The main parameters of the ventilation duct

The main criterion for choosing a ventilation duct is its throughput. It will not be possible for a person without special education to calculate its ability, since the formula is complex, but there are a lot of tables that reflect the required throughput, depending on the size of the box.

The main pattern is simple: the throughput depends on the available corners and irregularities in the duct design - the more there are, the more difficult it is for the air to function correctly. To remove the same volume of air in this case, more powerful equipment or a larger cross section is required.

The surface of the ventilation duct, both external and internal, can be smooth or corrugated. Also, the boxes can be round, square or rectangular, but round structures are preferable, since they have no obstacles for air exhaust and they are easy to clean. Boxes differ in the material of manufacture: plastic or metal.

Noise reduction methods and their characteristics

Before talking about ways to reduce noise, you should find the source from which this noise comes. There are several reasons for noise:

- Air circulating inside the hood. Moreover, the more obstacles encountered in the path of air flows, the stronger the noise will be.

- Exhaust pipes clogged with dust or other sediment can also cause noise, but this problem can be easily dealt with by cleaning the hood.

- The motor can also cause noise, while it is almost impossible to cope with this problem on your own. The motor can be located both in the housing itself and above - outside the room where the hood is working.

- Noise can also be caused by improper installation of the duct.

In many cases, you can perform soundproofing of the duct yourself. Consider ways to help reduce noise:

- Replace part of the air duct and install the same one, but with noise-absorbing materials of the same section. For this, you can use corrugation. This material is well protected from sounds, and also has high strength.

- Install a silencer of the required section. This type of silencer is equipped with sound-absorbing materials inside, so it will help to reduce aerodynamic and other noises.

- If the main noise comes from the fan, then you can try to replace it with a new one or substitute rubber pads under it, which will reduce the noise.

- Internal or external soundproofing of the duct. In this case, self-adhesive soundproofing for air ducts will be an ideal option. Firstly, it is easy and fast to work with it, and secondly, this material absorbs sounds well.

Features of installation of sound insulation in the ventilation duct

If you decide to insulate the hood in the kitchen or other room with your own hands, then you need to do the preparatory work. First, you need to clean the surface of the structure from the existing dirt. Secondly, prepare a working tool and material for soundproofing. Of the tools you may need a spatula, knife, glue.

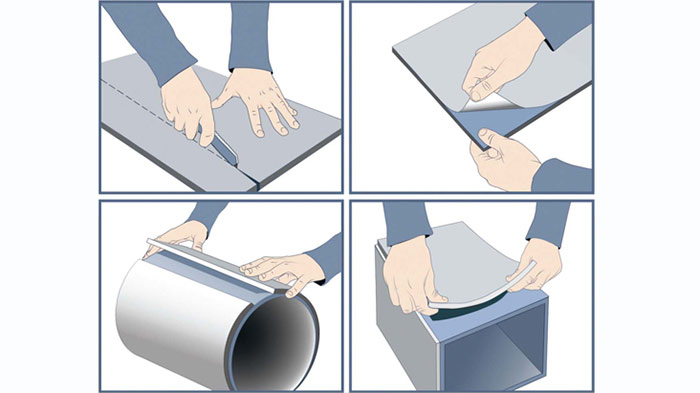

Now we will analyze the features of installation in stages:

- It is necessary to prepare materials for noise suppression, with a thickness of 3 to 9 mm, depending on the parameters of the box. The material can be polyethylene foam, which is most often used as a sound-absorbing material, moreover, it protects the structure from moisture and condensate.

- Then all uneven surfaces (corners, recesses, etc.) are pasted over with the selected material.

- The material is attached so that its reflective side is out.

- Joints and seams of the material must be sealed with metal tape. This will help to securely fix the edges of the canvas and hold them at the time of operation.

- To improve the effectiveness of the insulating structure, special materials are used and placed under the structure.

Noise isolation of the hood

Soundproofing the hood can be done independently. To do this, prepare the necessary materials:

- Drywall sheet.

- A metal sheet.

- Screwdriver and perforator.

- Construction scissors or knife.

- Self-tapping screws and dowels.

Let's move on to installation:

- First of all, it is necessary to make markings on the wall and ceiling in place of the future hood. Next, using dowels, attach the drywall profile.

- The next step is to prepare vertical racks from the profile, the length of which must match the length of the vertical size of the hood.

- Then attach the racks, observing the perimeter of the future structure. Next, mount the lower part of the ventilation unit.

- Mount a corrugated pipeline in the middle of the structure. Then prepare the remaining parts of the drywall construction and mount them using self-tapping screws and a perforator.

Sound insulation of ventilation systems is divided into the following parts:

Existing types of silencers

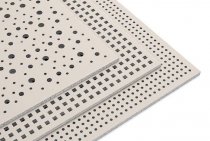

- Plate silencer. It is a structure that looks like a metal box, with a through hole for air flow, which is divided into sectors. Each formed cell is lined with soundproofing material. There is another design of the plate silencer, in which the noise-insulating segments are located between layers of perforated metal. This device effectively reduces the level of aerodynamic noise, but also significantly reduces the pressure in the system.

- Tubular silencers. It is made of two pipes, of which the inner one has many holes. The outer tube is the body of the product. Between the layers of metal is sound-absorbing material. As a rule, such devices are installed on air channels having a diameter of up to 500 mm.

Noise isolation of external equipment

Sound insulation of ventilation equipment located outside the building (ventilation units, fans) is carried out in two stages: the fight against noise propagating through hard contacts (structural noise) and noise propagating in the air (airborne noise).

Works aimed at excluding structural transmission are solved by installing equipment on individually selected vibration mounts. After the completion of these works, acoustic measurements are again carried out to determine the sound pressure levels directly from the units, without indirect sources that emitted noise earlier, on the basis of which the methods of combating airborne noise are selected. With proper soundproofing, vibration control steps are taken before equipment is installed. So for massive machines, with sufficient objective characteristics, a floating foundation is prepared, placed on an elastic cushion that excludes vibration.

Acoustic screens made of sound-absorbing and sound-proof materials are installed along the path of noise propagation. To improve noise protection characteristics, the side of the screen directed to the source is additionally provided with perforation. The reduction in the noise level from the source when using an acoustic screen occurs due to the formation of an acoustic shadow area located behind the screen. Screen type, screen materials, and screen dimensions are calculated on a case-by-case basis based on sound levels and frequencies, distance from the screen and sound test points, reduction requirements, and other factors.

When carrying out an acoustic calculation, in case of insufficient efficiency of the acoustic screen, soundproof shelters are used that cover the equipment from all sides. The design of shelters is similar to the design of screens.For air circulation, on the way it follows inside or outside the shelter (in the air exchange openings), jamming elements are placed that do not prevent the movement of air masses, but absorb sound.

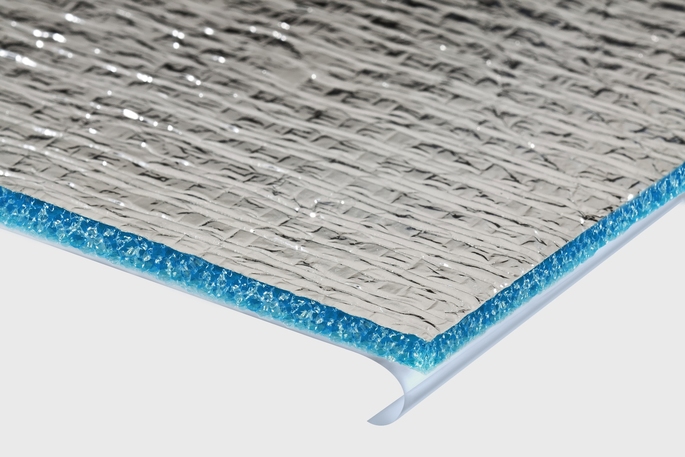

Designed for insulation of interiors of residential and industrial buildings, thermal insulation of equipment and pipelines, thermal insulation of air conditioning systems, air ducts, ventilation ducts, protection against condensation, as a "reflecting screen" behind central heating batteries.

Composition: foamed polyethylene, doubled with a heat-reflecting layer of aluminum foil on one side and a self-adhesive layer on the other.

Advantages:

- 1.Aluminum coating provides a high coefficient of thermal reflection - up to 97%.

- 2. Noise isolation.

- 3. The material reliably protects ventilation systems from the accumulation of condensate.

- 4. Due to its flexibility and small thickness, the material is used to isolate any form of metal surfaces.

Soundproofing Design Errors

When designing ventilation, certain errors can be made. They are the cause of the noise. Several mistakes are allowed, but it is better to foresee everything in advance. It is necessary to approach the solution of the problem in a comprehensive manner, you should start with calculating the power of the fans, choosing a scheme, determining the size and type of pipes

It is important to immediately determine where the dampers, branches, elbows for laying will be located

The ventilation system requires a special vibration protection device, which will eliminate the appearance of strong noise.

If you do not take into account all the features of the laying of the system, then the acoustic characteristics will be violated, noise will appear during operation. It does not bring comfort to those living in the house. To get rid of it, some ventilation begin to turn off or reduce its power. As a result, the ventilation of the premises is insufficient, and hence the accumulation of moisture, the formation of mold.

A similar situation is observed when air masses pass between false ceilings and ceilings. In this case, the system must be redone, since soundproofing the ceiling will no longer help. Experts advise to perform over non-residential premises, where the sounds of running ventilation do not matter much. For example, laying is possible over kitchens, bathrooms, corridors, pantries. If this is not possible, then it is necessary to use air ducts with thicker walls, use oval or round pipes with special soundproofing materials. Additionally, soffits assembled from gypsum panels can be used to soundproof ventilation.

Any ventilation system requires special vibration protection, which eliminates the appearance of high noise levels. It is recommended to use flexible hoses for connections, as they do not make such loud sounds during operation of the equipment. Noises appear due to the fact that a high air flow velocity is formed in the duct. Therefore, it is recommended to use special pipes of large sizes, they allow the air flow rate to be significantly reduced. Air turbulence can occur anywhere in an installed ventilation system. If you do not take special measures for soundproofing, then a high level of noise will cause a lot of inconvenience.

Noise insulation of air ducts

Soundproofing of air ducts, depending on the air flow rate, geometry and size of the pipes, can be carried out by installing sound attenuators and / or lining the ventilation pipe with heavy, high-density sound-proofing membranes with a backing of low-density damping material.

Mounted silencers are selected individually and may differ in their length, type (tubular, plate and chamber) and other factors.Due to the presence of sound-absorbing materials in its composition, the sound passing through the muffler is reduced. The presence of a distinct fan noise emitted by the duct may require the manufacture of a non-standard muffler, with an inner lining of denser and thicker sound-absorbing materials. The choice of installation location for the muffler is individual.

Lining of pipes with both soft and heavy materials must be carried out over the entire area of the air duct emitting noise. Insulation of only part of the perimeter is impractical, because this will certainly lead to poor results. The soft damping material is mounted butt-to-butt, the soundproof membrane is overlapped by 4-5 cm. In places where pipes pass through walls, it is imperative to exclude contact between the pipe and the wall, fill the existing gap with high-density sound-absorbing material and, when installing the membrane in this area, remove the overlap from the duct to wall

When applying facing layers, special attention will need to be paid to narrowing points, bends and other non-linear sections of the system. Often these areas require a double alternating layer of the above materials.

Noise insulation of air ducts located in places exposed to open sunlight should be carried out exclusively with the use of protective foil coatings. With a high air flow in the pipe, it is possible to transmit structure-borne noise to the ceiling through the stud and traverse, which are fasteners for the air ducts. Here it is necessary to break the rigid connection by placing the traverse under the previously insulated pipe, or, if this method seems laborious, install vibration washers at the junction of the traverse and the studs.

Soundproofing air ducts by creating a soundproof ceiling will require large financial and labor costs while obtaining less efficiency. When choosing actions aimed at combating noise, it must be remembered that the most effective struggle is to deal directly with the noise source.

As an alternative to the use of elastic materials, it is allowed to create a soundproof box around the source from heavy dense building boards, such as GVL or Knauf-superfloor, filled with sound-absorbing materials with a density of 40-60 kg/m3. This option is also more expensive, but its use in case of need for frequent access to units, filters, control systems is justified.

Rules for self-installation

In fact, there are no rules for mounting these devices. It is possible to install the noise dampening device both on the supply ventilation ducts and on the channels of the exhaust ventilation system.

- Relying only on hearing, these devices should not be mounted. Acoustic measurements should be made.,/

- On the basis of the measurements, it is necessary to connect the noise suppression equipment to the air duct, in the place of the greatest noise.

- You can make additional noise insulation by pasting the air duct with felt or wrapping it with mineral wool.

- If there are solid inclusions in the air flow of the ventilation system, then a coarse filter should be installed in front of the noise absorber.

When selecting the most efficient device, a rather complex system for calculating the interaction of acoustic vibrations of the fan, air ducts and the device itself with the manifested sound vibrations is used. For this, specialized equipment is used. But if you wish, you can always make a noise suppressor for ventilation with your own hands, which may be inferior in some respects to its production counterparts, but will be significantly cheaper than them.

Do-it-yourself noise absorption device in the ventilation system

In order to make such a noise suppressor with your own hands, you will need:

- A piece of galvanized pipe with the same diameter as the air duct of the ventilation system. The pieces are sold in 1m lengths.

- A piece of pipe, the diameter of which is 60 mm larger than the previous one.

- Insulation, which is also an effective sound insulator. It can be basalt wool, glass wool, any pressed organic fibers impregnated with a composition that prevents its combustion.

- Plastic clamps and 1 slate nail

- Rivet gun, hammer, pliers.

Let's start assembling

- The first section of the pipe must be made perforated, stepping back from both edges of 100 mm. To do this, use a nail and a hammer. Make holes every 10 mm.

- After that, wind 1 layer of basalt mat, 50 mm thick, onto the perforated pipe section. retreating from the edges by 80 mm. The sound-absorbing material is well tightened with 4 plastic clamps.

- From one edge of the larger pipe, retreat 60 mm, draw a line around the circumference and make cuts to it. Bend each “petal” along the marked line at 90 ° to the middle, after which make a mark on each, retreating 30 mm from the edge of each petal and bend at ° 90 along the pipe.

- We insert the first blank into the second, the petals will be both the stop for the insulator and the place where the pipes are attached to each other.

- On the other side of the pipes, repeat the operation with cutting the petals.

- The finished product can be installed in the gap of the ventilation duct, secured with clamps.

If, after installing it, the noise level dropped by at least 10-15 dB, then you got an excellent result and achieved the efficiency of industrial analogues.

Soundproofing of ventilation chambers

The placement of ventilation supply and exhaust equipment located in close proximity to the working premises is not uncommon. Also, to increase the usable area, often a part of the equipment is grouped with each other, freeing up new space. Work on soundproofing ventilation chambers will bring a significant effect when performing the following actions.

Improved sound insulation

Increasing the soundproofing capacity by installing soundproofing structures to existing walls around the entire perimeter of unwanted noise propagation. Preferably placed from the outside of the room to the existing walls. The presence of acoustic cracks and openings is not allowed. The high mass of the soundproofing system is one of the main factors influencing the achievement of high soundproofing performance. Often offered, constructions sheathed with drywall and filled with cotton wool will give a barely noticeable result. The level of sound insulation of the entrance group should not be lower than the sound insulation of the main part of the building envelope. This task is solved by installing two doors with a distance between them of at least 20 cm. As the main door, we use fire doors, which have a high mass and a hermetic vestibule. We recommend ordering a door with a metal sheet thickness of at least 2 mm.

Sound absorption improvement

To increase the sound-absorbing properties of the interior parts of the room by applying a sound-absorbing cladding covered with a sound-permeable fabric to prevent material particles from spilling out. The use of sound absorption inside the chamber significantly reduces the effect of superposition of reflected waves on the waves emitted by the equipment. In the high and medium frequency spectrum, the sound absorption efficiency is inversely proportional to the size of the chamber. The smaller the volume of the room, the more noticeable the result.

Vibration isolation

Eliminate the transmission of vibration from the equipment to the rigid elements of the camera. This problem is solved through the use of optimal vibration isolation mats or supports, selected based on the speed of the fans and the weight of the equipment.

What materials are used to reduce noise

Properly selected material is the key to successful work, so it should be selected taking into account the intensity of the air supply and the shape of the box. It depends on the thickness of the material.

The following materials can be used to reduce noise:

- Mineral wool or glass wool.

- Sound-absorbing plates made of polymeric materials.

- Materials containing organic fiber binders.

Using channel installations to dampen noise

To reduce noise in the ventilation ducts, special equipment is used, which is called "duct silencers". With this device, noise can be reduced to a minimum, but on one condition: proper installation.

The device is installed using fasteners inside the duct. Silencers are available in various shapes and sizes, so it is not difficult to choose them individually for each model of the hood.