carried out regardless of the quality of the base and the materials used for its construction using DSP, plywood or self-leveling compounds.

Answers 22

Michael. Excuse me, of course - but what a demon you have suffered to open the parquet - since you don’t have “teeth”. What bothered you before sticking your nose into this program. And then what is revealed. what area was dismantled - if a small area. so to speak out of curiosity and for analysis.then if there is no money, throw everything back into place. while crossing yourself - this will be the most budget option for you. A plus. the house is a panel house in Khrushchev, of course. but what is the total area in the end under the "maneuvers" should go. - I mean that maybe fifty dollars is not such a great figure - which the office asked you. And if you also live in the same area. then you don’t need to go to your grandmother - it’s definitely not expensive. In a word - at this stage, only solid questions - the course of chemical reactions in your brain. in addition, you can explain.

I can explain the course of chemical reactions. The parquet was opened in small areas, the largest of which is 0.3 sq.m in order to understand what is under it. (there was no need to open it, he just rises from the floor and doesn’t hold on to anything, the same age as the house in 1963) The floor area of the apartment is 45 sq.m. If it weren’t for the visible gaps in the passages and its not being fixed, I would have called the grinders and varnished it and wouldn’t have taken a steam bath. And so the people who came and looked (not even knowing what was under it) asked for half a dollar only for the work, which confused me (is it really so bad) and another 30 tons for the material. Isn't the floor golden, for Khrushchev 45 square meters is obtained. What can you offer yourself?

Michael. I am not Andryusha Simakov and others like him - who do not "weigh the vectors" - are already beginning to "marry" you. A plus for that. what I know is deletantism in the market. doesn't even thrive. and reigns - does not surprise me at all. that "ran" supposedly firms. and with their own eyes they saw the whole “pie” that your floors consist of as a X-ray). Here I agree with you - their handwriting is visible to the naked eye. Yet again. taking into account the fact that a loaf of bread costs 50 re - start a conversation about the fact that the total cost is for M2 of the floor. taking into account the work and materials, it is close to gold - I would not argue. But I can give you some hints. Do you Mikhail live in this area or is it free for work.

Then if you have a couple of months, then dismantle everything up to the floor slab. But dismantling (with the removal of all the "junk") can be just not qualified hands - because. as a rule, dismantling tasks do not cause great enthusiasm for a worthy performer. Next, you need to look for the artist (now I’m leaking the biggest secret to you for nothing)))) - who owns professional measuring equipment - namely, a laser level from serious Bosch manufacturers. hilty. stabilized. This step of yours will be a guarantee that the performer will not turn out to be a rogue. who took a sip of a couple of liters of beer. the whole further technological process will be determined by eye. ))). But in essence. - the cheapest option. this (if the differences in height over your entire area turn out to be insignificant) - level the floor slab with any. even the cheapest leveler. Then "thread" linoleum. laminate or parquet board. Why did I start talking at the beginning of this answer about your free time of two months. so this is because 1 cm of any equalizer or screed. with central heating on. those. in the warm season - for the production of any kind of parquet work (laminate, parquet board, piece parquet or solid board) - dries for 2 weeks. Those. if in the end the screed is even 4 cm. then the wood (and the laminate is also supposedly wood) on this "base can be laid after 2 months. Accordingly, when the batteries stop working. All these processes are stretched for an indefinite period. But the levelers and screed are the most - the most "free" options. like at work. as well as materials.

Thank you. I know about the level, I already put a couple of estimators in the stopper when I asked to measure the differences in the walls and floor)) But they have a “diamond” eye)) But with the drying of the leveler or screed for 2 months, it's sad.

Leveling the concrete base

There are several ways to independently provide a flat concrete floor surface, which is necessary for high-quality laying of a laminate. You can choose how to level the floor only after determining the degree of destruction of its surface.

To perform alignment work, you will need:

- construction laser level;

- meter ruler;

- a vacuum cleaner;

- electric drill with a special grinding nozzle;

- notched trowel or rule (depending on the leveling material).

If the concrete floor was made with high quality, then its surface will not be severely damaged even during long-term operation. And the resulting damage will only be superficial. In this case, you can level the floor under the laminate using an electric drill, fixing a special grinding nozzle on it. This allows you to eliminate small uneven floors. But with this method, the laying of the laminate can only be carried out after the concrete base has been thoroughly cleaned of dust. For this, an ordinary vacuum cleaner will do.

Tools for subfloor installation.

If there are small irregularities visible to the eye on the concrete floor (up to 5 mm), then grinding is not enough here, more complex alignment is needed here. It can be done using a self-leveling compound.

Following the instructions attached to the mixture, it must be diluted with water and poured. The general algorithm of this work looks like this: first, the concrete floor needs to be primed. Then the desired pour height is determined by the laser level, and marks are made on the walls with a pencil at this height. On the floor, the same height is marked by exposed beacons.

You need to prepare the mixture in small portions, as it quickly hardens. The mixture poured in a strip must be immediately leveled with a spatula. So, in small portions, along the exposed beacons, the floor is leveled. After pouring, you need to wait 3-5 days until the floor is completely dry.

Usually the old concrete surface after the removal of the floor covering does not look good. In this case, you will have to make a cement-sand screed. It is easy to prepare it yourself by mixing Portland cement, sand and water in a ratio of 1: 3: 3. Although in stores today you can find a ready-made dry mix and dilute it with the right amount of water.

The scheme of laying the coating on the draft floor.

The subsequent steps are very similar to leveling the floor under the laminate with your own hands using self-leveling compounds. With the help of a laser level, marks are made on the walls and beacons are set to the desired height. The prepared solution is laid out between the installed beacons and leveled by the rule along the laid beacons.

A day later, the beacons are removed, and the places where they were located are sealed with the same solution as the rest of the floor surface. After that, you need to wait for the screed to dry completely, periodically wetting it and avoiding drafts in the room. Laying the laminate after such alignment can be started no earlier than a month later.

The purpose of the leveling substrate under the laminate is it needed at all

So, along with laminate panels, it is simply necessary to purchase a substrate for them. Otherwise, the durability of the coating could be argued.

The first reason - why you need a substrate under the laminate - is to level the surface. Perhaps this quality is one of the most important. She is unlikely to be able to smooth out significant irregularities, but she is quite capable of correcting small differences in height by 0.3 cm per 1 running meter.

The substrate is also used for soundproofing. This is a kind of auxiliary layer, often used in high-rise apartments, where every step gives off a sound. The soundproofing substrate under the laminate is able to hide all sorts of noise.

You need a substrate for thermal conductivity. Such a bedding helps to increase the efficiency of the warm floor. because it has good thermal insulation properties.

For warm flooring, there are special layers that should be used.

The substrate layer is also used for moisture insulation. Since the composition of the lamellas includes compressed paper, it means that even moisture-resistant varieties swell when in contact with moisture.Laying the substrate under the laminate provides an additional degree of protection of the finish from the moisture associated with the concrete base.

How to level a wooden floor under a laminate with plywood

If you don’t know how to level a wooden floor under a laminate, then pay attention to plywood as the most affordable and easiest way. It does not require extensive knowledge in construction, it is carried out simply and quickly.

Thanks to this, leveling the floor with plywood for laminate becomes an operational process, and the owners are able to get the desired result in a short time.

Leveling a wooden floor under a laminate is carried out according to the following technology:

- Determination of height differences using a laser or water level. This is done by measuring the entire room and setting marks on the walls. With differences of more than 3 mm, plywood will have to be laid to level and secure the base.

- The simplest leveling method is without mounting the log (additional boards) and installing support bars. In this case, you need to make indents from the walls by 2 cm, lay sheets of plywood with a gap of 5 mm. With two layers of laying, brickwork is made, and the fastening passes through the highest points, evenly distributed.

- If the differences are large and up to 8 cm, then you will have to install mini-logs, mount slats and wooden boards to create a single network of supports. First, precise calculations are made, measurements are made, the dimensions of the elements are calculated, then gratings are laid and plywood sheets are laid on top. The lags are fixed with glue or self-tapping screws, and the gaps between them are filled with sealant or sealant.

- The third way of laying is called lathing, using turned supports. First, they are cut out of boards or plywood, and their thickness takes into account the height differences in the field. From the supports, a grid is made in the form of a square, laid on the floor, covered with plywood sheets. Sheets are fastened with self-tapping screws with dowels, varnished on top.

- To level the floor, plywood with a thickness of more than 1 cm, grades FK or FSF, which can withstand mechanical stress, is water and wear resistant, is suitable. It is better to choose the first grade, which does not contain defects and deformations, pre-treated with an antiseptic.

- Before laying plywood, it is advisable to check the condition of the communication pipes, if any, because after leveling the floor, access to them will be closed. Before laying, it is better to pre-fold the sheets of plywood, see how they look, and only then proceed to the final fixation.

DSP boards and plywood

Another way to level the concrete surface under the laminate is to use cement-bonded particle boards. Leveling begins with cleaning the surface of debris and dirt. Next, wooden boards are fixed to the base at the required level. The next step will be the fastening of cement-bonded particle boards to the previously installed wooden boards. Cement-bonded particle boards are fixed with self-tapping screws, and the gaps formed are covered with a special mass. After installing the plates, they should be covered with a substrate.

Leveling the floor with plywood is also effective. To do this, use plywood sheets and attach them to the logs. A step of thirty centimeters should be observed. Between the lags you need to lay a heat-insulating layer.

Before proceeding with the installation of laminate boards, you need to take care of the evenness of the concrete base on which you plan to lay the laminate. Leveling a concrete floor can be done in many ways, it can be a monolithic screed, self-leveling mixtures, and cement-bonded particle boards.

It is important to carefully prepare the working materials and ensure high-quality alignment, only in this case it will be possible to avoid cracking the laminate boards

Leveling a wooden floor

Leveling a wooden floor

It is advisable to level a wooden floor only if both the boards and the logs are in good condition, there are no rotten areas, wide cracks and other similar defects.If serious repairs are required, it is much easier to dismantle the floors to a rough screed and level them on concrete.

To prepare a wooden floor for laying a laminate, you will need:

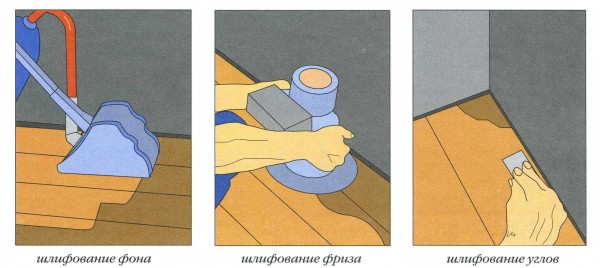

grinding or scraping machine;

Vibratory grinder

wood putty;

Wood putty

plywood sheets, cement-bonded particle boards, GVL or chipboard;

jigsaw;

roulette;

screws and screwdriver.

First, the floor surface is carefully sanded or treated with a scraper machine.

Chips and dust are removed, all minor defects are sealed with putty. Next, the base is primed twice, dried, plywood or other selected material is laid. Self-tapping screws are used for fastening, and cutting of the material is performed with an electric jigsaw. Now it remains only to properly lay the flooring.

Floor leveling with plywood

Floor leveling with plywood

How to level the floor under the laminate

To know how to level the floor under the laminate in the apartment, you must first decide how to do it. For those who want to do without the help of workers, for a free result, you will have to invest in materials. There are several options, the choice of which depends on the type of coverage:

- If the subfloor in a private house is concrete, then it is leveled with a mixture of sand plus cement, or with ready-made materials that have increased noise and heat insulation properties.

- If the floor is wooden, it is better to level it with plywood, but when it is old and rotten, then a concrete or dry screed will be required to help the surface self-level.

The screed is long and difficult to carry out, so you should take into account all the nuances of its implementation - raising the floor level, monitoring the absence of a slope near the surface. In addition to plywood, wooden floors are leveled with cement chipboard or chipboard, which simplifies the procedure. The alignment process includes the placement of beacons for the screed, the correct preparation of the mixture. The rest of the processes are easy and require minimal knowledge.

What to consider before starting preparatory work

#one. If the subfloor is made of concrete, you should check that it is even and level. If, according to these indicators, the concrete base is far from ideal, it is necessary to fill in a thin layer of self-leveling screed. Pre-fill the cracks in the concrete with mortar, carefully remove all dust and grease stains from the surface.

#2. If your subfloor is wood, you should make sure it is even and free of cracks before laying the laminate. If the wood is damaged or deformed, we recommend laying a layer of plywood 10-12 mm thick over the entire surface. Attach the plywood sheets to the wood subfloor or pre-laid joists with nails or self-tapping screws. We recommend that you mark the location of the joists on the walls so that you can use these marks when you start fixing the baseboards. To avoid problems in the future, be sure to read the manufacturer's instructions before laying plywood. In most cases, you should leave a 3 mm expansion joint between sheets. The gaps between the plywood sheets and the walls of the room should be sealed to create a moisture barrier and improve the heat and sound insulation of the room.

#3. If plywood does not fit into your renovation budget, you can use 11mm OSB boards. However, it should be remembered that OSB should not be used in places exposed to moisture, as the material will swell, mold and mildew may appear on it.

If you decide to prepare the floor for the laminate with your own hands, you will need the following:

- Using a level, make sure the floor surface is fairly level.

- Pour self-levelling screed if the floor is not level enough.

- Clean the floor surface properly with a vacuum cleaner.

Necessary materials and tools for leveling the floor

The main materials that will allow you to qualitatively level the floor are cement and sand. But the modern building materials market offers craftsmen to purchase ready-made mixtures. They have a number of significant advantages:

- have soundproof properties;

- keep warm;

- have strong bonding properties.

There are dry mixes separately for concrete and wooden floors. There are also these types:

- Priming - designed to prepare the surface for leveling.

- Repair - to eliminate serious defects and flaws.

- Sealing - for sealing cracks.

Also, the master will need tools:

- building beacons (they need to be placed for the screed);

- building level;

- mixer for mixing the solution;

- mixing container.

In addition to tools and materials, it is desirable to enlist support. Otherwise, the task may be overwhelming. This is especially true of the period when the screed will be poured.

Self-levelling compound

A self-levelling mixture for laminate can be purchased at a hardware store; for preparation, you need to dilute the finished dry mixture with water. The proportions are indicated on the back of the package. To make a self-levelling compound, you need to pour water into a clean vessel and gradually pour the dry mixture into it. The ingredients should be thoroughly mixed, for which a drill or mixer attachment is used. Depending on the thickness of the screed, the required consistency is made by pouring in the right amount of water. Stir the mass until all the lumps disappear and the color is uniform.

When the self-leveling mixture is ready, proceed to laying it. Start pouring the mixture from a high level of the base. The mixture begins to spread on its own on the surface. To speed up the spreading, use a wide spatula, which distributes the solution over the base. Next, the mixture is leveled using a spiked roller. When pouring a self-leveling mixture, a monolithic coating of each poured portions should be ensured. When pouring a new part, you need to use a spatula to connect with the previous poured portion. The joints of the poured mixtures are carefully rolled out. The pouring process requires speed, otherwise the poured mixture will begin to dry out.

Self-levelling mortar sets quickly, but it will take several days to reach maximum strength.

How to detect height differences and bumps

Several basic types of subfloor irregularities are determined. They can be called:

- cracks and crevices. As a rule, they are found in wooden bases. They are easiest to repair (for example, puttying). But usually they do not affect the evenness of the floor;

- influxes (pits). This is typical for poor-quality concrete screed and requires leveling due to the effect on the laminate described above after installation;

- height differences. Most often between wooden boards or concrete floor slabs.

The easiest way to determine the irregularities at the edges of the room, using a hydraulic level. To do this, the first flask is fixed near the so-called zero, control mark, and the second flask measures the level at each of the walls at a distance of about two meters. Control points in the floor can be set with self-tapping screws. The heads of the self-tapping screws should be at the level marked by the first bulb. Instead of a hydraulic level, you can also use a laser or conventional level, measuring height deviations along the walls. Threads are then tied onto the heads of the self-tapping screws, which can be pulled diagonally to detect deviations over the entire area of \u200b\u200bthe room.

There are three ways to correct the identified deficiencies. The use of methods depends entirely on the type of foundation, the nature and complexity of the irregularities.

Popular alignment methods:

- use of a leveling substrate;

- leveling the base (separately - concrete and wooden floors);

- use of flexible laminate.

It should be remembered that when choosing one or another method, the level of height difference plays an important role, which is measured in millimeters per square (linear) meter of area. Before laying the laminate on an uneven floor, you should make sure that the differences are no more than 2 millimeters per square meter of area.

Monolithic screed

A monolithic screed under the laminate is used with large differences in the heights of the concrete base. Before starting construction work, the surface should be cleaned of dust, dirt and debris. They start a monolithic screed with the installation of beacons and determining the level of the floor being erected. The step between the installed beacons should be observed 60-90 centimeters. The beacons are fastened to a solution of cement and sand. Beacons can be installed using long self-tapping screws; for this, holes are made on the concrete surface and dowels are driven into them. Next, proceed to pouring the concrete solution. To prepare concrete you will need:

- three parts of cement;

- one part sand;

- half of the water.

As a fill, you can use ready-made dry mixtures, which are diluted with water in the right amount. All proportions are indicated on the package. The filled solution should be leveled with a rule and, after hardening, remove the beacons. Beacons are removed after 24 hours. The resulting cracks are sealed with a new solution. After the solution has set, the surface should be rubbed and covered with plastic wrap. A layer of polyethylene will protect the poured surface from cracking, and irrigation of the laid concrete with water will help to avoid deformation. The concrete floor will reach its maximum strength characteristics after a month.

How and how to level a concrete floor under a laminate

Laminate is a popular flooring material. It is easy to assemble and can be installed without the involvement of specialists, which will save the budget. A wide range of colors will satisfy the most refined taste and wishes of the customer. The duration of the service life directly depends on the literacy of laying the laminate. Laminated boards bend under the weight of the load and the weight of people, if there are irregularities under it, moisture can penetrate into the cracks, which will lead to rapid wear of the coating. Therefore, one of the main requirements when laying flooring is a flat and even floor surface, without cracks, pits, roughness, bulges, bends and breaks.

Leveling with plywood or chipboard

This method is suitable for rooms with high ceilings. The essence of the process is that a dry screed is used. Plywood is not laid on the floor, but on the logs, which must first be installed. As a result, the height of the room is reduced by 10 cm.

A positive result in this case is possible only when the lags are located according to the horizontal level. If there are depressions, then wedges should be placed, and excess bulges should be cut off.

To level the floor with such methods, you need to follow these steps:

- Using the building level, mark the level to which the floor will reach.

- Perform preparatory work: lay out waterproofing, soundproofing and depreciation.

- Install lags. They can be purchased ready-made and made independently using bars.

- Be sure to control the distance: from the walls should be 3 cm, and between the lags - 40 - 50 cm.

- Fasten the lags with dowels.

- Lay out sheets of plywood or chipboard. Leave a gap between them of 0.2 - 0.4 mm.

- Fasten the sheets with screws. You should adhere to a step of 50 - 70 cm.

The big advantage of this method is that the laminate can be installed immediately. This is a significant time saving, which attracts craftsmen.

There is also another “dry” way to level the floor - use dry mixes.

The algorithm of actions will be as follows:

- Cover the floor with polyethylene to create a waterproofing.

- Close the corners with edging tape.It will absorb sound.

- A dry screed is made and leveled.

- Drywall and plywood are laid on top in two layers.

- Fasten the sheets with screws. If drywall will be used, then the optimal step is 50 mm. If other materials are selected, then the screws can be mounted away from each other.

The dry method also appealed to the masters due to the fact that they do not need to spend time preparing the solution. As a result, the floor is leveled, the room is isolated from extraneous sounds, and additional waterproofing will prevent the materials from losing their appearance and properties prematurely.

What is flexible laminate

A flexible solution for floor leveling - vinyl-backed panels that perfectly level the surface, absorbing all unevenness. In this case, the top layer is a mixture of polyurethane with aluminum oxide. It is strong enough.

This coating option is qualitatively better than others, since it allows you to compensate for height differences of up to 5 mm per linear meter of the floor, and fastening with adhesive locks ensures the integrity of the structure. The so-called vinyl-based floating floor is becoming more and more popular every day. Its only drawback is the high price.

You can lay the laminate according to the general recommendations. You can familiarize yourself with the installation process with the help of instructional videos. The service life of the floor depends on the quality of installation

In this case, it is extremely important to take into account the characteristics of the floor after leveling. It is necessary to ensure the complete drying of the concrete screed or the replacement of wooden elements subject to decay

Due to the timely elimination of floor irregularities, the owner of the house will provide himself with a cozy, warm atmosphere, and will also save money by avoiding the need for repairs for a long time.

A few tips for effective wood floor leveling

It is useful for a novice master to know the features of the procedure for leveling a wooden floor. These recommendations include:

The floor must be thoroughly cleaned of dirt and dust. Therefore, it is best to use a vacuum cleaner, brush and other cleaning devices.

Under the floor are many important communications. In order not to harm, they should be fixed and, if necessary, isolated.

The laminate is laid for many years, therefore it is rational to do everything so that it is comfortable to walk on it

To do this, insulate the floor.

All nails must be combed - this is the main point of the preparatory phase.

It is important not to skip the stage of puttying and grinding. Then the surface will become even smoother and even.

There should be no voids between the floorboards

Otherwise, moist air will flow through them under the floor. As a result, the tree will quickly begin to deteriorate and the flooring will have to be completely changed. You can close the voids with wooden strips, which must first be smeared with glue.

If cycling is chosen for the procedure, then the master must be prepared: have special glasses, a respirator, and earplugs. It is important to close the windows tightly, and it is best to seal them with electrical tape.

Scraping means starting work from a corner. You need to move diagonally. After that, go perpendicular to the previous path.

To smooth out irregularities, you need to use sandpaper. It is better to opt for fine-grained.

In the event that the wooden floor is completely rotten, then it must be completely torn off and the concrete base leveled. After that, according to the already known scheme, lay the laminate.

Floor leveling is no easy task. The choice of technique depends on many factors: the height of the ceilings in the room, the relief of the surface, its problematic and dilapidated.

You also need to pay attention to the preparation of the master and the presence of assistants nearby. If we talk about durability, then laying a laminate on a concrete floor is considered more reliable.

Even after many years passed, this design will hold.But it is better to work with this surface with an assistant to make everything perfect.

The tree is easier to process, but there is no complete certainty that moisture will not get into the middle and will not spoil the base over time.

Leveling the floor will require additional time and money to purchase materials, but you can be sure that the laminate will lie perfectly and last much longer.