No repair will be considered complete until the windows are in order. By themselves, window structures are usually mounted by specialists, so there are no special problems with them, which cannot be said about slopes. During the dismantling of old and installing new windows slopes come into complete disrepair. After all the work with the windows, they will have to be brought into proper form. With proper skill and a little theoretical preparation, the installation of slopes is quite doable with your own hands.

What can slopes be made of?

Three slope options are commonly used:

- Plasterboard.

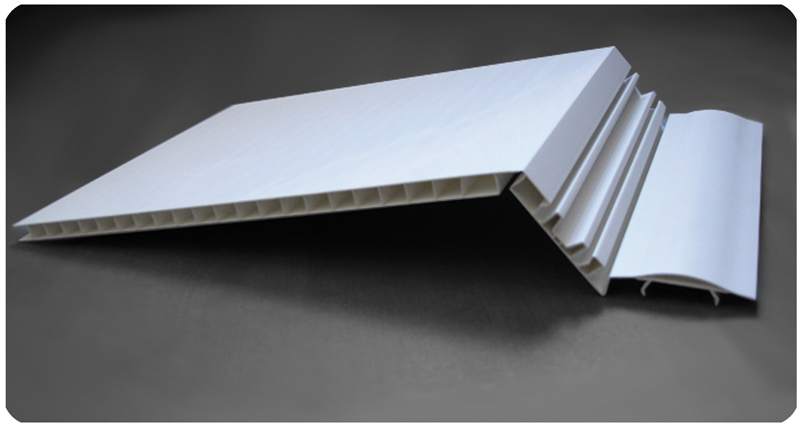

- Plastic.

- plastered.

It is very difficult to achieve perfect evenness of the slope surface with plaster and putty. This is only possible for a professional. With your own hands, you often get a wavy surface, which can soon crack and fall off.

The installation of plastic slopes is usually carried out together with the installation of the window. The surface is smooth. However, plastic is a cheap material. It can get hot and smell bad. This type of decoration is more suitable for office and public spaces.

Drywall slopes in many ways are an ideal option for a house or apartment. The material is easy to process, environmentally friendly. The result is an attractive, smooth and even surface. You should take a closer look at this option if you have to build drywall slopes with your own hands.

Preparation of surfaces for installation

In repair, the first stage of work is important - the preparation of the foundation. Having made a mistake at the very beginning, an undesirable result will turn out in the end. For slopes, it is very important to prepare the surface, which will serve as the foundation for the entire future structure.

- Cleaning the base for the installation of slopes. Any sharp object removes the remaining influx of mounting foam. If there are large chips, they should be covered with gypsum plaster or cement mixture. The surface is impregnated with antifungal primer - this will protect against unwanted processes.

- Protection of polyurethane foam in the seams. All seams that have been sealed with foam must be plastered. To do this, use a gypsum mixture and a small spatula.

- Drywall is afraid of moisture, so you should check all the junctions of the window with the window opening. It can blow through a small gap, as a result, condensate will form, which leads to the gradual destruction of the drywall sheet.

- To obtain the ideal slope level, a special corner is screwed to the window frame around the entire perimeter. The sheet should be fastened with ordinary self-tapping screws. This trick will help to avoid a large loss of window frame area.

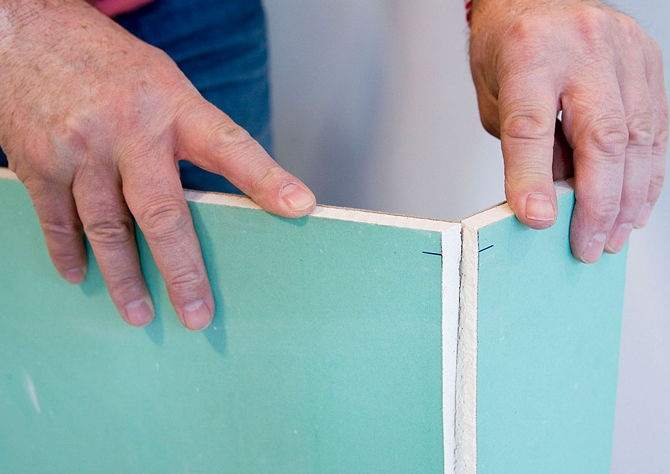

Important! To create slopes, use moisture resistant drywall green color with GKLV marking.

Installation of plasterboard window slopes

The most important and responsible stage. The final result of all work depends on the quality of its execution.

- The exact dimensions of the required sections are produced.

- Now you need to correctly and accurately cut a solid drywall sheet into the right parts. To begin with, cut out the upper part of the slope. Mounting holes are drilled if necessary. The resulting strip is applied to the installation site, outlined with a pencil. Then it is set using the building level.

- The remaining side and bottom parts are cut in the same way.

Cutting drywall sheet it is necessary as follows: in the right place, an incision is made with a cutting knife, then a piece of gypsum board is broken along the notch line by pressing from below.

The sheet is fastened in two ways:

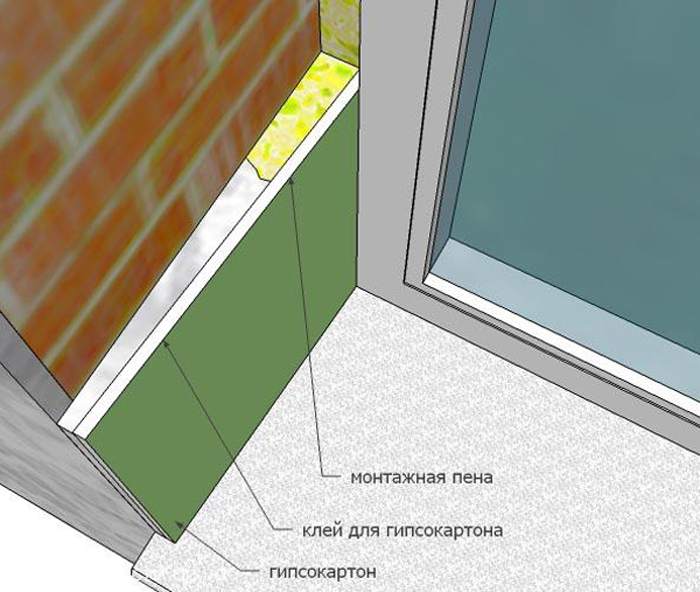

- drywall is glued with a special mounting adhesive;

- it is mounted on a frame made of galvanized profile.

Creating a slope by gluing

This method does not require a start profile. It is applicable when the surface is fairly even, but it is quite difficult to create a slope by pasting.

- All details of the future slope are cut out.

- The top is installed first. A special guide corner is screwed to it in advance, into which its upper part is inserted and glued. Precise installation will allow you not to make a mistake during the further installation of the side elements.

- The remaining elements are glued.

In most cases, the adhesive is applied to the entire plane. Usually, the approximate drying time of a particular brand of mounting adhesive is indicated on the packaging. If there is a need to reduce the setting time, then the glue is smeared with strips. All work is controlled by the building level.

Installation of a slope on a frame from a profile

Attaching the slope to the frame allows you to level very curved and curved surfaces. The basis of the whole structure is the starting profile. The work algorithm is as follows:

- Installation of guide profiles. The entire perimeter of the window frame is framed by a starting profile (UD). It is installed perpendicular to the floor. The profile should be fixed with self-tapping screws in increments of 50–60 cm.

If the frame is attached directly to the window frame, then a heat-insulating gasket is placed between it and the profile. It will help prevent freezing of the guides.

- Guides (CD) are attached in a perpendicular direction to the starting profile. They are fixed with drywall screws 30–35 mm long.

- The assembled structure of galvanized profiles is sheathed with drywall sheets. As a result, small gaps are formed between the slope and the wall or lintel. They are recommended to be filled with glue for drywall work.

Finishing the slope of drywall

As a result of the work carried out, a smooth slope surface was obtained. But without finishing, it will look untidy. In 90% of cases, latex putty and water-based paint are used for cosmetic repairs.

- All corners of the window opening are closed with a special perforated corner profile. It will protect them from chipping and loss of appearance as a result of erasing. The thickness of the profile is only 0.5–1 mm. It should be glued with glue on drywall.

- The entire glued surface is thoroughly smeared to avoid the formation of voids, which can lead to subsequent deformation of the slope angle. The corner is strongly pressed into the glue, the excess is removed with a rag or spatula.

- All corners and caps of twisted screws are carefully puttied. putty applied in two layers. It is important to let each layer dry for 3-4 hours.

- When the putty dries, the slope surface must be sanded. You can use a grinder for this. If this was not at hand, then grinding is done with a putty mesh or sandpaper. Do not be too zealous, latex putty is easy to process and polish.

- After grinding is completed, the slopes must be covered with deep penetration soil. It will saturate the entire surface and make it homogeneous. In addition, the primer reduces paint consumption and guarantees color uniformity over the entire area.

- The last stage is the coloring of the finished slopes. It is recommended to use a water-based paint with a water-resistant effect. The reconciliation of this type of material will make it possible to carry out wet cleaning of the window.

To avoid making mistakes, it is recommended to strictly follow these instructions. Good preparation, accurate measurements will get rid of most problems at the first stage of work.

The most common mistake is the gaps between the sheets of drywall at the junction. They appear from inaccurate measurements or errors in cutting.They are eliminated with liquid plastic, but the surface will no longer be completely monolithic - the joints will be noticeable.

Many problems with uneven corners can be solved by covering them with a wide plastic profile. Visually, this will correct the unevenness, but plastic always looks cheaper than natural material.

Following the above tips, everyone can make drywall slopes with their own hands.