Choice of soundproofing material

Gypsum boards of different brands have different soundproofing characteristics. Sheets have maximum protection against extraneous noise:

- Knauf;

- Aku-Line;

- Volma;

- Magma.

The cost of the material is about 700 rubles per sheet.

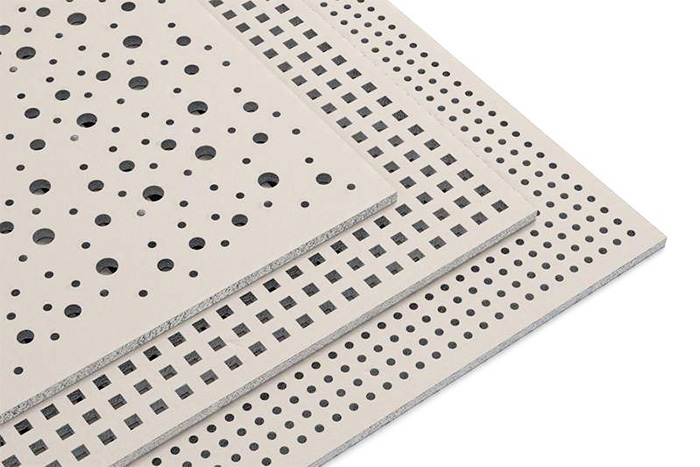

Acoustic drywall is a sheet with a large number of holes. This design reflects sounds from the surface of the walls.

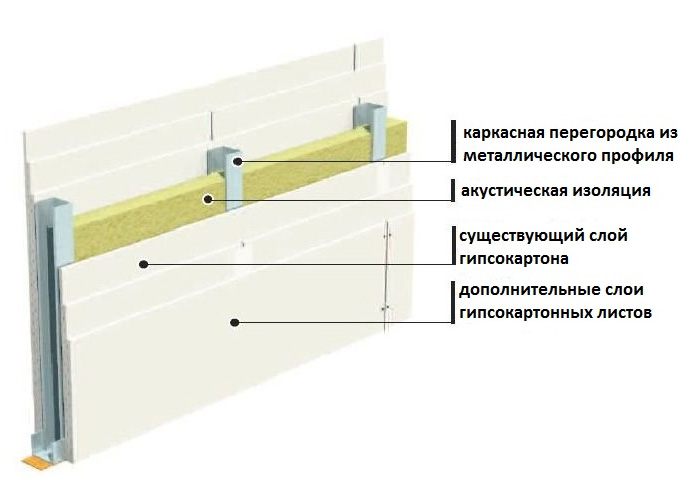

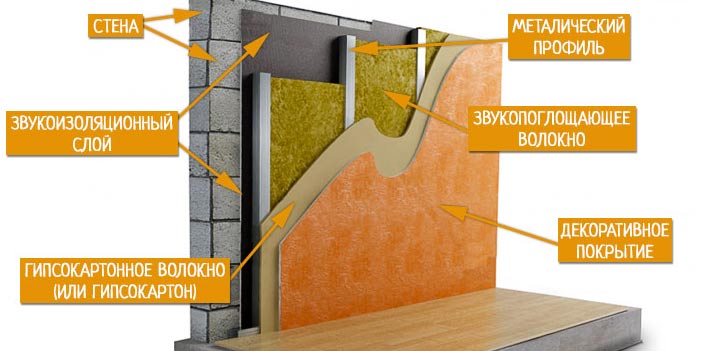

A soundproof plasterboard partition is a multi-layer construction, for the installation of which materials with sound-proofing properties are used. This applies not only to drywall and filler, but also to the frame and fasteners.

Materials for filling partitions

- Acoustic mats. Slab made of stone wool. The panel has a uniform surface, thanks to which sound waves are reflected from the surface. This material is environmentally friendly and safe.

Fiberglass boards. Plates are most in demand in the building materials market, since they have a number of advantages:

- not subject to decay processes;

- resistant to moisture;

- do not burn.

The soundproofing characteristics of the plates are much higher than those of other materials.

Soundproofing material is presented in the form of sheets and rolls, the most popular are mineral, basalt and ecowool, felt.

Elastic materials that are mounted between supporting structures. The main function is to neutralize sounds from impacts.

Panels made of polyester and polyurethane foam. Used for filling partitions and for mounting additional walls in the room.

In rare cases, the internal supporting surfaces are additionally glued with a cork or foil backing. However, in the case of drywall partitions, this option is ineffective.

Features of soundproofing plasterboard partitions:

- The best choice is materials based on mineral wool.

- Styrofoam is also used, but it only reduces the noise level, and does not absorb it. In comparison with other noise-absorbing materials, foam plastic is ineffective.

- As soundproofing, sprayers are used - these are cellulose fibers impregnated with glue. In the course of drawing on a surface it is possible to regulate thickness of a layer.

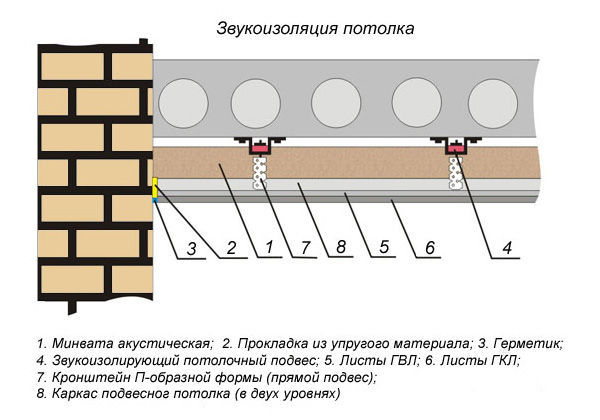

Should I install soundproofing in the ceiling?

A greater effect can be achieved if a floating floor is made in a room located above the head with a layer of insulation placed inside. This option is possible in a private house with a height of more than one floor. In the apartment, it makes sense to soundproof the ceiling in compliance with all technology requirements. They will be described next.

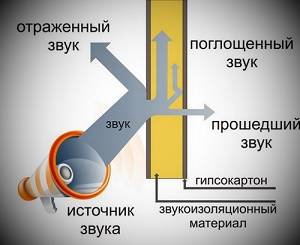

How does a sound insulator prevent noise from entering a room? Noise can be percussive - a mechanical effect on the ceiling (the sound of heels, falling objects on the floor) and air (talks, screams), which also falls on obstacles that arise on the way. In this case, the walls and floor. As a result, a person from below hears noise that propagates through the supporting structures through their structure. Partially absorb it helps soundproof material. But it's not enough. It is required to lay a sealing tape in the places where the ceiling adjoins the bearing bases.

Requirements for soundproofing materials and ceilings:

- During transportation, the material must be reliably protected from moisture;

- Storage is carried out in dry rooms with a normalized level of humidity, in packaged form;

- To create a sound insulation layer, it is recommended to use mineral wool, at least 4 cm thick, or extruded polystyrene foam;

- To ensure better noise absorption at the junction of the profiles with the walls and the draft ceiling, it is necessary to lay a sealing tape, which is glued to the base of each profile.

How to increase noise absorption in addition to the installation of an insulation layer?

You can “help” mineral wool or other material to absorb noise using some tricks in cladding:

- Sheathing with two layers of GKL sheets. For the ceiling, such a solution is not always relevant, but it is possible, taking into account the careful calculation of the weight of the structure, the thickness of the profiles, and components. One layer of GKL, 12.5 mm thick, increases sound insulation by 4 dB, 2 - by 8 dB;

- Increasing the space between the floor slabs and the new GKL base. The bigger it is, the better. Insulation can be laid in 2 layers. Such a solution is acceptable in rooms with a wall height of more than 2.7 meters;

- To make a ceiling without a strong connection to the wall - on suspensions, close the joints with sealant.

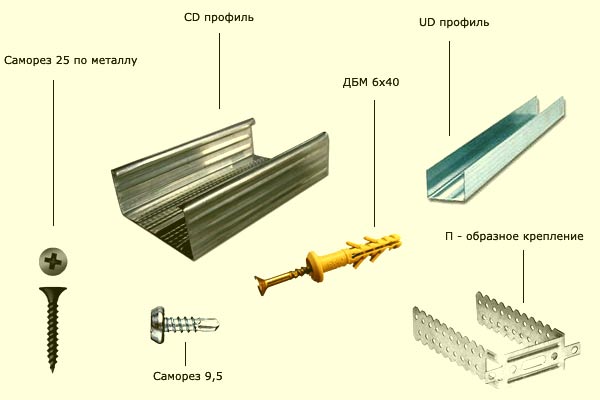

What is required

Naturally, standard materials are needed to assemble the ceiling base - guides and ceiling profiles marked UD and CD, respectively.

- Firstly, we need high-quality noise-absorbing fillers for plasterboard sheathing. Most often, mineral wool slabs (can be of various thicknesses), polystyrene foam (polyurethane foam), various natural materials - peat, coconut flakes, cork, sound-absorbing synthetic membranes are used for these purposes.

- Secondly, do not forget that the frame itself, on which the skin will be attached, has the properties to vibrate from vibrations, which means that this factor must be leveled. For this, an insulating tape is used, which is mounted around the perimeter of the base, serving as a damper between the guide profiles and the bearing walls of the building. Vibration hangers are an important element of the soundproofing frame of a plasterboard false ceiling.

A feature of vibration suspensions is the presence of a noise-absorbing element that dampens vibrations transmitted from walls and ceilings.

The most common version of a soundproofing ceiling is when soundproofing is provided by a filler made of mineral wool or foam.

It is not very convenient to use cotton wool in rolls; in any case, it will have to be cut into separate pieces in order to be laid in the false ceiling frame.

Briefly about the advantages of drywall bulkheads

Plasterboard sheets are deservedly in demand on a par with tongue-and-groove slabs in home improvement. Bulkheads assembled from GKL proved their positive qualities:

Affordable cost of system components.

The light weight of the structure, which is important for apartment buildings.

Easy installation and quick erection of walls.

Environmental safety and durability.

If necessary, it is possible to use moisture- or fire-resistant sheets. Modern soundproofing materials based on fiberglass or mineral wool also comply with all environmental and fire safety standards.

What not to do

In the absence of experience, mistakes can be made that can significantly spoil the sound insulation of walls made of plasterboard. The first mistake is inappropriate materials, such as polyurethane foam. It is not intended for soundproofing equipment and also does not meet fire safety standards. Styrofoam is also not very suitable for the device of a noise-absorbing layer. This material is an excellent heat insulator and is intended primarily for insulating the walls of the facade of a building.

It's from the side of the street. Using expanded polystyrene inside an apartment or house, you can provoke a transfer of the dew point inside under the plasterboard sheathing, as a result, mold may form, since water vapor will condense in this place.

It's from the side of the street. Using expanded polystyrene inside an apartment or house, you can provoke a transfer of the dew point inside under the plasterboard sheathing, as a result, mold may form, since water vapor will condense in this place.

Roll materials, membranes or mineral wool are mounted only with an overlap, they should not form gaps at the joints between individual panels.

What soundproofing material to choose

A plasterboard partition with high-quality sound insulation is a complex complex structure in which one or two insulating layers cannot be dispensed with.

You will need the right choice of the drywall sheets themselves, filling the partition, frame materials and even fasteners.

So, the minimum set that will allow you to dampen up to 30% of noise includes:

- Drywall GKL (GKLV) PC 9.5 or 12.5 mm thick - is located in two or three layers with gaps filled with soundproofing material, with or without an air gap.

- The main soundproofing layer is a sheet or roll material located in the gaps of the "pie". The most widespread are: ecowool, basalt and mineral wool, felt or other substances.

- Additional soundproofing layer - used less often and involves gluing the internal supporting surfaces with a cork, rubber-cork or foil substrate. For drywall partitions, the substrate is not very effective.

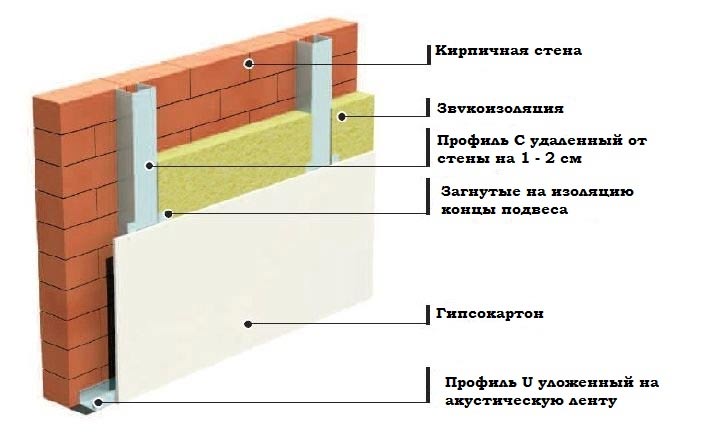

- Frame - is a supporting structure, usually made of aluminum profile. Serves for fixing drywall.

The following measures will help reduce the impact of this chain:

- use as an internal support sheet not drywall, but OSB boards;

- the use of microporous rubber gaskets between sheet materials and the floor, ceiling, walls;

- gluing frame profiles with soundproof tape materials;

- replacement of an aluminum profile with a bar made of durable types of wood, such as beech;

- installation in the walls of special soundproof dowels.

A correctly performed set of these actions will ensure at least 80% of noise dampening, which means that voices, music at medium volume and the sound of moving furniture behind the partition will be almost inaudible.

Installation and soundproofing of plasterboard partitions

Protection against the penetration of extraneous sounds into the room during the construction of hollow and frame partitions increases significantly with an increase in the density and mass of the material used for sheathing, in our case it is GKL, as well as the sound-absorbing qualities of the layer and the width of the air space between the sheathing.

- The construction of a false wall begins with marking on the floor or lower floor. With the help of a plumb line or a laser level (level), the lines are transferred to the ceiling and walls.

- According to the dimensions calculated during marking, the frame elements are cut.

- The guides of the frame of the structure are attached to the ceiling and floor, the fasteners are made with dowels, which are located in increments of no more than 100 cm. The frame is attached to the walls in the same way. To prevent the transfer of sounds and noises to the partition, an elastic strip, for example, polyurethane or cork tape, is laid between the surface of the ceilings and walls.

Such popularity is due to the presence of polymer inserts in suspensions, which dampen sound upon contact between metal parts.

- In the guide starting profiles (ceiling, floor), transverse racks are mounted and fastened with self-tapping screws, the pitch is not more than 60 cm. or 300 mm.

- Above the door openings, as well as at the junctions and joints of the plasterboard, additional frame racks are installed. A prerequisite - the joints of the sheets are always placed on the profile. To give the necessary rigidity to the structure, the racks around the door frame are reinforced by installing a wooden block inside the metal profile.

- Over the entire area of the sheet, with self-tapping screws, the sheathing web is fastened to the profile, a step of 25 cm. With a multilayer structure, the fastening step must be increased, but not more than up to 60 cm, in this case, the joints of the plates should be located in a run. The minimum allowed approximation of the location of the screws to the edge (joint) of the web is 10 mm.

- When placing fasteners (self-tapping screws, screws), it is necessary to ensure that they are screwed into the gypsum board only at a right angle, while penetrating into the metal racks by at least 10 cm.

- In order to allow the drywall sheet to expand and/or contract freely with changes in humidity or temperature, it is recommended to leave technological gaps:

- ceiling and edge of the canvas - 5 mm;

- floor and sheathing - 10 mm;

- between 2 blades with a straight edge - 6 mm;

- the folded edge of the canvas - without gaps.

As a result, the gaps, depending on the size and location, are puttied or covered with a reinforcing mesh and again covered with putty.

- After the installation of the casing is completed on the one hand, the necessary communications are carried out in the internal space of the frame and soundproofing is placed between the racks of the crate. If the thickness of the mineral wool or plates is less than the width of the profile, then its edges are inserted into the grooves of the racks, where they are additionally fixed with liners. When soundproofing drywall partitions, sound absorption boards can be glued to the inside of the frame.

- All communications, including wiring, must pass through the GKL sheathing only in special elastic sleeves, for example, made of porous polyethylene or a similar material.This is done in order to exclude the possibility of the formation of through cracks due to displacement of pipes due to temperature changes. All pipes passing through the interior of the false wall must be covered with the selected sound absorber on at least one side.

- The final stage is the installation of the second side of the false wall.

In this case, the surface of the floating floor will be in contact with the wall structure only through the soundproofing elements. Due to this, the floor will not only serve as a kind of barrier from various sounds, but also will not transmit impact noise to adjacent rooms.

Soundproofing plasterboard partitions

Properly selected material for soundproofing drywall partitions is a guarantee of peace and tranquility. Protecting from annoying conversations, music or TV in the next room, it helps to maintain nerves and healthy relationships.

A typical modern room divider is made of a wooden or metal frame sheathed with drywall on both sides. Such a wall poorly resists the passage of sound. If a similar redevelopment was made in the apartment, then only the soundproofing of plasterboard partitions will save you from noise.

The best materials

The most effective, 100% guaranteed result material does not yet exist and is unlikely to ever be made. There is also no universal, one-size-fits-all guide to follow when making a room barrier.

The effectiveness of activities depends on each stage. The very first is the installation of the frame. Its design will simply ring if you do not take protective measures - isolate the floor and ceiling from it. Without the use of a damper tape, it is impossible to achieve any significant results. An excellent damper is the proven Vibrostek-M tape.

As for the frame, there is not much to think about what to choose from - either a tree or a metal profile. Their indicators are approximately the same, and little depends on the choice in favor of one or the other.

Panels covering the frame play a significant role. Acoustic drywall manufactured by Knauf or similar products of the Aku-Line line manufactured by Giprok can significantly reduce penetrating noise.

A responsible approach to the task requires that the sheets fit into 2 layers. One layer alone does not give a qualitative result. Acoustic triplex, a specialized three-layer material for sound insulation, which is gaining popularity, can also be used as soundproofing for drywall.

A good triplex is produced under the brand name SOUNDLINE-dB.

The main role is played by the layer of filler laid between the panels. Good performance and suitability for domestic use in the apartment have sound-absorbing boards SHUMANET-ECO.

In the event that the partition has already been built, there is not much to choose from. But it is not necessary to disassemble it and rebuild it. Sound absorption can be significantly improved by using wall membranes. Thanks to them, the volume of reflected sounds directed at the surface of the walls is reduced.

The process of installing soundproofing in a plasterboard partition

A good result depends not only on the materials, but also on how correctly and responsibly the soundproofing is done. Here are the most significant stages:

- The soundproofing of a plasterboard wall in an apartment begins with the fact that its frame is mounted on a vibrating tape. It is laid in two layers, attached to the walls, floor and between themselves with vibro-sealant;

- Frame installation. It is advisable not to place sockets and switches on the future wall - sounds are transmitted through them very well. A rational solution would be to make the distances between the profiles corresponding to the size that the soundproofing plate has;

- Installation of plasterboard partition walls on one side. Acoustic drywall is mounted with perforation to the outside;

- Laying sound-absorbing plates in the interior partition. Their thickness determines what the thickness of the interior partitions will be;

- The final stage - the plates are closed with GKL. In order to do everything right here, the joints must be covered with vibrosealant.

What are the advantages of the material and are there any disadvantages

Gypsum fiber sheets, like other material, have their own

Advantages and disadvantages. The main disadvantage of GVL boards is its cost.

This material is currently somewhat more expensive than such materials as:

drywall, plywood, chipboard and MDF boards. Also among the minuses of his canvas

substantial weight

When making a frame, it is important to correctly calculate

an indicator of strength, since the mass of the plates is considerable. As for the cons,

this, perhaps, is all

Gypsum fiber has many advantages, which is why this

material is often used in modern construction. Thanks to

hypoallergenic qualities of the finish, it can be used for residential premises and in

particular children's rooms. The microporous structure of GVL sheets allows walls

breathe, which contributes to the protection of the surface to resist fungal

formations and mold.

Due to the hygroscopicity of the composition, the canvas can itself

regulate the humidity of the apartment. If the apartment has high humidity, then

the surface of the GVL absorbs it into itself. In case of increased dryness

gypsum fiber gives off moisture to create optimal climatic conditions. Also

It is worth mentioning the possibility of using GVL panels in rooms with

temperature fluctuations. Gypsum fiber sheet is an ideal finishing material

premises without heating.

Features of acoustic drywall

The words "acoustic" and "acoustic" in relation to building materials usually tell us that the material has soundproofing or sound-absorbing properties. For example, acoustic rock wool, soundproofing wall panels or rolled soundproofing material in the form of a membrane can reduce the noise level in the room by preventing sounds from outside and from neighboring apartments. But acoustic drywall is not on a par with these materials.

This error has crept into many construction sites and portals and misleads people, however, if you open the section on Knauf-Acoustic slabs on the official website, you will not see a word that this is a soundproofing material.

Why then do you need acoustic drywall? This material is used to improve the acoustic characteristics of the room. This means that he:

- reduces the level of background noise that occurs in the room itself;

- reduces loudness;

- eliminates the effect of "echo";

- improves speech comprehension.

Thus, according to the Knauf company itself, Knauf-acoustics drywall allows you to create a comfortable acoustic environment in any room, which is especially important for objects with increased requirements for it:

- in recording studios;

- in music classes, concert and rehearsal halls;

- in cinemas;

- in meeting rooms;

- in classrooms.

There is a place for an acoustic variety of GKL in the apartment. It will help solve the problem of boominess inherent in some rooms, and will be appreciated by music lovers, musicians who play at home, as well as home theater owners.

Tips for achieving the best soundproofing result under drywall.

- The technique of layer-by-layer penetration of noise through the layers should be observed, and then the sound insulation of plasterboard partitions will justify itself. All fasteners and structural elements must be installed with soundproof gaskets.

- The soundproofing effect will be greater if two separate frames are mounted, on which the skin will subsequently be fixed.

- Sheathing should be selected taking into account the required absorption coefficient Rw - a conditional characteristic that reflects the ratio between the soundproofing parameters of materials and noise in an apartment or on the street. It is better to choose such a coefficient from 0.8 and higher.

- The soft layer material should not be less than 100 mm. As a percentage, it should not be less than 50% of the volume of the soundproof partition.

- Acoustic mineral wool can be placed between the GKL frames in order to create a damping effect. In this case, the sound insulation coefficient is increased by reducing the resonance effect in the partition.

- It is necessary to achieve complete tightness of structures. Avoid any mechanical deformations, holes and cracks. Putty the joints using a shock-absorbing mesh. Use silicone sealant in places where electrical wiring and other communications are carried out. Mounting foam is not suitable due to its flammability.

A significant effect of soundproofing interior walls (approximately 30 dB) can be achieved using sound-absorbing membranes. Such elements are attached to the inside of the structure with glue. Soundproofing under drywall - there is no more ideal and justifiable way to protect against noise.

Features of working with Knauf-acoustics panels

When working with acoustic GCR, you need to remember some important points:

The joints of 4PK panels are puttied without the use of reinforcing tape. The edges are pre-cut with a slight bevel, the panels are mounted with a gap of 3–4 mm. The seams will be filled with Uniflot putty, the recesses from the self-tapping screws are puttied. after drying, the seams are puttied with finishing putty and polished.

- The connection of 4FK panels does not require additional processing, since the joining is carried out by means of folds.

- The implementation of arched structures is carried out by the method of dry and wet bending using plywood templates.

Main characteristics

And now let's find out, thanks to which the Knauf-acoustics plates have the above properties.

- Perforation on the surface. Many through holes act as resonators, providing sound absorption. As a result, sound waves quickly decay, falling into a kind of trap.

- The non-woven fabric on the back also has sound-absorbing properties. Depending on the design, you can choose GKL with black or white non-woven fabric.

Acoustic GKL "Knauf" has several options for the location and shape of the holes, which determine the model of the material:

- Fully perforated. On this model, the holes are distributed evenly over the entire surface.

- With block perforation. The holes are located on the plane in separate groups.

- With round perforation in the form of holes with a diameter of 0.8 cm.

- With square perforation, where the holes are made in the form of a square with a side of 1.2 cm.

- With scattered round perforation - the holes on the surface are arranged in a chaotic manner and have different sizes - 0.8 cm, 1.5 cm and 2 cm.

Necessary materials

Drywall walls are created on the basis of a frame made of metal profiles, but this will not be enough when creating sound insulation with your own hands.

- A damper tape is necessarily mounted under the guide profiles (for example, the Dichtung soundproofing tape). It will absorb vibrations transmitted from the wall to the frame. And you can also use its analogue, fiberglass spatula tape;

-

Another element of the frame when creating soundproof walls will be vibration suspensions. This is a modified type of direct suspensions with a noise-absorbing element.They, like the tape, absorb vibrations transmitted from the wall to the frame;

- As the main sound insulator, you need to choose mineral wool, which has excellent qualities for absorbing vibrations. You can also use felt or cork;

- Additionally, under the frame, you can lay a membrane film that has the ability to reduce the penetration of sounds.

In addition to these materials, it is worth buying plastic dowels, which resist vibrations better than metal ones.

And do not forget about the switches and sockets in drywall, they also conduct sound perfectly, they must be insulated with rubber pads in the form of washers.