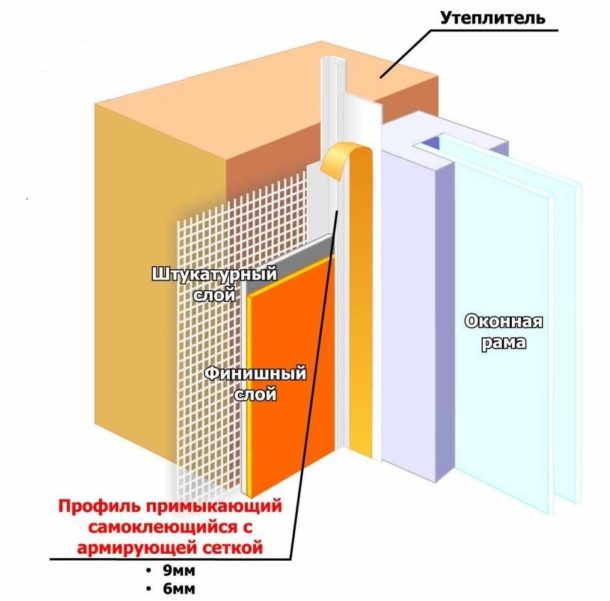

The weak point of the window slope is the line where the frame adjoins the wall. Cracks often form on the seam; with insufficient sealing, it is blown by the wind. Many problems arise during the plastering process: you need to carefully bring out a flat slope plane and at the same time make sure not to stain the frame and the double-glazed window with mortar. A special window adjoining profile with a reinforcing mesh will facilitate the work of the master. Let's find out what this element is for, how to choose and use it correctly.

Adjacent profile assignment

This product is a universal bar that performs several functions at once:

- Plaster: a strong fiberglass mesh securely holds the grout and reinforces it, preventing cracks after drying. In addition, the profile itself acts as a beacon. A spatula or a rule is supported on it and a neat and even slope is drawn out.

- Sealing: the element ensures the tightness of the seam at the junction of the slope to the window frame.

- Protective: not only prevents window contamination during plastering, but also resists atmospheric influences during further operation.

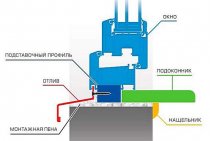

Profile device

This element is made of polyvinyl chloride in accordance with GOST 19111-2001. The material of the profile is resistant to impacts and temperature influences, is not afraid of ultraviolet rays, is easy to install, does not allow steam and water to pass through.

Structurally, the profile consists of the following elements:

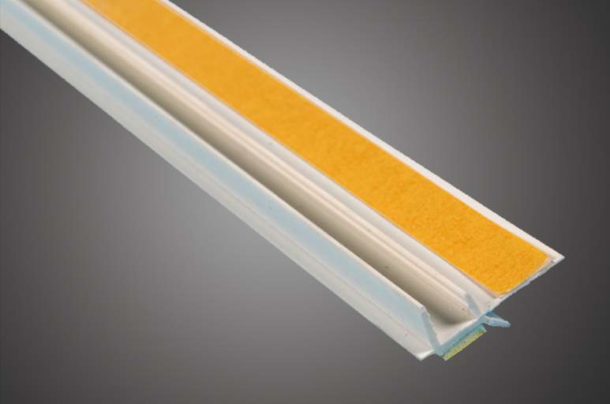

- Bases made of unplasticized (hard) PVC, on the back of which there is a self-adhesive sealing lamella made of polyurethane foam. It is with this part that the profile is glued to the frame. It allows the element to fit closely to the window frame, and also plays the role of a kind of damper gasket, compensating for the thermal expansion of materials and wind load. By extinguishing these vibrations, the lamella contributes to the preservation of the inelastic layer of slope plaster.

- Protective cuff - inserts made of soft plasticized PVC. After completing the finishing work, this part of the product remains in sight. It forms a neat and aesthetic junction of the slope and the window block and hides cracks that may eventually appear on the fillet weld.

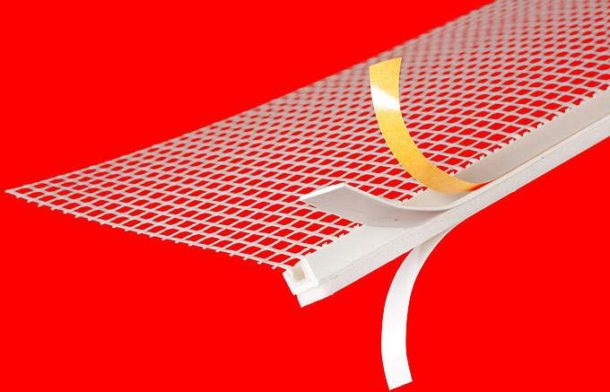

- Tear-off bar equipped with a strip of glue. After removing the protective film, it is easy to attach polyethylene or a membrane to it, which protects the window from contamination with plaster. After completion of work, this bar is easily separated from the box.

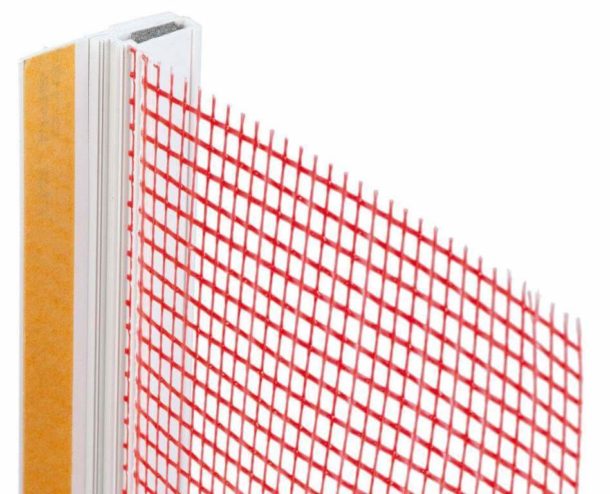

- Reinforcing mesh made of alkali-resistant fiberglass attached to an additional shelf.

The following video will tell you more about the profile device with a grid:

Self-adhesive plastic profiles with reinforcing mesh are used in the formation of slopes from the outside of the building and indoors.

How to choose

Some tips for choosing a profile:

- The element must necessarily have a protective insert-cuff that covers the junction of the slope and the frame, in the absence of this joint along the perimeter, the end of the sealing lamella made of foamed polyurethane will be visible, which easily absorbs moisture and dirt. It will get dirty more and more each time the window is washed, and it will look completely ugly.

- It is recommended to pay attention to the color of the product. It is desirable that it be made of virgin PVC, which has a pure white tint. At the end of the work, the grayish PVC insert will stand out against the background of the white frame and look not very aesthetically pleasing. In addition, a dirty gray profile made from recycled PVC is inferior in quality and breaks more easily.

- It is important to choose the right adjoining profile in height. On sale there are models with a height of 6, 8, 9 mm and more.With a standard finish with plaster and putty, you need to choose an element with a minimum height. If the slopes are insulated with foam, this value should be greater.

Model marking is as follows: 6 × 2400, where the first digit indicates the height of the profile, and the second - its length. For example, profile 9 × 2400: profile height - 9 mm, length - 2.4 m.

The following video will tell you about the rules for choosing an adjacent profile:

Installation

Mounting technology:

- A line is marked along which the profile will adjoin the frame. It is most convenient to use a laser level, but if it is not available, a bubble level is also suitable.

- The desired piece of the product is measured and cut off. To do this, use scissors for metal.

- For good adhesion, the frame is pre-cleaned of dust and other contaminants. Only under such conditions, the manufacturer guarantees the reliability of the resulting connection.

- The protective film is removed from the damper lamella, and the profile is glued to the frame along the marked strip. This is done as follows: after detaching a little film, the bar is set along the line and pressed against the box, after which the remaining protective layer is finally removed at an acute angle.

- After removing the protection, they glue the material that closes the window from dust and dirt - a plastic film or a special membrane.

- Having straightened the reinforcing mesh, the slope is plastered.

- After the plaster has dried, the tear-off strip is removed along with the film covering the window.

Work on the installation of the profile is carried out at a temperature not lower than +5 ˚C.

Visually, the entire process of installing this element is shown in the video.