Such a popular finishing material as GKL, in most cases, is attached to a special frame. Usually it is mounted from metal profiles. An alternative option is a crate made of wooden beams, which is very easy to assemble with your own hands. But do not be deceived by the ease of manufacture: wood is a capricious material, its use is far from always possible. Consider all the features of this design and find out when and how you can make a wooden crate for drywall on your own.

Features and disadvantages of wood lathing

The construction of a wooden frame under the gypsum board attracts with its low cost and ease of operation. Especially if a small number of boards remained during the repair, which can be used as slats for the supporting structure. In this case, you do not have to spend money on the purchase of a metal profile, as well as the necessary fasteners, for example direct hangers.

But you should also remember about the properties of wood that limit its use in construction:

- Wooden structures are subject to change in geometric dimensions with excessive or insufficient moisture. Drywall attached to such a crate will move with it, resulting in cracks that appear at the joints of the sheets. This is a constant process, as the wood gives off moisture when the room is dry or absorbs it when it is too humid.

- Alignment of walls with gypsum boards is often combined with insulation. Under these conditions, ventilation of the wooden parts of the crate is minimal, which leads to their rapid decay.

- Bars are not well suited for leveling walls. It is unacceptable to use wedges for lining: over time, the tree can bend under the influence of moisture and temperature, and weak areas form in the places of such linings.

- It is not recommended to use a wooden frame when finishing a plasterboard ceiling. This design does not have a sufficient margin of safety; it is better to use a metal profile for this purpose.

- It is unacceptable to use a wooden frame in rooms with a high level of humidity or temperature. Strictly speaking, a crate made of this material is only suitable for rooms with constant microclimate indicators.

- If it is planned to place electrical wires under the GKL surface, then metal guides must be used: wooden elements do not have a sufficient level of fire safety.

When can I make a frame for gypsum boards out of wood?

It is recommended to use a wooden structure for plasterboard sheets:

- In houses made of logs or timber. In this case, the crate is ideally combined with the material of the walls due to the same physical properties. It turns out that any change in humidity is compensated. In such conditions, drywall remains motionless and is not damaged.

- In ordinary apartments with perfectly flat walls. In this case, the timber frame will be a reliable basis for fixing the plasterboard.

Advantages

Advantages of a wooden crate:

- Simple installation, which can be done by hand.

- Available and cheap materials, more environmentally friendly than a metal profile.

- If all the necessary conditions are met, a properly installed crate will last a long time and will be a reliable basis for drywall sheets.

Tools and materials

First of all, you will need a wooden beam itself with a cross section of at least 40 × 40 mm. If it is planned to carry out insulation and soundproofing, then the beam must be chosen thicker, for example 40 × 80 mm. To prevent decay, it is impregnated with antiseptic and water-repellent solutions. It would be useful to treat it with a composition that improves the fire safety of the material.

Before installation, all wooden elements must be kept indoors for several days in order to adapt to its microclimate and take on their final geometric shape.

You will also need:

- Measuring tool: level, plumb line, tape measure.

- Pencil, coated cord.

- Perforator and dowels for attaching the timber to the wall.

- A screwdriver and self-tapping screws, as well as corners for connecting frame elements to each other.

- Hacksaw, hammer and construction knife.

As you can see, almost the entire tool can be found in the arsenal of even a novice master. To install a wooden frame and fasten drywall, you do not have to purchase specialized expensive fixtures.

Lathing installation

Preparatory work consists in removing the old coating if there is doubt about its strength. Things in the room can be covered with plastic wrap or other material.

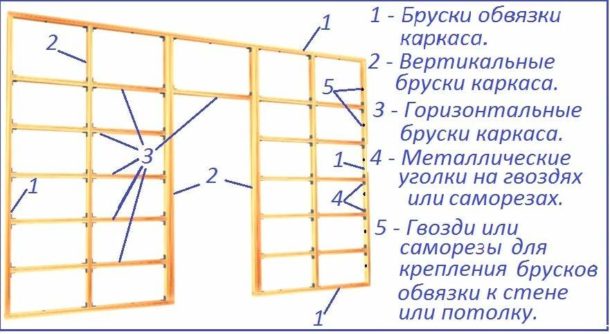

The order of the wooden frame device:

- First you need to do the markup. The size of the GKL determines the optimal step between the vertical posts - 600 mm. Thus, each sheet will be attached to three bars: one in the center, and two at the edges. The joints should be located on the surface of the rack, as shown in the photo.

- A horizontal beam is attached to the ceiling. Using a plumb line, the location of the rail on the floor is determined. They must be located strictly in the same plane.

In the case of a perfectly even overlap, horizontal bars can be attached directly to the wall. Here, the same thickness of all elements of the crate is of paramount importance: any error in size will result in frame irregularities.

- Vertical racks are attached to the beams on the ceiling and floor strictly according to the level. To the wall, they are mounted on dowel-nails, for which holes are pre-drilled in the rails and in the wall for fasteners.

In houses with wooden walls, you can mount racks to the base with wood screws. But you still need to drill holes: this eliminates the likelihood that the beam will crack.

- According to the markup, horizontal jumpers are attached. They provide structural rigidity and are located at the junction of drywall sheets.

The optimal step for attaching elements to the wall is 25–40 cm.

- You can strengthen the frame with the help of corners placed at the junction of vertical and horizontal racks.

Drywall fixing

GKL installation is carried out as standard:

- Pre-cut sheets are attached to the frame. Step between screws - 25 cm.

Please note: you need to take wood screws with less frequent and larger threads.

- The heads of the self-tapping screws are recessed deep into the sheet by 1 mm.

- Further reinforced and puttied joints, as well as the deepening of the heads of the screws.

- After grinding, the surface is primed and ready for further finishing.

More clearly, the process of creating a crate made of wood is presented in the following video. Questions on the topic ask in the comments.