Basic information about the operation of the installation and the process of coal mining

Coal-fired stoves may also have a certain degree of distribution. But, you see, using coal for the extraction of charcoal is not the most optimal and economical option. Therefore, most people and entrepreneurs use wood as a raw material for fire supply. The main process by which coal is converted is called hydrolysis. A lot of effort is needed to achieve this process. Here it is necessary to take into account each parameter. Incorrect adjustment can result in a poor quality product. This will reduce production rates and exacerbate the situation.

To prevent this from happening, it is necessary to clearly understand the process of making charcoal. In the process of burning wood, a special gas is released, which, in contact with wood, transforms it into the original product. Wood, as a raw material, is located in a separate chamber. This chamber has a small hole (or several holes) that allows heat to pass through to the wood. This steam, heated to the required temperature, acts on the wood, and it is gradually converted into the necessary charcoal.

The principle of operation of a charcoal kiln is quite simple, but it needs to be understood. There are several types of coal mining. In addition to the above, another conversion option is used. It involves the use of special vertical retorts. The process of creating material is significantly accelerated, but the amount of harmful substances increases significantly.

When this method of product extraction is used by large enterprises, in most cases additional equipment is installed that allows you to clean harmful fumes. This is done in order to avoid the ingress of harmful substances into the air, as their amount exceeds the permissible limits.

The coal-fired furnace is mounted from metal, less often from refractory bricks. Before using a metal structure, it is treated with special solutions that reduce heating and corrosion of the equipment walls with constant use. In turn, the retorts are made of a material that can withstand high temperatures.

The way you use your own gases helps to get the necessary positive moments. This process reduces the cost of materials and resources. Also, the level of profit is significantly increased by reducing costs. This aspect is important for the modern market. An entrepreneur who uses the installation for personal purposes receives a big benefit from such furnaces.

The process of creating an oven yourself

Many people prefer to make things on their own. The design of this device is very simple, therefore it will not be difficult to make it at home. The design requires a careful approach and at the same time easy to implement. The option of a mobile oven should be considered, as it is a priority. Everything is very simple and having collected the necessary materials, you can set up your own small production of charcoal.

First of all, we need skids. For this purpose, old children's sleds may fit. It will take some effort to remove them from the frame. But, you can leave them in their original form. A charcoal oven requires the use of some piece of metal to look like a shell. This body must be cylindrical. The choice of position depends on the preference of the manufacturer. It can be built both vertically and horizontally.It is necessary to build a pipe for the outflow of gases and a chamber for burning wood.

To make the camera, you will need a special metal that can withstand high temperatures and not get very hot. If the metal is very hot, it will begin to change shape, which will have a very negative effect on the manufacturing process. Although this design is simple to manufacture, you can create charcoal kilns with your own hands in another less complicated way.

The ancient method of making coal in pits has not been completely exhausted, and most summer residents successfully use it. But for a more profitable creation of charcoal, it is better to build a specially designed device.

The first step is to dig a hole that will fit the barrel. The barrel should fit freely in the dug pit. A brick should fit between the wall of the earth and the barrel. A small hole is mounted near the lid of the barrel, the diameter of which is 10 centimeters. The barrel is lowered into the pit in such a way that the hole is near the bottom of the pit.

The walls of the pit are lined with bricks. The top of the barrel is lined with fireproof material, which can be purchased at a hardware store if the household does not have such material. A layer of mineral wool is laid on top of the entire structure, which allows you to keep warm.

With little effort, a do-it-yourself charcoal stove is ready for use. An integral part of the process is compliance with fire safety rules. The structure will not be able to provide the same performance as the stoves in production, but coal will be enough to kindle a fireplace and cook food

It should be noted that the larger the barrel, the greater the opportunity to obtain high-quality coal and reduce the impact on the environment. Be careful when making charcoal, take care of your health

The main composite furnaces and its types

The charcoal kiln is sure to reproduce the required amount of product. The main point is that different designs have different parameters and process execution time.

In the production of this type of raw material, several types of products are used. This affects the location of the furnaces. In this way, devices can be divided into:

- Stationary - without the possibility of movement.

Mobile - able to move from object to object.

Each oven has a different design. At the moment, the following devices are known:

- corner

Round

The round apparatus has the shape of a tank. The corner apparatus resembles a standard Russian stove, which is found in some remote villages.

To understand how the process of charcoal mining takes place, it is necessary to consider in detail the principle of operation and the constituent elements. For example, consider how a round furnace works.

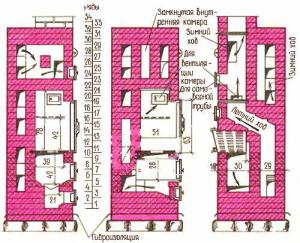

The furnace configuration consists of several parts. Each part is designed for a specific process. Processes depend on the technology of charcoal production. Wood, which is the raw material for making fire, is placed in a firebox or furnace chamber. Connection is carried out by means of a bunker in which a generator and a fan are installed. Also, there is a gearbox.

Through the air box, air from the fan enters the furnace itself. Ready coal enters through a special device, which is commonly called a "worm". There is a processing chamber where the conversion process takes place. A special lance is located above this chamber. Also, there is a cauldron and harness, which are actively used during the process of making charcoal.

As can be seen from the description, a small number of components makes it possible to obtain annually a large amount of wood raw materials, which are supplied to various spheres of human life.An excellent piece of information for those who use such a device for their own purposes is that such furnaces have the ability to operate on almost any type of fuel. It can be kindled with literally anything that can burn and maintain the optimum temperature. In this way, not only coal mining is carried out, but also the cleaning of the external space.

More detailed information about the device can be obtained during the training process, at the time of hiring or by reading additional literature. The device of a charcoal kiln is a necessary knowledge for the implementation and work with the equipment. Without initial skills and knowledge, access to maintenance of any complex and life-threatening structures is strictly prohibited.

The construction of the furnace

In order to fold the oven in accordance with all the rules, it is necessary to remember that the first row is being built without the use of mortar, that is, “dry”. There must be gaps between the bricks. Next, the mortar is placed with a trowel where it is supposed to place the corner brick. It is necessary to level the layer of mortar to get an even line. After that, the brick should be placed on the site prepared for it, you need to lightly press it and tap it with a trowel from above. Excess solution that will stand out from the cracks must be removed.

One of the ways to build a brick oven arch

The correctness of laying the corner brick is checked carefully - a plumb line will help in this. It is necessary to take into account during the control both horizontal and vertical lines.

The order of installation of all other bricks depends precisely on the installation of the brick from the corner of the structure and differs only in that it will be necessary to completely fill the vertical space with the fixing solution. Using a level, it is required to check whether the row is being erected smoothly, and to control the corners with a plumb line. This process is very important, since it depends on how the Russian stove will look at the end of its construction. All sutures need to be tied up.

An example of a professional "dressing" of brickwork

It is important not to forget to immediately lay down a place for the accumulation of ash - the design consists of four rows. In the third row, bricks are laid along ¾ of their main length

Using the "grinder" you will need to cut off the excess part. You should complete 4 next. Here the work is done by laying out bricks by ¾, but already in their width.

The next step is the device of the chimney. This process does not exceed the complexity of the masonry itself, but requires increased attention so as not to damage the load-bearing, main structures and beams, as well as the main roof slabs. The recommended pipe height is at least 5 meters. In order to facilitate the work and save a little on materials, you can not lay out the part of the pipe that comes out of the roof. This part can be replaced with a metal structure. The inner diameter of the pipe extending beyond the roof is 12 cm, the wall thickness is 1 cm. The elevation above the attic floors should be at least 1 meter. The joints are fixed with a metal mesh and a cement-based mortar.

There are many options for organizing a chimney

Thus, a Russian stove with your own hands is not an impossible task, but quite feasible work for those who use quality materials, show perseverance in work and attention to detail. Today, step-by-step instructions and drawings of the furnace allow you to build a structure in the house or in the bath that will serve reliably, performing its tasks.

The main condition is to strictly follow the recommendations of fire safety and not save on materials.

Do-it-yourself oven

Previously, it was in every home, but now the stove can be considered a highlight and national exotic.But this is a very convenient and functional thing that can combine heating, hobs, an oven and a warm bench, while having a wonderful design.

If you decorate the stove with tiled tiles or tiles, then the stove will turn into the center of the interior idea of the house. You can make such an oven with your own hands.

Orders - a detailed scheme of laying a brick oven

Orders of brick ovens can be obtained for free, and this is almost half the battle. After all, ordering is an exact instruction for placing each brick. The only thing you need is a little experience as a bricklayer. But who among those living in a private house has not encountered bricklaying at least once? Walls, sheds, braziers, fences ... now a stove.

In order for the house to be heated properly, it is necessary to make a calculation for a specific room, based on the heat transfer indicators of the planned furnace. The furnace must be of such power that it is possible to easily withstand the night until the next furnace.

It is very difficult to make such calculations on your own, but you can use the data of I.V. Kuznetsova. who calculated the average heat output per unit area of the furnace. So, an average stove of 1.5x1.5x2.5 m should be enough to heat an area of up to 100 square meters. m.

From this it is easy to push off and calculate the dimensions of the furnace for your home.

We choose the design of the furnace - Russian, blacksmith, Dutch or Swedish

When we have decided on the approximate dimensions of the furnace, you need to choose the necessary version of the furnace that you will lay. A large number of detailed schemes of Russian stoves - from small to large can be found on the site. Kuznetsov's bell-type furnaces and the so-called Dutch or Swedes are very popular.

Kuznetsovka is famous for its special design, which allows warm and cold gases to move in such a way that the efficiency of the furnace sometimes reaches 90-95%. In addition, the almost complete absence of soot and, accordingly, minimal care for the stove. On the site of the author himself, you can find up to 150 schemes of different masonry options.

Also, “Swedes” are popular in our area, but sometimes it is called “Dutch”, although this is not entirely true. Since the Swede is an independent heating and cooking stove. while Dutch women were used only as a heating supplement.

The choice of "Swede" is also good because it is a truly oven station wagon:

- Food is cooked on it.

- Heating.

- Possibility of a built-in oven.

Consider how to make such an oven with your own hands.