Warming up concrete with thermomats TEMS

Construction work using concrete is carried out year-round.

In the warm season, at constant positive temperatures, this material quickly gains its strength: at an average daily temperature of +17 +20 ° C and air humidity of about 90%, up to 70% per week.

In the event that at the beginning of the hardening process, the water in the solution freezes, then the process of its interaction with cement, called hydration, will stop.

Such a phenomenon will have a negative impact on both the durability of the structure and its performance. In order for the construction to continue at any time of the year, and even in the winter cold, special thermomats are used to warm up the concrete.

What it is?

What does it consist of?

The thermomat is intended for warming up of concrete and the designs made of it. This device consists of the following components:

- Infrared heating layer made of polymeric material "Impulse";

- heat-shielding and heat-insulating layer filled with air;

- layers of heat-reflecting materials;

- watertight polyvinyl chloride (PVC) sheath;

- bimetallic thermostats.

How is it arranged?

TEMS is made on the basis of the polymer "Impulse".

It is a flexible and flat heating element, which is embedded in a PVC sheath and closed, on the one hand, with a heat-reflecting and heat-insulating layer, 10-20 mm thick.

Power is supplied to the heating layer of the thermomat by means of a supply wire, at the ends of which switching connectors are installed.

To limit the level of temperature reached, bimetallic thermostats are used, which, when reaching a value of +70 ° C, turn off, and when it drops to +60 ° C, they turn on the system again. The outer shell of such a mat is made of waterproof materials, such as PVC fabric.

Flat heaters can be manufactured in any configuration and area.

Mat characteristics

In order to warm up concrete with building thermomats, there is no need to clutter up the construction site with various auxiliary devices, such as a transformer or station, as well as other connection equipment.

TEMS are distinguished by the following characteristics:

- typical (standard) size - 3.8 m2;

- dimensions - 3200x1200x10 mm;

- weight - from 2 to 6 kg;

- operating voltage - 220 V;

- maximum heating temperature - +70 ° C;

- power consumption during heating (W / m2) - from 300 to 400.

If you plan to buy a thermomat for heating concrete of a non-standard configuration or size, or a different power or voltage, then the manufacturer makes a project according to the given values and, after agreement with the customer, manufactures non-standard equipment.

Varieties and prices

Manufacturers produce, in addition to TEMS for concrete, thermomats for heating pipelines, equipment, various containers and soil, using them:

- Accelerating the hardening of concrete, structures and elements from it.

- Warming up the frozen soil before the start of earthworks takes about 20-36 hours.

- For heating columns and between plate joints.

- Mixed heating, when the ground is initially warmed up for earthworks, and after that TEMS is used to warm up the newly laid concrete and harden it more quickly.

Price

Today, the purchase of a new thermomat for concrete measuring 1200x3200x10 mm will cost, on average, from 9,600 to 10,000 rubles.

In this case, the price of 1 m2 will be from 2,300 rubles and more, depending on the complexity and configuration changes.

If a heat mat is needed for some one-time work, then renting a TEMS for the right time will help to avoid significant and unjustified costs for its purchase.

How to install and operate?

Since thermomats are electrical appliances, the rules for their operation do not differ much, let us recall the main ones:

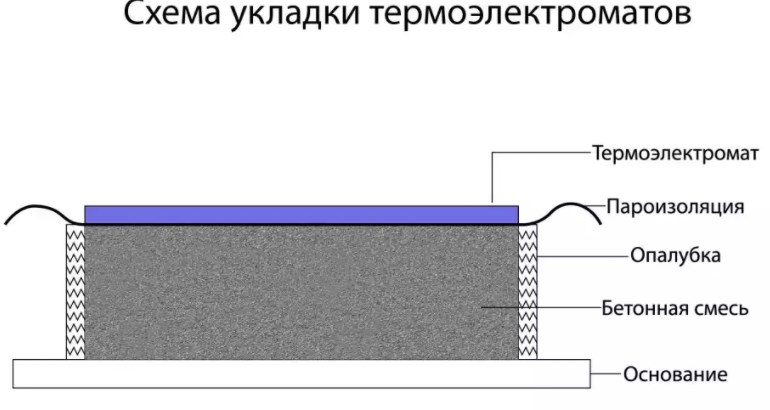

1. Laying and connection of TEMS is carried out only in the absence of current in the network.

2. Only an unpacked and fully unfolded mat, placed with the heating side down on the work surface, can be plugged into the network.

3. It is necessary to cover the concrete surface with plastic wrap, and only after that unfold and lay the device on it. The film will help prevent excessive loss of moisture from the mortar, and will also prevent the concrete from staining and sticking to the working surface of the mat.

5. It is forbidden to walk on the surface of working mats and put any equipment, materials or devices on them.

To facilitate vertical fastening, as well as for interconnection, special eyelets are installed along the edges of the thermomats.

What are the features of such products

The manufacturer certainly contributes to the existing technology, however, in most cases, the structure of the material used remains unchanged. The differences between the products are not significant.

Compound:

- temperature controllers;

- polymer film, which is used as a heat-radiating material;

- surface insulation;

- the heat reflector and air layer will be on only one side of the mat, which is what makes the technology so effective. This allows infrared rays to move only in one direction.

Advantages:

- Mats are easy to store and transport.

- Their use is limitless.

- There is no point in installing small substations, as well as another power source (transformer). A normal voltage line is more than enough.

- Profitability.

- The curing process is accelerated several times.

- The slightest temperature fluctuations in one of the sections are completely excluded.

- Heat diverges evenly over the entire surface of the site.

- Such products can be made on the basis of individual measurements, which simplifies their use.

- Installation will not cause trouble (regardless of the level and complexity of the formwork).

The technology of heating concrete with thermomats

1. Preparatory stage of concrete heating

At the preparatory stage, specialists evaluate the conditions and procedure for carrying out measures to warm up the concrete. The number of thermomats, the method of their installation and the connection scheme are calculated. If the dimensions of the site to be concreted do not allow laying thermomats for heating the concrete one at a time, then they are pre-fastened together, the power cable is connected.

2. The main stage of concrete heating

Thermomat TEMS.jpg1. A polyethylene film is laid on the poured concrete (to prevent premature evaporation of water and increase the service life of thermomats). 2. Thermal mats are laid on top of the polyethylene film for heating concrete, while their mutual overlap is not allowed. 3. Thermomats are connected to the supply wire according to the "parallel" scheme. 4. Power is supplied to the thermomats for concrete heating.

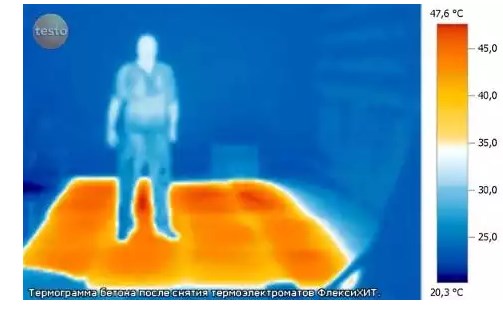

Concrete heating occurs automatically. The first 4-5 hours, all the released heat is absorbed by concrete and thermomats work without shutting down. Then, with the heating of the concrete, the temperature on the heating surface of the thermomat begins to rise and when it reaches 70 ° C, the sections are turned off. The thermomat sections are switched on again when the lower temperature threshold is reached (55-60°С)

With this mode of operation, the temperature of the concrete will not exceed 60-70 ° C, and therefore there is no danger of overheating. Practice shows that to achieve 70% of the strength of r28, 10-20 hours of heating the concrete with thermomats is enough, where r28 is the strength of concrete gained in 28 days at normal conditions. The grade of concrete and the initial conditions (air temperature, product thickness) should be taken into account. The heating time of concrete is directly proportional to the grade of concrete and inversely proportional to the thickness of the product. In order to avoid overheating and possible burnout of the thermomat, it is necessary to ensure sufficient heat exchange

It is not allowed to place between the mat and the heated object, any heat-insulating materials that prevent the transfer of heat power from the thermomat to the heated object.

3. The final stage of concrete heating After the concrete hardening process is completed, it is necessary to turn off the power supply to the thermomats for concrete heating. It is recommended to wait 1-2 hours after a power failure for the concrete temperature to gradually equalize with the ambient temperature. After that, the thermomats can be carefully removed. The service life of the thermomat directly depends on the careful attitude to it. Walking on thermomats and throwing heavy and sharp objects on its surface is not allowed. The thermomat can only be folded along special fold lines.

All StylingAbsolute

Features of using technology

Such "auxiliary" technologies are used at temperatures from +45°C to -40°C. In the warm season, the technology will be needed if it was decided to accelerate the hardening of the concrete base using infrared radiation. This will allow concrete to gain about 70% of its maximum strength in less than a day. In the natural course of events, this process would have dragged on for several weeks.

Main operational qualities:

- You should watch the mats and avoid even the slightest overheating. Laying is done in the usual way, but avoiding overlap.

- If there is a need to bend the mat (curvilinear surfaces), this should be done based on the existing markings on the surface of the mats. This is done in order to avoid further damage to the heating element.

- When the material reaches a temperature of 70°C, the thermomats should be turned off (if the thermostats have not worked).

- After it is completely turned off, the equipment remains in place until it cools down completely. After they have approached the ambient temperature, the equipment is removed.

If we are talking about heating a vertical surface, then the mats are tied to it with straps or clamps.

Principle of operation

In construction, thermomats are used quite often, therefore, a sealed and moisture-proof shell is used in the manufacture. Thus, the manufacturer extends their service life and facilitates transportation. The features include the independence of the functioning of individual sections of the thermomat. The source of infrared rays is carbon thermal film. Its reflective layer directs the flow of thermal energy in the right direction (to the object that needs to be heated).

A slight bend is possible, however, any bend must follow the special markings. Walking on the surface of the mats is prohibited. Dropping and throwing heavy objects is also not recommended.

The grounding (shielding) layer significantly increases the level of safety. The required temperature regime helps to maintain the existing thermostats. They are responsible for the reliability of the device as such.

Conclusion

The use of thermomats for heating concrete structures belongs to the category of modern and technologically advanced ways to speed up the necessary work. This method does not require the purchase or rental of additional electrical equipment that would be responsible for the temperature regime. The use of thermomats will allow concrete to be prepared in 10-20 hours (on average, it will take at least a week and a half to dry completely). Do not forget about the features of the emitted infrared rays, which are able to penetrate deep into any material, affecting its structure. Previously, only large enterprises used the technology, which preferred infrared rays to conventional steam.

The mats themselves are a heat-radiating film, in the shell of which there is a compact and flat heating element.The heat-reflecting and heat-insulating layer of the mat is located only on one side, which makes it possible to direct infrared rays in the right direction. The PVC sheath is quite flexible, so it is quite difficult to damage the heating element during transportation. The thickness of the product does not exceed 1.5 cm. In use, heat mats are simple and technologically advanced. Heating occurs evenly over the surface used.