How to prevent an explosion

To prevent the heater from exploding, it is necessary to strictly adhere to the basic rules for its operation. Your own safety and the safety of your property depend on it. These rules are quite simple, and it won't take much effort on your part to follow them. So, the rules for the safe operation of such equipment are as follows:

The oil heater must not be used in a horizontal position, otherwise it will overheat, which may cause an explosion.

- Do not use the device in a horizontal position. In this position, the equipment will instantly overheat. For such cases, a special thermostat is installed in the devices, which ensures their shutdown in case of overheating, but you should not tempt fate if it is possible to avoid dangerous situations.

- Do not leave the device unattended. This is especially true if you have small children or pets living with you. They may inadvertently change the settings of the appliance or turn it upside down. In addition, there is a high probability that children can get burned. The oil heater should only be operated under your supervision.

- After the summer season, when the device did not work for a long time, it is necessary to check the serviceability of its thermal relay before starting operation. During such a check, the instrument must switch off when the operating temperature has been reached. If this does not happen, then the heater cannot be used. It must be sent in for repair or thrown away and a new one purchased. The serviceability of the thermal relay is very important for the safe use of an oil heater, since most of the unpleasant consequences from their incorrect operation are associated with overheating of the device.

- A device in which a leak has formed cannot be repaired. Theoretically, it is somehow possible to close it, however, in this case, there will be less liquid inside the oil container, since a significant part of the oil can leak out even through a slight damage to the body. How the equipment will work with the missing mineral oil is unknown. The heater may behave unpredictably during operation.

It should be remembered that no electrical device can be absolutely safe. However, there are safer options than oil heaters. The modern market for such equipment offers many alternatives, so if you are worried about your safety, it is advisable to opt for a more modern and unpretentious model in operation.

In any case, if you use an oil heater, then you can avoid its explosion by following a few simple rules. Be careful and vigilant so that the heater in your house does not explode and cause damage to your property, health or even life.

Advantages and disadvantages of oil coolers

The disadvantages of such radiators are the strong heating of the surface (you can get burned or damage fusible things located nearby). Another important drawback is that all radiators significantly dry the air, and also increase the dustiness of the room (heat raises dust particles from surfaces).

The design and principle of operation of oil coolers

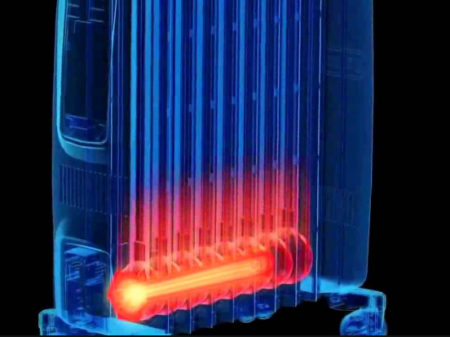

The working element of radiators is made of ferrous metal up to 1 mm thick. Metal parts are produced on a laser machine, since only their exact dimensions make it possible to achieve tightness during assembly. Small parts are formed by stamping. The elements of the device are connected by spot welding and pressing. The radiator is assembled from ready-made sections (a nipple connection is used). A heating element is placed inside the device, panels are mounted outside, a thermostat, regulator, and overheating protection are installed.Mineral oil is poured into the device. When the device is turned on, heating occurs in stages - first the heating element (heater) heats up, then the heat spreads to the oil and only then the case warms up.

Additional elements of oil coolers

To reduce the risk of burns, some radiator models are equipped with a protective cover. Such models are especially often used in children's rooms. The next additional element allows you to maintain optimal humidity in the room - manufacturers equip radiators with a metal container for water (heating up from the body, it evaporates). Another useful element is the fan. Some appliances are equipped with it to increase efficiency (the fan distributes warm air around the room).

Another useful detail is the timer. With it, you can control the inclusion of the device (the radiator turns on and starts heating the room at the set time).

Oil cooler power

The heat dissipation depends on the power level of the device. On average, for heating 10 sq.m. 1 kW is consumed. On sale you can find devices with a power of 1 to 3 kW. Almost all models allow you to adjust the heating level (2-3 positions), which saves energy.

Width and number of sections of oil coolers

The heating efficiency depends on the number of sections - the more there are, the more heat the device produces. Another important factor is the width of the sections. Here you need to find a middle ground - narrow sections reduce energy consumption, keep the temperature set longer, but warm the air worse (due to the small return area). Wide sections heat the room better, but they lose the set temperature faster, respectively, the device turns on more often and spends more energy.

Oil cooler weight

When purchasing a radiator, you should pay attention to its weight - it must correspond to the dimensions. If a sufficiently large device is light in weight, then this indicates the use of thin metal or a small amount of oil, which inevitably affects the quality of heating and the reliability of the device.

Oil cooler color

It is believed that radiators painted in a darker color heat the room better.

Based on this, it is better to pay attention to black radiators. However, experts argue that this factor, if it matters, is completely insignificant.

Rules for the operation of oil coolers

It is not recommended to install high-power devices in small rooms - they violate the microclimate. Do not install devices close to walls (the relay will constantly turn off the device, which will affect its efficiency). The optimal distance to the wall is at least half a meter.

It is not recommended to dry things on the radiator by closing the sections. It is better to hang them on a hanger, and put a heater next to them.

If the radiator turned over, you need to immediately turn it off, put it in its original position and wait a while (you can’t turn it on right away). In a device that has fallen on its side, oil flows from the heating element, which heats up to very high temperatures (about 800 degrees). This causes the radiator to rupture with oil and can cause a fire.

Do not turn on the device with a faulty overheating sensor (without turning off, the device will become very hot, which can lead to a fire).

You can not turn on the device that was in a cold room - you need to wait until it warms up to room temperature naturally. Otherwise, the body of the device will be damaged, oil will leak out.

In no case should you pull the device by the cord, moving it from place to place - violating the integrity of the wires, you will provoke a short circuit.

By choosing the right radiator and observing the simple rules for its operation, you can count on a long heater operation.

Operation of an oil-filled heater

The principle of operation of the oil cooler is as follows. When the device is connected to the mains, the device enters standby mode. To turn it on, you must select the operating mode, it is selected using an adjustable thermostat.

Other models on the case have two power adjustment keys, when one of them is turned on, the following circuit is connected: power is supplied to the fuse, then the current passes through the heater coil, indicator light and mode switch contacts. After that, it passes through the closed anti-tilt contacts, if the heater has a strong slope, these contacts are open and the device will not turn on. Then the current passes through the contacts of the emergency and adjustable thermostat and goes to the network. If you need to increase the heating rate, turn on the second coil of the heater using another key, which is connected in parallel with the first.

How do thermostats work? As the heating element heats up, the oil around it also begins to heat up and rise, cold comes in its place. This is how the entire volume of the coolant is mixed and heated.

Heat is transferred to the walls of the radiator, and then to the surrounding air. The thermostats in the lid begin to heat up. When the set temperature is reached, the thermostat activates and disconnects the circuit. After the thermocouple cools down, the contacts close and the heating process continues. For clarity, you can watch this video:

The safety thermostat protects against overheating and is set at the factory to the maximum temperature. If, for any reason, the service thermostat fails to open, the circuit will open the emergency device, preventing harm that may be done to the heater.

It can be returned to its working position by pressing the corresponding button. This design allows the owner to know about the occurrence of a malfunction, it must be eliminated before starting to use the device again. In the absence of such a button, the heater must have an emergency valve. A loss of power will also occur if the electric heater is tilted due to the tripping of the anti-tilt protection.

Main malfunctions

There are not so many reasons why an oil heater does not work. Conventionally, they can be divided into two parts - electrical and mechanical. A failure in the operation of electrical equipment most often occurs on the heating element and control communications - a thermal relay, a switch, thermal fuses. There may be a problem in the wiring, but this happens extremely rarely.

Mechanical damage includes various holes in the body, as well as the formation of shells on it, through which oil flows. As a rule, these are the fruits of corrosion activity. Determining the type of malfunction is not difficult. Mechanical failures are always associated with the presence of oil stains under the heater. All other faults are related to the electrical part.

Choosing an oil cooler according to the parameters

It is impossible to say clearly which company's heater is better. There is a huge selection of models on the market. The best manufacturers will always offer reliable enclosures and trouble-free security and adjustment systems.

But it is important to know how to choose an oil cooler according to the main parameters.

Power

The main criterion when choosing an oil heater is power. The recommended rate is calculated according to the area of the heated room at the rate of 100 watts per 1 sq. m. But this is the maximum selection rate.

In practice, in order to comfortably heat a room of 20 squares, 1500 watts of a heater is enough. At the same time, the greater the number of sections (the area of contact with air), the faster the room will warm up and the more stable and economical the operation of the device will be.

Radiator type

The radiator is chosen according to personal preferences.A flat heater fits comfortably against the wall, can be located behind the back of the sofa or even mounted on the wall. A sectional fixture with simple soldering is more compact, it is easy to place it near your favorite place in the room. A device with safety ribs or a tubular double body is the best solution for a nursery or an apartment where little fidgets are constantly running around.

Number of heating elements

A device with one heater is functionally and with sufficient power capable of acting as the main heating device. But the amount of heat can be excessive even when operating at half power output. Therefore, a model with two heating elements is more practical, it can be used as the main source of heat or an additional means of heating.

Adjustments

If we consider the rating of oil heaters, there are no models that do not offer at least two stages of heat transfer. But it is best to buy a product that has smooth adjustment. This is a heater with two heating elements of different power.

Such a device can operate in three modes - a weak heating element, a powerful heating element, two at once. These are the basic stages of heat transfer. Complementing this functionality with the main temperature sensor that controls the oil parameters, you can get a smooth adjustment that allows you to adjust the microclimate in the room at the request of the owner.

Security systems and components

In conclusion, consider another important aspect, how to choose the right oil heater. It has several nodes, the characteristics of which directly affect the service life, safety and likelihood of repair.

- Boil protection. If for some reason the oil temperature goes over a critical point, the radiator can simply break. To prevent this from happening, high-quality oil heaters are equipped with a mechanical two-component sensor. It operates independently of other instrument systems. If the temperature or pressure in the radiator is exceeded, the electrical circuit is broken. In this case, the fuse sensor fails, but its replacement is inexpensive compared to repairing a radiator or eliminating the consequences of a boiling oil release.

- Protection against dangerous parameters of the power grid. Short circuits, phasing, sudden voltage surges can cause a variety of troubles. Therefore, it is imperative that the oil heater is equipped with an electrically replaceable fuse.

- Design of thermostats. Reliable heaters are equipped with trouble-free, maintenance-free temperature sensors built on a bimetallic plate. Other circuits are unreliable and require maintenance. The bimetal plate works for decades, it is simple and quick to replace.

It is not difficult to take into account all the listed criteria and choose the right oil heater. It is enough to ask a few questions to the seller. If you do not forget to do this, the purchased device will last a long time and not cause trouble.

Rating of the best oil heaters

The best way to show how selection criteria work in practice is to get to know the great people in the oil heater market.

- Timberk TOR 21.1507 BC/BCL An excellent representative of the universal heater segment. It has seven sections, which is enough for intense heat transfer. A power of 1500 watts is enough for a room of 20 squares, while the device can be operated in operating mode even in an apartment with not the most modern wiring. The undoubted advantages include:

- the presence of two heating elements of different power (one of the regulators switches 3 modes, the second controls the oil temperature) for smooth adjustment;

- reliable mechanical temperature sensors;

- automatic protection against freezing and boiling of oil.

The device is made in a convenient case on wheels, a handle for movement and a cord compartment are provided.

UNIT UOR-723 Equipped with a fan, this oil cooler is designed to quickly heat up a room. With a power of 1500 watts, it is designed for a room of 20 squares. The heater is reliable due to the use of mechanical thermostats. At the same time, the device is light, the amount of oil is less than models similar in energy consumption. The intensity of heat transfer is increased by supercharging, so the radiator does not require significant reactivity (long-term temperature retention).

In the heater, a pair of heating elements of the same power, therefore, the return stages are with the same step. Paired with oil temperature control, you can smoothly set the speed of heating the room. For the convenience of the owner, the heater is equipped with a handle, and the wheelbase is wide enough so that the device remains stable and does not cause trouble.

UNIT UOR-997 A model that can be called a representative of the classics of oil heaters. Simple adjustment, three power output levels and a temperature controller allow you to heat a room with any characteristics. With a power of 1500 watts and designed for 20 squares, the device is able to create comfort in a larger area. It has 9 sections and a good chimney effect (heat transfer by radiation). By placing such a heater next to you, you can enjoy comfort even in a large unheated hangar.

Timberk TOR 21.1005 SLX This inexpensive oil cooler has a number of drawbacks that do not allow it to be given the highest quality rating. However, the model is very functional and is able to show excellent results in the room without significant parasitic heat loss. The main thing that users and service engineers note as negative features is electronic oil temperature control and only two wheels. The reliability of the circuit is lower than that of mechanical regulators. And moving the device is somewhat unusual: you need to lift one side by the handle.

The model has a power consumption of 1000 watts and in a stable mode of operation can be effectively used in a room up to 15 squares. Both low power and the number of sections prevent the device from exceeding the recommended area. There are only 5 of them, which does not allow giving energy to the air with sufficient intensity.

Timberk TOR 21.2512 BC/BCL A peculiar ideal completes the rating. The heater, which has as many as 12 sections and 2500 watts of power, can easily work as the main source of heat in a room up to 30 squares. In this case, the device:

- equipped with two heating elements with three degrees of energy return adjustment;

- equipped with a reliable mechanical oil temperature sensor;

- protected from freezing and overheating;

- made on a comfortable wheel base, with a handle and a compartment for the cord.

The heater is functional and can work even in a small room. Set to low output, it will simultaneously create enough heat and, in a stable operating mode, will consume a small amount of energy without loading the wiring. The only obstacle to buying can be a tangible price and a relatively high weight of 12 kg.

If none of the models fit any of the parameters, check out another rating of oil heaters.

Safe use of an oil heater

First of all, do not install a working device close to walls or pieces of furniture. To avoid overheating of the oil, the distance from the walls of the heater to any object must be at least 0.5 m. Since the oil cooler needs free space, there are no models for hanging on the wall among such devices. – Do not use them in bathrooms and near open water sources.

The wheels that an oil heater has does not mean at all that it can be rolled from room to room by an electrical wire - it will either come off or the contacts that power the device will come off.

The most severe consequences await the owner of the oil heater, who laid it on its side and left it on, as well as when operating with a faulty emergency shutdown temperature sensor. The temperature of the oil will reach a critical value, the pressure in the radiator will increase sharply and it will explode with the ejection of drops of hot oil in all directions, which often leads to furniture fires.

Why can't the electric heater be used in its "lying" position? The oil does not fill the internal capacity of the radiator completely - taking into account its thermal expansion, manufacturers "underfill" at least 10%. If the heater is placed on its side, the oil will drain to the side that faces the floor and the “wet” electric heating element will be partially exposed. Without oil absorbing heat energy, the included electric heater will heat up to a temperature of over 800 ° C in minutes, which will reduce the strength of the metal case and, as a result, a fire may occur. For this reason, it would be wise to choose an electric heater model with a built-in tip-over sensor - when triggered, it will turn off the power supply.

In conclusion, it should be noted that oil heaters are safer than fan heaters due to the lower operating temperature and the complete exclusion of unauthorized access to the electric heater.

flat radiator repair

Not all flat heaters make it possible to add the missing amount of oil or replace the old one with a new one. It depends on the specific device model. For example, domestic manufacturers have provided for such situations and equipped heaters with a special stopper. the hole with it is located at the bottom of the structure. The procedure for filling oil is extremely simple - you need to remove the plug and fill in the required amount.

By the way, it is important to know how much oil is allowed to be placed in the heater. It should fill 80% of the tank volume

If it is less, then it is likely that the tubular electric heater will not close completely and will start to overheat, as already mentioned above.

And in the case of an excess of oil, there may be a different effect. When it is heated, air is released and a certain “air cushion” is formed. Naturally, it requires a place to stay. If it is not enough, then the air begins to put pressure on the walls of the case. As a result, the radiator may swell and crack. Therefore, the amount of infused filler must be carefully monitored.

If we are talking about the repair of devices manufactured by non-domestic manufacturers, then there are two options. If the tubular electric heater is built into the housing in such a way that it cannot be removed, then there is simply no chance. In such cases, the best solution is to send the broken equipment to a landfill and purchase a new one.

If the heating element is removable, then you can fight for the performance of the oil cooler. To do this, remove the tubular electric heater and pour oil into the hole opened under it. Then insert the heating element into place.

Naturally, these works should be carried out only after the integrity of the hull has been restored. If you cannot do this or, in general, doubt the success of the entire event, then it is better to simply purchase a new device. Fortunately, their cost is not too high.

Faults

Most often, the following problems occur in oil coolers:

A crackling sound is heard when turned on and during the first 10-15 minutes of operation. If after this time the crack disappears, it's okay. It occurs when the oil inside the radiator heats up.

It is possible that drops of water got into it, which cause such a reaction. This is possible if the device was assembled in conditions of high humidity.

The radiator does not turn on. First, carefully inspect the cord and plug for cracks or creases. If they are not found, try plugging the heater into a different outlet.

If this did not work, then the problem is in the contact that has departed. Try to repair the device yourself or give it to a service center where experienced craftsmen will solve the problem.

The device turns on but does not heat up. At the same time, indicator lights, a fan and other additional devices on the case work.

The cause of such a breakdown is problems with the thermal relay; it cannot be eliminated without special tools. Contact the service center.

Oil is flowing. Such a breakdown appears due to a manufacturing defect (poorly sealed seam) or a long period of use of the device.

Over time, the metal at the junction burns out and becomes thinner, which leads to this kind of breakdown. Unfortunately, it is impossible to repair an oil leak either on your own or in a service center.

If the breakdown is serious, you should carefully consider the prospect of buying a new radiator, because sometimes repairs cost more than a new device.

Finned Heater Repair

In appearance, such heaters resemble the cast-iron batteries familiar to us. They are made of steel, the thickness of which is 1–1.2 mm. Sections are formed by pressing, and assembly is carried out by laser welding.

Since the material from which the radiator is made is not particularly thick, it should be borne in mind that it is susceptible to corrosive processes. In this regard, the body is covered with a special powder paint. If this layer is damaged due to mechanical impact, then at first one small area will rust, and then corrosion will “eat” a significant part of the body, and through damage will occur through which the oil will leak out.

Accordingly, the repair process of such a device includes three stages. First of all, it is necessary to restore the integrity of the case. Then fill it with a new portion of oil, and finally ensure the complete tightness of the structure.

It should be noted that in some finned heaters the heating element is rolled into the body. In such cases, repairs, unfortunately, are not carried out, since there is simply no way to replenish the volume of oil.

And in the case when the tubular electric heater is removable, there are no problems. It can be removed, then pour out the old oil, fill in new oil and return the heating element to its rightful positions.

It is important to know which filler can be used for oil heaters. There are two suitable options:

- transformer oil. Produced from oil by distillation. Characteristics of various compositions may differ from each other. However, different transformer oils can be successfully mixed without compromising quality. By itself, this substance is a dielectric. It has excellent heat-conducting properties, and does not lose them even in conditions of negative temperatures - up to -45 degrees;

- mineral oil. In general, it is intended for automobile transmissions, but it is quite suitable for our purposes.Its viscosity is almost the same as that of transformer oil. This allows you to be sure that the convection exchange will take place properly.

It is worth noting that of all automotive oils, only mineral oil can be used. Synthetic is not suitable here, since it has a much lower viscosity. In principle, the heater will still work, but the convection will become excessively active. As a result, the device will make noise, crackle and in every possible way act on the nerves of people, especially at night.

Engine oil must also not be used. They, unlike synthetic, the viscosity may be excessive. The heating element will have to make much more effort to create convection currents, which will certainly lead to its overheating. In addition, the cost of such a filler for our case is unreasonably high. The composition of motor oils includes various additives that are necessary for a car, but completely meaningless for heaters. It turns out that you overpay for something that you do not need at all.

It should be borne in mind that it is permissible to mix oils only within the same variety. For example, you can mix transformer with transformer, even if they are from different manufacturers and have different characteristics. But it is unacceptable to mix transformer filler with mineral or synthetic. The difference in viscosity, the incomprehensible interaction of additives - all this can lead to a malfunction of the radiator and even to its complete breakdown.

Waste engine oil is also prohibited in this case. There are too many foreign impurities in it: there are metal suspensions and substances formed as a result of fuel combustion. All this "garbage" will clog the radiator from the inside, greatly reducing its heat transfer, and it will have an extremely negative effect on the durability of the device.

transformer oil

Transformer oil is made from petroleum by distillation. It is characterized by low viscosity and good cleaning. Oil boils at 300 degrees. It is intended for pouring into circuit breakers, transformers and reactor devices. Due to its properties, it can also be poured into an oil heater.

The composition of transformer oil depends on the initial composition of the raw materials from which it is made. It may have some differences depending on the field where the oil was produced.

On average, transformer oil that can be poured into a heater has a service life of no more than 20 years. But it must be previously unused.

This liquid, due to its characteristics, can be operated even at low temperatures. The minimum mark can be - 45 degrees. Due to its low viscosity, it is able to efficiently remove heat.

Which is better

Before buying a radiator, you should calculate what area it will need to heat. The heating function depends on the power of the radiator and the number of sections.

The power is selected depending on the size of the room in which the radiator will work: 1 kW of generated electricity is needed per 10 square meters of the room.

The formula applies to rooms where the ceiling height is not more than 2.75 m. If the ceilings are higher, you can calculate the required power using the following algorithm:

- Multiply the length of the room by the width to get the area.

- Multiply the resulting number by the height of the room, so you get the desired volume.

- Divide the resulting figure by 25, because 1 kW of energy per 25 m3 is calculated. The result obtained is the power that is needed to heat the room.

Further, it is a matter of individual taste and financial capabilities. A simple oil heater has a standard set of features and is inexpensive.

Models equipped with fans, timers, humidifiers and remote controls are more expensive, but more comfortable to use.

Advantages of oil heaters

High level of device security. In an oil cooler, all heating elements are hidden inside, and the outer shell is heated to a temperature of no more than 60 degrees.

This eliminates the possibility of a fire when falling or burning the skin surface with tactile contact. The last factor is important in families with small children.

- Long service life. The device is designed in such a way that the components do not burn out due to long continuous operation. The device can work without turning off up to three days.

- The compact dimensions of the device and its mobility allow you to move it to different parts of the house or apartment. And noiselessness in work will not cause any discomfort.

- The price of oil coolers is affordable. The cost depends on the number of sections that are in the device.

- No odors are emitted during operation of the device. Radiators do not dry the air in the room, which means that you do not have to spend extra money on buying a humidifier.

- To install such a heater, you do not need special knowledge and tools. You just plug the device into a power outlet and enjoy the warmth.

Exploitation

Precautionary measures:

- Before using the device, make sure that the voltage in the apartment socket corresponds to that recommended by the manufacturers.

- If you are not using the appliance, unplug it from the socket.

- Do not leave the device on when no one is in the room.

- Do not cover the device with clothing, as this will cause overheating or fire. It is better to place it at a safe distance from flammable substances.

- Keep the appliance clean.

- In the event of a breakdown, do not try to disassemble the parts of the radiator yourself, it is better to leave this work to professionals.

- Supervise children closely if they are in the same room as the device is in operation. Do not allow them to play with the cord or appliance, as this may result in short circuit, electric shock or fire.

- Carefully monitor the condition of the device itself, wires and plugs. Do not use the heater if the cord or plug is damaged.

- The appliance is intended for domestic indoor use only.

Preparation for work

If the device was bought in the cold season, then it must be carefully unpacked, placed on wheel supports and left for at least 3 hours.

After that, plug the radiator into a grounded socket and leave it to work for 1 hour in a ventilated area. Thus, all extraneous odors, the appearance of which is possible at the initial stage, will evaporate.

Maintenance of oil coolers

Oil heaters do not require special maintenance during their service life, if there are no complaints or complaints.

- If you need to store the device for a long time, then wipe it with a slightly damp cloth from dust and dirt, disconnect the cord, roll it up carefully. Remove the support wheels and put in a box, which tightly close.

- When the heater is needed again, take it out of the box, dust it again, and assemble it. Carefully inspect the instrument for deformation or oil leakage.

Oil cooler disposal

When the oil heater becomes unusable, it must be disposed of according to the following scheme:

- Cut off the power cord from the unit.

- Drain the oil, which is dangerous for humans, and hand it over to a special collection point.

- The hull can be sold for scrap.