Drywall is widely used in the repair and decoration of apartments. However, coatings from it have one significant drawback: various hanging interior elements, such as shelves or cabinets, are very poorly held on their surface. Therefore, it is recommended to pre-strengthen the frame in the places of their attachment. But a more original and aesthetically attractive solution can be a niche in a plasterboard wall, which can be made by hand.

What are the advantages of GKL niches?

Recesses in the walls can perform both decorative and practical functions, so they are relevant for all rooms in the apartment. They are made in bedrooms, halls, hallways, kitchens, bathrooms and toilets. They allow:

- Save the free space of the room, "eaten up" when leveling the walls with drywall.

- Divide a room into separate functional areas.

- Organize convenient storage of books and small items on shelves placed inside a niche.

- Place household appliances with solid weight on the wall, such as a TV or audio system.

- Give the room a unique look.

Niches can be open or closed. In the latter case, they turn into original lockers. A good visual effect can be achieved if additional lighting is made in the recess with spotlights or LED strip.

Drafting

Each room is individual, so you will have to design a niche yourself, focusing on your own idea. You can get ideas here, and choosing a niche design for a TV will help This article.

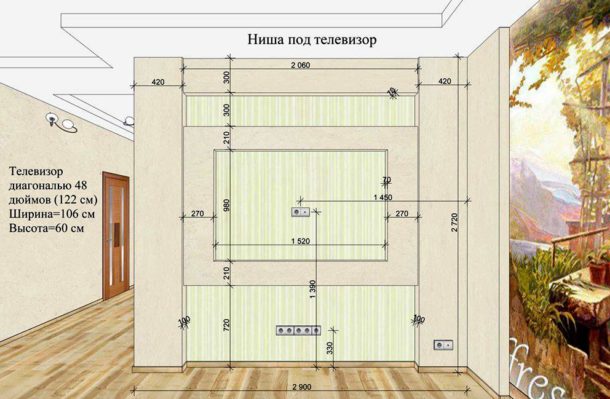

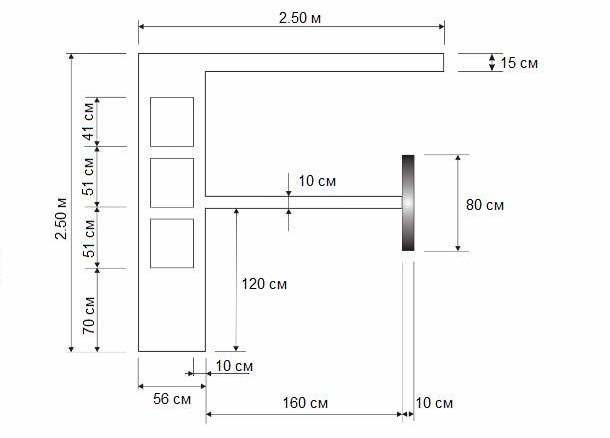

Having decided on the purpose and type of niche, first of all they make up its detailed drawing. It is needed to calculate the required amount of material.

The dimensions of the recess are calculated depending on its purpose: what is planned to be placed there, whether there will be a backlight, whether shelves are needed in the niche.

Special attention requires the installation of household appliances, such as a TV. In this case, it is necessary to provide for the following points:

- niche shelf must be strong enough to support the weight of the instrument. It should be additionally reinforced with horizontal jumpers. Some craftsmen advise making the shelves themselves not from drywall, but from plywood: it is more durable and can withstand a greater load.

- The niche depth must be calculated taking into account the gap between the appliance and the rear wall. It is needed not only to place wires or other communications, but also to exclude the heating of drywall from a working device.

Advice. It is desirable that the outer side of the installed equipment, such as a TV screen, be in the same plane as the niche boundary or be slightly pushed inward. So it is more difficult to accidentally touch it and knock it over from the shelf.

- Clearances are also needed on the top and sides for comfortable installation of equipment and its maintenance.

The drawing indicates all the elements of the future frame. When placing profiles, the dimensions of drywall sheets are taken into account in order to reduce the amount of waste. All elements from the GKL must be joined on the profile, and the joints are not recommended to be placed at the edges of the structure.

Necessary materials

Having made calculations according to the sketch, they purchase the necessary materials with a certain margin:

- Drywall. In most cases, an ordinary wall plasterboard with a thickness of 12.5 mm is used, but you can also take a thinner one, including an arched one. For rooms with high humidity, such as a bathroom, moisture-resistant drywall is used.

- The framework is made of the directing (UD) and rack-mount (CD) profile.

- If the base wall is uneven, straight hangers may be required.

- Damper tape providing sound insulation of the structure.

- Dowel-nails 6 × 60 mm for fixing rails to the wall, floor and ceiling. With a large layer of plaster, longer hardware is taken, for example 8 × 80 mm.

- Self-tapping screws for metal for fastening frame elements together.

- Putty and primer for drywall, as well as sickle mesh - to prepare the niche for finishing after assembly.

Tools

The standard set required for the construction of drywall structures:

- Metal shears for profile cutting.

- Perforator equipped with a drill of the desired diameter.

- Screwdriver. It is recommended to purchase a special drywall bit. It limits the depth of screwing screws and prevents damage to the material.

- Marking and measuring tools: tape measure, pencil, square, level and plumb.

- Spatula, brush and roller.

How to make a drywall niche with your own hands: creating a frame

Frame assembly instructions:

- The drawing from the sketch is transferred to the walls, floor and ceiling.

- The necessary pieces of the guide profile are cut off. Their back side is glued with a damper tape.

- The rails are mounted on the ceiling, wall and floor using dowels in 30–40 cm increments.

- Racks of the rear plane are installed: profile sections are cut 1–2 cm less than the height of the room. They are inserted into the guides on the floor and ceiling, and then fixed with metal screws or a cutter. They can be additionally attached to a flat wall with dowels. If the base surface is bumpy, then direct suspensions are used.

When the niche has a curvilinear configuration, you can use a flexible arched profile. Another option: cutouts in the form of a petal are made on the guide in the side walls, after which it will easily take the required shape. The desired bend is fixed with vertical jumpers.

- The necessary horizontal jumpers are made from the rack profile and fixed with self-tapping screws. The result is a flat frame of the back of the future niche.

- In the same way, mirror, the frame of the front part of the structure is assembled.

- Both structures are connected by horizontal jumpers. They are needed not only to create a recess contour or fasten shelves, but also for rigidity. Jumpers are made of a rack-mount profile and are fixed with self-tapping screws.

Drywall fixing

The cladding of the GKL frame starts from the back wall of the niche, if required, because often its role is played by a flat base surface. First, the recess is lined, and then the drywall is mounted on the front plane. In this case, several points should be taken into account:

- If it is supposed to place sockets or spotlights in a niche, then holes for them in drywall are cut out in advance.

- Chamfers are made at an angle of 45˚ in all places where individual plasterboard fragments will be joined.

- Sheathing elements forming right angles are installed so that the plane of one covers the end of the other.

- Fragments of plasterboard are mounted in increments of 20–25 cm. The fastening points on adjacent pieces are shifted relative to each other.

- To bend drywall, for example, for an arch-shaped niche, proceed as follows: the surface of the element is moistened with water and rolled with a roller with needles. Another option: a series of parallel cuts are made on the fragment, forming the desired bend. The smaller the radius, the more often the cuts. Only the cardboard layer on one side of the element should be cut.

Preparing for finishing

The assembled drywall structure is prepared step by step for a fine finish:

- All corners are additionally reinforced with special perforated corners: this will protect them from damage during operation.A small layer of putty is applied to the corners, after which a corner is pressed into it. Excess mixture protrudes through the holes and is removed with a spatula.

- The seams are glued with a reinforcing mesh, and then sealed with putty. After it dries, grouting is done with fine sandpaper. The technology of work is described here.

- The holes formed by the heads of the self-tapping screws are sealed with putty, and then overwritten.

- The entire niche is covered twice with a primer. The application of the second layer occurs only after the complete drying of the first.

Before finishing with wallpaper or paint, the structure is puttied; this is not necessary before laying tiles or decorative stone.

Adhering to simple rules and recommendations, creating a drywall niche on your own will not be difficult even for a novice master. Ask questions about the installation process in the comments!