The kitchen is the place in the apartment that should be equipped with maximum practicality and the use of durable and at the same time environmentally friendly materials. Therefore, the choice of furniture for the kitchen should be approached not only in terms of the beauty of the interior, but also taking into account the features of its operation. The countertop plays a key role in organizing the space here, because it is on it that we place various kitchen appliances and cook. One of the best options in all respects are chipboard kitchen countertops.

Advantages and disadvantages of chipboard products

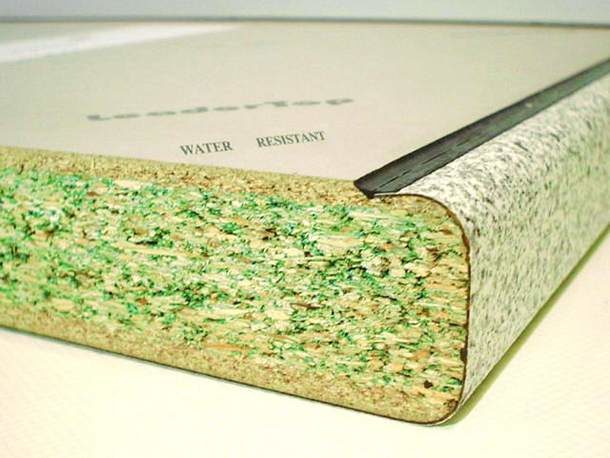

Chipboard is a sheet consisting of compressed sawdust and shavings impregnated with a special binder. There is a kind of chipboard, covered on one side with plastic or laminating film - chipboard. On the reverse side, such plates are reinforced with several layers of moisture-resistant kraft paper.

A tabletop made of this material has the following advantages:

- Relatively low cost of the product.

- Excellent moisture resistance.

- Such a countertop is suitable for a kitchen in any style - the choice of colors and imitations of various materials is huge.

- The ability to create a flat surface without joints and seams.

- High strength and resistance to mechanical and thermal damage.

- Eco-friendly material safety.

- Ease of transportation, installation and maintenance of the product.

- Durability.

A few downsides to this product:

- The need to seal the seams when installing built-in household appliances and sinks - water falling on unprotected sections will cause chipboard to swell.

- Significant damage to the plate cannot be repaired - it will have to be completely replaced.

But with the right approach to installation and careful operation of the countertops, these disadvantages will never spoil your kitchen set.

Dimensions of chipboard kitchen worktops

Before you choose the design of a new countertop for your kitchen, you should decide on its size. This is necessary so that in the end the area of free space on it meets your needs and the possibilities of the room.

Thus, the dimensions of the countertops for the kitchen from chipboard are determined taking into account:

- kitchen footage;

- the location and size of the lower modules of the headset;

- owner's preferences and needs.

The standard width of the countertop is 60 centimeters, but this parameter can vary from 40 to 120 centimeters.

A chipboard plate can be of various lengths - it depends on the design of the headset, the number of cabinets, the functions assigned to the countertop, etc. The maximum length of the blanks is approximately 4 meters.

The thickness of the plates varies from 26 to 38 millimeters. Foreign manufacturers offer a thickness of exactly 38 millimeters, and domestic ones - most often 28 and 38 millimeters.

Such a parameter as the thickness of fiberboard depends on what functions the countertop will perform. If heavy kitchen appliances will stand on it, and the stove itself will be installed without solid supports (bedside tables), then it is better to choose the maximum thickness - 38 millimeters. If the design of the headset itself is very durable, then you can not be afraid to choose chipboard with a thickness of less than 38 millimeters.

What are pressed board countertops?

In addition to size, countertops can differ in facing materials and their shapes. Their price also varies depending on these parameters.

The manufacturing technology of chipboard plates provides for the use of the following materials for their lining:

- Plastic. With its help, laminated products from chipboard are created.Thanks to plastic, they acquire moisture resistance, resistance to dirt and mechanical damage, and the service life of the product increases. The most common type of coverage.

- Melamine. This is a synthetic decorative coating, which is paper with an image printed on it, coated with melamine resin. It has excellent moisture-repellent properties and resistance to mechanical and chemical damage.

- Veneer. Chipboard of this type is covered with a layer of veneer, then fixed with varnish. Veneered chipboard sheets are not very popular due to their poor resistance to various kinds of damage.

Thus, from 0.4 to 0.8 mm of protective coating is added to the existing 38 mm. This parameter is quite insignificant, therefore it is not specified when choosing the size of the product.

The shape of the tabletop can be:

- T-shaped;

- angular (in the form of the letter G);

- U-shaped (used in large kitchens, may be part of bar counter);

- with a recess for a chair or easy access to the sink / hob;

- straight;

- with a trapezoid angle.

Table top shape is selected based on the availability of free space in the room and the design of the entire kitchen set. It can even be located in the center of the kitchen, join the windowsill or be an independent continuation of the kitchen set.

The cost of products from chipboard

There are many factors that affect how much a quality chipboard countertop costs. For example, its design, material quality, edge processing methods. Thickness and size are of great importance. Naturally, the price of a plate with a thickness of 26 mm will differ significantly from the cost of a product with a thickness of 38 mm.

- The average price of a 38 mm countertop with a glossy surface of a standard width of 60 cm and a length of 305 cm varies between 3,000–4,500 rubles;

- the cost of a product 38 mm with a matte surface 60 × 305 cm is 2,500–6,000 rubles;

- a three-meter slab of maximum width - 120 cm - will cost from 8,500 to 11,000 rubles;

- for a slab of 28 mm, 60 cm wide, the price will start from 1,800 rubles, for a 120 cm one - from 7,000 rubles.

Accessories for countertops also differ in cost, for example, for 28 mm, the price for accessories will be from 120 to 200 rubles, and for 38 mm - 160 to 250 rubles.

In addition, cutting, delivery and installation of countertops can be added to the cost.

Conditions for the durability of pressed worktops

Despite the fact that chipboard is a very durable and practically undamaged material, there is a possibility of damage to it. In order for this not to happen, certain conditions for using such a countertop must be observed. There are only two of them:

- Professional installation. Even if your countertop is installed perfectly evenly, without unnecessary seams and joints, there is a possibility of its swelling due to the influence of moisture. Therefore, even an expensive product ordered from a foreign company, but mounted without proper sealing of all sections, will not last long for its owners. Conversely, a chipboard sheet, properly installed and protected from water ingress, will last as long as the most expensive one.

- Careful operation. Scratches on a stone, wood, or steel surface can ruin the look of a countertop without compromising its functionality. But chips, scratches and punched indentations on chipboard worktops will open access to moisture to the body of the plate. This will lead to damage to the product, which will no longer be restored to its original form.

You can avoid most problems by following simple rules: use cutting boards, hot coasters, and do not spill boiling water on the surface. With proper care, a chipboard countertop will become an excellent functional and interior solution for your kitchen.