Why does the heating boiler constantly turn off

Similar problems occur both in new, newly installed units, and those that have served for several years. The reason is external and internal factors. Often users complain that the boiler turns off and does not turn on after a long period of inactivity. For example, in the country, you start the device only upon arrival, which can cause the system to freeze.

The main causes of the problem lie in:

- Incorrect selection of power.

- Heating system or hot water supply (DHW).

- Smoke extraction unit.

- Gas line.

- Electrical part.

- Incorrect adjustment.

Both wall-mounted and floor-standing boilers are susceptible to malfunctions. What to do to eliminate them? Find the cause and try to fix it.

Reasons for frequent switching on and off of a gas boiler

It happens that a newly installed device, after setting up, commissioning, starts turning on and off too often. Such a device, although it should automatically regulate its work, however, such a process clearly indicates failures in the system. This can adversely affect the life of the device, because the working elements begin to wear out quickly, and the device itself will fail.

There are reasons why a heated boiler works quite often. In any case, it is better to contact a specialist if you do not have enough professional experience, because you need to be careful when handling blue fuel. The main reasons for switching on and off heating equipment with frequent intervals:

- wrong device selection. The power is provided for a large room, and the installation of the unit was carried out in a small room;

- incorrect installation of the circulation pump;

- the temperature range is incorrectly set;

- there is no thermostat in the room; for this reason, the operating state of the device is adjusted according to the temperature indicators of the coolant.

Important! This problem is quite simple, but there are times when you have to replace the device with another model.

Closed type turbocharged problems

Sometimes it happens when installing a new chimneyless apparatus, periodic attenuation of the flame. In this case, you need to check the components and parts. The problem is identified by the following factors:

ignition of the igniter is accompanied by periodic attenuation - this indicates the failure of the thermocouple, which affects the actuation of the valve. It is made in the form of a copper tube with a bimetallic piece at the end. When different metals come into contact, the voltage rises to 20-45 watts. This problem keeps the gas valve open. The thermocouple must be replaced with a new one; it cannot be repaired;

- failure or clogging of the thrust sensor - a flat part is combined with the fuel valve. When the leading contacts close and the burner ignites, ignition occurs - this indicates the need to replace the sensor. Oxidized contact areas can be cleaned with sandpaper with fine abrasives;

- in the event of a malfunction of the circulation pump, it is necessary to carry out a complete diagnosis of the unit and its replacement;

- yellow flame is due to the fact that the jet is clogged. You can clean it if you have experience with gas appliances.

Most of the causes can be eliminated with your own hands, however, this will require some knowledge and a lot of time.

Boiler use

You can find out the whole truth about the conspiracy related to the selection, operation and maintenance of heating boilers of all manufacturers and models.

As for gas boilers, there are no subtleties here, you need to set the temperature you need and turn on the device, after a while the heating radiators will start to warm up the room.

The combustion process of fuel-fired boilers includes the following steps:

-

Grid cleaning

. With the help of a spatula, the ash is moved along the grate, and it falls down. -

Camera cleaning

where ash accumulates. -

Cleaning the walls of the furnace chamber

from soot. Wipe the walls with a dry cloth. -

Chimney cleaning

scheduled, once a year. In case of violation of traction, they are cleaned as necessary.

If the furnace is fired with coal, it is necessary to make sure that a grate for burning coal is installed in the chamber; when switching to another type of fuel, replace it.

Ignition stages:

Gas boilers are the most economical, easy to install and subsequently operate type of heat generators used in autonomous heating systems. However, like any engineering equipment, gas boilers can sometimes fail, and the most common type of failure is self-extinguishing of the burner. To understand why the gas boiler goes out or find out the cause of other problems, you need to know about the types of boilers and the principles of their operation.

Repair of wall-mounted and turbocharged units

Modern products have a complex design, they are equipped with electronics and a security system. Even in such instances, you can independently eliminate minor problems.

To find faults, you need to study the instructions for using the device. The technical documentation contains error codes that appear on the display of the unit. The heat generator does not work for the following reasons:

- Light indicators are not illuminated, the heater does not turn on;

- Automatic ignition is not carried out when the device is turned on, in which the display and network notifier are lit;

- Extinguishing occurs after starting the main burner.

In such situations, the voltage supply is immediately checked, if it is supplied to the device, it is required to proceed to subsequent repair points. Initially, the front panel of the device is unscrewed, the front cover is removed. The remaining manipulations are performed step by step:

- the fuse box is checked, if a faulty element is present, it is replaced with a new part;

- when the equipment is started, the workflow begins;

- if the product turns on and stops working again, then you need to seek help from the master, since this problem cannot be fixed without professional knowledge.

It is possible to eliminate other signs of failure of the device when describing the error code. You can deal with such breakdowns yourself:

- A clogged sump can be easily cleaned after turning off the generator from the electrical network and shutting off the taps;

- The jamming of the rotor or the appearance of airiness affects the operation of the circulation pump. These causes are eliminated by unscrewing the large screw to bleed air and turning the rotor with a screwdriver. When completely dry, the parts are mounted in place;

- Low pressure on the pressure gauge without leakage in the system itself is eliminated by pumping air into the expansion tank;

- If the pressure is low due to leakage, the faulty area should be repaired and water added to the heating system.

Minor breakdowns are quickly eliminated by our own efforts, and there is no need to call the master, whose work requires additional financial costs.

https://youtube.com/watch?v=QFqyaaim-HE

When designing your home, you need to take care of the future heating system. After all, comfort, as well as the health of all residents of the house, depends on high-quality heating. In order for the heating system to work effectively, you need to select a suitable heating boiler and install it in the system in compliance with all rules and technologies.If the boiler is installed incorrectly, then various kinds of problems may occur in the future. The most common problem is the frequent switching on and off of the heating boiler. But not everyone knows the possible causes of such a problem. Therefore, in our article we will consider the reasons for the frequent switching on and off of the gas boiler, as well as ways to eliminate them.

The boiler does not gain temperature

Electric

Let's try to figure out why your electric boiler does not reach the set temperature, as a result of this you have cold batteries.

The reasons may lie in the following:

- If you have several heating elements for heating

, perhaps one of them is not connected, the problem may be caused by poor contacts of the wires suitable for the heating element, or it has burned out. -

Wiring in your home does not match the power consumption of the machine

. Perhaps the reason lies in the wrong section of the wires. If, nevertheless, this is due to insufficient voltage in the network or its surges, the solution may be to connect through a voltage stabilizer. - If only one of the batteries remains cold, while the others are within the specified temperature range, this most likely indicates the formation of an air lock

.

To remove air, you will need to do the following:

It happens that the heating elements are clogged with scale, and the temperature does not rise to the set value. For example, on the Mora TOP model, this problem occurs very often due to poor water quality. For cleaning, it is necessary to remove the heating elements, the top layer of scale can be cleaned with a screwdriver, scraping off large scale elements, then soak the heating elements in a special solution.

Gas

By the way! Did you know that a heating boiler from any manufacturer can explode at any moment - "".

Before buying a boiler, correctly calculate the power suitable for your room size. If the problem is poor draft, it is necessary to clean the chimney, clean the chamber from which the air flows, directly the combustion chamber. If these manipulations do not work, install the draft regulator.

In case of poor performance due to fuel, you should first carefully study the instructions and clearly determine what exactly you can heat your model with. When purchasing a supply for the heating period, first buy a small batch for a couple of days, and, having made sure of the quality, you can make a purchase for the season. If the reason is in the volume of the chamber, make the bookmark incomplete.

Too much power

In no case should a boiler be installed with a larger capacity than required for a particular room. It is necessary to accurately calculate the required power. After all, a lack or excess of power can adversely affect the operation of the equipment. Therefore, if you did not manage to calculate the required power on your own, then you can turn to specialists who will correctly make all the calculations.

But in order to determine the power, it is not enough to know the area of \u200b\u200bthe heated room. The following factors influence the power value:

- Material of the walls of the house;

- Material of windows and doors;

- Room area;

- The climatic conditions of your area.

But there are many resources on the Internet where you can find online power calculations. For an approximate calculation, you can use them.

But if you bought a heating boiler and noticed that the power is much higher than required, then you need to solve this problem. First you need to find out how often the boiler can turn on during normal operation. In order to ensure normal operation for a boiler with increased power, it is necessary to install a four-way mixing valve in the hydraulic system. This option will show excellent results. But you will also have to spend a considerable part of your funds.

If your appliance has a multi-stage burner, you can try lowering the burner.

Another way is to connect the boiler to the boiler. In this option, in addition to lowering the power of the gas heating boiler, it will be possible to provide the house with hot water. In order to determine the power of a single-circuit and double-circuit heating boiler, it is necessary to use different schemes. It is better to choose boilers with the minimum power required to heat your home.

In order to correct the problem of frequent switching on of the boiler, as well as to reduce fuel consumption, a thermo-hydraulic distributor can be used instead of a mixing valve. Its cost is of course much more, but the result is much more effective.

Malfunctions of electrogas equipment

- There is no indicator light.

- No ignition when LEDs and operating display are on.

- Extinguishing of the burner after ignition.

- filter cleaning - carried out after the device is completely turned off, the valves are closed. The filter part is washed under running water and installed in place;

- when an air lock is detected, excess fluid in the pump is unscrewed the main central screw, air is released and the rotor of the device is scrolled with a screwdriver. After complete drying, the parts are installed back;

- low pressure in the system is eliminated by pumping air mass into the area of \u200b\u200bthe expansion tank located inside the structure. The pressure must be 0.2 bar lower than in the system itself.

These recommendations allow you to eliminate minor causes of breakdown with your own hands without the help of professionals.

Methods for eliminating the causes of shutdown of units

Incorrect unit power

If the gas boiler often turns on and off, then this indicates that the power of the unit is too large for this room. As a result, the device quickly gains the desired temperature and turns off. Frequent on-off leads to increased wear of boiler parts

Therefore, before buying a gas device, it is important to calculate the optimal indicator of its power based on the area of \u200b\u200bthe heated room, its insulation and other factors.

For a large private house, floor-standing gas boilers with a capacity of 35 kW or more are suitable. For apartments and small cottages, it is better to purchase compact hinged models that fit perfectly into a small kitchen or hallway.

If the boiler is already installed, then the problem of excess power can be solved by the following methods:

- installation of four-way valves;

- reconfiguring the gas burner to the minimum mode;

- connecting a boiler or other systems so that part of the boiler's power is spent on them.

Low line pressure

Typically, the causes of low gas pressure are such factors:

- Fuel meter malfunctions. The device may emit suspicious sounds or noise. On a faulty device, the readings change jerkily or the arrow does not move at all. Contact a specialist to fix the problem.

- Protective sensors have worked - if the system has noticed a fuel leak, then the operation of the unit is blocked. The leak also smells like gas. If such a problem occurs, turn off the gas boiler and call the gas service master.

- The filter is clogged - it should be cleaned.

Reverse thrust

If a back draft occurs and the flame goes out, the gas boiler protection system is activated and it turns off.

The situation can be corrected only by eliminating the reverse thrust. To do this, it is necessary to identify the cause of its occurrence. For example, adjust the design of the chimney, install a deflector, etc.

Back draft also occurs with poor ventilation in the room.It is easy to check this - the flame will burn well when the window is opened. The following factors worsen ventilation:

- hermetic plastic windows;

- hermetically sealed doors;

- too powerful hood in the kitchen.

In this case, measures should be taken to improve ventilation.

Chimney problems

A common problem for gas boilers of open and closed type is frost that forms at the outlet of the chimney. Hot combustion products exit the pipe and are converted into condensate, which freezes on the tip. This frost blocks the flow of air, the fire goes out and the boiler is turned off. It is necessary to clean the ice and the air flow will resume.

If frost forms regularly, then you need to insulate the chimney.

A classic chimney is more prone to all sorts of blockages. It can get there:

- garbage;

- pipe elements;

- soot, soot, dry leaves;

- sometimes even birds and the remains of their nests get into the pipe.

Voltage fluctuations in the network

If the voltage in the mains drops below the indication provided by the operating mode of the unit, the security system will turn off the gas boiler. When the voltage returns to normal, the unit will start again.

To avoid this problem, you should install an uninterruptible power supply.

Fan malfunctions

In turbocharged gas boilers, air is supplied and combustion products are removed using a fan. If this node fails, the boiler will turn off.

In this case, it is necessary to diagnose the fan, clean it of clogging, replace damaged parts, and inspect the wiring.

Pump problems

If the pump fails, the coolant circulates poorly through the system. As a result, the radiators do not heat up, and the automation turns off the gas boiler.

If the circulation pump was recently included in the system, and after that the unit began to turn off, then errors may have been made during its installation.

Burner problems

If the gas boiler turns off all the time, then you should check the functioning of the burner:

- If ignition does not occur and the flame immediately goes out, then most likely the problem is in the nozzles - they should be cleaned of soot and excess air should be released. It is also advisable to check the position of the ignition electrode and, if necessary, clean it.

- If the flame goes out after a short burning, then the ionization electrode should be diagnosed.

- There is a separation of the flame and the nozzle is noisy - it is necessary to adjust the gas supply. Sometimes this happens due to excessive traction.

we just installed a new boiler, it quickly picks up temperature and when it heats up it feels like the kettle starts to boil and goes out and at the same time the batteries are cold

Types of gas boilers

According to the type of installation, boilers are divided into wall-mounted and floor-mounted units.

Floor gas boilers are characterized by greater power, which means the ability to heat large areas of premises, long service life due to the fact that heat exchangers for such heat generators are made of steel or cast iron. For floor boilers, a separate room is required - a furnace.

Wall-mounted boilers are more compact and have less weight, which allows them to be installed on the walls of rooms. This type of heat generators is characterized by limited power, shorter service life, increased requirements for the quality of cleaning of the coolant and heated water. Gas boiler malfunctions can vary depending on the type of installation.

By design, boilers are divided into single-circuit, used only for space heating, and double-circuit, intended, in addition to heating, for heating hot water.

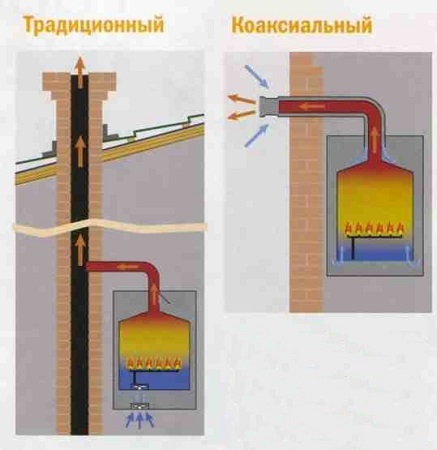

According to the type of removal of combustion products, heat generators are equipped with systems with natural or forced draft.In the first case, the units are connected to a traditional chimney, which is led to the roof of the building, and the exhaust gases are emitted due to natural draft. To ensure it, ventilation ducts are arranged according to certain rules. One of them is that the upper level of the chimney must be located at least 500 mm above the roof ridge, or at the same level with it at certain distances from the ridge. The reason why the gas boiler blows out may be that these conditions are not met. Boiler units with natural draft are equipped with open combustion chambers or atmospheric burners, while the air for the burner is taken from inside the room.

In the second case, the boilers are equipped with a coaxial chimney, which is a “pipe in pipe” design, which is led out through the wall of the room. The air necessary to support combustion enters from the outside through the outer pipe, and combustion products are removed through the inner pipe. In forced draft boilers, closed combustion chambers are installed.

A variety of Bosch gas boilers

And, finally, according to the method of ensuring the circulation of the coolant, boiler units are divided into volatile and non-volatile. In volatile boilers, there are circulation pumps powered by the mains and creating pressure in the heating system. In addition, volatile boilers are equipped with sophisticated automation that controls and maintains the established operating modes, including an electronic ignition system. Non-volatile heat generators do not require connection to electrical networks, and the movement of the coolant occurs due to natural pressure drops as a result of its heating. Ignition of non-volatile boilers can be done using a piezoelectric element, by pressing a button.