The quality of ceilings in many apartments, even new buildings, often leaves much to be desired. Leveling them with drywall sheets is one of the most common finishing options. But the services of professionals will be expensive, and in order to save on them, you need to figure out how to make a plasterboard ceiling with your own hands. Otherwise, such savings can lead to very disastrous consequences.

Advantages and disadvantages of plasterboard ceiling

A plasterboard suspended ceiling has many advantages over other options for finishing this surface:

- GCR is an absolutely environmentally friendly material. Its varieties can be installed in any residential premises.

- You can assemble a plasterboard ceiling without using a specialized expensive tool.

- Its installation does not require special building skills.

- If, before making a false ceiling of plasterboard, you think over the location of various communications, then later they can be hidden behind its plane. It can also be placed there recessed ceiling lights.

- Drywall itself has good heat-insulating and noise-absorbing properties, but the design of such a ceiling makes it possible to strengthen them by placing sound-proofing materials in the niche of the frame.

- Such a ceiling is made quite quickly with a minimum amount of dust and other contaminants of the apartment.

- Drywall allows you to implement the most daring design ideas: create multi-level structures, various niches and arches.

- As a result of installation, a perfectly flat surface is obtained, suitable for all types of further ceiling finishing.

Naturally, it was not without drawbacks:

- The design "eats" at least 5 cm from the height of the room. This parameter may increase with a significant curvature of the ceiling surface, when installing lighting fixtures. So before you make a drywall ceiling, you need to assess whether the room will become too low. However, for the vast majority of apartments, the loss of a few centimeters of height is not critical.

- It is inconvenient, if not impossible, to sew sheets of drywall onto the ceiling alone. So it’s worth looking for a partner with whom the structure will be assembled.

- Over time, various defects may occur on the ceiling, for example, cracks will appear at the joints of the sheets. But this can be completely avoided if you know how to properly make a frame, attach drywall and putty on it.

Necessary materials and tools

Before making a plasterboard suspended ceiling, you should purchase material and prepare certain tools. From the materials you will need:

- Directly the drywall sheet itself. For rooms with high humidity, such as a bathroom, you should take its waterproof variety.

- Rails and ceiling profiles. The total length of the guide profiles coincides with the perimeter of the room, and a drawing is needed to calculate the footage of the ceiling profiles. It is clear that for each room it will be different. Bearing profiles are arranged in increments of 600 mm, in addition, they will be required for mounting the crossbars. Having calculated their required number using the drawing, we add about 5% more “in reserve”.

- Various fasteners for the ceiling: direct hangers, single-level connectors (“crabs”), dowel-nails or anchors, self-tapping screws for fixing drywall and “bugs” - small screws for metal. They should also be taken with a margin: while the structure is being assembled, they may break or be lost.It is better if there are a few extra fasteners left than a couple of pieces are not enough.

To install drywall on the ceiling, you do not need any specialized tool. You will need:

- Perforator with a drill of the appropriate size. Usually dowels with a diameter of 6 mm are used.

- Screwdriver.

- Metal scissors. Some masters prefer to use a grinder.

- Measuring tools: tape measure, water or laser level, paint cord for beating lines.

- Hammer, painting knife.

Marking the profile attachment points

To make it clear how to independently make a drywall ceiling, it is enough to get acquainted with the installation procedure for a simple ceiling in one level. More complex structures are assembled using the same techniques.

Before collecting drywall frame on the ceiling, it is necessary to carefully measure the attachment points of the profiles. It should be remembered that the minimum distance from the base surface of the ceiling to the inside of the GKL is equal to the thickness of the profile used.

Just in case, it is better to play it safe and take a larger distance between the surfaces of the base and suspended ceilings. If you have incorrectly determined the lowest point of the ceiling, in the absence of a height reserve, the surface is bound to curve.

- Along the entire perimeter of the room, a line for attaching the guide profile is marked on the walls. To do this, use a level, for reliability, carnations are hammered in the corners of the room and nylon threads are pulled between them.

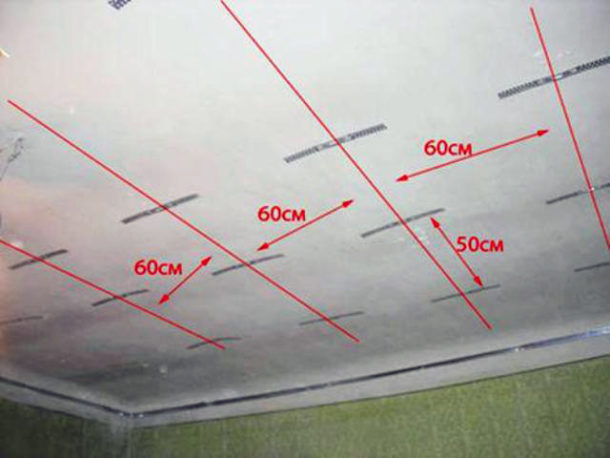

- Ceiling profiles are marked. The extreme ones are located at a distance of 250-300 mm from the wall, the rest - in increments of 600 mm.

- The transverse profiles will be fastened with the same step. As a result, a grid with cells of 600 × 600 mm should be obtained on the ceiling.

- Places of fastening of direct suspensions are outlined. Divide the sides of the cells in half. Thus, they will also be located at a distance of 600 mm from each other.

Frame assembly

How to make a frame yourself? With proper markup, this is not difficult at all:

- Mounted guide profiles. Holes are drilled with a puncher through 35–40 mm, fasteners are made on dowel-nails, much less often on anchor bolts. It is important that both guides certainly lie in the same plane.

Attached to the side of the profile adjacent to the wall self-adhesive sealing tape. It will improve the sound insulation of the future ceiling.

- Holes for suspensions are drilled in the ceiling surface. The center of this fastener should be located strictly along the marking lines. Suspensions are attached to the dowel-nails, and their edges are bent down. It turns out a figure in the form of the letter "P".

- Ceiling profiles are mounted. They are inserted into the guides, fixed with the help of "bugs". They are also used when connected with direct suspensions.

- Each profile is set according to the level; a number of holes are provided for fixing in the hangers. After the screws are screwed in, the protruding parts of the "whiskers" can be bent so that they do not interfere with the installation of the GKL.

- The crossbars are attached to suspensions, and they are connected to the longitudinal profiles with the help of "crabs". At the same time, all the same small self-tapping screws for metal - “bugs” are used.

- After assembly, the entire frame is checked again with a level. It is much easier to fix the flaws at the frame assembly stage than after fixing the drywall.

Fastening and putty GKL

Self-tapping screws with a length of 25 to 45 mm are used as fasteners, depending on the thickness and number of sheets. They are screwed in in increments of 25-30 mm, the heads are slightly recessed, so that later they can be easily puttied.

Before installing drywall, all communications should be carried out and holes drilled in the sheets for lighting fixtures.

Sheets are arranged in a checkerboard pattern. It is clear that all joints must be on the surface of the profiles. For cutting sheets, you can use an ordinary hacksaw.

Do not mount the sheets close to the wall. Leaving a gap of 1-2 mm, you can prevent the deformation of the structure during thermal expansion. A decorative corner glued around the perimeter will easily hide this gap.

Before puttying the ceiling, it is better to wait a couple of days. Then the sequence of actions will be as follows:

- All joints are cleaned. Usually there are special chamfers along the edges of the drywall sheet. If they are absent, then they are made with a planer even before installation or with a knife after the sheets are installed.

- The seams are covered with putty, a reinforcing tape is laid on top and slightly pressed into the wet solution.

- After drying, the seams are leveled with putty, and the attachment points of the self-tapping screws are also covered.

- The surface is leveled with fine sandpaper, after which a layer of finishing putty is applied to the ceiling.

In the future, such a ceiling can be painted, wallpapered or other finishing materials can be used.

Price

Professional installation of a ceiling on one level without puttying and finishing in Moscow and St. Petersburg will cost an average of 400-600 rubles / m2, a two-level ceiling from 500 to 1000 rubles / m2, depending on the complexity of the design.